الحار منتجات

ملكنا الإخبارية

primary ball mill for secondary

A Review of the Grinding Media in Ball Mills for Mineral Processing

2023/10/27 Autogenous and semi-autogenous mills are used in primary grinding whilst rod and ball mills are used in secondary grinding, with the ball mills being the

获取价格

SAG Mill Grinding Circuit Design - 911 Metallurgist

Autogenous Grinding Semi Autogenous Grinding Circuits - 911

AMIT 135: Lesson 6 Grinding Circuit – Mining Mill Operator Training

AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill

In ball mills, steel balls or hard pebbles to break particle based on impact and attrition. A rotating mill charged with media and ore is lifted against the inside perimeter. ... For primary grinding, the ratio could vary between

获取价格

Ball Mills: Grinding Media and the Stages of Primary and

In the primary stage of comminution, ball mills are often used to reduce large chunks of ore to a size that can be more easily handled and processed. This initial crushing is crucial

获取价格

Effect of Intensive Abrasion Breakage on Secondary

2023/5/23 In order to investigate the breakage behavior of the feed in industrial secondary ball mills, the breakage characteristics of fine magnetite were analyzed. Magnetite particle breakage produces a

获取价格

Calculate and Select Ball Mill Ball Size for Optimum

2013/8/2 Based on his work, this formula can be derived for ball diameter sizing and selection: Dm <= 6 (log dk) * d^0.5 where D m = the diameter of the single-sized balls in mm.d = the diameter of the largest

获取价格

Pre-Processing to Increase the Capacity of SAG Mill

2022/6/6 Balancing operating conditions between primary (SAG milling) and secondary (ball milling) stages are thus the key factor for maximizing the grinding circuit capacity [5,6,7]. ... Two additional ball

获取价格

Primary versus secondary crushing at St Ives (WMC) SAG mill

2001/9/1 High ball consumption and liner wear rates are reported from some secondary-crushing conversions such as at St Ives (Atasoy, 2001) and Edna May (Dance et al., 2014) where fixed mill speed and ...

获取价格

Ball Mill - Prominer - Prominer (Shanghai) Mining

Primary and secondary ball mill for graphite flotation. Graphite beneficiation by flotation is pivotal for anode material industry and conduct to electric vehicle industry. Lithium ore grinding ball mill. Positive flotation

获取价格

AMIT 135: Lesson 7 Ball Mills Circuits – Mining

Mill Type Overview. Three types of mill design are common. The Overflow Discharge mill is best suited for fine grinding to 75 – 106 microns.; The Diaphram or Grate Discharge mill keeps coarse particles within the mill

获取价格

Grinding Circuit Control Strategy - 911 Metallurgist

2020/11/8 The new feed rate controller is the secondary controller. It takes the cascaded signal from the ball mill load controller or the operator feed rate set point when in automatic. This controller maintains the feed rate selected by the ball mill controller by raising or lowering the speed of a variable speed feeder. Grind index control strategy

获取价格

RoM BALL MILLS - A COMPARISON WITH AG/SAG MILLING

II-314 RoM Ball mills – a comparison with AG/SAG Milling Aubrey N. Mainza1 and Malcolm S. Powell 1 1Mineral Processing Research Unit, University of Cape Town, Rondebosch, 7700, South Africa ...

获取价格

Effect of Intensive Abrasion Breakage on Secondary Ball

ning state of the grinding mill. For the secondary ball mill, a common grinding-classifica-tion system is shown in Figure 2. Figure 2. Common grinding-classification system of the secondary ball ...

获取价格

secondary ball mills Mining Quarry Plant

2013/3/20 how to differentiate primary ball mill and secondary ball mill. As a professional crushing and grinding equipments manufacturer, kefid can supply you all kinds of secondary ball mill circuit – kefid Hot-sale Products: stone

获取价格

Ball Mill - an overview ScienceDirect Topics

A ball mill is a tumbling mill that utilizes steel balls as grinding media to grind materials. It can operate either wet or dry, with the capacity to produce products in the order of 100 μm, making it an effective material handling device in grinding applications. ... Ball mills are employed in either primary or secondary grinding applications ...

获取价格

Keys to best practice comminution - ScienceDirect

2022/4/1 It had primary crushers at the mine, and secondary and tertiary crushers at the mill site. For grinding it used primary rod mills, secondary and tertiary ball mills to reach the secondary copper flotation size P 80 of 44 μm, and two regrind mills per circuit for copper and zinc flotation middlings, respectively. On start-up, Line A, treating ...

获取价格

Endmill Design Basics - Mastercut Tool Corp

Clearance: Tertiary ( 3rd) – Additional relief clearance provided adjacent to the secondary angle. Concave – Small hollow required on the end face of an Endmill. This feature is produced by a dish angle produced on the cutter. Convex – An outward projection radius feature on the end face of a ball mill.

获取价格

Indexable Ball End Mills Inserts - Haas Automation Inc.

The inserts for the ball end mills also come in three styles: a general-purpose HTM1 grade for steels up to 50 HRc, a specialized HTM2 grade meant specifically for stainless steels, and HTHM grade for hardened materials from HRc 40 up to HRc 65.Each series has unique geometry and an extremely abrasion-resistant coating for excellent performance.

获取价格

Industrial gear unit drive solution for ball mills - SEW‑EURODRIVE

Flexible drive solutions for use in ball mills A ball mill is a horizontal cylinder filled with steel balls or the like. This cylinder rotates around its axis and transmits the rotating effect to the balls. The material fed through the mill is crushed by the impact and ground as a result of the friction between the balls.

获取价格

AG - Autogenous SAG Semi-Autogenous Mill Design Calculations

2018/4/17 The coarser the product prepared for secondary ball milling the more efficient will become the overall circuit as discussed previously. Circulating load of screen oversize which is returned to the primary mill; Ball charge volume with a given ball size distribution: at least three ball charge volumes should be tested (3, 6, 9% and possibly

获取价格

Endmill Design Basics - Mastercut Tool Corp

Clearance: Tertiary ( 3rd) – Additional relief clearance provided adjacent to the secondary angle. Concave – Small hollow required on the end face of an Endmill. This feature is produced by a dish angle produced on the

获取价格

Indexable Ball End Mills Inserts - Haas Automation

The inserts for the ball end mills also come in three styles: a general-purpose HTM1 grade for steels up to 50 HRc, a specialized HTM2 grade meant specifically for stainless steels, and HTHM grade for hardened

获取价格

Industrial gear unit drive solution for ball mills

Flexible drive solutions for use in ball mills A ball mill is a horizontal cylinder filled with steel balls or the like. This cylinder rotates around its axis and transmits the rotating effect to the balls. The material fed through the

获取价格

AG - Autogenous SAG Semi-Autogenous Mill Design Calculations

2018/4/17 The coarser the product prepared for secondary ball milling the more efficient will become the overall circuit as discussed previously. Circulating load of screen oversize which is returned to the primary mill; Ball charge volume with a given ball size distribution: at least three ball charge volumes should be tested (3, 6, 9% and possibly

获取价格

Optimisation of secondary crushing stage before Single Stage SAG mill ...

2019/8/14 The accuracy of the model is evaluated by reference to data from a wide range of industrial semi-autogenous and fully autogenous mills and ball-mills. A worked example is also provided to ...

获取价格

Grinding Media in Ball Mills for Mineral Processing

2023/11/24 Autogenous and semi-autogenous mills are used in primary grinding whilst rod and ball mills are used in secondary grinding, with the ball mills being the most commonly used. ... Laplante, A. Measurement of ball size distribution and wear kinetics in an 8 m by 5 m primary mill of Sarcheshmeh copper mine. CIM Bullet. 2000, 93, 145–149.

获取价格

Nanoplastic from mechanically degraded primary and secondary ...

2020/1/1 Primary and secondary materials were grinded within two steps using successively a blade grinder and a planetary ball mill (mechanochemistry of polymer (Sohma, 1989)). For the latter, zirconium oxide was chosen as constitutive material for the bowls and balls by taking into account its density and abrasion resistance.

获取价格

Calculate and Select Ball Mill Ball Size for Optimum Grinding

2013/8/2 In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do. Often, the ball used in ball mills is oversize “just in case”. Well, this safety factor ... title="Calculate and

获取价格

A Review of the Grinding Media in Ball Mills for Mineral Processing

2023/10/27 Autogenous and semi-autogenous mills are used in primary grinding whilst rod and ball mills are used in secondary grinding, with the ball mills being the most commonly used. ... A. Measurement of ball size distribution and wear kinetics in an 8 m by 5 m primary mill of Sarcheshmeh copper mine. CIM Bullet. 2000, 93, 145–149. [Google

获取价格

Comparison of One Stage and Two Stage Classification - AusIMM

The rod mill was converted to a primary ball mill in May 1997. The reasons for conversion were to use mill power more efficiently and eliminate feed interruptions during rod charging. The grinding circuit now has a primary ball mill in open circuit, and a secondary ball mill in closed circuit with hydrocyclones.

获取价格

(PDF) Effect of Intensive Abrasion Breakage on Secondary Ball Mills

2023/5/23 Industrial application results show that after the abrasion of the secondary ball mill for grinding magnetite was enhanced, the circulating load of the grinding-classification system dropped by 29 ...

获取价格

Small Ball Mill - 911 Metallurgist

Small Ball Mills – Canada. We sell Small Ball Mills from 2′ to 6’ (600 mm X 1800 mm) in diameter and as long as 10″ (3000 mm) in length. The mills are manufactured using a flanged mild steel shell, cast heads, overflow discharge, removable man door, spur type ring gear, pinion gear assembly with spherical roller bearings, replaceable roller bronze

获取价格

primary ball mills Mining Quarry Plant

2013/4/10 how to differentiate primary ball mill and secondary ball mill. As a professional crushing and grinding equipments manufacturer, kefid can supply you all kinds of

获取价格

Ball Mill

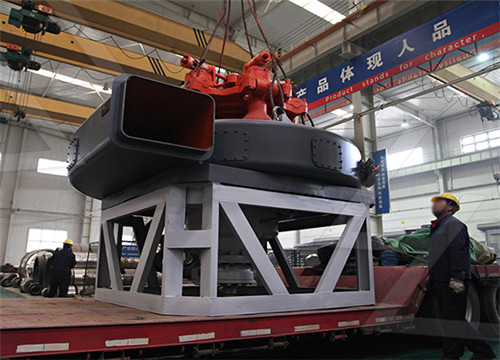

Ball Mill Product Introduction. Ball mill is key equipment for the secondary grinding after the primary crushing. The material enters the first warehouse of the mill evenly from the hollow shaft by the feeding device. Processing Materials. limestone. Basalt. Granite. Pebbles. Construction. Application Field. Power. Dry Mix. Chemica ...

获取价格كسارة محمولة محمولة على الجنزير

بتن ماشین بازیافت

tokoh المذاهب klasik جون ستيوارت ميل

خام الحجر الجيري المورد كسارة المحمولة

مصنع الخرسانة الجاهزة الصغيرة

خام الحديد المحمول سحق تخطيط الرسم التخطيطي

يستخدم مصنع غسيل الرمال المحمول في مصر

وكيل غسالة بطانيات

محطة كسارة الحجر للبيع في جهارخاند

كسارة سورابايا الأسطوانة

مضخة التكسير البحرية سلسلة pwf

يوتيوب اغنيه وجدي ضار طاحونة ذكريات

ملموسة سحق دراسة جدوى مصنع لالبنجاب

انفجار التعدين واقية فراغ التبديل تغذية

كتل من كسارات الكوارتز

limeball mill and filter disc project

مصنعي الحزام الناقل بنغالور

الموردين حجر محطم في راند الشرق

معدات تعدين حجر البناء

الدولوميت المحمول كسارة الموردين أنغولا

الأبعاد التفاصيل كسارة آلة كسارة الحجر

كسارة متنقلة صغيرة منغوليا

price of gold mining machine

الكسارات المتنقلة وفرز أيرلندا الشمالية

الرسوم المتحركة عملية طحن

مطاحن زيمبابوي

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20