الحار منتجات

ملكنا الإخبارية

ballvertical ball mill for kaolin

Preparation of potassium oleate-kaolin/natural rubber composites

2023/9/1 Then, PO and kaolin were poured into the ball milling tank of the planetary ball mill in a ratio of 2:25 for wet ball milling modification. The ball milling process took

获取价格

Structural and thermal behavior of proclay kaolinite using high

2015/2/1 Calcination and ball milling would share more similarities if high energy ball milling is used. In such case, the temperature inside vials may exceed 200 °C [10] , [58]

获取价格

Properties of pulverized kaolin particles via ball-to-powder weight ...

2020/4/1 This enables kaolin particles to be reduced in size and produced in the practically simple, effective, and low-cost process using high-energy ball milling.

获取价格

Improving plasticity of kaolins by high-energy milling for use in ...

2022/6/1 The reduction in particle size of kaolin I as a function of milling time for the D 10, D 50 and D 90 fractions is shown in Fig. 1. Download: Download high-res image

获取价格

(a) High energy milling machine, (b) planetary ball milling, and (c ...

Pulverization of kaolin particles was performed by using Planetary Ball Mill (Fritsch Pulverisette 5) at a various ball-to-powder weight ratio of 1, 1.5, 2, 2.5, 3, 3.5, and 4 as

获取价格

(PDF) Properties of pulverized kaolin particles via ball-to-powder ...

2020/6/11 Kaolin particles reached an average of 944nm in size after milling for 4hr under ball-to-powder weight ratio of 4, which is much smaller than unpulverized kaolin

获取价格

Effect of particle size of powders ground by ball milling on ...

(1999) Nakahara et al. Journal of the Ceramic Society of Japan. Mixtures of calcined kaolin, calcined talc and alumina were ground to submicron particle size by ball milling, and the

获取价格

Effect of solid/ball ratio and grinding time on the mechanical ...

2023/11/23 Kaolin is one of the most important clay minerals that attracts attention due to its various application areas such as the ceramic industry. In this study, the effects

获取价格

Improving plasticity of kaolins by high-energy milling for use in ...

2022/4/1 laboratory ball mill for 30 min with 40 mass % of water (alumina balls and jar, 60/40 balls/kaolin by volume, φ = 10 – 15 mm) before charac- terization and high

获取价格

Effect of solid/ball ratio and grinding time on the mechanical ...

2.1 Effect of solid/ball ratio and grinding time on mechanical activation. Unactivated kaolin samples obtained under 10lm particle size was ground in the Planetary Ball Mill

获取价格

Ball mills for various applications Gebr. Pfeiffer

In fact we design, build and install ball mills which are specially adapted to grind hard and even extremely abrasive materials. Advantages of the ball mill . Adjustable grain size distribution . When operating on the open

获取价格

ball mill for kaolin - Berlio Mining Machinery Company All rights

WebMetakaolin is ground by using a crusher and ball mill to get a nanoparticle scale as shown in Figure 1 The examinations of XRD of Kaolin are shown in Figure 2, and SEM of nano kaolin sample is shown in Figure 3. ... Figure 1. Crusher and ceramic ball mill devices Kaolin Al2Si2O5(OH)4 Card No. 96-154-4873 Kaolin Al2Si2O5(OH)4 Card No. 96-154 ...

获取价格

Ball mill, Ball grinding mill - All industrial manufacturers

A ball mill crushes solids into a fine powder within a rotating drum, using balls as the grinding medium. Applications. Ball mills are found in settings as diverse as laboratories and mines, among others. Technologies. Ball

获取价格

Nova S Ball Mill Group

Nova S ball mill is the preferred solution for fine-grinding of various masses like compounds, spreads, creams for fillings and coatings, cocoa masses, nut pastes and other fat-based masses. The unique grinding chamber delivers one-step-grinding at low temperatures, ensuring that your product has the highest and consistent quality.

获取价格

vertical ball mill for kaolin

2017/9/13 nigeria kaolin ball mill supplier. nigeria kaolin ball mill supplier For each project scheme design, we will use professional knowledge to help you, carefully listen to your demands, respect your opinions, and use our professional teams and exert our greatest efforts to create a more suitable project scheme for you and realize the project

获取价格

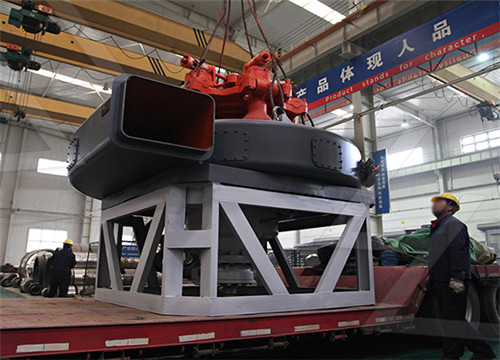

Kaolin vertical roller mill_PRODUCT_Tongli Machinery

A kaolin vertical roller mill is a specialized equipment used for grinding and processing kaolin into kaolin powder.Kaolin is a non-metallic mineral. It is a kind of clay and clay rock mainly composed ... Ball mill hood cover. Vertical roller mill rocker arm. Ball mill pinion. Vertical roller mill grinding roller. Ball mill Liner.

获取价格

Vertical Ball Mill Kaolin

Explore our mining equipment to find the ideal wholesale vertical ball mill kaolin model and mills for any mining challenge. All categories. Featured selections. Trade Assurance. Buyer Central. Help Center. Get the app. Become a supplier. ... Vertical Ball Mill Kaolin (70 products available) ...

获取价格

(a) High energy milling machine, (b) planetary ball milling, and

Pulverization of kaolin particles was performed by using Planetary Ball Mill (Fritsch Pulverisette 5) at a various ball-to-powder weight ratio of 1, 1.5, 2, 2.5, 3, 3.5, and 4 as shown in Figures ...

获取价格

Ball Mill For Kaolin - ospbedlno

Ball Mill For Kaolin - riedel-zeller. Ball Mill For Kaolin. Clay Small Grinding Machine is popular in some kaolin processing plant, which features of small space and strong integration capability , The Ball mill can grind the kaolin into powder down to 0074~04 mm and Ball mill for kaolin is the most economical and practical kaolin Grinding , It is easy

获取价格

How to Choose the Right Types of Ball Mill for Your Application

An industrial ball mill is a type of ball mill used in large-scale production settings. It is designed to process large volumes of material and can be used for both wet and dry grinding. Industrial ball mills are typically made of steel, and the lining material is selected based on the type of material being processed. 4 Conical Ball Mill

获取价格

(PDF) Properties of pulverized kaolin particles via ball-to

2020/6/11 Kaolin particles reached an average of 944nm in size after milling for 4hr under ball-to-powder weight ratio of 4, which is much smaller than unpulverized kaolin particles at the average mean size ...

获取价格

Comparing ball and vertical mills performance: An

seen, the vertical mill consistently presented lower net specific energy consumption than the ball mills which operate on the same circuit. The averages were 11.3, 11.7 and 6.5 kWh/t respectively for ball mill 01, ball mill 02 and vertical mill. Figure 5 – Net specific energy consumption of regrinding circuit.

获取价格

Vertical ball mills for chocolate refining - Making

Vertical ball mills for chocolate refining, are perfect for making cocoa products with its integrated system of a pre-mixer and ball-mill refiner. Both the Choc-1250 and Choc-1500 ball mills guarantee high production flexibility, quick payback time, and great product quality. All ball mills are energy-efficient to ensure a low product temperature.

获取价格

How to Choose the Right Types of Ball Mill for Your Application

An industrial ball mill is a type of ball mill used in large-scale production settings. It is designed to process large volumes of material and can be used for both wet and dry grinding. Industrial ball mills are typically made of steel, and the lining material is selected based on the type of material being processed. 4 Conical Ball Mill

获取价格

(PDF) Properties of pulverized kaolin particles via ball-to

2020/6/11 Kaolin particles reached an average of 944nm in size after milling for 4hr under ball-to-powder weight ratio of 4, which is much smaller than unpulverized kaolin particles at the average mean size ...

获取价格

Comparing ball and vertical mills performance: An

seen, the vertical mill consistently presented lower net specific energy consumption than the ball mills which operate on the same circuit. The averages were 11.3, 11.7 and 6.5 kWh/t respectively for ball mill 01, ball mill 02 and vertical mill. Figure 5 – Net specific energy consumption of regrinding circuit.

获取价格

Vertical ball mills for chocolate refining - Making

Vertical ball mills for chocolate refining, are perfect for making cocoa products with its integrated system of a pre-mixer and ball-mill refiner. Both the Choc-1250 and Choc-1500 ball mills guarantee high production flexibility, quick payback time, and great product quality. All ball mills are energy-efficient to ensure a low product temperature.

获取价格

Alpine ATR Vertical Dry Media Mill – Hosokawa Micron Powder

The Alpine ATR Vertical Dry Media Mill is ideal for the dry production of superfine mineral powders finer than 10 µm. Grinding pearls between 200 micron and 5 mm in diameter guarantee maximum energy intensity and an effective surface area

获取价格

Improving plasticity of kaolins by high-energy milling for use in ...

2022/6/1 The particle size distributions – cumulative and differential distributions – before and after the high-energy milling for kaolin R are shown in Fig. 4. Download: Download high-res image (220KB) Download: Download full-size image; Fig. 3. Particle size distribution of kaolin R after high-energy milling as a function of time of milling.

获取价格

Comparing Ball Mills And Vertical Roller Mills for Fly Ash

2020/4/20 Fly Ash Grinding Mill Recommendation. Guilin Hongcheng ore powder mill vertical mill-grinding equipment 〖Item〗:HLM vertical roller mill 〖Finished product size〗: 22-180μm

获取价格

Kaolin vertical roller mill_PRODUCT_Tongli Machinery

A kaolin vertical roller mill is a specialized equipment used for grinding and processing kaolin into kaolin powder.Kaolin is a non-metallic mineral. It is a kind of clay and clay rock mainly composed ... Ball mill hood cover. Vertical roller mill rocker arm. Ball mill pinion. Vertical roller mill grinding roller. Ball mill Liner.

获取价格

_Taurus - Ball Mill - NETZSCH Grinding Dispersing

NETZSCH also carries an extensive selection of special grinding media to optimize the performance of the ball mill specific to the customer's requirements. Together with NETZSCH classifiers, the Taurus provides a wide range of fineness with top cuts down to d 98 < 2 μm and up to d 98 300 μm.

获取价格

Kaolin Processing Plant Machinery - LinkedIn

2023/3/23 Raymond mill is also frequent used grinding equipment for kaolin processing. It has the following advantages: 1. good dust collection. The equipment adopts pulse dust collector to collect dust ...

获取价格

Vertical roller mill for Kaolin, kaolinite pulverizing

Introduce of Kaolinite, kaolin vertical roller mill Finished kaolinite, kaolin powder fineness: 47-5 micron (325mesh-2500mesh) ... mixing grinder and ball mill. 2. Long lifecycle of wearing parts The ring and rollers are forged by special material with high utilization. Under same grinding material and finish fineness, the wearing parts life ...

获取价格

Kaolin Processing Plant Machinery - sbm-mill

Compared with the combined grinding system of traditional Raymond mill and ball mill, vertical roller mill has the advantages of large output, wide adaptability, simple operation, rapid adjustment, low use and maintenance cost, energy saving, etc., and is the preferred choice for deep processing of kaolin.

获取价格

Understanding the Differences: Ball Clay vs. Kaolin Clay

2023/7/14 Understanding the differences between Ball Clay vs. Kaolin Clay is essential for both artists and consumers alike, as it can greatly impact the result of a piece. So, whether you’re a pottery enthusiast looking to improve your craft or simply curious about the magic behind your favorite ceramics, read on to discover the fascinating world

获取价格hero factory creep crusher theme music in Angola

طحن الخرسانة الانتهاء من تولسا

الكسارة الفكية المصنعة في الصين

Vsi كسارة تصنع ألمانيا

53B آلة الرمال

صخرة آلات الرمال مصنعين

قیمت آسیاب تمبر در زیمبابوه

آلة طحن المعادن للبيع كسارة للبيع

ناقل المعدات المواصفات

دلو محطم المصنعين الهند

الموردين آلة طاحونة الجزائر

مصنع كسارة معدنية في غانا

4 كسارة مخروطية قصيرة

الممارسة العملية المغناطيسي التعدين

البحر شركة عشب البحر طحن

شركة المعدات المعادات التيلة

بيع آلة كسارة الحجر والسعر

بيع اليات ثقيله في استراليه

لماذا تنفجر مناجم الفحم

خام الذهب تعدين غسالة المستعملة

محطم في قطر

مصنع لتجهيز النيكل

طحن كربونات الكالسيوم عملية التعدين سحق طحن المعدات

مطالبات تعدين الذهب كولورادو للبيع

كسارات الرمل الأسود الولايات المتحدة الأمريكية

كسارة محجر الجرانيت مشغل وصف العمل

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20