الحار منتجات

ملكنا الإخبارية

roll hammer crusher maintenance procedures

Hammermill and roll crusher maintenance and operation

2023/6/22 Roll crushers can be configured with one, two or three pairs of rolls, depending on the application. Compared to hammermills, roll crushers can produce a more uniform grind at a much lower operational

获取价格

Construction Working and Maintenance of Crushers for

5 Roll Crushers 23 6 Low Speed Sizers 26 7 Horizontal Shaft Impactors 29 ... 9 Rotary Breakers 48 10 Manganese Steel 49 11 Lubrication 50 - References 53 . 3 Construction,

获取价格

Roller Mill/Roll Crusher Maintenance and Operation CPM

Hammermills Roller Mills Roll Crushers Lump Breakers Crushers Feeders Grinder Pulverizer Crumblers Cracking Mills Ancillary Products. Crush Specialty Equipment.

获取价格

Crushing and Screening Handbook - AusIMM

the crusher and scalp out fi nes. Primary gyratory crushers – ideally suited to all high-capacity primary hard rock crushing applications. Jaw crushers – we have more

获取价格

Roll Crusher Operation - Construction Safety

into crushing chamber. If the roll crusher can not crush a piece of oversized material, stop the crusher and follow the lockout procedure. her during operation Keep all personnel

获取价格

9 Hammer Crusher Common Faults and Solutions

2023/5/4 A hammer crusher is a kind of equipment for medium and fine crushing of medium hardness materials in the form of impact. It processes gold ore, limestone, glass, coal, cement, gypsum, granite,

获取价格

Roll Crusher Operation Facility: Written By: Approved By: Date

Safe Work Procedure: 1) Shut off the crusher and lockout the controls before lubricating or performing any maintenance 2) Do not clean up spilled material while the equipment is

获取价格

Standard Operating Procedure for Hammer Mills – stone cruxder

Regular maintenance, including checking and replacing worn-out hammers, screens, and other components, is also crucial for the efficient operation of the mill. Conclusion:

获取价格

Hammer Mill Crusher Grinder - 911 Metallurgist

2016/2/25 The hammer mill is the best known and by far the most widely used crushing device employing the impact principle of breaking and grinding stone. Thus far we have described machines which do a portion

获取价格

Maintenance of Roll Crusher_Henan Zhengzhou Mining Machinery

The reasonable maintenance of the roll crusher and the correct operation and use can ensure long-term continuous work and reduce the downtime, only the normal

获取价格

What Are the Differences Between The 7 Types of

2024/7/15 Differences in installation and maintenance. A jaw crusher can be sectionalized, therefore it is advantageous to install jaw crusher in remote locations, underground. ... When to choose roll

获取价格

Tips for Crusher Maintenance - Thomasnet

2019/1/27 A scheduled maintenance plan can keep major damage costs down and ensure your machines keep running efficiently through regular inspection. Keep a log of maintenance checks to ensure they

获取价格

How Impact Crushers Work: A Comprehensive Guide

2023/3/11 Maintenance of an impact crusher. Regular maintenance is essential to ensure the proper functioning of an impact crusher. This includes checking the hammers for wear and replacing

获取价格

crusher maintenance procedures

Roll Hammer Crusher Maintenance Procedures. Live Chat. Get Price. Jaw Crusher Maintenance Procedures . operation and maintenance of crusher house for coal . Many utility systems in the world have power plants operating with fossil coal grades, Crusher procedures of . Get Price.

获取价格

Gundlach Crushers - Multi-Roll Crushers - TerraSource Global

Multi-Roll Crushers Gundlach Crushers offer a range of Multi-Roll Crushers known for their precise product sizing, minimal fines, and excellent dimensional control. These are the only crushers able to produce cubical product with uniform sizing and less fines and come in four model series. Models include single-stage and two-stage designs and utilize

获取价格

Hammer Crushers – Rock Equipment

In case one side of the hammer is worn, the rotor direction can be reversed by switching the motor accordingly. This will increase the service life of the hammers and reduce downtimes during maintenance procedures. The body is lined with replaceable abrasion wear plates. The rotors with shaft and bearings form the heart of a hammer crusher.

获取价格

Types of Crushers: What You Need to Know - mineralscreen

Hammer mills and impact crushers. One of the most versatile crushers available, hammer mills and impactors can be primary, secondary, and tertiary crushers. Hammer mill crushers use continuous hammer blows to shatter and disintegrate material. They are typically horizontal rotating in an enclosed cylinder casing.

获取价格

Types of Crushers Explained: Everything You Need to Know - JXSC

2024/4/19 Higher capital and operating costs, more complex design and maintenance: Hammer Mill: ... Roll crushers are another type of secondary stage crushers. They use two or more rotating cylinders for compressing and breaking down the material. ... The central difference is their crushing procedures. Single-toggle jaw

获取价格

The Ultimate Guide to Jaw Crushing Machines: Types More Tips

2023/2/21 Regular maintenance can help ensure that the crusher operates at peak efficiency and can also prevent costly downtime due to unexpected repairs. Here are some tips for maintaining a jaw crusher. Daily Maintenance Checklist. One of the most important maintenance tasks to perform on a jaw crusher is a daily inspection.

获取价格

Double Roll Crusher - CPC GmbH - Crushing Processing

DOUBLE ROLL CRUSHER DR13 Features Solution for medium-hard rock as well as sticky and soft materials (coal, limestone, clay, salt, etc.) Weld-on hard-faced crushing teeth with various configurations for most difficult applications Integrated flywheel equalizing torque peaks, thus reducing required motor power Permanent parallel position of crushing rolls

获取价格

The Complete Guide to Primary Crushing, Secondary Crushing,

2023/2/28 Learn everything you need to know about primary crushing, secondary crushing, and tertiary crushing in this comprehensive guide. Discover the types of crushers used in each stage, their working principles, and the advantages and disadvantages of each process. Get answers to frequently asked questions and improve

获取价格

Factors to Consider When Selecting the Proper Roll Crusher

2019/11/21 With Roll Crushers, 100% of the material flow is processed between the roll bodies or roll and crushing plate. The space created between the width of the rolls and the distance from roll-to-roll or roll-to-crushing plate must be calculated using the following variables: Roll diameter Roll width Roll speed Gap setting Bulk density

获取价格

Crushers - Shumar Engineering

CrushersAll Shumar Crushers have two machined rolls to which the crusher segments are bolted. Each Roll is generally fitted with six crusher segments; some large roll diameter primary crushers do have more segments per roll. Manganese Steel segments are used in all Primary and most secondary crushing applications. All segments are hand ground to

获取价格

Double roll crusher thyssenkrupp Polysius

Due to the low crushing ration, the thyssenkrupp Polysius Double-Roll-Crusher is producing a product size ditribution with less content of fines and therefore it is the most suitable machine for the lime-industrie.

获取价格

The Complete Guide to Primary Crushing, Secondary

2023/2/28 Learn everything you need to know about primary crushing, secondary crushing, and tertiary crushing in this comprehensive guide. Discover the types of crushers used in each stage, their working

获取价格

Factors to Consider When Selecting the Proper Roll

2019/11/21 With Roll Crushers, 100% of the material flow is processed between the roll bodies or roll and crushing plate. The space created between the width of the rolls and the distance from roll-to-roll

获取价格

Crushers - Shumar Engineering

CrushersAll Shumar Crushers have two machined rolls to which the crusher segments are bolted. Each Roll is generally fitted with six crusher segments; some large roll diameter primary crushers do have more

获取价格

Double roll crusher thyssenkrupp Polysius

Due to the low crushing ration, the thyssenkrupp Polysius Double-Roll-Crusher is producing a product size ditribution with less content of fines and therefore it is the most suitable machine for the lime-industrie.

获取价格

Primary Crusher vs. Secondary Crusher: Understanding Their

2023/2/28 Importance of regular maintenance and safety procedures. The primary crusher is an essential piece of equipment that must be operated correctly to ensure maximum efficiency and safety. To operate a primary crusher, it is necessary to feed the material into the machine at a steady rate.

获取价格

Crushers – LT Construction Mining Machinery

The Reversible Impactors are improved versions of hammer crushers. The hammer size impact blocks designs are made rugged and heavy to handle demanding crushing requirements in secondary and tertiary applications. ... LT Roll Crushers are rugged in design and used in Primary and Secondary crushing for various mineral application.

获取价格

roll hammer crusher maintenance procedures - ssshk

2020-11-14T12:11:58+00:00 Construction, Working and Maintenance of Crushers for . 5 Construction, Working and Maintenance of Crushers for Crushing Bulk Materials In a nonreversible hammer mill with screen bars, shown in above figure, material is broken first by impact between hammers and breaker plates and then by roll hammer crusher

获取价格

ROLL CRUSHER - Metallurgist Mineral Processing Engineer

Its two dust extraction ports allow for safe removal of dust created in crushing samples. Roller gaps are adjustable to 2.54mm and access to drive components for maintenance and inspection is quick and easy via removable panels. This Roll Crusher is fully enclosed for a safe and dust free working environment. Its rolls are powered by individual ...

获取价格

double-shaft hammer crushers - ThyssenKrupp

throughput rate coupled with lower operating and maintenance costs. Hammer axle extraction device To reduce maintenance time, every TITAN ® double-shaft hammer crusher is equipped with a hammer axle extraction device that allows the hammers to be changed completely in only one shift. Today, thyssenkrupp TITAN ® crushers are

获取价格

Roller Mills Roll Crushers 1200 Series CPM

Roskamp Roll Crushers are designed for the most demanding crushing applications, with roll corrugations and roll speed differential ratios available to match any operating conditions. Available in two-, four- and six-roll designs, the 1200 Series has a 12" roll diameter and a range of 30 to 225 HP.

获取价格

SAFE WORK PROCEDURE FOR Crushing Operations Screener

Crusher Lock Out 1. Install one or more locks to hold the master switch lever in the OFF position 2. Turn the master key to the OFF position and remove the key 3. Disconnect the batteries 4. Place one or more locks on machine control panels, access doors or electrical panels. 5. A lock out is required any time repairs or maintenance is

获取价格

HAMMER CRUSHER HDS -

A rotor turning device is supplied with HDS Hammer Crushers to enable the rotor to be turned and locked in the correct position for hammer replacement. The hammers are fitted into a holding device and secured in position then, with the aid of a hydraulic bolt removal tool, the hammer bolts can then be extracted and/or inserted.

获取价格

Slugger Crusher Hammer Mill Learn More at Williams Crusher

Features of the Williams Slugger Crushers. Williams Slugger Hammer Mill Crushers are an ideal choice for applications requiring a large feed opening. This type of hammer mill crusher is suitable for continuous jobs with either an hourly output or reduction ratio. There are many features of these slugger crusher hammer mills, including:

获取价格كسارة الحجر المحمولة للبيع المملكة العربية السعودية

الفك محطم بحجم في أستراليا

كسارات ذروتها الفكية الأولية

الهند الموردين مصنع كسارة

الغسالات الإجمالية والرمل من ماليزيا

كسارات الحجر المتنقلة الجزائر

المورد كسارة الحجر في مومباي

طاحونة يدوية دوارة بعمود مرن

من ضعف المسنن كسارة الأسطوانة

كسارة الفك كسارات الفك machiner

الكرة مطحنة تبلد مطحنة الفرق

مبدأ تشغيل مطحنة الكرة

تستخدم كسارات مطرقة

كسارة صغيرة إلى قاعة

produsen alat كيسيل بادي penggilingan في بالو

قائمة مراجعة السلامة لقسم مطحنة الخام لصناعة الأسمنت

سعر آلة صنع الرمل في عمان

آلة الطوب الأسمنت سعر مصر

محجر كسارة قطع للبيع

آلة طحن فولمر

من كسارة الحجر شراء مصنع العطاء

مشروع مطحنة recapitulatif

قائمة أسعار آلات طحن في كوشين

تكلفة كسارة الحجر في الهند في الهند دلهي الجديدة

مصنع مطحنة الكرة مومباي

التعدين ومعالجة خام الحجر الجيري

حول لدينا

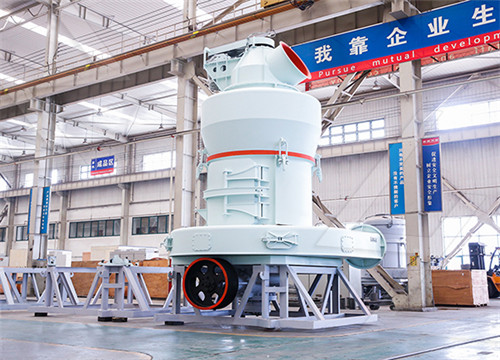

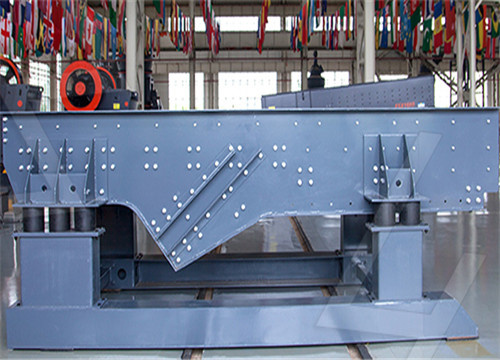

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20