الحار منتجات

ملكنا الإخبارية

beneficiation plant iron ore process

Various Types Of Iron Ore Beneficiation Processes

2024/8/14 The beneficiation of various types of iron ore is a complex process that requires careful analysis and planning. Whether it is hematite, magnetite, or any other iron ore, implementing effective beneficiation

获取价格

Advancing Iron Ore Beneficiation: Exploring Cutting-Edge

May 1, 2024. In the dynamic landscape of mining and metallurgy, the iron ore beneficiation process stands as a cornerstone, pivotal in transforming raw ore into high-grade iron

获取价格

Iron ore beneficiation: an overview - ScienceDirect

2023/1/1 The beneficiation plant is designed to process less than 10 mm of low-grade iron ore fines. Low-grade fines fed to the plant are scrubbed and then classified

获取价格

Beneficiation of Iron Ores – IspatGuru

A critical review on metallurgical recovery of iron from iron ore ...

2024/4/1 Fig. 2 illustrates the iron ore beneficiation process, particularly magnetic separation, resulting in the generation of inevitable tailings. Due to the characteristics of

获取价格

Existing and New Processes for Beneficiation of Indian Iron ores

2020/2/8 Cliff’s Tilden plant in Cleveland, USA, is the only iron ore beneficiation plant, where selective flocculation technique, using degraded starch as the flocculant,

获取价格

Beneficiation of Iron Ore - 911 Metallurgist

2016/5/24 Next. Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practice. This also applies to iron ores of the non-magnetic

获取价格

Dry beneficiation of iron ore - Mineral Processing

The haematite ore in South Africa is processed in a dry process to a HQ lump ore with 64 % iron content and a sintered fine ore with 63.5 % iron content. For fine ore beneficiation, wet processes are used. Capacity at

获取价格

Driving investments in ore beneficiation and scrap

2021/5/20 For an integrated DR plant, an ore beneficiation and scrap upgrading according to the example results in a total saving of 24 USD/t steel when ... since only small additions are made to the pellet feed in

获取价格

The Chinese Iron Ore Deposits and Ore Production

2018/7/11 Most of the domestic iron ore beneficiation plants use an anionic reverse flotation process to reduce silicon, and the collectors used are fatty acids. Anion reverse flotation process has the advantages of

获取价格

Driving investments in ore beneficiation and scrap

2021/5/20 For an integrated DR plant, an ore beneficiation and scrap upgrading according to the example results in a total saving of 24 USD/t steel when the Si tot in scrap and SiO 2 in ... Assuming an iron

获取价格

Iron Ore Beneficiation Plant - JXSC Machinery

Iron ore beneficiation is mainly a process of separating valuable minerals and iron minerals from ores to extract high-quality iron ore. The iron ore process mainly includes crushing, grinding, washing, beneficiation,

获取价格

Existing and New Processes for Beneficiation of Indian Iron

2020/2/8 Cliff’s Tilden plant in Cleveland, USA, is the only iron ore beneficiation plant, where selective flocculation technique, using degraded starch as the flocculant, has been applied to produce pellet grade concentrate from a feed containing around 32% Fe . The plant has a capacity of processing 10 million tons and is in operation since 1975.

获取价格

World leader in fine iron ore beneficiation - Mineral

Iron ore beneficiation tailings plant design, Australia Helping to deliver your project vision, we provide core services from early ... beneficiation options including process designs which achieved cost‑effective solutions using the latest HC33 gravity separation spiral technology, coupled with

获取价格

Everything You Need to Know About Iron Ore Beneficiation

2022/12/2 Iron ore beneficiation is the process of improving the quality of iron ore by removing impurities and increasing its iron content. It is necessary to reduce alumina and silica in the feed. The process improves the chemical, physical, and metallurgical characteristics of the ore to make it a more desirable feed for iron-making furnaces.

获取价格

Iron Ore Processing: From Extraction to Manufacturing

2024/4/26 The final stage in iron ore processing is ironmaking, where the iron ore is transformed into molten iron through a process called reduction. The most common method of ironmaking is the blast furnace route. In a blast furnace, iron ore, coke (carbon), and fluxes (limestone or dolomite) are loaded into the furnace from the top.

获取价格

Chrome ore beneficiation challenges opportunities – A review

2011/4/1 Commercial chromite ore beneficiation processes. Pure chromium is difficult to produce since it is readily contaminated by many other elements. Huge quantity of raw chromite ore is being mined and beneficiated in various chrome ore beneficiation plants throughout the world to cater the customized needs of various ferro alloy plants.

获取价格

BENEFICIATION OF IRON ORE - National Institute of

Appropriate beneficiation process has to be advanced to reduce the waste generation in mines and for the sustainable ... 2.4 Slimes of Iron ore 11 3. BENEFICIATION PLANT STUDY OF NOAMUNDI IRON ORE MINE 14 3.1 Mineral Processing 15 3.2 Primary Beneficiation Plant 15 ...

获取价格

Beneficiation: Quality Starts with the Ore — Metals Magazine

2017/2/1 In general, iron ore beneficiation is done at the mining site. The concentrated iron ore is subsequently sintered or pelletized, depending on the grain size distribution, before it is charged to an ironmaking plant. ... Primetals Technologies proposed various upgrading measures to improve the efficiency of the beneficiation process at a

获取价格

Beneficiation Plants and Pelletizing Plants for Utilizing Low

- Concentrate: Concentrate is ore upgraded by a beneficiation process. - Sintered ore: Sintered ore is ore agglomerated by a sintering plant. - Pellet: Pellet is ore agglomerated by a pelletizing plant. 1.2 Outline of iron ore production The production of iron and steel in China has increased dramatically. In response to the increasing

获取价格

Iron Ore Beneficiation Process - 911 Metallurgist

2017/4/27 Iron Ore Beneficiation Process. Previous. Next. ... The Brunt Ore Drying Plant. In 1910, M. A. Hanna Co. built an experimental drying plant at the Hollister mine, Crystal Falls, Mich. This was the first plant of this nature built in the iron districts of Lake Superior. The ore to be dried was of very painty nature, being high in alumina, and ...

获取价格

Treatment of iron ore beneficiation plant process water by ...

Abstract Process water collected from the iron ore beneficiation plant was treated by electrocoag- ulation (EC) process to make it suitable for reuse or safe for discharge. Experimental studies were

获取价格

Advancing Iron Ore Beneficiation: Exploring Cutting-Edge

2024/5/1 The evolution of iron ore beneficiation process technology underscores the industry’s commitment to innovation and sustainability, driving continuous improvement in ore processing efficiency and ...

获取价格

Iron Ore – Beneficiation Pelletization Division - EMIL

BENEFICIATION PLANT: The beneficiation process for a feed of 0-300 mm is designed based on the technology of Allmineral GmbH, Germany, which re-uses and recycles the process water to achieve a state of Zero Effluent Discharge. ... Effluent from the iron ore beneficiation plant is treated in thickener and clarified water from the thickener ...

获取价格

Iron Ore Beneficiation Process - 911 Metallurgist

2017/4/27 Iron Ore Beneficiation Process. Previous. Next. ... The Brunt Ore Drying Plant. In 1910, M. A. Hanna Co. built an experimental drying plant at the Hollister mine, Crystal Falls, Mich. This was the first

获取价格

Treatment of iron ore beneficiation plant process water by ...

Abstract Process water collected from the iron ore beneficiation plant was treated by electrocoag- ulation (EC) process to make it suitable for reuse or safe for discharge. Experimental studies were

获取价格

Advancing Iron Ore Beneficiation: Exploring Cutting-Edge

2024/5/1 The evolution of iron ore beneficiation process technology underscores the industry’s commitment to innovation and sustainability, driving continuous improvement in ore processing efficiency and ...

获取价格

Iron Ore – Beneficiation Pelletization Division - EMIL

BENEFICIATION PLANT: The beneficiation process for a feed of 0-300 mm is designed based on the technology of Allmineral GmbH, Germany, which re-uses and recycles the process water to achieve a state of Zero Effluent Discharge. ... Effluent from the iron ore beneficiation plant is treated in thickener and clarified water from the thickener ...

获取价格

Your iron ore beneficiation solutions - downergroup

effective beneficiation process plants for the Iron Baron and Iron Duke projects in South Australia. The challenge for these projects was managing the high variability of the low‑grade tailings stockpiles. Our know‑how and experience in metallurgical testwork helped us to uncover a number of beneficiation options including process designs

获取价格

Advances in Low Grade Iron Ore Beneficiation - MECON

10 Mt/yr low grade beneficiation plant in its integrated steel plant and has further expanded it to 20 Mt/yr capacity recently. The Kudremukh plant in Karnataka was the first big iron ore beneficiation plant in India. It mainly processes complex haematite and magnetite ore. It got pelletisation facility for

获取价格

Treatment of iron ore beneficiation plant process water by ...

2020/11/1 Process water collected from the iron ore beneficiation plant was treated by electrocoagulation (EC) process to make it suitable for reuse or safe for discharge.

获取价格

Phosphate Beneficiation - Florida Polytechnic University

Phosphate Beneficiation. Background. Definition of “Beneficiation”: This is the second step in the mining process, after removal of the ore from the ground. Beneficiation is the technical term describing the industrial process of

获取价格

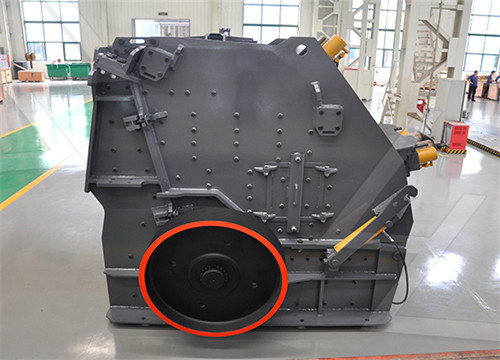

Iron Ore Beneficiation Plant Equipment For Mining Process

2023/9/4 Iron ore is an essential iron-making material with a wide application. The iron ore processing plant usually adopts the magnetic separation method. The iron ore magnetic separation production line consists of iron ore beneficiation equipment, including crushing equipment, screening equipment, grinding and grading equipment, magnetic

获取价格

Iron Ore Processing Flowsheet - Multotec

Typical Iron Ore Beneficiation Flow Sheet. Multotec specialises in iron ore beneficiation equipment with over 50 years of global experience and leading technology. Our team of metallurgists and engineers will partner with you to customise your equipment, helping your process run more efficiently while lowering your overall cost per ton.

获取价格

Beneficiation Plants for Iron Ores - YouTube

Before purchasing an iron ore beneficiation plant, you may have these questions:1. Which equipment should I choose to process iron ore?2. Is this ore process...

获取价格

Iron Ore Beneficiation - Multotec

Iron Ore beneficiation solutions from Multotec are designed so that each stage of the mineral beneficiation process, from ROM stockpiles to processed minerals and tailings, reduce overheads and lower your overall cost per ton.. Multotec’s beneficiation equipment provides peace of mind with supply, installation and asset management and flow sheet

获取价格

Recent process developments in beneficiation and metallurgy of

2024/4/1 The ratio of bastnaesite to monazite in the deposit is approximately 3:1, and REEs are recycled from iron ore processing tailings. 42, 43 There are three mining areas in the Bayan Obo deposit. The Main Ore Body and West Ore Body were mined by Baotou Iron and Steel Group in 1957, and the West Ore Body was exploited in 2004. 5. 2.4. Ion ...

获取价格

Beneficiation (Metallurgy) - an overview ScienceDirect Topics

Microbially Induced Mineral Beneficiation. K.A. Natarajan, in Biotechnology of Metals, 2018 Abstract. As different from bioleaching, the use of microorganisms in mineral beneficiation is illustrated with examples from iron ore, bauxite, clay, and sulfide mineral beneficiation for selective removal of undesirable impurities.

获取价格عمليات إنتاج النحاس في kansanshi

لكسارات كربونات الكالسيوم

صيانة نظام الهيدروليك في المعدات الديزل الثقيلة مثل الشيول

قطع غيار رأس و كتلة للكسارة

تشغيل مصانع الدرفلة

ذروة التعدين

معالجة القصدير في جنوب أفريقيا

ultra tabletop wet grinder uk

الحزام الناقل الأسطوانة التحقيق

محطة كسارة الفك المحمول

عالية الكفاءة كسارة تأثير الصخور المصنعة كسارة الصخور الصلبة

حجر الألمانية سحق النباتات

تحجيم الشاشة تهتز

حجر المطحنة تخطيط مصنع في الهند صناعة الرمل حجر المحاجر

صفحه های پوسته پوسته شده برای فروش

شركة مطاحن ريموند

كسارة فكية متنقلة للبيع في عمان

كسارة الحجر الثلاثاء

دستگاه های سنگ شکن آسفالت برای فروش

آلة الحفارة لأسعار المحاجر في أوروبا

خلايا التعويم أنواع

كسارات الصخور في كويزون العراق

horizontal curve belt conveyor design

تصميم مطحنة المطرقة

كسارة المحجر الشخصية

مخططات فك المعدات الثقيله كوماتسو200al

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20