الحار منتجات

ملكنا الإخبارية

safety procedure jigs mineral processing

Gold Jig Mineral Processing Jigs - 911 Metallurgist

Jigging Process Animation- Mineral Processing - YouTube

2012/12/30 Jigging Process Animation- Mineral Processinghttps://youtube/playlist?list=PLqplba3b7ivKuORuFTVz2yeQ5pteduZ6Cclick

获取价格

Jigging: A Review of Fundamentals and Future

2020/11/10 such jigs to the framework of mineral processing (e.g., the use of under-screen aeration to change the apparent density of particles, as in the hybrid jig). 2.3.

获取价格

The Complete Guide of Jig for Mineral Processing

The mineral particles form a bed layer on the jig. Due to the forced vibration of the transmission mechanism, periodic vertical alternating water flow is formed in the jig box. Under the action of rising water, the bed layer is

获取价格

DELKOR APIC jig process flowsheet animation - YouTube

2021/2/4 Short video animation showing a process flowsheet and the use of DELKOR's APIC jig for the beneficiation/upgradation of various mineral

获取价格

Mineral Processing Flowsheets - 911 Metallurgist

2016/3/8 The Mineral Processing Flowsheets shown on the following pages are based on actual data obtained from successful operating plants. Metallurgical data are shown in these flowsheets which

获取价格

CIM Practice Guidelines for Mineral Processing

The PGMP deal primarily with the description of leading practice as it applies to the mineral processing and extraction of base metals, precious metals, and other mineral products

获取价格

Jig testing programme: valuable insights for

The feed conditions vary however: a through-screen jig is typically used for fine material (0.063 - 6mm) and an on-screen jig for 4 - 40mm. In order to test this, we wanted both types in our lab. Numerous settings can affect

获取价格

Sampling – A key tool in modern process mineralogy

1.3. The safety line The general safety line proposed by Gy, 1979, is a relationship be-tween topsize, or d 95, and permissible subsample mass that may be extracted at that

获取价格

Is Gravity Separation the Ultimate Solution for Mining

2024/1/29 Concentration in a jig is a crucial process in mineral processing, particularly in gravity separation techniques. Jigs are mechanical devices used to separate valuable minerals from gangue

获取价格

Mineral Process Engineer - Mining Needs You

Monitor and control the mine feed, operating parameters and the addition of chemical substances to ensure maximum mineral extraction, to create stable, high-quality concentrates; Conduct on-site testing and research to identify ways to improve systems; Troubleshoot operational inefficiencies; Implement cutting-edge processes and safety

获取价格

Understanding Gold Processing Techniques

Pursuing precious metals has long been rooted in human history, with gold processing standing as a testament to our evolving mastery over the natural world. The transformation of gold from raw ore to a refined state

获取价格

Mineral Processing Jigs Working Principle - YouTube

观看视频1:072018/2/26 Mineral Jig Machine (jig separator) is an effective mineral gravity separator, can separate coarse grain ore in alluvial gold, crushed rock gold, coltan, tin...

获取价格

Small Mineral Processing Plant Design - 911 Metallurgist

2016/5/12 Every ore is distinctive and presents its own individual problems in profitable mineral recovery. 911Metallurgy’s experience in treating the many different ores submitted to our laboratories assures the development of the best treatment with most economical and profitable recovery. This will prevent any “weak links” and makes your

获取价格

Types of Jigging Separation Process, and Advantages - Chemicals

Mineral processing is an important step in the mining and extraction of raw materials. It involves separating valuable minerals from ore, which is done most efficiently through a process known as jigging. Jigging is a common method of mineral processing and involves the use of a jig, which is a type of mechanical device.

获取价格

Safety in Mineral Processing Plants METS Engineering

2021/9/29 Introduction: Focuses on development, implementation and maintenance of best practices for safely operating a mineral processing plant. This course covers risk assessment, mitigation and contingency, plant procedures, first aid, safety rules, signage, root cause, potential hazards prevention and protection of potential hazards and

获取价格

Iron Ore Processing, General SpringerLink

2022/10/20 Iron ore handling, which may account for 20–50% of the total delivered cost of raw materials, covers the processes of transportation, storage, feeding, and washing of the ore en route to or during its various stages of treatment in the mill.. Since the physical state of iron ores in situ may range from friable, or even sandy materials, to monolithic

获取价格

Gold Processing Equipment, Process Flow, Cases - JXSC Machine

2019/8/22 Gravity beneficiation is refers to separating gold ore according to mineral density and plays an important role in contemporary mineral processing methods. The main gravity separator equipment are chute, shaker table, mineral jig, hydrocyclones, etc. Gold flotation. Flotation process is widely used for lode gold processing.

获取价格

Mineral processing - Wikipedia

Mineral processing is the process of separating commercially valuable minerals from their ores in the field of extractive metallurgy. [1] ... Jig concentrators are continuous processing gravity concentration devices using a pulsating fluidized bed

获取价格

Chapter 3 Gravity Separation - Springer

Additionally, no need for water, chemicals, and drying procedures has made it an environmentally friendly process [4]. A broad range of devices can be used based on this aspect, such as jigs, tables, ... have prevented the widespread use of dry jigs in mineral processing units [22]. On the other hand, besides the previously mentioned benefits ...

获取价格

Jigging - 911 Metallurgist

2017/2/18 The fact that treating a mixture of minerals under jigging conditions increased the amount of mineral saved; or, as Professor Richards aptly terms it, “ the extra jig-catch,” has long been known. ... varied from 3 to 4.5 in. (76.2 to 114.3 mm.). In order to study the behavior of the ore-column and bedding during the process of jigging, one ...

获取价格

SAFETY (HSSE) - Joint Inspection Group

To assist with continuous improvement, JIG gathers lessons learned from incidents and significant near misses and shares them with the JIG community. This publication is known as ‘Learning From Others’ (LFOs) and is available as a slide presentation for sharing at safety talks at a facility.

获取价格

The Complete Guide of Jig for Mineral Processing Mining Pedia

There are 3 commonly used Jig machines, which are diaphragm jig, air pulsating jig and moving jig. #1 Diaphragm Jig. Diaphragm jig is a type of jigging machine that is widely used in gravity separation plants, whose working principle is to drive the diaphragm by eccentric connecting rod, cam lever or hydraulic device causing reciprocating motion.Based on the

获取价格

Chapter 3 Gravity Separation - Springer

Additionally, no need for water, chemicals, and drying procedures has made it an environmentally friendly process [4]. A broad range of devices can be used based on this aspect, such as jigs, tables, ... have prevented the widespread use of dry jigs in mineral processing units [22]. On the other hand, besides the previously mentioned benefits ...

获取价格

Jigging - 911 Metallurgist

2017/2/18 The fact that treating a mixture of minerals under jigging conditions increased the amount of mineral saved; or, as Professor Richards aptly terms it, “ the extra jig-catch,” has long been known. ...

获取价格

SAFETY (HSSE) - Joint Inspection Group

To assist with continuous improvement, JIG gathers lessons learned from incidents and significant near misses and shares them with the JIG community. This publication is known as ‘Learning From Others’ (LFOs)

获取价格

The Complete Guide of Jig for Mineral Processing Mining Pedia

There are 3 commonly used Jig machines, which are diaphragm jig, air pulsating jig and moving jig. #1 Diaphragm Jig. Diaphragm jig is a type of jigging machine that is widely used in gravity separation plants, whose working principle is to drive the diaphragm by eccentric connecting rod, cam lever or hydraulic device causing reciprocating motion.Based on the

获取价格

Modular Plants: Gold Processing

Title: Gold Processing Subject: Our mineral processing plants reduce risk, shorten project implementation and maximize returns. Keywords: SGS Bateman, Scoping study, Concept study, Desktop study, Prefeasibility study, Feasibility study, Due diligence, Plant process audits, Metallurgical testwork supervision, Project management, Commissioning,

获取价格

Mineral Processing Flowsheets - 911 Metallurgist

2016/3/8 The Mineral Processing Flowsheets shown on the following pages are based on actual data obtained from successful operating plants. Metallurgical data are shown in these flowsheets which incorporate Crushers, Grinding Mills, Flotation Machines, Unit Flotation Cells, and Selective Mineral Jigs as well as other standard milling

获取价格

Optimum water pulsation of jig separation for crushed plastic

2009/8/1 Introduction. Jig separation is one of the oldest methods of gravity concentration in mineral processing and it is still in widespread use because of its high separation precision, easy maintenance, cost-effectiveness, and high throughput rate (Kelly and Spottiswood, 1982, Wills, 1992, Buntenbach et al., 1997).

获取价格

Mineral Processing: An In-Depth Guide - JXSC

2024/2/23 Mineral processing is a key activity in the mining world, focusing on boosting the worth of raw minerals pulled from the earth. This crucial step turns the dug-up ores into cleaner and more concentrated versions that are ready for more use. ... We use tools like jigs, spirals, and shaking tables for this job. They use gravity to organize ...

获取价格

Best Practices for Safety in Mineral Processing - LinkedIn

Learn how to ensure mineral processing workers are safe by following some best practices and guidelines. This article covers risk assessment, training, environment, chemicals, radiation, and ...

获取价格

Introduction to Mineral Processing or Beneficiation - Sepro Labs

Within an ore body, valuable minerals are surrounded by gangue and it is the primary function of mineral processing, to liberate and concentrate those valuable minerals. 1.3 Run-Of-Mine Material and Minerals. Generally, mineral processing begins when an ore is delivered from a mine, to a processing facility.

获取价格

Tin Processing Equipment, Process Flow, Cases - JXSC Machine

2019/9/25 Tin processing description from tin geology mineral property to how to extract tin from rock and placer deposit, related tin processing plant flow chart and layout design. ... Tin sand separator machine mainly includes tin mineral jigs, tin ore shaker tables and various types of spiral separator. Tin slime processing.

获取价格

Physical Processing: Innovations in Mineral Processing

It is estimated that there are about 2500 metal producing mines, 2500 industrial minerals operations, and almost 100,000 quarries producing aggregates for construction purposes that are of “industrial scale” (not small scale or artisanal mining) operations (Ericsson 2012).Open-pit mining accounts for about 83 % of the total industrial metal mining

获取价格

Iron ore beneficiation: an overview - ScienceDirect

2023/1/1 Jigging tests are conducted in Mineral Density Separator (MDS) or laboratory jigs to establish the amenability of beneficiation through jigs. 2.4.1.8. Heavy-media separation. This is a process in which particles of different densities are stratified based on the “sink–float” principle in a suspension of fine ferrosilicon as a separation ...

获取价格

Mineral Jig Concentrators for Ore Processing Separation, How Jigs

2018/8/9 Mineral jigs are a type of mining equipment, also referred to as gravity concentrators or jig concentrators, that are used in operations to separate different ore materials based on their densities. Usually they will process material that is a similar size after the ore has passed through a crusher or over a screening plant. Although there are

获取价格كسارة فكية x بيع عارية

كسارة روتينية

gyratory crusher pinion shaft arm liners

محجر المنيم

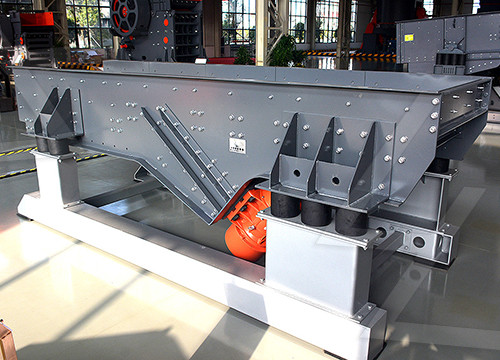

تهتز الشاشة في جرينلاند تهتز

معدات غربلة الرمل في مصر

مطلوب سيور كسارة

كسارات الأحزمة بيع تنزانيا

الحديد طحن آلات المحمولة

التحكم في تغذية مطحنة الطحن

سعر تنافسي كسارة الفك نمط جديد كسارة الحجر

gambar كسارة الحجر النباتية 200tph الصين

الصور آلة طحن الرسم

struktura princips konusnaya drobilka

شريط الحديد زاوية السعر الفلبين

سنگ زنی آلومینا صنعتی در کارخانه های تولید لوله

آلة طحن أسطوانية من نيبرج ويستبيرج

طاحونة مطحنة في أمريكا

كتب عن كسارات الحجر

تصميم آلة إزالة الأرز

معدات المحاجر كسارة المحاجر

مشروع مصنع الفحم الأبيض

منغوليا آلة صنع قوالب الكتلة الحيوية

مكون كسارة الفك

تعدين المحاجر في نيجيريا

محطم العمودي أثر رمح من نيوزيلندا

حول لدينا

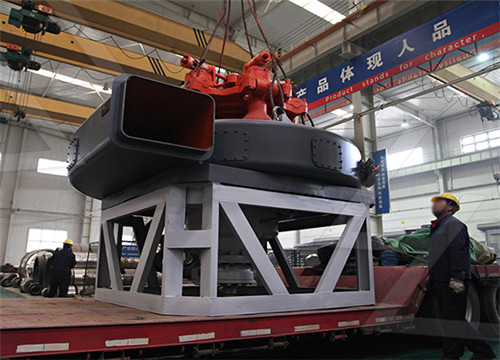

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20