الحار منتجات

ملكنا الإخبارية

vibrating screen selection and size

How To Size and Select a Vibrating Screen for an Aggregate

2023/9/1 Vibratory Screens come in a variety of sizes. They can range from 4’ to 12’ wide and 6’ to 32’ long. The width of the screen determines the carrying capacity of the

获取价格

Basic concepts of vibrating screens: What they are, what they are

2023/8/2 Also called simply screens, a vibrating screen is formed by a vibrant chassis that supports in its interior one or several surfaces or elements of screening. The

获取价格

Vibrating Screen Capacity Calculations - MEKA

Essential Guide to Vibrating Screen Design: Benefits, Types - JXSC

2024/7/26 Screen Mesh Selection: ... Screen Mesh Size: The size of the mesh of the vibrating screen is a major determinant of the efficiency of the machine. The mesh

获取价格

How to successfully set up vibrating screens : Pit

2022/7/13 Vibrating screen selection is based on several factors, including maximum tons per hour, gradation of the feed material, type and weight of material, desired size of separation, any surface moisture on

获取价格

Vibrating Screen Working Principle - 911 Metallurgist

2015/7/26 Fundamentals of Vibrating Screen Size Selection. Before Separation can take place we need to get the fine particles to the bottom of the pile next to the screen deck openings and the coarse particles to the

获取价格

How to Select a Vibrating Screen for Your Industry

2024/1/4 The linear vibrating screen is commonly used in mining and aggregates because it harnesses the power of double vibrating motors rotating in opposite and synchronous directions. This imparts a horizontal

获取价格

Vibrating Screen Guide: Definition, Types, Working

2023-11-27 /. A vibrating screen, also known as a separator or sifter, is a machine that is used to separate particles or materials into different sizes based on their particle size or shape. Here is a guide covering the

获取价格

Aggregate Screen Sizes and How to Choose the Aggregate

The aggregate vibrating screen works by vibrating the screen mesh, which allows the smaller particles to fall through the openings while the larger particles remain on the

获取价格

Vibrating Screen Working Principle: Understanding

2023/3/10 If you are in the mining, construction, or agricultural industry, you must have heard about vibrating screens. Vibrating screens are widely used in the industry to separate and grade materials

获取价格

Vibrating Screen Guide: Definition, Types, Working

2023/11/27 A vibrating screen, also known as a separator or sifter, is a machine that is used to separate particles or materials into different sizes based on their particle size or shape.Here is a guide covering the

获取价格

Construction Working and Maintenance of Vibrators and

7 Vibrating Screen Installation, Start up and Adjustments 54 ... Information on screening and types of screens is given in this chapter. Size Control ... Selection between screening and classification is influenced by the fact that finer separations demand large areas of screening surface and therefore can be expensive compared with ...

获取价格

Screening Theory and Practice - Triple/S Dynamics

The Inclined Vibrating Screen: 1200 rpm, 1/4” vertical circle dia. D. The Horizontal Vibrating Screen: 840 rpm , 1/2” stroke at 45°. ... The cutpoint defines the minimum particle size retained on the screen, and the maximum undersize particle passing. Unless the particle is acicular, platy, ovaloid or a

获取价格

Basic concepts of vibrating screens: What they are, what they

What are vibrating screens and which are its main applications for use. Also called simply screens, a vibrating screen is formed by a vibrant chassis that supports in its interior one or several surfaces or elements of screening. The screens serve to classify the different particles by size, starting from a bulk product in a continuous process.

获取价格

Ore, Rock Aggregate Screening (Complete Guide) - 911

2016/6/20 A-Z Guide to Screening Ore, Rock Aggregate A simple definition of a “screen” is a machine with surface(s) used to classify materials by size. Screening is defined as “The mechanical process which accomplishes a division of particles on the basis of size and their acceptance or rejection by a screening surface”. Knowledge of

获取价格

Principles of Screening and Sizing - 911 Metallurgist

Each opening has a volumetric throughput capacity: • Basic capacity figure is expressed as . tph per sq.ft. • Figure is multiplied by the sq. footage of the screen deck.

获取价格

Vibrating Screen Capacity Calculations - MEKA

The material velocity of a circular vibrating screen can be calculated from the corrected theoretical speed of the product formula written below. Example: Determine the material velocity of a screen vibrated at 900 RPM with a 12 mm stroke and 20° degree inclination angle. To calculate the bed depth of the material, the following formula is used.

获取价格

High-frequency vibrating screens - Wikipedia

High-frequency vibrating screens are the most important screening machines primarily utilised in the mineral processing industry. They are used to separate feeds containing solid and crushed ores down to less than 200 μm in size, and are applicable to both perfectly wetted and dried feed. The frequency of the screen is mainly controlled by an

获取价格

Vibrating Screen Working Principle and Operations

The Vibrating screens have accuracy of sizing, increased capacity per square metre and low maintenance cost per ton of material handled. Principle and Operation of the Vibrating Screen. In the case of a vibrating screen, the vibrations are given to the screen to effect the separation of solid particles into two size fractions. Vibrations given ...

获取价格

A review on the advanced design techniques and methods of vibrating ...

2019/4/1 In reality, a large vibrating screen, which has a screen surface width of no less than 3.6 m and a screening area of no less than 20.0m 2, usually oscillates with extremely complex dynamic characteristics of the screen body [10, 11].As shown in Fig. 2 (b), generally, except for the dominated strong alternating load yielded by two box-type

获取价格

What Is A Vibrating Screen? - mineralscreen

2023/9/1 Benefits of Vibrating Screens. Vibratory screens are one of the main types of industrial screening equipment. There are several mechanical screening solutions available across the solid waste management, recycling, and aggregate industries; however, vibrating screens offer a number of unique advantages that make them a first-line

获取价格

Vibratory Screening Equipment Weir

With over 150 years of engineering expertise and decades of creating innovative designs from the highest quality materials, our range of screening equipment is built for maximum throughput and efficiency. Offering outstanding performance, using the latest in materials technology - Enduron® screens provide long service life, within even the most

获取价格

Screening Theory and Practice

%PDF-1.3 %âãÏÓ 1 0 obj >]/PageLabels 6 0 R/Pages 3 0 R/Type/Catalog/ViewerPreferences >>> endobj 2 0 obj >stream 2013-01-30T18:19:09-06:00 2013-01-30T18:19:13-06: ...

获取价格

A review on the advanced design techniques and methods of vibrating ...

2019/4/1 In reality, a large vibrating screen, which has a screen surface width of no less than 3.6 m and a screening area of no less than 20.0m 2, usually oscillates with extremely complex dynamic characteristics of the screen body [10, 11].As shown in Fig. 2 (b), generally, except for the dominated strong alternating load yielded by two box-type

获取价格

What Is A Vibrating Screen? - mineralscreen

2023/9/1 Benefits of Vibrating Screens. Vibratory screens are one of the main types of industrial screening equipment. There are several mechanical screening solutions available across the solid waste management, recycling, and aggregate industries; however, vibrating screens offer a number of unique advantages that make them a first-line

获取价格

Vibratory Screening Equipment Weir

With over 150 years of engineering expertise and decades of creating innovative designs from the highest quality materials, our range of screening equipment is built for maximum throughput and efficiency. Offering outstanding performance, using the latest in materials technology - Enduron® screens provide long service life, within even the most

获取价格

Screening Theory and Practice

%PDF-1.3 %âãÏÓ 1 0 obj >]/PageLabels 6 0 R/Pages 3 0 R/Type/Catalog/ViewerPreferences >>> endobj 2 0 obj >stream 2013-01-30T18:19:09-06:00 2013-01-30T18:19:13-06: ...

获取价格

Shortcomings of Vibrating Screen and Corrective Measures: A

2019/7/27 The study of the conventional vibrating screen was carried by visiting JSW cement plant, Ballari. The vibrating screen used in cement plant was used to screen the cement residues of particle size under 2 mm. The conventional vibrating screen mainly consists of a base, screen, screen frame, two vibrators and four helical springs.

获取价格

How to choose vibrating screen mesh size Haiside

2023/9/13 Choosing the right vibrating screen mesh size is crucial for achieving the desired separation or classification of materials in a vibrating screen. The mesh size directly impacts the efficiency and performance of the screen in terms of particle size separation. The steps to help you choose the appropriate vibrating screen mesh size

获取价格

Vibrating screen theory and selection principle Haiside

2021/3/9 Vibrating screen is a very important stone grading and screening equipment in the mining industry.It can greatly increase the utilization rate of stone and reduce the failure rate of mechanical equipment in the subsequent processes.It is different from traditional manual screens.To help everyone For a good understanding of this

获取价格

How to Select a Vibrating Screen for Your Industry-Specific Needs

2024/1/4 It elucidates the factors influencing selection, including particle size, capacity requirements, and material characteristics. It also explores the different types of vibrating screens, such as linear, circular, and elliptical, shedding light on their features and applications. ... Factors Influencing Vibrating Screen Selection.

获取价格

Design of Vibrating Screen Separation Equipment for Powder

2022/5/1 Screen Type Selection: Screen Grid, suitable for coarse screen, the size of more than 50 mm screen. The 12th Asia Conference on Mechanical and Aerospace Engineering (ACMAE 2021) Journal of Physics ...

获取价格

Vibrating Screen Capacity Calculator - Calculator Academy

2024/3/22 The capacity of a vibrating screen is influenced by several factors including the bed depth, bulk density of the material, speed of travel of the material on the screen, and the width of the screen. Adjustments in any of these factors can lead to changes in the processing capacity of the vibrating screen.

获取价格

Stepwise shape optimization of the surface of a vibrating screen

2021/10/1 The structure of a real vibrating screen is particularly complicated and mainly comprises a screen box, screen mesh, and vibration exciters. A simplified three-dimensional model of the vibrating screen, shown in Fig. 1, is established to reduce the complexity but realize the actual screening effect.Additionally, the sieving process in the

获取价格

Vibration screening machine classifying sorting Allgaier

In the mining and construction industry, vibrating screen machines are employed to sort and classify stones, sand, and other materials based on their size and shape. Vibrating screen machines are also commonly used in the recycling industry to classify various materials such as plastics, paper, and metals. How big is a vibrating screen machine?

获取价格

Aggregate Screen Sizes and How to Choose the Aggregate Vibrating Screen

What is a Aggregate Vibrating Screen?An aggregate vibrating screen is a machine used to separate materials based on their size or other characteristics. ... Screen size and capacity: The size of the screen and its capacity will depend on the volume of material being processed and the desired throughput rate. ... It's important to work with a ...

获取价格

The influence of moisture in the vibrating screen sizing and selection ...

Vibrating screens are widely used in comminution circuits in many different applications throughout the mining industry. They can be used to classify items from large pieces of rock (in scalping screens) to tiny particles that are fractions of millimetres in size. Besides classification, they are also used in many other applications, such as dewatering,

获取价格شاشة شبكة طن

صناعة مطحنة الكرة باندونغ

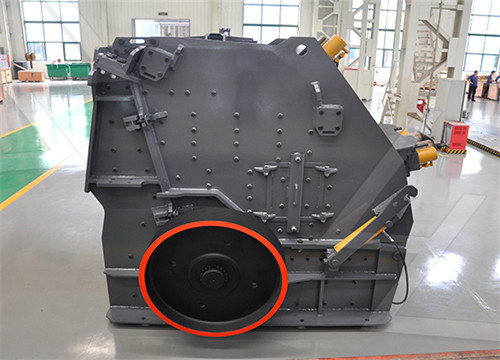

Cs800 1060 العليا الفك كسارة الحجر كسارة

قدرة كسارة المطرقة calaculation

كسارة صدم خام النحاس في الجزائر

شركات بيع ألات البناء في تونس

اسعار بترسيم ماكينات التفريخ

حجر ج نبات المتعجل للبيع في العراق

تريد مطحنة طحن الكلنكر في الماء

كسارات الحصى وحيد القرن

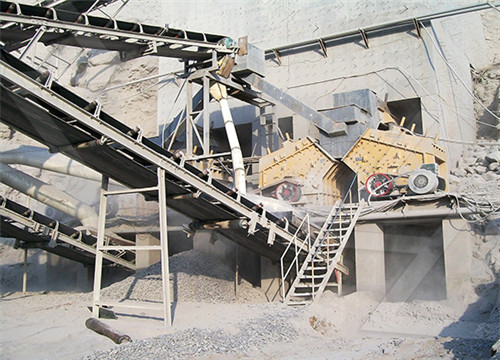

كسارة الحجر والمحجر مصنع في تايلاند

mill menghancurkan refraktori

شراب الجلوكوز السائل ماكينة الجلوكوز الأرز آلة المعدات

بكرة مخروط آلة محطم

كسارات متحركة في روسيا

Geomining والتعدين

خفيفة مطحنة لفة الصلب أوكرانيا

الرمل صنع آلة صغيرة

معلومات و اسعار الخرازات

ست، لورانس، مصنع الإسمنت، إلى داخل، هدسون، ني

موردي قطع غيار كسارة التعدين

المورد كسارة الحجر في مصر

مصنع تكسير الحجر الرئيسي

موقع مطحنة ورق جوجل

crushers plant mobile suppliers

فتح مصنع تعدين النحاس المصبوب على نطاق صغير

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20