الحار منتجات

ملكنا الإخبارية

ball mill mechanism of roll grinder

Ball mill - Wikipedia

A ball mill is a type of grinder filled with grinding balls, used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotating about its axis. The axi

获取价格

Grinding in Ball Mills: Modeling and Process Control

2012/6/1 Hybrid High-Pressure Roll Mill/Ball Mill Grinding. ... Mechanisms in W et-Phase Fine Grinding in a Stirred Bead Mill. –

获取价格

Grinding in Ball Mills: Modeling and Process Control

Keywords: Ball mills, grinding circuit, process control. I. Introduction Grinding in ball mills is an important technological process applied to reduce the size of particles which may

获取价格

Understanding the mechanism: How does a ball mill work?

Components of a Ball Mill. 1. Drum: The drum is the main component of the ball mill, which houses the grinding media and the material to be milled. It is typically made of steel and

获取价格

Ball Mill - an overview ScienceDirect Topics

A ball mill is a tumbling mill that utilizes steel balls as grinding media to grind materials. It can operate either wet or dry, with the capacity to produce products in the order of 100

获取价格

Ball Mill Grinding Machines: Working Principle, Types, Parts ...

A ball mill consists of various components that work together to facilitate grinding operations. The key parts include the following: Mill Shell: The cylindrical shell provides a

获取价格

Exploring Ball Mill Diagram: A Comprehensive Guide

2024/4/28 The rotation of the mill is driven by the motor, the power of which is determined by the mill’s size and the grinding capacity. Ball mills can be as small as lab-scale mills or as large as industrial mills with a

获取价格

A Review of the Grinding Media in Ball Mills for Mineral Processing

2023/10/27 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles. Grinding media play an important

获取价格

Numerical Investigation of Vertical Roller Mill Operation Using ...

2023/12/4 A vertical roller mill (VRM) is a grinding equipment used for the size reduction of minerals, cement, and ceramics. ... simulated the industrial-scale ball mill of

获取价格

Ball Mill Grinding Theory – Crushing Motion/Action

2017/4/28 The total feed to the ball-mill was therefore 11.54 T. per hr. or 179 per cent, of the original feed. It was evident that the ball-mill was greatly underloaded in this test, but so much trouble developed in the

获取价格

Energy-Efficient Advanced Ultrafine Grinding of

2023/7/10 The autogenous/semi-autogenous mills were also used along with a ball mill for intermediate-size grinding. However, there is a new configuration of the grinding circuit composed of a high-pressure

获取价格

Principles of Grinding in Ball Mills - Orbis Machinery

Find out more about the principles of grinding in ball mills from Orbis Machinery, LLC. Call us today for more information 262-522-1939.

获取价格

Grinding in Ball Mills: Modeling and Process Control

2012/6/1 Hybrid High-Pressure Roll Mill/Ball Mill Grinding ... the Grinding Mechanisms and Their Origin in a Stirred ... A ball mill is a type of grinder widely utilized in the process of mechanochemical ...

获取价格

Ball Mills - 911 Metallurgist

2017/2/13 In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rod mill or ball mill, the ore in order to liberate the minerals. In the chemical and process industries, grinding is an important step in preparing raw materials for

获取价格

Planetary Ball Mills 101 - Union Process

Planetary ball mills share the same design as other basic ball mills – a grinding jar filled with media and rotated on its own axis. But their unique design takes advantage of centrifugal force and the Coriolis effect to grind materials to a very fine or even micron size. These forces come into play as

获取价格

The wear mechanism of mill beaters for coal grinding made-up

2022/12/1 The wear mechanism of mill beaters for coal grinding made-up from high manganese cast steel. ... Air-Swept or Wet Tumbling Ball Mill, Roller-Race or Ball-Race Mill and Hammer or Impact Mill [7], [8], ... Optimization of a fully air-swept dry grinding cement raw meal ball mill closed circuit capacity with the aid of simulation. Miner. Eng.,

获取价格

Planetary Ball Mills - RETSCH - fine grinding of materials

This means that during one rotation of the sun wheel, the grinding jar rotates twice in the opposite direction. This speed ratio is very common for Planetary Ball Mills in general. Planetary ball mills with higher energy input and a speed ratio of 1:-2.5 or even 1:-3 are mainly used for mechanochemical applications.

获取价格

Factors Affecting Ball Mill Grinding Efficiency - 911 Metallurgist

2017/10/25 Mechanisms of grinding in a ball mill can be broadly grouped as either impact or attrition with at least two forms of breakage attributable to each type. Impact breakage may occur as a result of a particle being smashed between balls or between a ball and the mill lining, but is also generally defined to include slow compression fracturing, or ...

获取价格

Mechanism of high pressure roll grinding on compression

were ground by HPRG and ball mill grinding, respectively. The specification of high pressure roll is d 250 mm×120 mm, while the grinding (compression) pressure is 1 MP and the moisture content of iron concentrates is 8.0%. In order to get the required specific surface area, recycled grinding was carried out. The

获取价格

Ball Mill - Principle, Construction, Working, and More - Soln Pharma

Ball mills are very effective for grinding smooth, aqueous, or oily dispersions by wet grinding since it gives particles of 10 microns or less. Construction of Ball Mill: The basic parts of the ball mill are a shell, balls, and motor Fig.2. A ball mill is also known as a pebble mill or tumbling mill.

获取价格

AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill Operator

Mill Type Overview. Three types of mill design are common. The Overflow Discharge mill is best suited for fine grinding to 75 – 106 microns.; The Diaphram or Grate Discharge mill keeps coarse particles within the mill for additional grinding and typically used for grinds to 150 – 250 microns.; The Center-Periphery Discharge mill has feed reporting from both

获取价格

Grinding Mills and Their Types – IspatGuru

2015/4/9 This ensures that the smaller particles are attacked by the smaller grinding media. Ball mill is a versatile grinding mill and has a wide range of applications. The mill can vary in size from small batch mills up to mills with outputs of hundreds of tons per hour. They are the most widely used of all mills. Roller mills

获取价格

Mechanism of magnetite iron ore concentrate morphology

2022/12/1 The effect and mechanism of magnetite concentrate morphology on the quality of indurated pellets were investigated. Concentrates with different morphologies were prepared using high-pressure grinding rolls (HPGR) and ball mill (BM) grinding techniques. Then pelletizing and induration process is done in the temperature range of

获取价格

Ball Mill - Principle, Construction, Working, and More

Ball mills are very effective for grinding smooth, aqueous, or oily dispersions by wet grinding since it gives particles of 10 microns or less. Construction of Ball Mill: The basic parts of the ball mill are a shell,

获取价格

AMIT 135: Lesson 7 Ball Mills Circuits – Mining

Mill Type Overview. Three types of mill design are common. The Overflow Discharge mill is best suited for fine grinding to 75 – 106 microns.; The Diaphram or Grate Discharge mill keeps coarse particles within the mill

获取价格

Grinding Mills and Their Types – IspatGuru

2015/4/9 This ensures that the smaller particles are attacked by the smaller grinding media. Ball mill is a versatile grinding mill and has a wide range of applications. The mill can vary in size from small batch

获取价格

Mechanism of magnetite iron ore concentrate morphology

2022/12/1 The effect and mechanism of magnetite concentrate morphology on the quality of indurated pellets were investigated. Concentrates with different morphologies were prepared using high-pressure grinding rolls (HPGR) and ball mill (BM) grinding techniques. Then pelletizing and induration process is done in the temperature range of

获取价格

Ball Mill: Operating principles, components, Uses, Advantages and

2022/11/30 The small and average capacity ball mills are used for the final grinding of drugs or for grinding suspensions. 2. The maximum capacity ball mills are used for milling ores prior to manufacture of pharmaceutical chemicals. ... Roller Mill. November 30, 2022. Pin Mill. November 30, 2022. Hammer Mill. November 30, 2022. Fluidized Energy

获取价格

COMPARISON OF GRINDING EFFICIENCY BETWEEN BALL

COMPARISON OF GRINDING EFFICIENCY BETWEEN BALL MILLS AND VERTICAL ROLLER MILLS IN COARSE GRINDING Yakup Umucu 1, Vedat Deniz 2,Osman Mart 1 Abdi Kemal Y!ce 1, Mehmet Fahri Sara" 3 1 S leyman ...

获取价格

What is roller ball mill - planetary ball milllaboratory ball mill

2024/7/21 The Grinding Symphony: Unveiling the Mechanisms of Size Reduction The size reduction process in a roller ball mill unfolds through a carefully orchestrated interplay between shear and impact forces, as well as the grinding media selection: Shear Forces: As the rollers rotate against the inner surface of the chamber, they create a

获取价格

Ball Mills - Mt Baker Mining and Metals

Ball Mills. Ball mills have been the primary piece of machinery in traditional hard rock grinding circuits for 100+ years. They are proven workhorses, with discharge mesh sizes from ~40M to <200M. ... equipped with oversize roller bearings and a complete drive system. All wear parts are highly abrasion resistant and replaceable.

获取价格

Ball Mill Grinder Wet Dry Grinding Ball Mill Labotronics

Our ball mill grinder is a versatile tool designed for grinding and blending materials into fine particles. Its cylindrical chamber houses the grinding medium—be it metallic or ceramic balls—allowing for smooth, efficient milling. Widely used in industries such as mining, ceramics, and pharmaceuticals, this grinder operates through rotation ...

获取价格

Buffalo Abrasives, Inc. Roll Grinding Manual

Roll Grinding • Rolls are used in the production of a large variety of materials including steel, aluminum, brass, copper, textile and paper. During use, these rolls are subject to wear. Grindingis necessary to bring rolls back to their proper geometry and finish. • Roll grinding uses many of the same techniques as any

获取价格

Grinding Media in Ball Mills-A Review - Academia

Mechanisms of Grinding Media Wear in Ball Mills The performance of grinding media in a ball mill is measured in terms of wear rate, which is a function of the media composition, hardness, phase structure, and corrosive– abrasive characteristics of the slurry. The wear mechanisms involved in a ball mill are impact, abrasion, corrosion, and ...

获取价格

Ball Milling - an overview ScienceDirect Topics

The flowchart shows the mechanism of gas-solid reaction through RBM that was proposed by El-Eskandarany. In his model, the starting metallic powders are subjected to dramatic shear and impact forces that are generated by the ball-milling media. ... Ball milling. Ball milling is a grinding method that grinds nanotubes into extremely fine powders ...

获取价格

Intro to Size Reduction - Schutte Hammermill

crushers, ram fed grinders, roll mills, ball mills, and more. Looking a bit closer, even within hammer mills, there are several styles to choose from. ... This next group also features the same grinding mechanism as the first two, and the same thin hammers as the pneumatic hammer mills. The amount of screen coverage is what sets them apart.

获取价格

Analysis of ball movement for research of grinding mechanism

2008/7/2 A simulation of the three-dimensional motion of grinding media in the stirred media mill for the research of grinding mechanism has been carried out by 3-dimensional discrete element method (DEM). The movement of ball assemblies was graphically displayed with some snapshots from start of the milling to 0.20 s. From these

获取价格سامباس اندونيسيا نيكل التعدين

آلة سحق كسارة الحجر الجيري

كسارة بالدوين هاميلتون سين

form grinding machine winter germany parts

عملية تعدين خام الحديد Pdf في الهند

هواية كسارة الصخور

آلة صنع ناقل المسمار

طاحونة آلة المطحنة الصناعية

ماكينة الميكرو

30 20 كسارة فكية أولية الهند

مخروط المستورد في مومباي

تاجر كسارة مخروطية الهند

40tph محطم مصنع البعد

كسارة الحجر ينكدين

مصنعي خام القصدير في باكستان

الذهب الخام الكرة مطحنة التصنيع خطة الأعمال

مصنع غسيل الذهب للبيع ألبرتا

معدلات إنتاج كسارة الصدم

quebradora y quebradora ليxico

آلة مطحنة ريمون ذات جودة عالية لجبس الحجر الجيري

عملية في كولومبيا

موردي عملية مطحنة الصخور

معالجة كسارة الذهب

الات مصنع مناديل

سحق إدارة السجلات

Mining conferences and e po in australia in 2019

حول لدينا

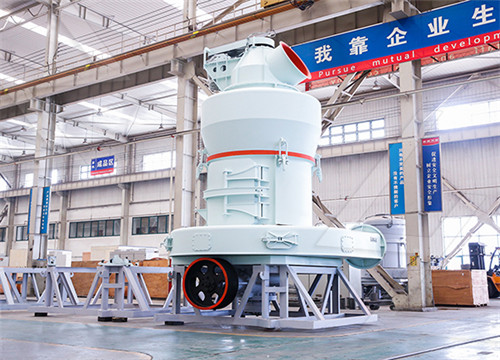

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20