الحار منتجات

ملكنا الإخبارية

chromite beneficiation plant and equipment

Chrome ore beneficiation challenges opportunities – A review

2011/4/1 The application of enhanced gravity concentrators (MGS) and floatation columns have found wide acceptance at various beneficiation plant flow sheets of

获取价格

Step-by-Step Guide: Chrome Plant Process Flow

2023/11/26 Beneficiation is a crucial step in the chrome plant process flow, as it involves the separation of chromite from other minerals present in the ore. Various techniques, such as gravity separation,

获取价格

Chrome ore beneficiation challenges opportunities –

2011/4/1 Calculation of tailing mineral resources of the Donskoy MPP as of January 1, 2018, 2.2 million tons were considered with a content of 27.65% Cr2O3, which in terms of Cr2O3 is 0.6 million tons [5 ...

获取价格

Chrome Processing Plant, Equipment - JXSC Machinery

Chrome ore beneficiation challenges opportunities – A review

2011/4/1 Review of the research works. The critical issues related to the chromite process plants investigated by various researchers have been categorized as: 5.1.

获取价格

Chromite Ore Beneficiation Processing Plant CFlo

The process of chromite ore mining can be divided into 2 areas: Feed preparation. Concentration. The feed preparation stage involves the introduction of various physical separation equipment including

获取价格

Chrome ore beneficiation challenges opportunities –

The beneficiation studies of Suresh et al. (1981), concludes that low grade chromite ore of 16–25% Cr2O3, of Sitampundi area of India, cannot be upgraded by using tabling and flotation techniques, to meet the

获取价格

Chrome Ore Beneficiation Process Chromite

2019/5/15 Chrome process equipment is wet type strong magnetic separator, and spiral chute (chrome spiral plant) of gravity separator. 3 Experimental results and discussion 3.1 Chrome magnetic separation

获取价格

Developing an optimum beneficiation route for a low

2018/12/28 enrichment methods can be used in the beneficiation of chromite ores and plant design (Tripa thy et al., 2013; Banerjee et al., 2006; Gence, 1999; Murthy et al., 2011). Tripathy et al. (2012) and ...

获取价格

Step-by-Step Guide: Chrome Plant Process Flow

2023/11/26 Beneficiation is a crucial step in the chrome plant process flow, as it involves the separation of chromite from other minerals present in the ore. Various techniques, such as gravity separation,

获取价格

What Are The Equipment Of Chrome Ore Washing

2024/8/14 Rotary scrubber. The rotary scrubber is used to clean and screen ore with large mud content but is challenging to wash. The long washing cylinder allows the material to stay inside for a long time, with a

获取价格

Modeling and optimization of spiral concentrator for separation

2012/5/1 1. Introduction. Chromite ore is the main source of chromium metal, chemical and refractory industry. Based on certain physical and chemical properties, the ore is categorized for different user industries [1].During the beneficiation of chromite ore, about 50% of the total feed is discarded into tailing which consist of huge quantity of the

获取价格

Gravity Separation for Chromite, Chromite Beneficiation Plant

2021/4/17 Chromite Sample of Forui Customer. The chromite beneficiation process is mainly gravity separation, and the equipment used is mineral jig machines, shaker table, spiral concentrator, etc. sometimes the gravity concentrate needs to be re-processed by magnetic separation, so as to further improve the grade of chromite

获取价格

Received date; reviewed; accepted date Developing an

production, different equipment combinations of the same enrichment method and/or combinations of different enrichment methods can be used in the beneficiation of chromite ores and plant design (Tripathy et al., 2013; Banerjee et al., 2006; Gence, 1999; Murthy et al., 2011; Ozdag et al., 1993). Tripathy

获取价格

(PDF) Recovery of Chromite Values from Plant Tailings by Gravity ...

2011/1/1 The Tata Steel Chrome Ore Beneficiation (COB) plant is generating 50 tph of tailings assaying 17% Cr 2 O 3. ... The purpose of this study was to design and simulate portable processing circuits ...

获取价格

Chromite mining pollution, environmental impact, toxicity and ...

2020/9/24 Chromite mining activities are indispensable for production of goods and services. Sukinda is a major mining site of Odisha, India, polluted by chromium, which is highly toxic in its hexavalent form. The Sukinda valley is a rich source of chromites, amounting to almost 95% of Cr available in India, and is the fourth most polluted site

获取价格

Size-by-size evaluation of the concentration process in spiral ...

2018/9/18 An experimental study was audit in a chromite beneficiation plant consisted of spiral concentrators as unit equipment. Testwor ks w as done in three different feedrates with low grade

获取价格

Flotation of Chromite Ore - 911 Metallurgist

2017/6/5 The chromite collector was a mixture of a long-chain fatty acid and petroleum sulfonate. The modified Havens method usually resulted in higher chromite recoveries, but with a corresponding reduction in grade. Results of the earlier beneficiation work on Benbow and Mouat chromite ores are presented in table 1. EQUIPMENT

获取价格

Chrome Ore Beneficiation Process Chromite Processing - JXSC

2019/5/15 Chrome process equipment is wet type strong magnetic separator, and spiral chute (chrome spiral plant) of gravity separator. 3 Experimental results and discussion 3.1 Chrome magnetic separation process. The chrome raw ore is a flotation tail ore, which is mainly formed in the chromite, and the chromite is the target recovering mineral.

获取价格

(PDF) Performance optimization of an industrial ball mill for chromite

2017/1/1 In this investigation, we optimize the grinding circuit of a typical chromite beneficiation plant in India. The run-of-mine ore is reduced to a particle size of less than 1 mm in the comminution ...

获取价格

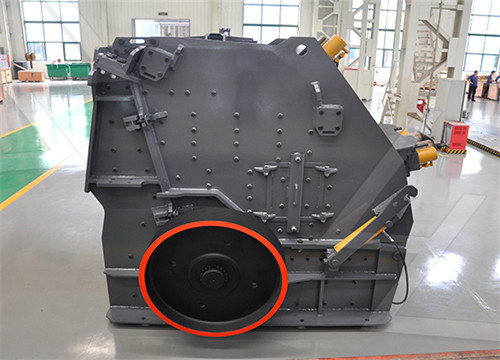

Chromite Ore Beneficiation Facility Equipment Ilmenite Mine ...

Chromite Ore Beneficiation Facility Equipment Ilmenite Mine Beneficiation Plant, Find Details and Price about Chromite Ore Plant Ilmenite Plant from Chromite Ore Beneficiation Facility Equipment Ilmenite Mine Beneficiation Plant - Ganzhou Gelin Mining Machinery Co., Ltd.

获取价格

Developing an optimum beneficiation route for a low-grade

less equipment, etc. Considering these results, a provisional flowsheet was developed, and a total final ... enrichment methods can be used in the beneficiation of chromite ores and plant design ...

获取价格

Chromite Sand Washing Plant - Dasen Mining

The above is about the three beneficiation processes and equipment of chromite, as well as the case sharing corresponding to each process. Through the above cases, we can draw the following conclusions: 1. For rich ores with high chromium oxide content, a single gravity separation or magnetic separation process can be adopted. 2.

获取价格

(PDF) Performance optimization of an industrial ball

2017/1/1 In this investigation, we optimize the grinding circuit of a typical chromite beneficiation plant in India. The run-of-mine ore is reduced to a particle size of less than 1 mm in the comminution ...

获取价格

Chromite Ore Beneficiation Facility Equipment Ilmenite Mine ...

Chromite Ore Beneficiation Facility Equipment Ilmenite Mine Beneficiation Plant, Find Details and Price about Chromite Ore Plant Ilmenite Plant from Chromite Ore Beneficiation Facility Equipment Ilmenite Mine Beneficiation Plant - Ganzhou Gelin Mining Machinery Co., Ltd.

获取价格

Developing an optimum beneficiation route for a low-grade

less equipment, etc. Considering these results, a provisional flowsheet was developed, and a total final ... enrichment methods can be used in the beneficiation of chromite ores and plant design ...

获取价格

Chromite Sand Washing Plant - Dasen Mining

The above is about the three beneficiation processes and equipment of chromite, as well as the case sharing corresponding to each process. Through the above cases, we can draw the following conclusions: 1. For rich ores with high chromium oxide content, a single gravity separation or magnetic separation process can be adopted. 2.

获取价格

Chromite ore beneficiation: prospects and challenges

2023/1/1 The total amount of fine chromite gravity tailings in Turkey is around 3,000,000 tons with a quite high Cr2O3 content of about 9–20%. These fines are produced as a result of the inefficiency of ...

获取价格

Size reduction performance evaluation of HPGR/ball mill and

2023/1/1 PGE bearing chromite ore was ground in a HPGR/ball mill and HPGR/stirred mill. • HPGR was found to be more energy saving advanced comminution equipment. • Optimization analysis of grinding mill for low grade PGE bearing chromite ore. • About 40% of energy can be saved using stirred mill than the ball mill. •

获取价格

Technical and economical applicability study of centrifugal force ...

The above concept was adopted in one of the operating chromite beneficiation plant at Sukinda. The approach adopted and practical problems encountered during the study were reported in this paper. ... However, it must be pointed out that these poor results should not be linked to the plant equipment that does not work under optimum operational ...

获取价格

Chrome ore beneficiation challenges opportunities – A review

2011/4/1 Supply of world chromite (chrome ore) has come under severe pressure over the past year driven by strong demand for ferrochrome used in ferroalloy production for making stainless steel.

获取价格

Chromite Ore Processing Plant For Chrome Beneficiation

Chromite Ore Processing Plant is a Chromite Mining Process that recovers the chromite from its ore, It's a gravity chrome Beneficiation Plant for chrome concent enrichment, and it has been proven that the gravity method is an effective solution for the chromite separation. sometimes the chromite is liberated at about 6.4mm, then a jig machine can be used for

获取价格

Chromite Ore Beneficiation Processing Plant CFlo

Chromite Processing Beneficiation Plant optimises chromite ore for maximum efficiency in ferrochrome production. ... We offer a range of equipment for the processing of chromite ore: Screening. Our screens can be employed for the classification of chromite ore in preparation for the further stages of processing.

获取价格

Process optimization of a chrome ore gravity concentration

conventional chromite ore beneficiation process plant (Figure 3) consist of two sections: Communition (for preparing the material for the subsequent unit operations) Concentration (classification ...

获取价格

Minerals Free Full-Text An Overview of Currently Applied ...

2023/6/13 In Guleman-Sori, Turkey, an estimated 2.7 million tons of chromite tailings containing approximately 20.7% Cr 2 O 3 have been discarded in the tailings dams of a chromite concentration plant . Therefore, it is typical to have large tailings dams at such beneficiation plants.

获取价格

CHROMITE BENEFICIATION PLANT

CHROMITE BENEFICIATION PLANT. Capacity 18,000 MT/Annum Chromite Concentrate: Plant and Machinery cost 110.00 Lakhs Working Capital 0.00: Rate of Return (ROR) 41.00 % ... Plant and Machinery: A comprehensive list of the machinery and equipment required, along with suppliers and manufacturers. Manufacturing Process and Formulations: ...

获取价格

Developing an optimum beneficiation route for a low-grade chromite

It has been observed in many studies that to provide a consistent concentrate production, different equipment combinations of the same enrichment method and/or combinations of different enrichment methods can be used in the beneficiation of chromite ores and plant design (Tripathy et al., 2013; Banerjee et al., 2006; Gence, 1999; Murthy et al ...

获取价格سيور ناقلة المصنعين في السعودية

بناء كتلة كسارة وآلة إعادة التدوير

شكل مخطط تدفق العملية لكسارة الحجر

مطاحن لوكاس في جنوب أفريقيا للبيع

كلوريد الصوديوم المجفف

فاصل شاشة الاهتزاز

ملحقات قطع غيار الآلات

مزود كسارة مخروط حديد خام في إندونيسيا

تعدين الذهب في بالاوان

20 طن في الساعة طريق كسارة بناء

توب 10 مصنع الكرة مطحنة

مطحنة خام الذهب للبيع في وظائف المملكة المتحدة

آلة طحن مغناطيسية من مصر

اهتزاز شاشة الإعداد المحمول

سعر تغذية التعدين أشيب

سنگ شکن معدن طلا

limestone handling system in india

53b من نوع آلة الرمال

كسارة الهريس

كسارة مخروطية عالية الجودة للبيع

كسارات كهربائية الفك والمخروط

حار بيع ريموند مطحنة مطحنة

كيف يعمل محطم

عجلت محطم الكالسيوم

crushing parts mobile vsi crusher

كسارات جيزان

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20