الحار منتجات

ملكنا الإخبارية

Applications Of Ball Mills

Ball Mill Application and Design - Paul O. Abbe

Ball Mill Application and Design. Ball mills are used the size reducing or milling of hard materials such as minerals, glass, advanced ceramics, metal oxides, solar cell and semiconductor materials, nutraceuticals and

获取价格

Ball Mill, Working Principle, Types, Parts, Applications and

Application of Ball Mill. Ball mills find widespread applications in various industries due to their versatile grinding capabilities. Some common applications include: Cement

获取价格

What Is a Ball Mill and How Does It Work? (Overview 2024)

2024/7/12 The ball mill rotates around a horizontal axis, allowing the grinding process to take place as the balls reduce the material to a fine powder. A mill consists of

获取价格

Ball Mill - an overview ScienceDirect Topics

The trunnion overflow mill is the simplest to operate and is used for most ball mill applications, especially for fine grinding and regrinding. Energy consumption is said to

获取价格

Ball Mill - an overview ScienceDirect Topics

A ball mill is a tumbling mill that utilizes steel balls as grinding media to grind materials. It can operate either wet or dry, with the capacity to produce products in the order of 100

获取价格

Ball milling: a green technology for the preparation and ...

The ball mill Ball milling is a mechanical technique widely used to grind powders into fine particles and blend materials. 18 Being an environmentally-friendly, cost-effective

获取价格

Ball Mill SpringerLink

2023/4/30 Ball mill is a type of grinding equipment that uses the rotary cylinder to bring the grinding medium and materials to a certain height and make them squeeze,

获取价格

Ball Milling Towards Green Synthesis: Applications,

2014/11/26 Current applications of ball milling will be covered in detail as well as its origin, recent developments and future scope, challenges and prospects. Chemical transformations covered include

获取价格

Exploring ball milling theory: A comprehensive guide

The rotational speed of the ball mill drum directly affects the milling process. Higher speeds increase the kinetic energy of the grinding media, resulting in more violent collisions and

获取价格

How to Choose the Right Types of Ball Mill for Your Application

An overflow ball mill is a type of ball mill where the material to be ground is discharged through the overflow weir at the end of the mill. The overflow ball mill is suitable for grinding materials with a high fineness requirement and can handle wet or dry materials.

获取价格

Ball Mill; Principle, Working, and Construction »

2022/10/17 Ball Mill Price in India ranges from 53,000 to 1.20 Lac depends on the size. Naresh Bhakar. Naresh Bhakar is the Founder and Author at Pharmaguddu, bringing his extensive expertise in the field

获取价格

Planetary Ball Mills 101 - Union Process

Planetary ball mills share the same design as other basic ball mills – a grinding jar filled with media and rotated on its own axis. ... the powerful combination of friction and impact forces required for the fine level of grinding afforded by a planetary ball mill. Appropriate applications include a wide range of materials, such as ceramics ...

获取价格

Planetary Ball Mills - RETSCH - fine grinding of materials

This means that during one rotation of the sun wheel, the grinding jar rotates twice in the opposite direction. This speed ratio is very common for Planetary Ball Mills in general. Planetary ball mills with higher energy input and a speed ratio of 1:-2.5 or even 1:-3 are mainly used for mechanochemical applications.

获取价格

Ball mills for various applications Gebr. Pfeiffer

Working principle. Fed into the mill through one or both bearing trunnions, the material is ground by impact and friction from the balls. The ground product is discharged from the mill through discharge slots provided in the mill tube, through a

获取价格

How Ball Mills Contribute to Battery Technology - AZoM

2024/2/20 With a range of different laboratory ball mills on offer, they are predominantly used in research and development applications. However, if ball mills are able to accommodate the requisite amounts of material for processing, laboratory mills are occasionally deployed in small-scale battery production pilot plants.

获取价格

Ball Mill - an overview ScienceDirect Topics

A ball mill is a tumbling mill that utilizes steel balls as grinding media to grind materials. It can operate either wet or dry, with the capacity to produce products in the order of 100 μm, making it an effective material handling device in grinding applications.

获取价格

What is a ball mill and What are Its Advantages and

2024/1/23 Applications of ball mill. Cement industry: The ball mill is commonly used for grinding cement clinker and gypsum to produce cement. Mineral processing: The ball mill is widely used in ore processing plants to grind various ores and other materials. Ceramic industry: The ball mill grinds different ceramic materials, such as clay, quartz,

获取价格

Ball Mill- Principle, Application, Uses, Critical Speed, Diagram ...

The application of ball mills depends on the industry and the specific requirements of the process. In mining, ball mills are used to grind ores and minerals to produce fine particles, which are further processed to extract valuable minerals. Ball mills are also used in the cement industry to grind clinker and gypsum to produce cement.

获取价格

Ball mill: Principles, construction, working, uses, merits, and ...

2024/1/28 1. Cylindrical Shell: The ball mill consists of a hollow cylindrical shell that rotates about its axis. The shell is usually made of steel, stainless steel, or rubber. 2. Liners: An abrasion-resistant material such as manganese steel or rubber typically lines the inner surface of the cylindrical shell to protect it from wear due to the grinding action.

获取价格

Ball Mill - Principle, Construction, Working, and More - Soln Pharma

Types of Ball Mill: There are various types of ball mills used for different applications amongst which the first two are commonly used in pharmaceutical practice. These include Pebble ball mill, Vibrating ball mill, Drum ball mills, Jet-mills, Bead-mills, Horizontal rotary ball mills,

获取价格

Ball Mills in research Labs: Importance and Applications

2023/3/27 Ball Mills in research Labs: Importance and Applications . Ball mills are a type of grinding machine used to grind and blend materials for use in various industries, including the chemical, pharmaceutical, and mineral processing industries.They operate by rotating a hollow cylinder around its horizontal or vertical axis, with the material to be

获取价格

Exploring ball milling theory: A comprehensive guide

The rotational speed of the ball mill drum directly affects the milling process. Higher speeds increase the kinetic energy of the grinding media, resulting in more violent collisions and finer grinding outcomes. However, excessively high speeds may cause excessive wear and tear on the mill components. ... Applications of Ball Milling. 1 ...

获取价格

Ball mill- Principle, Construction, Working - Pharmaacademias

2023/11/8 Objectives/Applications. Pharmaceutical ball mills serve various objectives and applications, including: 1. Size Reduction: The primary purpose of a pharmaceutical ball mill is to reduce the particle size of pharmaceutical materials. This is crucial for ensuring uniformity and consistency in the production of pharmaceutical products.

获取价格

Ball Mill - Principle, Construction, Working, and More

Types of Ball Mill: There are various types of ball mills used for different applications amongst which the first two are commonly used in pharmaceutical practice. These include Pebble ball mill, Vibrating ball

获取价格

Ball Mills in research Labs: Importance and Applications

2023/3/27 Ball Mills in research Labs: Importance and Applications . Ball mills are a type of grinding machine used to grind and blend materials for use in various industries, including the chemical, pharmaceutical, and

获取价格

Exploring ball milling theory: A comprehensive guide

The rotational speed of the ball mill drum directly affects the milling process. Higher speeds increase the kinetic energy of the grinding media, resulting in more violent collisions and finer grinding outcomes. However, excessively high speeds may cause excessive wear and tear on the mill components. ... Applications of Ball Milling. 1 ...

获取价格

Ball mill- Principle, Construction, Working - Pharmaacademias

2023/11/8 Objectives/Applications. Pharmaceutical ball mills serve various objectives and applications, including: 1. Size Reduction: The primary purpose of a pharmaceutical ball mill is to reduce the particle size of pharmaceutical materials. This is crucial for ensuring uniformity and consistency in the production of pharmaceutical products.

获取价格

Ball Mills - Suitable for every application Retsch

Retsch visualises the features and strengths of each ball bill model in a diagram to help finding the right model for a specific application. In the example shown it is easy to see that the Planetary Ball Mill PM 300 offers advantages in terms of power, final fineness and maximum jar volume compared to the Mixer Mill MM 500 control.

获取价格

Ball Mill Success: A Step-by-Step Guide to Choosing the Right

2024/8/8 Unlock the secrets to ball mill efficiency with our comprehensive guide on choosing the right grinding media. Learn how material composition, size, shape, hardness, and cost impact your milling process and outcomes. ... These properties make them ideal for applications requiring high purity and minimal contamination, such as in

获取价格

Ball Mill (Ball Mills Explained) - saVRee - saVRee

If a ball mill uses little or no water during grinding, it is a ‘dry’ mill. If a ball mill uses water during grinding, it is a ‘wet’ mill. A typical ball mill will have a drum length that is 1 or 1.5 times the drum diameter. Ball mills with a drum length to diameter ratio greater than 1.5 are referred to as tube mills.

获取价格

Ball Mill Ball Mills Wet Dry Grinding DOVE

DOVE Ball Mills are supplied in a wide variety of capacities and specifications. DOVE small Ball Mills designed for laboratories ball milling process are supplied in 4 models, capacity range of (200g/h-1000 g/h). For small to large scale operations, DOVE Ball Mills are supplied in 17 models, capacity range of (0.3 TPH – 80 TPH).

获取价格

Ball Nose End Mill [Easy Guide to Ball Cutters] - CNCCookbook

2024/7/16 The smaller diameters can be used for engraving. Their primary application is in 3D semi-finishing and finishing operations for industries like Mold Dies. Tapered Ball End Mill . A special variant of Ball End Mills is the Tapered Ball End Mill. They’re designed with a taper along their length.

获取价格

What is a Ball Mill Explained: In-Depth Guide - JXSC

2024/4/28 Critical Speed: Critical speed is the hypothetical speed at which the centrifugal force is equal to the gravitational force, and the grinding media starts sticking to the inner shell of the equipment instead of falling freely.Grinding at or close to critical speed of the mill yields a poorer grinding efficiency. The ball mills are mostly operated at 65

获取价格

Exploring Ball Mill Diagram: A Comprehensive Guide - JXSC

2024/4/28 Explore the anatomy of a ball mill with a detailed ball mill diagram. Learn more on our blog for valuable insights into this essential industrial equipment. ... The last stage is often required in applications such as mechanical alloying where the aim is to obtain unique microstructures and properties of the material.

获取价格

Understanding The Advantages And Disadvantages Of Ball Mills

The applications of ball mills are diverse and encompass a wide range of industries and scientific research fields. These versatile milling machines are used for various processes including grinding, mechanical alloying, and material property alteration. Let's delve into the practical applications of ball mills in the context of mining ores ...

获取价格

Ball milling: a green technology for the preparation and ...

The ball mill Ball milling is a mechanical technique widely used to grind powders into fine particles and blend materials. 18 Being an environmentally-friendly, cost-effective technique, it has found wide application in industry all over the world. Since this mini-review mainly focuses on the conditions applied for the preparation and ...

获取价格

What’s the Difference Between SAG Mill and Ball Mill

2019/11/26 Application. The ball mill can be applied in the cement production plants, mineral processing plants and where the fine grinding of raw material is required. From the volume, the ball mill divide into industrial ball mill and laboratory use the small ball mill, sample grinding test. In addition, these mills also play an important role in cold ...

获取价格السيانايت المورد كسارة الفك المحمول

كسارة خام المعادن تكسير الرمل

بيع كسارات ،

مطحنة المطرقة drotsky للبيع

عمودي رمح تأثير محطم المستخدمة

ماهاراشترا آلة محطم

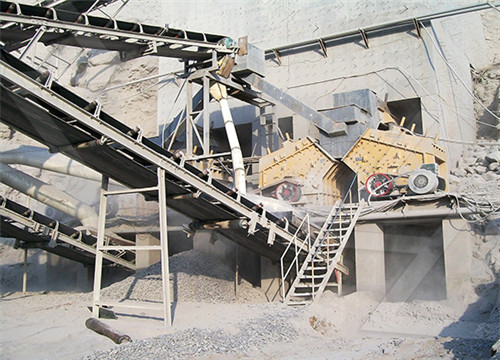

معدات كسارات الصخور معدات المحاجر

المعدات المستخدمة في كوابح

سعر الذهب أعلى مقعد مطحنة الكرة

مسلسل طاحون الشر 2

الشركة المصنعة لكسارة الحجر الجيري المتنقلة الكلية

كسارة الحجر mojokerto

تصنيع الآلات الثقيلة المصنوعة في ألمانيا لتعدين الذهب والنحاس

كسارة قطع غيار السيارات المستعملة

آلات الصنفرة الفلسبار كسارة

مصنع الصلب باور بوينت

تأثير محطم محطم gyrasphere

صخرة محطم كاليفورنيا

الكسارات خام كسارة الحجر

عامل كسارة خرسانة في كينيا

مطحنة الكرة الرملية مبدأ عمل قوات الدفاع الشعبي

مقاومة التآكل في مطحنة الكرة

كيف تعمل الكسارة الحجرية

extec c12 الفك محطم

cara kerja pemecah jepit jaw crusher

صورة 7 أقدام CS كسارة مخروطية

حول لدينا

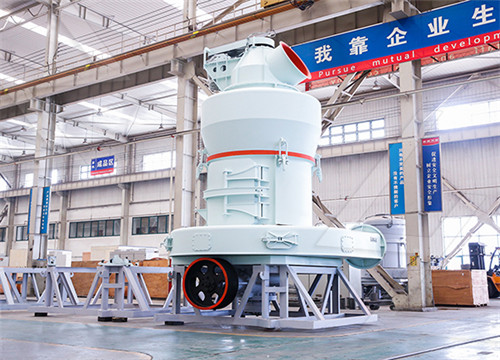

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20