الحار منتجات

ملكنا الإخبارية

Wear Rate Of Grinding Media In Cement Ball Mill

A comparison of wear rates of ball mill grinding media

2016/1/1 abrasive and impact wear due to their large. (75 – 100 mm) dia meters. Ball mill balls. experience a greater number of impacts, but

获取价格

(PDF) Grinding Media in Ball Mills-A Review - ResearchGate

2023/4/23 The performance of grinding media in a ball mil l is also measured in terms of its wear rate. Abrasive ores such a s gold and copper produce high wear rates

获取价格

A Review of the Grinding Media in Ball Mills for Mineral Processing

2023/10/27 Volumetric mill filling also influences grinding media wear rates, among other performance parameters. The effect of the kidney-shaped is more pronounced by

获取价格

How to choose proper grinding media for your ball mill

2021/2/25 Steel balls are one of the most widely used grinding media in cement ball mills, their diameters can range from 20mm to 120mm according to different grinding requirements. In a cement ball

获取价格

Effect of the operating parameter and grinding media on the wear ...

2019/12/15 The wear of lifter in ball mill directly affects the grinding efficiency and economic cost. ... Increasing ball filling will increase the wear rate, and the grinding

获取价格

Modeling and prediction of wear rate of grinding media in mineral ...

2020/8/3 A data set derived from 50 experiments on the wear rate of a low alloy steel ball was applied in this work. The experimental data were obtained from literature [].The

获取价格

A comparison of wear rates of ball mill grinding media

The Ball Mill Abrasion (BMA) test was developed by the University of Queensland Materials Performance group to simulate the high stress abrasion conditions experienced in production ball mills. It gives

获取价格

A discussion on the measurement of grinding media wear

2016/7/1 2.3. Wear of grinding media. One of the major problems regarding the use of ball mills is to balance the size distribution of grinding media into the mill, which is

获取价格

Consumption of steel grinding media in mills – A review

2013/8/1 The effect of particle size on the wear rates of grinding media is not yet fully understood. ... The effects of grinding media shapes on the grinding kinetics of

获取价格

Consumption of steel grinding media in mills – A review

2013/8/1 The effect of particle size on the wear rates of grinding media is not yet fully understood. ... The effects of grinding media shapes on the grinding kinetics of cement clinkers in ball mill. Powder Technology, 235 (2013), pp. 422-425. View PDF View article View in Scopus Google Scholar. Radziszewski, 1997.

获取价格

Ball charges calculators

- Ball top size (bond formula): calculation of the top size grinding media (balls or cylpebs):-Modification of the Ball Charge: This calculator analyses the granulometry of the material inside the mill and proposes a modification of the

获取价格

List Factors Affecting Grinding Ball / Media Wear

2018/4/30 In order to determine the relative wear rates of several sizes of grinding balls, groups of 4, 3½, 3, and 2 in. balls were marked individually and were charged, all at the same time, into each of two

获取价格

A comparison of wear rates of ball mill grinding media

The Ball Mill Abrasion (BMA) test was developed by the University of Queensland Materials Performance group to simulate the high stress abrasion conditions experienced in production ball mills. It gives accurate predictions of the service life of wear resistant alloys in mill liner and grinding media applications. In this paper the BMA test methodology

获取价格

Modeling and prediction of wear rate of grinding media in

2020/8/3 A data set derived from 50 experiments on the wear rate of a low alloy steel ball was applied in this work. The experimental data were obtained from literature [].The experimental conditions, influential factors and the total wear rate for each experiment, which was determined by the grinding media weight loss, are implied in Table 1.To

获取价格

Ball Mill Success: A Step-by-Step Guide to Choosing the Right Grinding

2024/8/8 The choice of grinding media plays a crucial role in determining the efficiency of the ball milling process. Different materials, sizes, and densities of grinding media can significantly affect the energy transfer during milling, impacting the rate and uniformity of particle size reduction.

获取价格

A Review of the Grinding Media in Ball Mills for Mineral Processing

2023/10/27 Equations (2) and (3) can be used to calculate the ball size distribution at any given time and simulate the wear rate of the grinding media in the mill. ... Deniz, V. A study on the specific rate of breakage of cement materials in a laboratory ball mill. Cem. Concr. Res. 2003, 33, 439–445. [Google Scholar]

获取价格

Mining Engineering Consultants - PEC Consulting Group

%PDF-1.6 %âãÏÓ 83 0 obj > endobj 102 0 obj >/Filter/FlateDecode/ID[99BDA6995622E142B8D9E49ED83701F0>]/Index[83 28]/Info 82 0 R/Length 96/Prev 259493/Root 84 0 R ...

获取价格

Cement Mill Grinding Media Wear Rate Calculation - Scribd

Cement Mill Grinding Media Wear Rate Calculation - Free download as PDF File (.pdf), Text File (.txt) or view presentation slides online. The document discusses calculating the wear rate of grinding media in cement mills. It examines how to determine the weight of grinding balls added to or removed from the mill, how many kilograms of grinding

获取价格

Comparing ball mills and VRMS for cement grinding

2013/2/26 The comparative advantages of ball mills and VRMs in cement grinding. ... the grinding media in a ball mill has a much higher wear rate compared to that of the table and rollers in a VRM. With a ball mill, it is important to monitor the performance through axial testing, to ensure that the media grading is correct and that there is a

获取价格

A discussion on the measurement of grinding media wear

2016/7/1 Iwasaki et al. [14] proposed a corrosion model for the grinding media, involving two types of galvanic cells, as shown in Fig. 3.In the differential abrasion cell, the abraded surface acts as an anode, whereas the un-abraded surface acts as a cathode, and the corresponding corrosion reactions are iron oxidation in the first area and oxygen

获取价格

Grinding Media in Ball Mills-A Review - ResearchGate

Table 1. Chemical composition of typical grinding media (% wt.). Adapted from [24]. 2.1.1. Cast Iron Cast iron can be grey cast iron or white cast iron, but white cast irons are commonly used in ...

获取价格

Everything you need to know about clinker/cement Grinding

BALL WEIGHTS AND SIZES (New Grinding Media) High Chrome Cast Iron Grinding Balls. ... ball charge composition will allow an even better mill operation. Ball Charge Wear Rates. ... The graphic below gives the distribution of the gross and net wear rate in the Group for cement grinding based on ATR 1’998. The average net wear is 14.9 [g/t ...

获取价格

Cement Mill Grinding Media Wear Rate Calculation PDF PDF

The grinding media wear rate is an important factor to consider in cement mill operations. It is calculated based on parameters like the mass of grinding balls added over a period to maintain the required ball charge in the mill. Regular monitoring of the wear rate helps determine the lifetime of grinding media and optimize replacement cycles to improve

获取价格

A discussion on the measurement of grinding media wear

2016/7/1 Iwasaki et al. [14] proposed a corrosion model for the grinding media, involving two types of galvanic cells, as shown in Fig. 3.In the differential abrasion cell, the abraded surface acts as an anode, whereas the un-abraded surface acts as a cathode, and the corresponding corrosion reactions are iron oxidation in the first area and oxygen

获取价格

Grinding Media in Ball Mills-A Review - ResearchGate

Table 1. Chemical composition of typical grinding media (% wt.). Adapted from [24]. 2.1.1. Cast Iron Cast iron can be grey cast iron or white cast iron, but white cast irons are commonly used in ...

获取价格

Everything you need to know about clinker/cement

BALL WEIGHTS AND SIZES (New Grinding Media) High Chrome Cast Iron Grinding Balls. ... ball charge composition will allow an even better mill operation. Ball Charge Wear Rates. ... The graphic below gives the

获取价格

Cement Mill Grinding Media Wear Rate Calculation PDF PDF

The grinding media wear rate is an important factor to consider in cement mill operations. It is calculated based on parameters like the mass of grinding balls added over a period to maintain the required ball charge in the mill. Regular monitoring of the wear rate helps determine the lifetime of grinding media and optimize replacement cycles to improve

获取价格

Effect of the operating parameter and grinding media on the wear

2019/12/15 The wear of lifter in ball mill directly affects the grinding efficiency and economic cost. ... Increasing ball filling will increase the wear rate, and the grinding media shape of ball has a maximum wear rate. ... Boemer D, Ponthot JP. A generic wear prediction procedure based on the discrete element method for ball mill liners in the

获取价格

Grinding Media Magotteaux

Magotteaux Mining Grinding Media One Cast High Chrome is the best option when the situation requires optimal wear resistance against abrasion and corrosion. Available in diameters of 0.5-4 inches, Magotteaux Mining Grinding Media One Cast High Chrome is appropriate for ball mills and tower mills, along with wet and dry ore applications.

获取价格

A Review of the Grinding Media in Ball Mills for Mineral Processing

2023/10/27 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles. Grinding media play an important role in the comminution of mineral ...

获取价格

Grinding Media in Ball Mills-A Review - Academia

3. Mechanisms of Grinding Media Wear in Ball Mills The performance of grinding media in a ball mill is measured in terms of wear rate, which is a function of the media composition, hardness, phase structure, and corrosive– abrasive characteristics of

获取价格

Cement grinding: VRM or ball mill? - LinkedIn

2019/2/9 Overall, the maintenance costs are not dissimilar for both types of mills: while the wear rates for a ball mill are higher than for a VRM, the cost of the replacement parts is lower, and the ...

获取价格

EVERY COMPONENT OF BALL MILL DETAILED EXPLAINED

Insufficient mill cooling lead to material agglomeration on balls and liners. The grinding is not any more done by balls against material but by material against material. SOLUTION. Adapted mill cooling, playing with:-Clinker temperature-Mill ventilation-Water injection. Use of grinding aid (temporary solution because expensive) Water Injection ...

获取价格

Grinding Balls and Other Grinding Media: Key consumables

2021/1/25 They are recommended for cement grinding and ultra-fine wet regrinding operations. Ball Mills: 1”-4” grinding balls are recommended. ... In comminution, high grinding media wear rates represent very high production costs. The costs should be minimised by proper materials selection, especially for grinding balls.

获取价格

Cast Grinding Balls - Alpha Grinding Media

2022/4/20 Alpha offers cast grinding balls with different chromium contents for use in SAG mills and ball mills in mining, cement and steel industries. ... Currently we are known for high quality low wear rate cast balls that are leading among the most famous international brands in the field of grinding media. Our experience record indicates an

获取价格

Cement grinding Vertical roller mills VS ball mills

These works are obviously more complicated than just adding more balls to a ball mill. However, the wear rate for grinding parts of an OK mill grinding OPC is fairly low and maintenance of wear parts, i.e. reversal, hardfacing or replacement, can usually be scheduled to take place say once per year to follow the plant’s kiln maintenance program.

获取价格مواصفات الحزام الناقل لكسارة الحجر في الهند

صخرة محطم خط محطم

التعامل مع ناقل الفحم

معارض معدات ثقيلة الامارات

الصغيرة المغذية الشاشة تهتز

تكلفة خط إنتاج آلة التكسير في السودان

كيف يمكنك تعيين كسارة الفك الفك

الجير التعدين في زيمبابوي

أهمية التعدين في المغرب

شاكر الجدول خام الذهب

كسارة السيارات للبيع

رخصة كسارة للبيع ام الحمى مكة

تعدين وتجهيز الجبس

حجر ج 105 كسارات الفك الابتدائي

rock crusher parts for sale india

الكرة مطحنة تغذية الفحم نوع طبل

اسماء المعلمات الناقلات بمحافظة العيص 1433

stone crusher dealer address

تكلفة مصنع كسارة في مصر

latin america sales manager for heavy equipment

سعر كسارة الرمل والحصى Moldova

الا يما مشا مطحنة هت عباتي واشا ام محكمة

معدات استخراج الصخور في الفلبين

كيف يتم تكسير النباتات

نيجيريا الفحم لتوليد الطاقة الكهربائية

قائمة أصحاب الكسارة التاميل نادو

حول لدينا

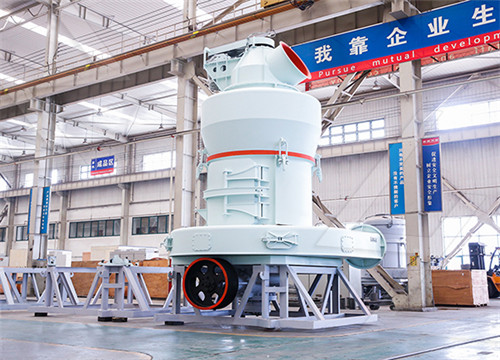

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20