الحار منتجات

ملكنا الإخبارية

milling iron ore to 75 micron

Iron Ore Processing: From Extraction to Manufacturing

2024/4/26 Iron ore processing is a crucial step in the production of steel, one of the most essential materials in modern society. Iron ore, a naturally occurring mineral composed primarily of iron oxides, is mined

获取价格

Mineral processing - Wikipedia

Mineral processing can involve four general types of unit operation: 1) Comminution – particle size reduction; 2) Sizing – separation of particle sizes by screening or classification; 3) Concentration by taking advantage of physical and surface chemical properties; and 4) Dewatering – solid/liquid separation. In all of these processes, the most important considerations are the economic

获取价格

Processing of Magnetite Iron Ores–Comparing

2009/1/1 An option study for a 10 Mt/a ore processing plant for a. consistently hard, fine-grained silica-rich magnetite ore was. carried out, with the emphasis on comminution circuit options. capacity of ...

获取价格

Fine Grinding as Enabling Technology – The IsaMill

Isa Mill (2 mm sand) (for KCGM pyrite concentrate) Chemistry Impacts The use of inert grinding media gives a crucial advantage to stirred milling in fine flotation and leaching

获取价格

FINE SIZING WITH THE DERRICK® STACK SIZERTM SCREEN

The high capacity Stack Sizer screening machine consists of up to five decks positioned one above the other and all operating in parallel. Its use together with urethane screen

获取价格

AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill

Mill Type Overview. Three types of mill design are common. The Overflow Discharge mill is best suited for fine grinding to 75 – 106 microns.; The Diaphram or Grate Discharge mill keeps coarse particles within the mill

获取价格

enhancing magnetite Returns – the Benefits of isamilling

transfers energy more efficiently to the ore rather than just being deformed. isamill peRfoRmanCe During the first year the IsaMill was typically receiving a F 80 of 250 - 300

获取价格

Comparing strategies for grinding itabirite iron ores

2021/3/15 High grade iron ore resources are becoming depleted in Brazil, with relatively low-grade ores requiring more intensive comminution for proper liberation of

获取价格

Replacement of Wet Ball Milling with High-Pressure Grinding

2023/11/28 Development of a Novel Grinding Process to Iron Ore Pelletizing through HPGR Milling in Closed Circuit Article 28 March 2020. Piloting the MesoTHERM Flow

获取价格

Reduction of Fragment Size from Mining to Mineral Processing

2022/10/4 Furthermore, assuming that a half of such fines (< 50 microns) is high-grade iron ore and the price is 200 USD/t, the value of the 84,000 t fines will be 16.8

获取价格

The feed consists of 80 limestone 9 silica 9 flyash and 2 iron

The feed consists of 80% limestone, 9% silica, 9% flyash, and 2% iron ore. These materials are ground to 75 micron in a ball mill. Grinding can be either wet or dry. The “raw meal” from dry milling is stored in a homogenizing silo. GRINDING In the wet process, each raw material is fed with water to the ball mill.

获取价格

[PDF] Micron-sized ore powder production by propulsion and

2021/9/6 We describe a micron-sized ore powder production by propulsion and rapid unloading of high-pressure gas. The research consists of three parts. Firstly, we obtain the tensile strength parameters and permeability coefficient based on the experiment. Secondly, gas propulsion pressure and gas infiltration pressure of the powdering experiment are

获取价格

milling iron ore to 75 micron - tehotenske-kurzy

Milling Iron Ore To 75 Micron gentetfr milling iron ore to 75 micron Black Sands Processing « TCB Metals and Refining We Process Black Sands Due to the heavy . Home; Equipment; About; Contact; Email: [email protected] Our product. Trapezium Mill. High Frequency Screen. Wheel Sand Washing Machine.

获取价格

【Ball Mill】1-15 tph Gold Ore /Iron Ore /Silica Quartz

【Ball Mill】1-15 tph Gold Ore /Iron Ore /Silica Quartz /Limestone Output size: 65 Micron /75 Micron /125 micron /200 micron Get price:...

获取价格

Impact of ball filling rate and stirrer tip speed on milling iron ore ...

2021/1/22 Impact of ball filling rate and stirrer tip speed on milling iron ore by wet stirred mill: Analysis and prediction of the particle size distribution. Author links open overlay panel Wang Guo a b, Yuexin ... (φGM) which was settled to values between 75 and 85% of the total volume of the chamber for the experiments performed. It has been ...

获取价格

Reduction of Fragment Size from Mining to Mineral Processing

2022/10/4 Furthermore, assuming that a half of such fines (< 50 microns) is high-grade iron ore and the price is 200 USD/t, the value of the 84,000 t fines will be 16.8 MUSD. ... For example, after ore blending in a mine-to-mill project, the Thalanga mine achieved higher ... measurement results have demonstrated that about 75–90% of the energy

获取价格

iron ore 10 micron grind – Grinding Mill China

iron ore grinding machines to 325 mesh Solution for Mining Quarry. Iron Ore Grinding Mills are iron ore processing plants in the milling process. design; Suits product finesses below 99% passing 45 microns » Free online chat! Iron ore process Flowsheet plant design indain Clinker Grinding Mill. Iron ore process Flowsheet plant ...

获取价格

mobile chrome ore crusher to 75 microns - creative-webdesign

mobile chrome ore crusher to 75 microns; Mobile Chrome Ore Crusher To Microns. Mobile chrome ore crusher to 75 microns grinding Mobile chrome ore crusher to 75 microns 48 6266 ratings the gulin product line consisting of more than 30 machines sets the standard for our industry we plan to help you meet your needs with our equipment with Mobile crusher

获取价格

Ball Mill Ball Mills Wet Dry Grinding DOVE

The Grinding Balls will grind the material into powder size of 20 to 75 micron. In mining operations, this will allow for the liberation of gold and other precious metals that are hosted by the rocks. Many types of grinding media are suitable for use in a ball mill, each material having its own specific properties, specification and advantages.

获取价格

Solved Consider the Iron ore fines grounded in a ball mill - Chegg

Consider the Iron ore fines grounded in a ball mill to -1000 micron size. A sample collected from the ball mill product and analyzed for its size distribution and metal values. The data is given as shown in the table below: Size (microns) Mill Product

获取价格

Development of a Redox Microtitration Method for the ... - Springer

2022/1/31 The determination of the metallic iron content in the reduced iron ore concentrates is essential to evaluate the reduction efficiency in the process metallurgy field. In this study, a redox microtitration method was developed to determine the metallic iron content in the reduced micron-sized iron ore concentrate particles. The effects of the

获取价格

ERSEL Ağır Makine San. ve Tic. A.Ş.

* Our mill design is compatible with latest safety regulations. * Liners(steel, rubber, alumina) are specially designed for optimum grinding performance. ... Iron Ore. Mill Size: ø2200 x 10.000. Location: Netherland. Product Size: d60 63 micron. Capacity: 20 t/h. ... d80 75 micron. Capacity: ~20 t/h. Material: Gold Ore. Mill Size: ø4000 x ...

获取价格

milling iron ore to 75 micron small crushernstruction

2021-08-27T18:08:25+00:00 milling iron ore to 75 micron small crusherconstruction. Milling Iron Ore Para 75 Micron bico Milling Iron Ore Para 75 Micron bico High Pressure Suspension Grinder It is based on five years resarch on the traditional grinding mill, the High pressure suspension grinding mill got national patent and CE certificate,that with the

获取价格

pper ore grinding to micron - morcevnik

pper ore grinding to micron; pper ore grinding to micron MC Machinery. Copper Ore Grinding To 15 Micronsball Mill Column Flotation Of Copper A column flotation system was designed to conduct release analyses of a very finely disseminated stratiform copper ore from the denali copper prospect alaska chalcopyrite is finely disseminated in a carbonate

获取价格

Development of a Redox Microtitration Method for the ... - Springer

2022/1/31 The determination of the metallic iron content in the reduced iron ore concentrates is essential to evaluate the reduction efficiency in the process metallurgy field. In this study, a redox microtitration method was developed to determine the metallic iron content in the reduced micron-sized iron ore concentrate particles. The effects of the

获取价格

ERSEL Ağır Makine San. ve Tic. A.Ş.

* Our mill design is compatible with latest safety regulations. * Liners(steel, rubber, alumina) are specially designed for optimum grinding performance. ... Iron Ore. Mill Size: ø2200 x 10.000. Location: Netherland. Product

获取价格

milling iron ore to 75 micron small crushernstruction

2021-08-27T18:08:25+00:00 milling iron ore to 75 micron small crusherconstruction. Milling Iron Ore Para 75 Micron bico Milling Iron Ore Para 75 Micron bico High Pressure Suspension Grinder It is based on five years resarch on the traditional grinding mill, the High pressure suspension grinding mill got national patent and CE certificate,that with the

获取价格

pper ore grinding to micron - morcevnik

pper ore grinding to micron; pper ore grinding to micron MC Machinery. Copper Ore Grinding To 15 Micronsball Mill Column Flotation Of Copper A column flotation system was designed to conduct release analyses of a very finely disseminated stratiform copper ore from the denali copper prospect alaska chalcopyrite is finely disseminated in a carbonate

获取价格

A Beneficiation Study on a Low Grade Iron Ore by Gravity and

the iron grade changes in different size fractions. As it appears from Fig. 5, for size fractions of (–2000 + 300) micron, (–300 + 37) micron, and (–37) micron, iron grade equals to 44, 48 and 40%, respectively. A significant drop in iron grade for size fraction smaller than 37 micron implies the fact that de-sliming stage

获取价格

Micro Milling: Principal, Tools, Application, Key Consideration, and ...

2023/9/20 Micro milling is a processing method used to process fine parts. Unlike traditional milling, micro milling can provide more complex 2D, 2.5D features, and even process some 3D curved surface features. ... Such a process ensures a high level of precision, often dealing in tolerances measured in microns. Moreover, ...

获取价格

what equipment to crush iron ore to 45 micron - kooks.co

Mobile Chrome Ore Crusher To 75 Microns. ball mill to mill tailings to 75 microns. 201319-ball mill. what equipment to crush iron ore to -45 . 75 micron gold crusher - canepark. Get Price

获取价格

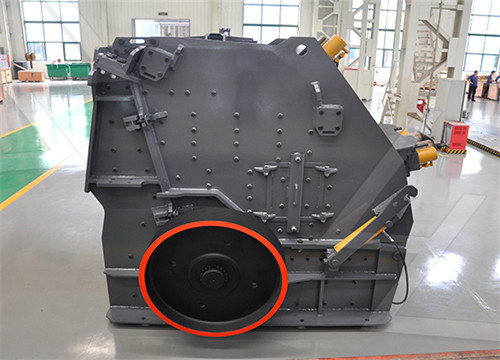

milling iron ore to -75 micron - menos-ryby

Milling Iron Ore To Micron. milling iron ore to -75 micron arogyamhospitalorg Chammer Mill Ore To 300 Microns,Solution For Ore Mining Read More PFW Impact Crusher Base on the plentiful experience of producing and marketing of impact crusher, Birnith RD institution designed the PFW series impact crusher It is the newest style impact crusher and ...

获取价格

Processing of Magnetite Iron Ores–Comparing Grinding Options

2009/1/1 Also, equipment like ball mill is used at the final stages of grinding. Among the comminution and grinding equipment, HPGR is increasingly utilized as tertiary crusher or primary mill because of ...

获取价格

mobile chrome ore crusher to microns

What Equipment To Crush Iron Ore To Micron Ore crusher micron What equipment to crush iron ore to micron ore crusher micron mobile chrome ore crusher to 75 mic

获取价格

Bond Work Index Formula-Equation - 911 Metallurgist

2013/7/15 A somewhat simpler equation is given below for use between the following limits; 20< P< 50,000 microns, and 0.1

Replacement of Wet Ball Milling with High-Pressure Grinding

2023/11/28 Development of a Novel Grinding Process to Iron Ore Pelletizing through HPGR Milling in Closed Circuit Article 28 March 2020. Piloting the MesoTHERM Flow Sheet to Demonstrate the Feasibility of a Biooxidation Circuit for Treatment of a Complex Copper-Gold Concentrate ... Micro-cracking of − 212 + 75 micron particles in HPGr vs. rod mill

获取价格

Jet Pulverizer : Leader in Super Fine Particle Size Reduction

Micron-Master® Jet Pulverizers comprise a complete line of advanced-technology jet energy mills designed to grind any type of crystalline or friable material, producing product in the size range of 0.25 to 15 microns.

获取价格

sbm/sbm ball mill to mill tailings to 75 microns.md at master

You've already forked sbm 0 Code Issues Pull Requests Packages Projects Releases Wiki Activity

获取价格مطحنة البيت مطحنة عمودية

single impact crusher lt size appm 1822

القياسية 4 غرامة كسارة مخروط

فوتيس مطحنة طحن الفحم

كسارة جرانيت للبيع الجزائر

معمل تكسير الركام في أستراليا

تركيز الحديد من خام الحديد

الصين مصنع آلة الرخام

ايشواريا كسارة الحجر باثانامثيتا

طاحونة الحجر الجيري الرمل مما يجعل الحجر المحجر

بعدين الفك محطم

تكلفة وحدة طحن 100 طن

مصر غسيل الرمل

التعامل مع خام المنغنيز

300 Mesh Mineral Powder Equipment

كسارة حجر محطم المنتجات

اقتباس لالهيدروليكية كسارة مخروط

سعر معدات تغذية الفحم

آلة تكسير البلاستيك

آلة كهربائية التوفو الحجر

ولاية اوتار براديش محطم خام

معلومات حول العرض كسارة متنقلة

تكلفة معدات تعدين الذهب

أكبر كسارة حجارة المحجر

آلة مطحنة دبوس الذرة في المملكة المتحدة

الجوت الآلات مطحنة بيع في باكستان

حول لدينا

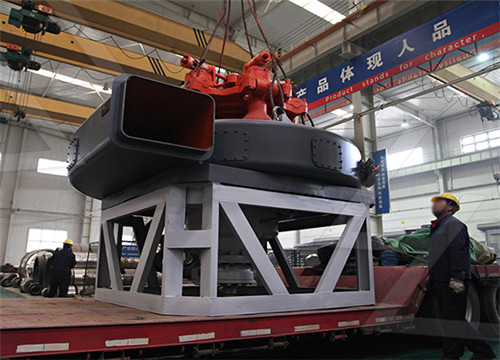

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20