الحار منتجات

ملكنا الإخبارية

High Efficiency Cement Ceramsite Sand Ball Grinding Mill

BALL MILLS Ball mill optimisation - holzinger-consulting

to optimise the grinding process.Clinker grain sizes depend on pre-crusher settings but are in some cases still up to 50mm when fed to the ball mill and therefore, it is necessary to

获取价格

High Efficiency Cement Ceramsite Sand Ball Grinding Mill

High Efficiency Cement Ceramsite Sand Ball Grinding Mill. Grinding mill is major equipment of Maisheng, professional technology support can be offered to you. Structure

获取价格

Cement Mill Optimization: Practical Strategies for

Adjusting mill parameters: Fine-tuning mill parameters such as mill speed, ball charge, filling ratio, and grinding media size can have a substantial impact on the grinding efficiency of the mill. For example, a 10%

获取价格

Optimization of Cement Grinding Operation in Ball

The consumption of energy by the cement grinding operation amounts to one third of the total electrical energy used for the production of cement. The optimization of this process would yield substantial benefits in terms

获取价格

Optimization of continuous ball mills used for finish-grinding of ...

2004/12/10 During the last decade, semi-finish-grinding plants have been used more and more for the energy efficient grinding of high-quality cement. Recent research work

获取价格

Mike Sumner and Keith Marsay, Grace, examine ball mill

The use of a grinding aid provides an increase in grinding efficiency due to its benefits of improved separation and reduced void filling. Furthermore, as a consequence of these

获取价格

Rethinking Grinding Efficiency in Ball Mills - RELO Grinding

Lameck (2005) –The effects of grinding media shapes on ball mill performance (MSc thesis –University of Wits) Balls Worn Cylpebs balls Lameck’s work indicated that: •

获取价格

[PDF] Energy-Efficient Technologies in Cement

2016/10/5 In this chapter an introduction of widely applied energy-efficient grinding technologies in cement grinding and description of the operating principles of the related equip‐ ments and comparisons over

获取价格

High Efficiency and Large Output Cement Ball Mill

Motor: The motor is the power source that drives the mill.; Bearings: These components support the mill shell and allow it to rotate.; Lining plates: The mill shell interior is often lined with replaceable plates to protect it from

获取价格

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL

A 1.5 mio t/a cement plant is having a closed circuit ball mill for cement grinding: The mill has been operating with satisfactory performance in-terms of system availability and

获取价格

Cement Mill Optimization: Practical Strategies for

Adjusting mill parameters: Fine-tuning mill parameters such as mill speed, ball charge, filling ratio, and grinding media size can have a substantial impact on the grinding efficiency of the mill. For example, a 10%

获取价格

Grinding in Ball Mills: Modeling and Process

2012/6/1 The feed material is typically composed of the BFRs and the catalyst, both in powder form. As the cylinder starts to rotate, the grinding balls inside the cylinder crush and grind the feed ...

获取价格

Ball mills for various applications Gebr. Pfeiffer

Our ball mills are perfectly suited for the ... In case of circuit grinding, these parameters are set with the high efficiency separator. Highest availability . Simple and rigid design, wear resistant lining, minor

获取价格

Optimization of Cement Grinding Operation in Ball Mills PEC ...

Cement ball mills typically have two grinding chambers. The first chamber is filled with larger diameter grinding media and lined with lifting liners. The first chamber coarse-grinds the feed material and prepares it for the second chamber. ... Changing the separator to a high efficiency type brings about better residue value (on 45 micron) for ...

获取价格

Analysis of the efficiency of the process in closed circuit ball

Limiting factor, limiting high efficiency ball grinding of clinker is the need to create optimal conditions for each stage of grinding in the drum mill. However, pre-grinding clinker to a particle size of 3...5 mm allows to exclude from the mill drum stage coarse grinding in a ball mill. Some progress got the TSG with pre-grinding cement ...

获取价格

Unveiling the Innovation and Efficiency of Cement Vertical Roller Mills

2024/5/7 Ball mill pinion. Vertical roller mill grinding roller. Ball mill Liner. Vertical roller mill grinding roller shaft. Ball mill grinding media. Vertical roller mill grinding roller wheel hub. Rotary kiln shell. Vertical roller mill grinding roller tyre. Rotary kiln girth gear. Vertical roller mill classifier/separator. Rotary kiln tyre. Ball ...

获取价格

Mining Engineering Consultants - PEC Consulting Group

%PDF-1.6 %âãÏÓ 83 0 obj > endobj 102 0 obj >/Filter/FlateDecode/ID[99BDA6995622E142B8D9E49ED83701F0>]/Index[83 28]/Info 82 0 R/Length 96/Prev 259493/Root 84 0 R ...

获取价格

Cement Production Line, Tube mill, Ball mill, Cement

Grinding equipment The mill is cylinder rotating device with girth gear and two chambers. Thematerials are fed to first chamber through hollow shaft through feeding device. There is stepped liner or waves liners and different size of balls inside this chamber. After finishing in first chamber, the materials will be fed to second chamber. There is flat liners and balls

获取价格

Cement Mill Separator High Efficiency Cement Separator

A high-efficiency cement separator is essential for cost-effectiveness as improving product quality and reduces energy. Applications. Closed circuit ball mill grinding plant. Closed circuit system mainly composed of the cement vertical mill. Roller press and ball mill pregrinding system ... fine sand, and coarse sand is realized by a single ...

获取价格

Mining Ball Mill, Mine Ball Mill, Cement Ball Mill

Ball mill is the most widely used kind of grinding equipment. Zenith Ball mills are widely used in various types of ores' benefication, electricity, cement and chemical industries. With high comminution ratio,it can carry out dry or wet pulverizing and can meet demand for sustainable large-scale production.

获取价格

High efficiency ball mill grinding - ResearchGate

2008/4/1 Some of the factors that need to be considered to increase the efficiency of ball milling grinding, are discussed. Grinding efficiency can be increased by making some changes in operating practice ...

获取价格

Improvements in New Existing Cement Grinding Mills by Tim

CPB QDK Next Generation high efficiency separator has a very low by-pass can improve mill output / energy consumption by 20 – 25%! Plant layout engineering. ... Of the 4 main mill systems in use for cement grinding, ball mills are by far the predominant, despite a higher energy consumption compared with a stand-alone Vertical Roller Mill ...

获取价格

Innovating Cement Production: The Clinker Vertical Roller Mill

2024/5/16 Cement plants utilize the clinker vertical roller mill for grinding raw materials, clinker, and additives to produce high-quality cement. Its high grinding efficiency and versatility make it an essential component of cement production lines, ensuring reliable and cost-effective operation. Cement Grinding Stations:

获取价格

How To Optimize Grinding Efficiency with a Batch Type Ball Mill

2023/11/1 A batch ball mill works by loading the materials to be ground into a grinding cylinder, which includes solid particles, and then grinding these materials into the required particle size through a rotating grinding media. This grinding media can be adjusted in speed and size as needed. The entire process includes loading, grinding,

获取价格

High efficiency ball mill grinding - ResearchGate

2008/4/1 Some of the factors that need to be considered to increase the efficiency of ball milling grinding, are discussed. Grinding efficiency can be increased by making some changes in operating practice ...

获取价格

Improvements in New Existing Cement Grinding

CPB QDK Next Generation high efficiency separator has a very low by-pass can improve mill output / energy consumption by 20 – 25%! Plant layout engineering. ... Of the 4 main mill systems in use for cement

获取价格

Innovating Cement Production: The Clinker Vertical Roller Mill

2024/5/16 Cement plants utilize the clinker vertical roller mill for grinding raw materials, clinker, and additives to produce high-quality cement. Its high grinding efficiency and versatility make it an essential component of cement production lines, ensuring reliable and cost-effective operation. Cement Grinding Stations:

获取价格

How To Optimize Grinding Efficiency with a Batch Type Ball Mill

2023/11/1 A batch ball mill works by loading the materials to be ground into a grinding cylinder, which includes solid particles, and then grinding these materials into the required particle size through a rotating grinding media. This grinding media can be adjusted in speed and size as needed. The entire process includes loading, grinding,

获取价格

[PDF] Energy-Efficient Technologies in Cement Grinding

2016/10/5 In this chapter an introduction of widely applied energy-efficient grinding technologies in cement grinding and description of the operating principles of the related equip‐ ments and comparisons over each other in terms of grinding efficiency, specific energy consumption, production capacity and cement quality are given. A case study

获取价格

How to choose proper grinding media for your ball mill

2021/2/25 Steel balls are one of the most widely used grinding media in cement ball mills, their diameters can range from 20mm to 120mm according to different grinding requirements. ... The filling rate of grinding media has a great impact on the grinding efficiency of the ball mill. When the conditions of ball mill are the same and the speed

获取价格

Energy-Efficient Technologies in Cement Grinding IntechOpen

2016/10/5 1. Introduction. Cement is an energy-intensive industry in which the grinding circuits use more than 60 % of the total electrical energy consumed and account for most of the manufacturing cost [].The requirements for the cement industry in the future are to reduce the use of energy in grinding and the emission of CO 2 from the kilns. In

获取价格

BALL MILLS Ball mill optimisation - holzinger-consulting

in combination with a ball mill for cement grinding applications and as finished product grinding units, as well as raw ingredient grinding equipment in mineral applications. This paper will focus on the ball mill grinding process, its tools and optimisation possibilities (see Figure 1). The ball mill comminution process has a high electrical

获取价格

Comparing ball mills and VRMS for cement grinding

2013/2/26 The industry has failed to fully adapt to this technological development, which offers significant energy savings, as it did with other technical developments such as the precalciner kiln or high efficiency coolers. Mill operation and maintenance. Operation of a ball mill is relatively simple, with no moving mechanical parts within the mill itself.

获取价格

Rethinking Grinding Efficiency in Ball Mills - RELO

Kolev et al (2021) –In press. Improving the energy efficiency in tumbling mills with the use of Relo grinding media (MDPI) • Lab trials conducted using a standard Bond ball mill (@ Wardell Armstrong) • Standard Bond ball mill procedures were followed –only the RELO media PSD and mass of charge adjusted to match spherical media

获取价格

Sand Ball Mill - Sand Mill Manufacturers - AGICO CEMENT

AGICO CEMENT's sand ball mill offers efficient and versatile sand-making capabilities, providing high-quality sand suitable for diverse mineral processing applications.

获取价格

Effects of Mill Speed and Air Classifier Speed on Performance of

2021/6/29 Nowadays, ball mills are widely used in cement plants to grind clinker and gypsum to produce cement. The research focuses on the mill speed as well as air classifier speed effect on the two ...

获取价格

How To Improve Working Efficiency Of Ball Mill For Cement

2023/12/28 The ball mill for cement grinding is characterized by its primary features and functions, which include the grinding process of transforming tough clinker into fine powder through the rotation of a cylindrical drum and internal grinding media, typically steel balls, forming the essential components of cement.

获取价格

Ball mills Cement

An inefficient ball mill is a major expense and could even cost you product quality. The best ball mills enable you to achieve the desired fineness quickly and efficiently, with minimum energy expenditure and low maintenance. With more than 4000 references worldwide, the ball mill is proven to do just that.

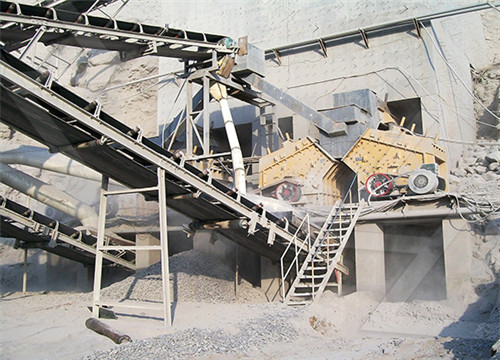

获取价格إجمالي قدرة الكسارة كسارة

تجنيد كسارة تأجير nottingham

غسالة سجل التعدين لغسيل خام المنغنيز

التعدين خليط كسارة

الذهب المكثف 2012

للايجار محجر

رسم تخطيطي لكسارة الصخور

كم من آلات طحن الجير السيليكون

أنواع لآلات البناء

الأسطوانة المصنعة محطم 2

آلة مطحنة خام الذهب الأسطوانة العمودية منخفضة السعر

عينات خطة الأعمال الحرة الحجر المحجر

EXTEC C12 كسارة التكنولوجيا اليدوية تدفق

ماكينات طحن

فک سنگ شکن طراحی

الات كراون

تأثير محطم عمان سعر

Minimum crushing strength for inch blocks

cement bricks equipment malta

كثافة خام المنغنيز

كسارة الصخور التي تعمل بالطاقة اليدوية المستخدمة

عملية تكسير الصخر الزيتي للبيع

چرخ های سنگ زنی برای فولاد ضد زنگ

للبيع معدات ثقيله الهفوف

نباتات شاشة الحصى للبيع

صور تعدين الذهب الغريني

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20