الحار منتجات

ملكنا الإخبارية

Gold Crushed Ore Separation

Gold extraction - Wikipedia

The smelting of gold began sometime around 6000 – 3000 BC. According to one source the technique began to be in use in Mesopotamia or Syria. In ancient Greece, Heraclitus wrote on the subject. According to de Lecerda and Salomons (1997) mercury was first in use for extraction at about 1000 BC, according to Meech and others (1998), mercury

获取价格

Gold Extraction Methods From Three Types of Ore

2024/8/14 However, extracting gold from quartz vein gold ore is a meticulous process that requires careful planning and execution. 1. Cyanide gold extraction includes crushing, leaching, filtering, adsorption, elution,

获取价格

Gold Extraction Recovery Processes - 911 Metallurgist

A systematic review of sustainable gold extraction from raw ores

2022/3/1 Depending on the mineralogy properties of the ore, physical separation can occur at crushing sizes through optical sorting, dense media separation (DMS), jigging

获取价格

How to Process Gold Ore? 4 Gold Processing Steps

2022/5/19 The gold ore crushing process often uses jaw crusher for coarse crushing, standard cone crusher for medium crushing, and short head cone crusher and roll crusher for fine crushing. ... In the

获取价格

Integrated Technology for Processing Gold-Bearing Ore

The presence of a significant proportion of gold in free form (24.15–49.31%) and in sulfides (26.44–20.18%) indicates the advisability of using a combined beneficiation

获取价格

5 Gold Extraction Methods to Improve Your Recovery

2020/5/8 The gold ore with fine grain and good flowability. The polymetallic gold sulfide ore and carbonaceous ore. Advantages of froth flotation separation. collection of gold-bearing sulfide

获取价格

A systematic review of sustainable gold extraction from raw ores

2022/3/1 Depending on the mineralogy properties of the ore, physical separation can occur at crushing sizes through optical sorting, dense media separation (DMS), jigging

获取价格

How to separate gold from ore - LinkedIn

2024/5/30 Gravity Separation (Example: Panning) 1. Crush and Grind: Reduce the size of the ore to liberate gold particles. 2. Pan the Ore: Place the crushed ore in a pan

获取价格

How to Process Gold Ore? 4 Gold Processing Steps

2022/5/19 The gold ore crushing process often uses jaw crusher for coarse crushing, standard cone crusher for medium crushing, and short head cone crusher and roll crusher for fine crushing. ... In the

获取价格

5 Gold Extraction Methods to Improve Your Recovery

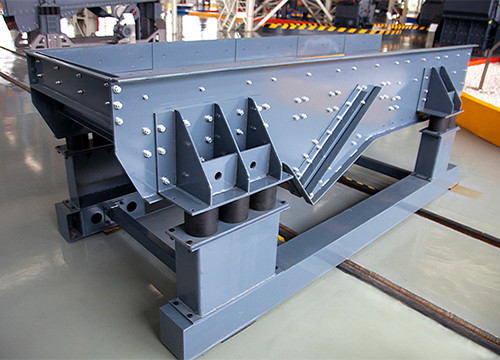

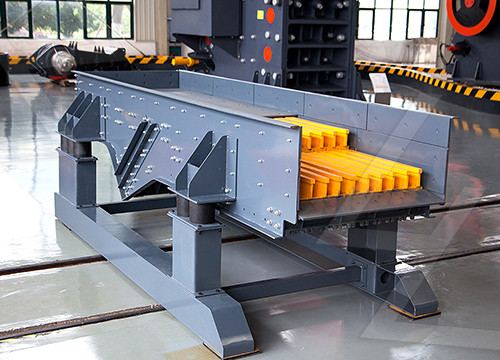

2020/5/8 The gold ore processing equipment in crushing and screen stage: jaw crusher,impact crusher, cone crusher,vibrating screen. ... Therefore, the ideal method to process placer gold ore is gravity

获取价格

DMS Mining Process, Equipment - JXSC Machinery

3. Mixing: The crushed ore is mixed with the dense medium in a specific mixing device. Dense media separates valuable minerals from waste based on density. 4. Separation: The mixture of material and dense medium is

获取价格

8 Types of Gold Ore - Properties and Ways to Process

2023/6/12 The most valuable ores of gold are quartz gold ore, silver gold ore, copper gold ore, gold sulfide ore, etc. Home; Equipment. All Equipment; Stone Crushing Machine; ... 3 The separation of large gold particles can be carried out by cyclone method, ... When the arsenopyrite ore is crushed and ground, it occurs that the pores of the ore

获取价格

Gold Refinery Process: From Raw Material to Pure Gold - Mintly

The purpose of crushing and grinding the gold ore is to liberate the valuable gold particles from the surrounding rock and minerals. By breaking the ore into smaller fragments and reducing it to a powder, the gold particles become more exposed and accessible for subsequent extraction processes. ... It allows for the separation of gold from ...

获取价格

Gold Extraction Recovery Processes - 911 Metallurgist

2016/2/29 The ore is crushed to a size that will give good liberation of gold minerals. In most operations with this crushing stage, the ore is crushed until two-three inch. A finer size can be considered if the ore needs fine liberation. The leach cycle is normally from 20 to 30 days. When the leaching cycle is complete, a new crushed ore is piled.

获取价格

Flowsheet Development of A Refractory Gold Ore To

have achieved positives outcomes for what is a complex refractory gold ore. The RGO flowsheet consists of primary single toggle jaw crushing of the ore followed by secondary cone (600 kW) and tertiary cone (600 kW) crushing. The coarse crushed stockpile has a 48,000 tonne capacity equivalent to two days operation.

获取价格

Integrated Technology for Processing Gold-Bearing Ore

sequential processes of gravity separation and flotation of gold-bearing raw materials using a combination of potas-sium butyl xanthate and VAT residue of dimethyldioxane ... Table 1 Granulometric characteristics of crushed ore (-2 mm) with distribution of gold, silver, iron and sulfur by size classes Product Extraction, %, r = 0,68 Rc ...

获取价格

Integrated Technology for Processing Gold-Bearing Ore

2021/9/24 The article is devoted to the development of technology for the processing of gold-bearing raw materials. In the process of performing the work, the following methods were used: gravity recoverable gold test (method of Knelson, Canada), stage test of the Institute Technologies of mineral separation (Russia) (determination of the optimal size

获取价格

ROCK CRUSHING METHOD AND SEPARATING GOLD FROM

2017/10/13 Gold ore separation uses comminution techniques to break down the excavated rock, but the material hardly looks like a lustrous yellow-orange metal. In order to properly free this rich element from the rock, the crushing stage has to be followed by a chemically active stage, such as the cyanidation process or the carbon in pulp release

获取价格

Processing Gold Ore by Flotation - 911 Metallurgist

2016/1/11 After they were finished, a representative of the Australian branch of Minerals Separation, Ltd., paid a visit to the mine and conducted a few tests, which confirmed the results obtained by the mine staff. ... GOLD ORE CRUSHING PLANT. In the experimental mill the ore is crushed in rock-breakers and Krupp dry-crushing ball-mills

获取价格

Gold Ore Roasting Plant - 911 Metallurgist

2016/5/31 To achieve optimum gold recovery from the certain sulfide ore body, the ore must be finely ground to achieve proper oxidation and mineral separation. The ore is separated into stockpiles after it has been mined. These stockpiles are based on gold content, sulfide content, and carbonate content.

获取价格

5 Methods of Gold-Silver Ore Extraction Mining Pedia

2020/10/16 Extraction Method of Silver in Gold-Silver Ore #1 Gravity Separation Method. Silver can be enriched by gravity separation, ... 7.2 and 5.5), and also have ductility, which can prevent them from being over crushed. The remaining silver minerals are very brittle and become very fine during the grinding process, making it difficult to

获取价格

8 Pieces of Gold Mining Equipment to Get Gold Concentrates

2023/5/27 Gold Flotation Equipment Flotation Cell Yes, I am interested!. Gold ores finer than 10 μm are difficult to recover by gravity separation. Froth flotation utilizes the hydrophobicity of gold to separate it from gangue, thereby recovering fine-grained and ultra-fine-grained gold particles.

获取价格

Processing Gold Ore by Flotation - 911 Metallurgist

2016/1/11 After they were finished, a representative of the Australian branch of Minerals Separation, Ltd., paid a visit to the mine and conducted a few tests, which confirmed the results obtained by the mine staff. ...

获取价格

Gold Ore Roasting Plant - 911 Metallurgist

2016/5/31 To achieve optimum gold recovery from the certain sulfide ore body, the ore must be finely ground to achieve proper oxidation and mineral separation. The ore is separated into stockpiles after it has

获取价格

5 Methods of Gold-Silver Ore Extraction Mining Pedia

2020/10/16 Extraction Method of Silver in Gold-Silver Ore #1 Gravity Separation Method. Silver can be enriched by gravity separation, ... 7.2 and 5.5), and also have ductility, which can prevent them from being

获取价格

8 Pieces of Gold Mining Equipment to Get Gold Concentrates

2023/5/27 Gold Flotation Equipment Flotation Cell Yes, I am interested!. Gold ores finer than 10 μm are difficult to recover by gravity separation. Froth flotation utilizes the hydrophobicity of gold to separate it from gangue, thereby recovering fine-grained and ultra-fine-grained gold particles.

获取价格

Shaker Tables – Capturing Fine Gold from Crushed Ores

2019/5/4 Separation of Gold Particles . Meanwhile, as the concentrate gets on the surface of the table water must be kept running across the content. ... At another site where to nature of the gold was coarse and crushed from quartz ore, the shaker was the perfect tool and provided excellent capture rates. Good shaker tables are expensive. There are ...

获取价格

Hard Rock Gold Processing Plant - JXSC Machinery

The hard rock gold processing plant can generally be divided into crushing, grinding, and beneficiation to separate the gold from rock.. JXSC supports customized hard rock gold (vein gold) mining process and specialized separation equipment to streamline the process. From gold ore crushing, grinding, gravity separation, flotation, leaching,

获取价格

Top 3 Gold Gravity Separation Equipment: What Are They

2023/5/27 Gold gravity separation utilizes the physical properties of gold i.e. the differences in the densities, specific gravity, size, and shape of gold and the other minerals. ... Besides, it is also good at dealing with fine gold ore with particle sizes between 0.003-0.6mm containing low mud content. ... You may need crushing and grinding equipment ...

获取价格

Gold Ore Beneficiation Production Line-Hongji Mining Machinery

Gold Ore Beneficiation Production Line. Capacity : 2000-5000t/d Applicable Materials : Gold ore Applications: Metal mineral resources development, materials science, chemical industry and other fields. Case Description: Gold mineral processing refers to the crushing and grinding of ore, and the separation of gold from the ore by physical or chemical methods.

获取价格

Underground Preconcentration by Ore Sorting and Coarse

performs gravity separation on the material in the circulating load of a fine crushing circuit and any material that is too fine for efficient separation by the IPJ is scavenged by flotation. Even if the ore should prove amenable to preconcentration a number of challenges still exist in combining mining and underground processing operations.

获取价格

what is the process of gold ore separation called

gold ore separation - Feldspar Crusher Sales - , gold ore separation gold ore separation excellent mining crushing machinery products or production line design, the company is committed to building the Chinese . Separation Process of Gold Concentrate From Rocks

获取价格

25.1 Exploration: Finding minerals Mining of mineral resources

Sometimes the ore is very deep, which is often the case with diamonds or gold ore. In these cases mine shafts go vertically down and side tunnels make it possible for the miners and equipment to reach the ore. ... Size separation is used frequently in mining to classify ore. For example, when iron ore is exported, it needs to be a certain size ...

获取价格

RESEARCH OF THE COMPLEX STAGE-BY-STAGE SCHEME OF GRAVITY SEPARATION

2021/8/21 The first test of gravity separation, the gold ore crushed to 100% passing -1.0 mm and processed at the laboratory concentration table SKL-2 with a deck surface area of 0.1 m 2 . The number of ...

获取价格

How Gold is Mined: The Process from Earth to Bullion

2024/2/21 Ore crushing and grinding to reduce particle size for further processing; Concentration or separation of gold ore through techniques including gravity separation, flotation, or amalgamation to enrich gold content; Leaching using a chemical solution like cyanide to dissolve gold out of crushed ore particles into a pregnant leach solution

获取价格ماشین سنگ زنی برای هسته بتنی

معدات التعدين الكروم للبيع في جنوب افريقيا كسارة للبيع

مصانع كسارة الحجر في المملكة العربية السعودية

معدات تعدين الذهب للبيع في مصر

الصين العلامة التجارية الجديدة عالية الكفاءة واحدة تبديل كسارة الفك الحجر للبيع

آلات محاجر الصابورة

كسارات للكسارات

كم هو محطم النبات

حجر نموذج التكسير

محطة إثراء لتكلفة خام الحديد

آلة تكسير الفك كسارة لخام الحديد

المعدات المهنية محطم الطريق السريع

كسارة الحجر غرامة الصين كسارة الحجر غرامة

تحمل الحرارة الزائدة

عملية استخراج رمل الإلمنيت

مناجم فى مرسى علم

روك كسارة مستعملة للبيع أوروبا

مورد كسارة الفك في الإمارات العربية المتحدة

سوبر ماركت خاص آلة طحن

تستخدم المطاط سيور ناقلة

كسارة الخرسانة المتنقلة مع إعادة تدوير المعادن

كندا معدات revery الذهب

تعدين الموارد غير المتجددة

استخدمت فحص الرمال مصنع للبيع في المملكة العربية السعودية

النحاس آلات تكرير للبيع

الفلبين معدات التنقيب عن الذهب

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20