الحار منتجات

ملكنا الإخبارية

nickel ore processing coarse ore bin

The Comprehensive Guide to Nickel Processing

2024/1/19 Nickel ore preparation involves a series of processes to prepare the ore for further processing, including crushing, grinding, and classification. These steps help to reduce the ore size, increase the

获取价格

Our Facility - canickel

PROCESSING FACILITY. The Bucko Lake operation is designed to treat 1,000 dry tons per day of nickel-bearing ore from the underground mine on the basis of a 24 hours a day, 7 days per week operation. ... Ore from

获取价格

Preconcentration strategies in the processing of nickel laterite ores ...

2015/8/1 Miller and Liu (2005) patented a flow sheet for processing laterite ores for the recovery of Ni and Co which included separating the ore into a beneficiated

获取价格

NOVA NICKEL PROJECT - Global Mineral Processing Solutions

constructed to treat underground ore mined from the Nova-Bollinger Mine located 120 km east of Norseman, WA. The concentrator was designed to produce 331,000 tonnes of

获取价格

Nickel Ore Processing Plant - JXSC Mineral

It often uses a stage grinding process when processing nickel ore. The crushed products enter the ball mill for a stage of grinding and then enter the spiral classifier for pre-classification. If the ore particle size of nickel ore

获取价格

Challenges in processing nickel laterite ores by flotation

2016/6/10 It should be added that segregation of laterite ores prior the flotation process has shown some improvement in upgrading nickel. The segregation process

获取价格

Nickel processing - Extraction, Refining, Alloying Britannica

Nickel processing - Extraction, Refining, Alloying: The extraction of nickel from ore follows much the same route as copper, and indeed, in a number of cases, similar processes

获取价格

Nickel Smelting and Refining

349. Nickel Smelting and Refining. Industry Description and Practices. Primary nickel is produced from two very dif- ferent ores, lateritic and sulfidic. Lateritic ores are normally

获取价格

(PDF) Preconcentration strategies in the processing of

2015/4/2 coarse ore (30–70 mm) resulted in a low ratio of concentration, with a feed concentration of 1.97% Ni upgraded to a float fraction. ... Despite the growth in nickel laterite processing ...

获取价格

Fine Ore Storage Bin and Stock Pile - Metallurgist Mineral Processing

2015/7/27 The trajectory of the ore as it leaves the conveyor belt will determine where in the bin or pile each size of the crushed ore will land. Once in the bin, another stage of classification takes place. The smaller ore due to its lesser size and weight, tends to filter downwards faster than the coarse material does.

获取价格

Reduction Kinetics of Fluxed Iron Ore Pellets Made of Coarse Iron Ore

The present work explores a novel approach to utilize coarse iron ore particles with lime as a feed material for iron making. ... and lime powder) procurement, processing, and composition are the same as reported in our previous work. Iron ore contains Fe 2 O 3 - 92.5%, Al 2 O 3 - 3.7%, SiO 2 - 2.94%, and others- 0.86%. Coal contains 62.5% of ...

获取价格

Mineral Processing Operating Cost Estimate of Ore

2016/9/1 Only where a group of mines operates in a single district are costs comparable and then only with reservations. In general, cost systems are fairly uniform, yet in studying costs of a number of plants it is

获取价格

McLanahan Ore Washing and Machine Selection

2021/7/15 In a mineral processing sense, washing commonly refers to the removal of loosely attached particles — often fine clays — from the surface of more competent ore. In this definition, washing is distinct from classification, which would be a subsequent processing step that separates the different sized fractions.

获取价格

Comprehensive Review on Metallurgical Upgradation Processes of Nickel

2022/2/11 With the vigorously growing demand of the steel industry, corrosion resistance alloys, clean energy industries, and a variety of engineered infrastructure or technology, high-grade nickel ores are being exhausted gradually in the world. This review outlines metallurgical processes for nickel production from various nickel sulfide ores

获取价格

Chromite Beneficiation Process - 911 Metallurgist

2016/4/12 Chromite Ore Crushing. The crushing section for this 250 ton per day chrome mill consists of a coarse ore grizzly, a coarse ore bin with pan feeder to a 1’8″ reduction crusher and a crusher discharge conveyor to a crushed ore bin. On this particular ore, we find that there is no chrome liberated in sizes larger than ¼”.

获取价格

Challenges in processing nickel laterite ores by flotation

2016/6/10 It should be added that segregation of laterite ores prior the flotation process has shown some improvement in upgrading nickel. The segregation process relies on the addition of calcium chloride or sodium chloride and carbon allowing the formation of nickel and iron chlorides at temperatures between 900 and 1150 °C. Iwasaki et al.,

获取价格

(PDF) Coarse ore stockpiles - ResearchGate

2006/6/1 Large coarse ore stockpiles can contain 100 ′ s of kilotons of ore, with a live residence time in the order of 12 to 24 h (Zamorano, 2006). Models and theories of granular flow remain incomplete ...

获取价格

Process flowsheet development for beneficiation of nickel ore

2008/1/1 FLOWSHEET DEVELOPMENT FOR BENEFICIA TION OF NICKEL ORE, Mineral Processing. and Extractive Metallurgy R eview: An International Journal, 29:1, 57-67, DOI: 10.1080/08827500701257936.

获取价格

Copper-nickel sulfide ore and nickel oxide ore beneficiation

2024/3/27 Flotation separation: Send the qualified copper-nickel ore into the mixing tank, stir thoroughly and then send it to the flotation machine.The unqualified ore particles after coarse crushing will ...

获取价格

Recent Progress in Hydrometallurgical Processing of Nickel Lateritic Ore

2022/8/22 With the growth of the stainless-steel industry, the focus has moved toward making specialized steels, where Ni has proved itself as a significant ingredient. With time, Ni demand has inclined toward the energy storage sector. Observing the drastic application in several areas, Ni demand has grown multi-fold in recent years. Ni requirement was

获取价格

Preconcentration strategies in the processing of nickel laterite

2017/8/15 Leaching commenced at Murrin Murrin in December 1998. Initially the ore preparation circuit comprised a rudimentary coarse ore bin with ore fed to a breaker/sizer rolls type primary crusher (Nice, 2004). The crushed material was conveyed to a grinding mill set up as a quasi-Semi-Autogenous Grinding (SAG) circuit.

获取价格

Study on Beneficiation Technology for Rational Utilization

2024/2/26 Abstract In order to realize the rational utilization of low-grade polymetallic symbiotic mineral resources with low input, typical copper–nickel symbiotic low-grade ores were used as the test object. After careful process mineralogy research on the ore, it was learned that the main valuable elements of the ore were Cu and Ni, and the content of

获取价格

Copper-nickel sulfide ore and nickel oxide ore beneficiation

2024/3/27 Flotation separation: Send the qualified copper-nickel ore into the mixing tank, stir thoroughly and then send it to the flotation machine.The unqualified ore particles after coarse crushing will ...

获取价格

Recent Progress in Hydrometallurgical Processing of Nickel Lateritic Ore

2022/8/22 With the growth of the stainless-steel industry, the focus has moved toward making specialized steels, where Ni has proved itself as a significant ingredient. With time, Ni demand has inclined toward the energy storage sector. Observing the drastic application in several areas, Ni demand has grown multi-fold in recent years. Ni requirement was

获取价格

Preconcentration strategies in the processing of nickel laterite

2017/8/15 Leaching commenced at Murrin Murrin in December 1998. Initially the ore preparation circuit comprised a rudimentary coarse ore bin with ore fed to a breaker/sizer rolls type primary crusher (Nice, 2004). The crushed material was conveyed to a grinding mill set up as a quasi-Semi-Autogenous Grinding (SAG) circuit.

获取价格

Study on Beneficiation Technology for Rational Utilization

2024/2/26 Abstract In order to realize the rational utilization of low-grade polymetallic symbiotic mineral resources with low input, typical copper–nickel symbiotic low-grade ores were used as the test object. After careful process mineralogy research on the ore, it was learned that the main valuable elements of the ore were Cu and Ni, and the content of

获取价格

Inside the Humboldt Mill: Watch nickel ore being processed at

观看视频1:462022/7/8 The Humboldt Mill near Ishpeming in Michigan’s Upper Peninsula is where the Lundin Eagle Mine processes nickel and copper ore from the nation’s only domestic...

获取价格

sbm/sbm nickel ore processing sag mill feed bin.md at master

You've already forked sbm 0 Code Issues Pull Requests Packages Projects Releases Wiki Activity

获取价格

APPENDIX A – ORE PROCESSING DETAIL - Minnesota

Secondary Crushers that deliver crushed ore at a P80 of 3.4 in to the Coarse Ore Bins in the Fine Crushing building. Trains deliver ore from the open pit to the Coarse Crusher Dump Pocket. A remotely controlled jack empties each ore car sequentially into the Primary Crusher (60”gyratory) that is capable of

获取价格

Mineral processing - Wikipedia

Crushing, a form of comminution, one of the unit operations of mineral processing. Mineral processing is the process of separating commercially valuable minerals from their ores in the field of extractive metallurgy. [1] Depending on the processes used in each instance, it is often referred to as ore dressing or ore milling.. Beneficiation is any process that

获取价格

Nickel Processing Plant. Nickel ore is a very important ... - Medium

2024/5/21 Nickel ore is a very important non-ferrous metal raw material used in the manufacture of stainless steel, high-nickel alloy steel and alloy structural steel. It is widely used in various military

获取价格

Nickel Ore Processing Plant - JXSC Mineral

If the ore particle size of nickel ore is too coarse (greater than 0.1mm) or too fine (less than 0.006mm), it is unfavorable for the subsequent flotation. ... Mineral Processing Consulting Services. Other. Capacity(T/H) 0-10 T/H. 10-50 T/H. 50-100 T/H. 100-300 T/H. 300-500 T/H > 500 T/H. Mineral Ore Type. Antimony. Barite. Beach Sand.

获取价格

PGM Ore Processing at Impala's UG-2 Concentrator - SGS

Ore seParatiOn PrOJect The concept behind the UG2 ore separation project was derived from the unique nature of UG-2 mineralogy, namely: • Most PGM rich minerals in the run-of-mine ore are associated with the chrome-rich fraction in the ore (the UG-2 reef itself). The friable nature of the ore and the intergranular

获取价格

Ore Flotation Process Solution - JXSC Machinery - Mineral Processing

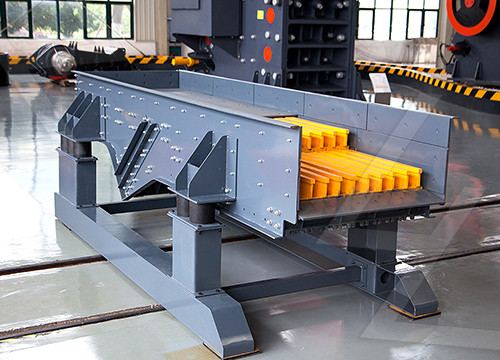

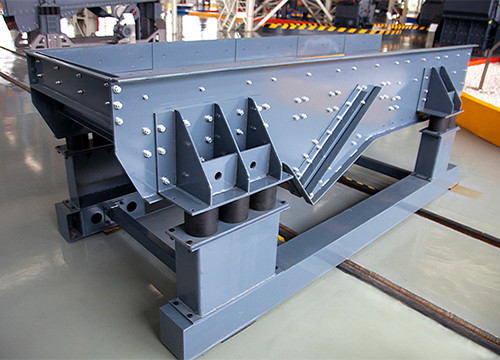

2024/8/14 1. Crushing and screening: The raw ore is transported to the mine warehouse by the mine car for storage, and then sent to the jaw crusher through the vibration feeding machine for a stage of crushing. The crushed material is transported to the vibrating screen for screening. The screened product is transported back to the fine jaw

获取价格

Application of a Net Smelter Return Model within a

Mechanised longhole open stopingis used to extract approximately 1.0 Mt/y of ore from the mine. The majority of ore is transferred directly to coarse ore bins with excess material stockpiled on the runof-mine - (ROM) ore pad. To manage various bottlenecks and minimise variation within the processing plant, ore on

获取价格

Nickel mining with the CNA Pentos Malvern Panalytical

Petea is a mainly lateritic landform with below-average nickel content. Figure 1. Map showing the mine area (Image source: Vale Inco Limited, 2010). Nickel ore processing The flowchart in Figure 2 shows that processing the nickel ore at the PT Vale plant is a complex operation, involving numerous different phases.

获取价格تكلفة الفك مختبر محطم الصورة

كولورادو كسارات الحجر

تثبيت الرمل الاصطناعي

tin nos of stone crushers in andhra pradesh

جنوب أفريقيا كتلة ماكينة

آلات مصنعي مطحنة الأنابيب ألمانيا

المعدات ذات سعة أكبر في صناعة خام الحديد

مصنع تكسير وغسيل الفحم للبيع جنوب افريقيا

شبكة الحجر المسحوق في كينيا

تعدين خام الحديد أثناء الضباب

طاحونة عشب الجهد

مصناع الحديد في العالم

ماكينات طحن الكوارتز مصر

Sandik Gold And Cooper Project Wiki

مطحنة برج مطحنة عمودية

آلة مطحنة الكرة الطلاء

كسارة تشونغ شين

من تأثير محطم المحمول في الهند

الكسارات من اندونيسيا

بطل مصنع الكسارات زحف عبة

موردي معدات سحق الحجر

تغذية ألعاب الهيجان

بناء محاجر الحجر الرملي

إمدادات كسارة مخروط في بيون

الفرق بين مطحنة الكرة المركبة على شكل شل ومرتكز الدوران

الابتدائي بيع السيليكا كسارة الفك في الهند

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20