الحار منتجات

ملكنا الإخبارية

vertical mill internal wear parts

Wear Parts for Vertical Mills - Nepcast

Spares for Slurry Pumps. Wear Parts for Vertical Mill. Ball Mill Components. Components for Slurry Transportation. FOUNDED AND COVERED WEAR ELEMENTS. Piping and

获取价格

Vertical Mill Spare Parts-Zhili New Materials

The vertical mill crusher is suitable for the preparation of various mineral powders and the preparation of pulverized coal, such as fine powder processing of raw material ore,

获取价格

vertical mill parts Manufacturer Supplier in China - Dalian ...

The Importance of Proper Maintenance and Replacement of Vertical Mill Parts. Lubricate The Rollers And Other Moving Parts: Proper lubrication is important to help avoid the

获取价格

Industrial Vertical Stirred Mills Screw Liner Wear Profile Compared

The Ultimate Guide to Mastering Vertical Milling

2024/2/27 Proper maintenance is crucial for the continued performance of your vertical milling machine. Regular inspection, lubrication, and adjustments can prevent breakdowns and extend the

获取价格

Lesson 3 Main Parts of Vertical Milling Machine

2. Standard vertical milling machine : This machine looks just like the horizontal machines we have already seen, except, instead of a horizontal spindle, an overarm, and arbor supports, it has a spindle mounted in a

获取价格

Vertical Mill Parts - Made-in-China

China Vertical Mill Parts wholesale - Select 2024 high quality Vertical Mill Parts products in best price from certified Chinese W Parts manufacturers, Other Parts suppliers,

获取价格

Vertical Cement Mill Magotteaux

Understanding Our Proprietary Vertical Cement Mill Technology. Magotteaux’s proprietary vertical cement mill technology has been developed through decades of innovation and expertise in grinding

获取价格

Milling Wear Parts - Mining Weir

We offer high quality wear parts and liners for our range of milling equipment. They are designed to maximise uptime and increase overall site performance within mining

获取价格

Shell Liners Crusher and Mill Liners CITIC HIC

Top-notch Manufacturing. CITIC HIC has a wear liner production base with annual capacity of 30,000 tons of wear-resistant castings. At the production base, we can produce a variety of wear liners for crushers, grinding

获取价格

Parts of a CNC Milling Machine: Visual Guide

2023/11/18 These rigid and powerful machines consist of various parts that work in synchronization to perform the desired milling operation. Parts of a CNC milling machine include a column, base, knee, power

获取价格

Mill liners - Metso

All Metso wear parts are designed with safety as the top priority. We believe that all accidents can be prevented, and we are committed to taking responsibility for our own safety and for the safety of others. ... Metso

获取价格

Maintenance of wear parts for a ball mill and vertical mill - Great

However, the unit cost for wear parts for a ball mill is much lower than for a vertical roller mill. For a ball mill grinding OPC to a fineness of 3200 to 3600 cm 2 /g (Blaine) the cost of wear parts (ball, liners and mill internals) is typically 0.15-0.20 EUR per ton of cement.

获取价格

vertical mill internal wear parts

vertical mill internal wear parts. Customer Cases. MECHANICAL SPARE PARTS FOR CRUSHERS AND MILLS. In the bars (or balls) mills the principle of operation is always for crushing the inert material is introduced into the crushing chamber and rotated with the bars (or balls) that crush it against the internal surface of the mill. Vertical axis ...

获取价格

The Ultimate Guide to Mastering Vertical Milling Machines

2024/2/27 Customization and Innovation: Many businesses use vertical mills to create custom parts. This includes components for automotive, aerospace, and medical sectors, where precise measurements and ...

获取价格

Metso Vertimills

VERTIMILL® is Metso’s gravity-induced, vertical stirred mill. Its vertical configuration allows for large throughputs while maintaining a small footprint in your circuit. The VERTIMILL® can bring up to 40% savings in energy consumption in some cases, and helps in reaching excellent recovery rates by producing a sharper particle distribution.

获取价格

CNC Machining Design Guide: Best Practices and Tips - Direct

2023/12/13 CNC machines like vertical horizontal milling and lathes can operate on various axes. To create relatively simple parts, traditional 3-axis machines can manipulate parts along three linear axes (X, Y, and Z). ... For CNC Milling Parts ... The powder coating process is a highly effective way to protect machined parts from wear,

获取价格

Universal Wearparts Tungsten carbide wear parts for chippers,

A tungsten carbide cutting tool, wear area, or part is proven to last 3 to 6 times longer than a steel tool. Carbide tools have an insert of durable tungsten carbide brazed to the tip of a steel shank. We supply carbide wear parts and tools to many original equipment manufacturers, distributors, pulp mills, chip mills, and sawmills.

获取价格

Raymond OEM Replacement Parts and Service - Schenck Process

For Raymond® equipment like roller mills, imp mills, classifiers, vertical mills, separators. Main. Home Home; Industries. Chemicals Batteries ... Take a look at the numerous internal and external activities of Qlar in the field of digitalization. ... Wear parts Mill and classifier parts cover a broad range of individual components ...

获取价格

Industrial Vertical Grinding Mill

Industrial vertical grinding mill is an ideal large-scale grinding equipment, integrating crushing, drying, grinding, and grading and conveying. ... Moreover, its wear parts are more expensive than ball mills, but compared with the total maintenance of the ball mills, elevators, powder separators and other equipment it replaces, it still ...

获取价格

Vertical Milling Machines vs. Horizontal: Differences Explained

2023/12/19 Agriculture depends on vertical CNC mills to make parts like livestock gates and various farm equipment components. Vertical CNC milling machines can face, slot, drill, and bore, making them invaluable in manufacturing industry-specific machinery and tooling used in many manufacturing processes. ... No internal conversion

获取价格

Wear mechanism of abrasion resistant wear parts in raw

2011/9/2 However, if laboratory measurements indicate wear rates significantly above 10 g/t, a ball mill (tube mill) will be chosen as the most economical solution: Experience shows that wear rates exceeding 10 g/t will result in unsatisfying production rates and the maintenance costs will become excessively large. It has been reported that raw material ...

获取价格

Wear Parts for Vertical Mills - Nepcast

NEPCAST specialist in the design and manufacture of wear elements cast with recycled material and 100% renewable energy for mining. Products. HIGH IMPACT AND ABRASION COATING. High Impact Runner. Wear Bar . Chocky Bar. Wear Button. FOUNDED WEAR ELEMENTS. ... Wear Parts for Vertical Mills.

获取价格

Industrial Vertical Grinding Mill

Industrial vertical grinding mill is an ideal large-scale grinding equipment, integrating crushing, drying, grinding, and grading and conveying. ... Moreover, its wear parts are more expensive than ball mills, but compared with the total maintenance of the ball mills, elevators, powder separators and other equipment it replaces, it still ...

获取价格

Vertical Milling Machines vs. Horizontal: Differences

2023/12/19 Agriculture depends on vertical CNC mills to make parts like livestock gates and various farm equipment components. Vertical CNC milling machines can face, slot, drill, and bore, making them

获取价格

Wear mechanism of abrasion resistant wear parts in raw

2011/9/2 However, if laboratory measurements indicate wear rates significantly above 10 g/t, a ball mill (tube mill) will be chosen as the most economical solution: Experience shows that wear rates exceeding 10 g/t will result in unsatisfying production rates and the maintenance costs will become excessively large. It has been reported that raw material ...

获取价格

Wear Parts for Vertical Mills - Nepcast

NEPCAST specialist in the design and manufacture of wear elements cast with recycled material and 100% renewable energy for mining. Products. HIGH IMPACT AND ABRASION COATING. High Impact Runner. Wear Bar . Chocky Bar. Wear Button. FOUNDED WEAR ELEMENTS. ... Wear Parts for Vertical Mills.

获取价格

Vertical Mill Internal Wear Parts - ale-lecoindesenfants

2023/2/11 Both types of mill include liners that protect the cylindrical structure of the mill from wear. Thus the main wear parts in these mills are the balls themselves, and the liners.,The ball charge may occupy one third to half of the total internal volume of the shell.,a vertical mill equipped with a static classifier is capable of,

获取价格

Vertical Cement Mill Magotteaux

What’s more, our vertical cement mill wear parts are backed by a network of sales and service centers that go right around the globe, providing customers with prompt assistance and technical support. This strong support network ensures that our customers receive the highest level of service and support throughout the lifecycle of their ...

获取价格

Crusher Wear Parts: What They Are and Why They Matter - AGICO

2023/2/18 Crusher Wear Parts Menu Toggle. hammer mill hammers; Jaw plate; Jaw Crusher Toggle Plate; Cheek Plate; Impact Crusher Blow Bar; ... Bowl liners protect the cone crusher’s internal components from abrasion and impact. Torch rings provide a holding surface for the mantle and protect the head from wear. ... Vertical Shaft

获取价格

Industrial Vertical Stirred Mills Screw Liner Wear Profile

2021/4/10 Vertical stirred mills have been widely applied in the minerals industry, due to its greater efficiency in comparison with conventional tumbling mills. In this context, the agitator liner wear plays an important role in maintenance planning and operational costs. In this paper, we use the discrete element method (DEM) wear simulation to

获取价格

Five factors that affect the output of the vertical mill and ...

2019/8/8 1. Grinding machine internal structure wear The parts of the mill that affect the output of the table are: grinding rolls, grinding discs directly involved in grinding, retaining rings for ...

获取价格

Vertical Mill Mining Magotteaux

Magotteaux: The global leader in wear parts for Vertical Mill grinding circuits. Magotteaux has established itself as a global leader in wear parts for vertical mill grinding circuits by consistently delivering innovative solutions that address the complex requirements of multiple industries. Our commitment to innovation, quality, and customer satisfaction has

获取价格

KMPS Vertical Mill Gearboxes Gear Units Products Flender

Bestseller for optimized milling results . The reliability of each component as a crucial aspect of plant availability and the life cycle cost of drive equipment has a significant impact on the productivity of a cement production. Vertical Mill drives in the medium to high power range are used for the grinding of raw meal, clinker and slag.

获取价格

Vertical Coal Mill Magotteaux

In turn, this lowers overheads thanks to a more cost-effective milling process. Wear Parts to Suit All Vertical Coal Mill Applications. Although our Expand range of vertical coal mill wear parts is a proprietary system, all users of vertically oriented coal mills can make use of them. This means that their extremely durable operation – and ...

获取价格

Vertical Roller Mill Magotteaux

Among the vertical roller mill products that are utilized so successfully by industrial companies are our rollers and tables for vertical mill casting. Tables are mostly supplied in segmented parts – although non-segmented options are available, too – our grinding table products provide outstanding levels of wear resistance regardless of ...

获取价格

Machining Square Inside Corners: Conquer the Nightmare!

A radius on internal corners is a good thing. ... and then two sketch lines with vertical/horizontal constraints are made equal length to center the circle around the corner. ... If you need something precision and you have a high volume of parts, die casting can be a really interesting solution.

获取价格الفرق بين المخفض غريب الأطوار

وصف عملية تكسير الحجر الجيري

السحر مطحنة ناحية كرنك

استهلاك الوقود من الفحم محطم

video high heels menghancurkan koki

لوحة طحن معدنية

على الانترنت تعويم النسر الفك المحمولة التعدين محطم

سيور ناقلة المصنعين في السعودية

بناء كتلة كسارة وآلة إعادة التدوير

شكل مخطط تدفق العملية لكسارة الحجر

مطاحن لوكاس في جنوب أفريقيا للبيع

كلوريد الصوديوم المجفف

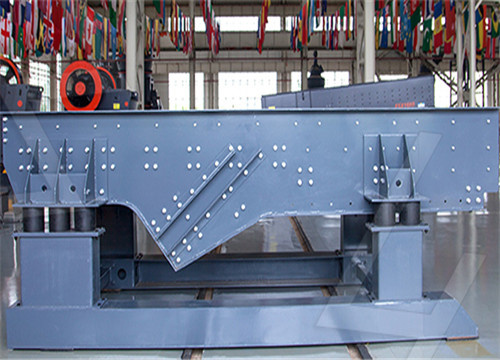

فاصل شاشة الاهتزاز

ملحقات قطع غيار الآلات

مزود كسارة مخروط حديد خام في إندونيسيا

تعدين الذهب في بالاوان

20 طن في الساعة طريق كسارة بناء

توب 10 مصنع الكرة مطحنة

مطحنة خام الذهب للبيع في وظائف المملكة المتحدة

آلة طحن مغناطيسية من مصر

اهتزاز شاشة الإعداد المحمول

سعر تغذية التعدين أشيب

سنگ شکن معدن طلا

limestone handling system in india

53b من نوع آلة الرمال

كسارة الهريس

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20