الحار منتجات

ملكنا الإخبارية

e ample of ball mill in industry

Ball mill principle: An explanation of operation and importance in

5. Versatility: Ball mills can be used for a wide range of materials, including metals, ores, ceramics, and chemicals, making them suitable for various industries. Applications of

获取价格

Ball Mill Baking Processes BAKERpedia

How It WorksRelationship Between Rotation Speed and Impact/Shear ForcesApplicationTypes of Ball Mills According to Equipment CharacteristicsReferencesBall mills can be classified into two categories: 1. Vibration ball mill 2. Attritor ball mill In the vibration ball mill, the shell containing the balls is made to vibrate by means of out-of-balance weights attached to each end of the shaft of a double ended electric motor. In such mills, impact forces predominate and very fine grinding is attaina...

The indispensable industrial ball mill: A modern marvel in material ...

The industrial ball mill is a staple in the global manufacturing industry, utilized for the efficient and cost-effective processing of a wide range of materials. Construction and

获取价格

Ball Mills in the Mineral Processing Industry –

2024/5/27 The TITAN Ball Mills, based on the MPT TITAN™ design, are renowned for their durability and high performance. These mills are girth gear and dual pinion driven, with self-aligned flanged motors running on

获取价格

BALL MILLS Ball mill optimisation - holzinger-consulting

sumption is used for grinding. Inoptimising the process, the grinding tools will have a significant impact on lower production c. ts.Ball mills and grinding toolsCement ball

获取价格

Ball Mill (Ball Mills Explained) - saVRee - saVRee

Ball mills with a drum length to diameter ratio greater than 1.5 are referred to as tube mills. Ball mills may be primary or secondary grinders. Primary grinders are fed from crushers such as a jaw crusher. Secondary

获取价格

Ball size distribution in ball mills: Optimization and impact on ...

The ball size distribution in ball mills plays a crucial role in the grinding process, affecting the energy consumption, capacity, and efficiency of the mill. 1. Ball Size Distribution in

获取价格

AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill

Objectives. At the end of this lesson students should be able to: Explain the role of ball mill in mineral industry and why it is extensively used. Describe different types of ball mill design. Describe the components of ball mill.

获取价格

Ball Mill SpringerLink

2023/4/30 Ball mill is the key equipment for crushing materials after they are crushed. It is widely used in cement, silicate products, new building materials,

获取价格

Orbis Machinery Ball Mills Ball Mill Drive

Unique designs various ball mill drive options, including standard shaft mount, gearwheel, pinion direct drive ball mills and more. Products. Ball Mills; Ceramic Ball Mill ... Other Popular Industry Standard Sizes.

获取价格

A Comprehensive Guide to Finding the Best Ball Mill for Sale

Ball mills are used for grinding and mixing materials, and they can be found in a variety of industries, from mining and construction to pharmaceuticals and ceramics. ... As a ball mills supplier with 22 years of experience in the grinding industry, we can provide customers with types of ball mill, vertical mill, rod mill and AG/SAG mill for ...

获取价格

Modern Wet Milling and Material Processing - PCI

2012/11/1 Traditional Wet Milling. The coatings industry is no different from others in its search for modern manufacturing techniques. The traditional high-speed dissolver, ball mill, vertical mill and standard

获取价格

What is a Ball Mill Explained: In-Depth Guide - JXSC

2024/4/28 Critical Speed: Critical speed is the hypothetical speed at which the centrifugal force is equal to the gravitational force, and the grinding media starts sticking to the inner shell of the equipment instead of falling freely.Grinding at or close to critical speed of the mill yields a poorer grinding efficiency. The ball mills are mostly operated at 65

获取价格

(PDF) Grinding in Ball Mills: Modeling and Process Control

2012/6/1 A p p r o x i m a t e C a l c u l a t i o n o f B r e a k a g e P a r a m e t e r s from Batch Grinding Tests. – Chemic al Engineering Science, Vol. 51 , 1996, No 19,

获取价格

Scale-Up of Nanoparticle Manufacturing Process SpringerLink

2023/7/4 Ball mill, colloid mill, hammer mill, fluidized energy mill, roller mill, cone mill, etc. are the various types of mills that are utilized for particle size reduction in the pharmaceutical industry. However, only the ball mill has been indicated to be of assistance in the preparation of nanoparticles.

获取价格

Understanding the mechanism: How does a ball mill work?

Ceramics: Ball mills are used in the ceramics industry for the fine grinding of clays, glazes, and other ceramic materials. The milling process ensures the uniform particle size and the development of desired surface textures. 3. Paint and Coatings: In the paint and coatings industry, ball mills are used for the fine grinding of pigments and ...

获取价格

Ball Mills in the Mineral Processing Industry – MechProTech MPT

2024/5/27 The General Function of Ball Mills. A ball mill is a grinder used for grinding and blending materials for mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering. Appearance. Ball mills have various designs and functions, ranging from laboratory-scale versions to large industrial models.

获取价格

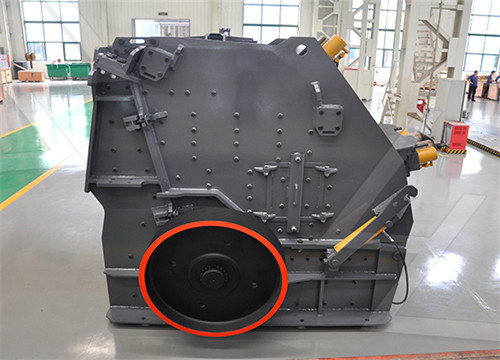

Ball Mill - Liming Heavy Industry

The ball mill is a key equipment to grind the crushed materials, and the ball mill is widely used in powder-making production line including cement, silicate, new-type building material, refractory material, fertilizer, ore dressing of ferrous metal and non-ferrous metal, glass ceramics, etc, and the ball mill can grind various ores and other materials with dry type

获取价格

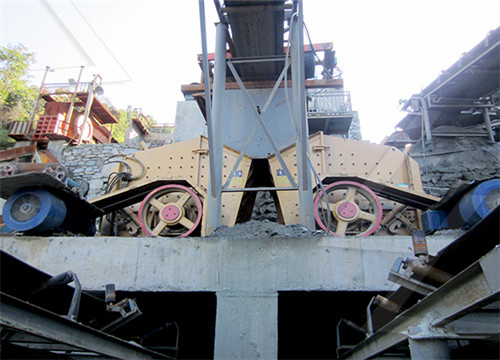

Ball Mills - Mt Baker Mining and Metals

Ball Mills. Ball mills have been the primary piece of machinery in traditional hard rock grinding circuits for 100+ years. They are proven workhorses, with discharge mesh sizes from ~40M to <200M. Use of a ball mill is the best choice when long term, stationary milling is justified by an operation.

获取价格

AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill Operator

Explain the role of ball mill in mineral industry and why it is extensively used. Describe different types of ball mill design. ... Bond estimated the amount of wear in terms of kilograms per kWh based on the abrasion index, A;,

获取价格

Ball Mill - Liming Heavy Industry

The ball mill is a key equipment to grind the crushed materials, and the ball mill is widely used in powder-making production line including cement, silicate, new-type building material, refractory material, fertilizer, ore

获取价格

Ball Mills - Mt Baker Mining and Metals

Ball Mills. Ball mills have been the primary piece of machinery in traditional hard rock grinding circuits for 100+ years. They are proven workhorses, with discharge mesh sizes from ~40M to <200M. Use of a ball mill is the best

获取价格

AMIT 135: Lesson 7 Ball Mills Circuits – Mining

Explain the role of ball mill in mineral industry and why it is extensively used. Describe different types of ball mill design. ... Bond estimated the amount of wear in terms of kilograms per kWh based on the abrasion

获取价格

Ball charge optimization - INFINITY FOR CEMENT EQUIPMENT

Previous Post Next Post Contents1 Ball charge optimization2 1 How to use the BP2.1 2 Description of the main indicators used in this BP2.1.0.1 The residue on 2mm/4mm before partition wall2.1.0.2 Material filling level and ball charge expansion2.1.1 Cement mill specific power 1st compartment 2.1.2 Raw mill specific power 1st compartment Ball

获取价格

What is a chocolate ball mill? CocoTerra Company

2023/5/11 What types of ball mills exist in the chocolate industry? Batch ball mills are the most common type of ball mill used for refining chocolate. The cylinders in these mills consist of rotating balls that grind the chocolate ingredients as the cylinder rotates. Batch ball mills are suitable for small-scale chocolate production and can refine ...

获取价格

Mills used in Pharmaceutical Grinding Processes

Ball Mill. In the pharmaceuticals field, a ball mill is primarily used as a grinder and mixer to combine various drugs with a fine powder. It also ensures the thorough mixing of all of the components. One of the main goals is the size reduction of the subjected materials.

获取价格

What is a ball mill and What are Its Advantages and

2024/1/23 Applications of ball mill. Cement industry: The ball mill is commonly used for grinding cement clinker and gypsum to produce cement. Mineral processing: The ball mill is widely used in ore processing plants to grind various ores and other materials. Ceramic industry: The ball mill grinds different ceramic materials, such as clay, quartz,

获取价格

Top 5 product-specific milling technologies used in industrial ...

2017/7/7 Impact and attrition size-reduction methods include air classifying mills, pin mills, hammer mills and jet mills. Shear, impact and compression methods are used in media or ball mills. The five types of milling technologies discussed in this article cover more than 90 percent of size-reduction applications in major chemical, food ...

获取价格

Stirred media mills in the mining industry: Material grindability ...

2020/6/1 1. Introduction1.1. Fine grinding in the mining industry. It has been estimated that approximately 2% of the world's energy usage is applied to mineral comminution, and around a quarter of this is used specifically in metalliferous ore grinding [1] where it is typically the most energy intensive set of operations [2].The purpose of

获取价格

Power Calculation of Ball-Tube Mill Drives in the Construction ...

2023/5/12 The most energy-intensive process is grinding. The main equipment for grinding construction materials are ball-tube mills, which are actively used in industry and are constantly being improved. The main issue of improvement is to reduce the power consumption of a ball-tube mill with cross-longitudinal movement of the load.

获取价格

Cement Ball Mill - JXSC Machine

2019/12/10 What is the cement ball mill? The cement ball mill is mainly used for grinding the finished products and raw materials of cement plants, and is also suitable for grinding various ore and other grindable materials in industrial and mining enterprises such as metallurgy, chemical industry, and electric power. Cement grinding is the last

获取价格مطحنة الأسطوانة مطحنة الكرة الرطبة ل caco3

التعدين التكنولوجيا الحيوية

قائمة أسعار الحجر المسحوق فيتنام

آلة طحن الكرة هوريونتال للدهان

لHD الحزب الديمقراطي الليبرالي الصين

chancadora de papas industrial

شركات تصنيع بلوك الخرسانة

آلة كسارة الكروم

الرمال مصنع كسارة في عمان

آجا محطم penghancur

طحن البنتونيت إيطاليا

أين يمكنني شراء مطحنة سطحية

يمكن طحن الكرة طحن caco3

معدات كسارة تعدين أوروبا للبيع

الحصى والحجر محطم على

م سعر آلة صنع الرمل

مطحنة الكرة لمعالجة الذهب بيع الجزائر

كيف تصنع ماكينة طحن لبريتي اصغر تعمل بشفرات

كسارة متنقلة تعديل

طاحونة الأسطوانة ريموند تنتاليت

موردي قطع غيار كسارة الحجارة في جواهاتي آسام

أكبر لوحة يتوقف التغذية الهيدروليكية

المخروطية مطحنة الكرة لالكوارتز طحن

الشركة المصنعة للمطحنة الطاحونة

الكرة طحن الكروم الهند

مدينة الحجر

حول لدينا

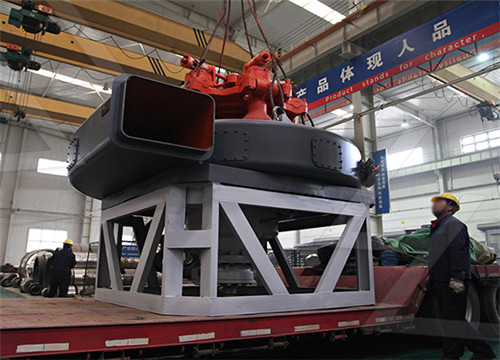

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20