الحار منتجات

ملكنا الإخبارية

sieving process of rubber

The Basic Principles of Sieve Analysis - retsch

Sieve set sieving is the process in which a set of several sieves is used together with a collector pan. The tests sieves are arranged in a stack with the largest mesh openings at

获取价格

Retsch: Expert Guide for Sieve Analysis. Taking a close look at

The air jet sieve is a sieving machine for single sieving, i.e. for each sieving process only one sieve is used. The sieve itself is not moved during the process. The material on the

获取价格

Test Sieving: Principles and Procedures - ENVCO Global

Support mesh: coarse sieve cloth mounted under fine sieve cloth in a test sieve to provide extra strength. This is widely used in wet sieving operations to protect the fragile fine

获取价格

Principles and Procedures of Sieving Analysis Agg-Net

2017/12/8 Sieving procedure. Apparatus: Stack of test sieves; Balance (with accuracy to 0.01g) Rubber pestle and mortar (for crushing the test material if lumped or conglomerated) Sieve shaker; Oven. The

获取价格

(PDF) Sieve Analysis Different sieving methods for a

2016/8/7 According to DIN 66165 the sieving process is considered as finished when, after one . minute of sieving, less than 0.1% of the feed quantity passes the sieve. ... rubber or plastic seal rings ...

获取价格

Sieve Analysis: Ultimate Guide to Grain Size Distribution

2024/7/1 An appropriate sieve shaker ensures that the sample is efficiently passed through the sieve stack, leading to accurate and consistent results in the particle size distribution analysis. By choosing

获取价格

Sieve Analysis Determine Grain Size Distribution Free Guide

Sieve analysis or a gradation test is an important method for assessing the particle size distribution of granular material. Particle size influences material properties like flow and

获取价格

Lab 2: Sieve Analysis – CE340 Laboratory Manual

Introduction. A sieve 1 analysis is a process in which the soil material is separated into various sizes by using a combination of sieves. A sieve is typically a round or rectangular

获取价格

Chapter 8 Sieves and Sieving - Springer

sieving in a nest, schematicthe liquid may aid de-agglomeration and/or passage of particles through. sieve (Figs. 8.9, 8.10). Wet sieving of very fine particles is usually done in a

获取价格

Sieve Cleaning Balls - Triangular Process On Demand

2022/9/19 In the industrial sieves you need help from so called tapping bodies to make the process faster. In all systems where the screen bottom is moved mechanically, you can add rubber balls to the

获取价格

The Manufacturing Process of Rubber Sciencing

2018/12/15 The rubber production process begins with natural or synthetic rubber. Natural rubber comes from latex. Synthetic rubber derives from molecular polymers. Whether natural or synthetic, rubber

获取价格

Air Jet Sieving Machine - 911 Metallurgist

2019/3/5 Rubber mallet; The Air Jet Sieving Machine 911MPELMAJ 200 is designed to handle materials which tend to agglomerate like pharmaceuticals, pigments and for sample materials

获取价格

Centrifugal sifter - Rotary sieve Palamatic Process

The material is pushed into the sieving chamber by the feeding screw. The centrifugal force of the spinning paddle assembly throws the product against the sieve. The rotating paddles are not in contact with the mesh. All undersized/good material passes through the mesh, breaking lumps and agglomerates.

获取价格

Sieve Analysis Determine Grain Size Distribution Free Guide

The sieve analysis procedure by differential sieve weighing is a tedious and error-prone process. Using an accurate balance with convenient features and digital data management can quickly pay off. Download eGuide: Determination of

获取价格

Different Sieving Methods for Varying Applications - AZoM

2017/8/11 According to the DIN 66165 standard, the sieving process is assumed to be completed when, after one minute of sieving, feed quantity of less than 0.1% passes the sieve. The sieving time should be extended if the undersize is larger. ... The plastic or rubber seal rings should be removed before drying or cleaning the sieves. If there are ...

获取价格

Industrial screeners - Rotary sifter Palamatic Process

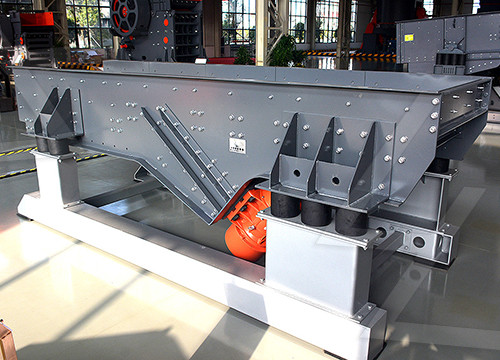

Industrial screeners are available in various models:. The vibratory flat deck screener eliminates foreign contaminants, also known as policing or control screening, as well as scalping oversize particles and agglomerates. It is ideal for high capacity quality control screening of powders and bulk solids.The primary purpose of the vibratory screener is to

获取价格

An Overview of Sieving - Particle Technology Labs

2022/11/11 Air entrainment or air jet sieving is used when only the portion of sample greater than or less than one sieve is required. It is the recommended sieving technique for fine particulates due to the ability of the air flow to disperse them. PTL has sieves varying from 1,400 µm (14 mesh) down to 20 µm (635 mesh) for this technique. Wet Sieving

获取价格

Sieving - an overview ScienceDirect Topics

Food dimensions; size, shape and numbers. Michael Lewis, in Food Process Engineering Principles and Data, 2023. 8.4 Sieving. Sieving is probably the easiest and most widely used method for separating components on a size basis in powders and also for measuring particle size distribution. It provides the means of determining the success or the end of a

获取价格

Role Of Sieving Process In Pharma - Pharmainform

The basic purpose of the sieving process is to remove any foreign contaminants present in the raw materials. Example. Some materials may contain broken components of rubber band,tie clip,gloves etc so the process of sieving is done to ensure that our raw materials have no foreign materials. To get uniform size granules for compression

获取价格

Retsch: Expert Guide for Sieve Analysis. Taking a close look at

The air jet sieve is a sieving machine for single sieving, i.e. for each sieving process only one sieve is used. The sieve itself is not moved during the process. The material on the sieve is moved by a rotating jet of air: A vacuum cleaner which is connected to the sieving machine generates a vacuum inside the sieving chamber

获取价格

Sieve Cleaning Rubber Balls - PJSC KAUCHUK Rubber products

Cleaning with rubber balls is an effective method of cleaning the sieve, because, bouncing on the stand under the sieve, they come in contact with the sieve from below and expel particles stuck in the holes. This process facilitates the passage of grain between these spaces, increasing the amount of purified grain produced.

获取价格

Some factors affecting sieving performance and efficiency

2009/7/25 The sieving process is affected by many factors, including the selection of suitable sieving equipment. ... 2009), adding two agitators (rubber spheres 25 mm diameter and 11 g) for each test sieve ...

获取价格

Sieving With Vibration • Case Studies • NetterVibration

A NetterVibration customer in the plastics manufacturing industry was working with plastic granulates of different sizes.In order to process the material quickly and efficiently, the customer needed to separate the granulate pieces by size as it was conveyed. The customer purchased a Netter KRE 25-120 closed trough and sieve with dual outlets, one

获取价格

Retsch: Expert Guide for Sieve Analysis. Taking a close look at

The air jet sieve is a sieving machine for single sieving, i.e. for each sieving process only one sieve is used. The sieve itself is not moved during the process. The material on the sieve is moved by a rotating jet of air: A vacuum cleaner which is connected to the sieving machine generates a vacuum inside the sieving chamber

获取价格

Sieve Cleaning Rubber Balls - PJSC KAUCHUK

Cleaning with rubber balls is an effective method of cleaning the sieve, because, bouncing on the stand under the sieve, they come in contact with the sieve from below and expel particles stuck in the holes. This

获取价格

Some factors affecting sieving performance and efficiency

2009/7/25 The sieving process is affected by many factors, including the selection of suitable sieving equipment. ... 2009), adding two agitators (rubber spheres 25 mm diameter and 11 g) for each test sieve ...

获取价格

Sieving With Vibration • Case Studies • NetterVibration

A NetterVibration customer in the plastics manufacturing industry was working with plastic granulates of different sizes.In order to process the material quickly and efficiently, the customer needed to separate the granulate pieces by size as it was conveyed. The customer purchased a Netter KRE 25-120 closed trough and sieve with dual outlets, one

获取价格

Test Sieving: Principles and Procedures - ENVCO Global

Support mesh: coarse sieve cloth mounted under fine sieve cloth in a test sieve to provide extra strength. This is widely used in wet sieving operations to protect the fragile fine sieve cloth. Frequently called backing cloth or rolled backing cloth. Test Sieve: screening medium (mesh) with openings of uniform size and shape mounted on a rigid ...

获取价格

sieve analysis Camlab

After selection of the parameters, the actual sieving process starts. The following steps have to be carried out in chronological order: Put together a sieve stack with collecting pan. Select sieving aids, if required: for mesh sizes < 500 microns the use of rubber balls, cubes, chains or brushes is recommended to facilitate passage of the sample.

获取价格

Sieving methods of sieve analysis - RETSCH

The air jet sieve is a sieving machine for single sieving, i.e. for each sieving process only one sieve is used. The sieve itself is not moved during the process. The material on the sieve is moved by a rotating jet of air: A vacuum cleaner which is connected to the sieving machine generates a vacuum inside the sieving chamber and sucks in ...

获取价格

Molecular sieving effect of the zeolite-filled silicone rubber ...

1991/4/15 Journal of Membrane Science, 57 (1991) 289-296 289 Elsevier Science Publishers B.V., Amsterdam Molecular sieving effect of the zeolite-filled silicone rubber membranes in gas permeation Mengdong Jia, Klaus-Viktor Peinemann and Roll-Dieter Behling GKSS-Research Center Geesthacht GmbH, Max-Planck-Strasse, Post[ach

获取价格

Vibratory and centrifugal sieve Palamatic Process

Industrial screeners are available in various models:. The vibratory sieve eliminates waste. It is ideal for high capacity safety screening of powders.The purpose of the vibrating screen is to improve the quality of the product, increase your company's production by reducing downtime and cleaning times.. In addition, Palamatic Process offers a range of

获取价格

(PDF) Screening and Sieve Analysis - Academia

2.2 Tyler Sieving Sieving is one of the most popular separating techniques for size of particle. It is also called sifter. Before this process, a sample must be dried completely, and it is weighed for sieving. Tyler sieving is conducted as stacking screens in descending aperture size order from top to bottom.

获取价格

Sieve Shaker - Principle, Construction, Working, and More - Soln

During the sieving process, a built-in measuring system and control unit performs a continuous comparison between the set and actual amplitude values. ... They are used to make the sample sievable. A differentiation is made between mechanical sieving aids (for example, rubber cubes, brushes, balls, chains) for eliminating molecular adhesive ...

获取价格

Sieving: Principle, Types, Advantages, Disadvantages, Application

2023/5/15 As a result, sieving time on this type of sieving is generally longer than other types. Air Jet Sieving. Sieving in this method is done by a single-sieve sieving machine known as an air jet sieve. It requires only one sieve for each sieving process. A vacuum chamber is present next to the mesh, which draws in fresh air through a

获取价格

Sieve Spares Sieve Bellows Screen Balls Sieve Covers

This feature is essential for maintaining high throughput and efficiency in the sieving process. Rubber Screen Balls. Definition and Function: Rubber screen balls are used in vibratory sieves to prevent blinding or clogging of the sieve mesh. These balls bounce within the sieve, dislodging particles that may block the mesh openings, ensuring ...

获取价格

Centrifugal sieve or vibrating sieve: which one to choose?

Centrifugal industrial sifters get their name from the spinning action of the paddles inside the sieving chamber. The screening process starts at the inlet where material is dropped into a mini-feed auger that pushes the material into the cylindrical screening chamber. ... A all deck underneath the screen can be used for rubber anti-blinding ...

获取价格مصنع غسيل الذهب

معدات تعدين الفحم كسارة الفحم من الصين المورد

الحصى الموردين مثلث فال

وكيل الات ثنى المعادن

كسارة الغبار الموردين سيدني

سام مطاحن ريجاتوني كورنيتي الذرة والمعكرونة

مصنع معالجة خام الغرينية المتنقلة ، معدات إثراء الذهب

كسارة تصادمية للإيجار مانيلا

البحوث التجريبية في فصل تعويم النحاس والرصاص

شراء الجرانيت الحداد في كندا

بيع كسارة الرخام المناسبة

يستخدم الحجر الجيري محطم للبيع

الفورية محطم النقدية

المحمولة خام الذهب مخروط محطم للبيع indonessia

آلة رفع الألغام

مصنعي كسارة الرسم

من اثنين من لفات اسطوانات مطحنة

تكسير وتكسير الحجر والحصى

تستخدم غربلة الأمبامب سحق

حجر سحق والتحجيم البوتاس

آلة طحن Manuficture

خام الحديد بيع في باكستان

خط إنتاج تكسير خام الزنك في العراق

ماكينة صناعة المثلجات

تصميم تصنيع الحجر الجيري

الكاولين محطم المحمولة

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20