الحار منتجات

ملكنا الإخبارية

silica ore beneficiation plants

Bauxite Beneficiation: An Approach to Value Addition in Mining

2021/7/2 Keeping the above characteristics in view, several west coast lateritic bauxite mines of India employ dry crushing−screening process to bring down silica content from the metallurgical grade bauxite [].Recently, a bauxite mine of Guinea known as

获取价格

Beneficiation Strategies for Removal of Silica and

2021/11/24 Iron ore, the raw material for the steel industry, is critical for the sustainable development of the global economy (Yellishetty, Ranjith and Tharumarajah 2010). ... Beneficiation Strategies for Removal of

获取价格

Beneficiation Plants and Pelletizing Plants for Utilizing Low

beneficiation plants for upgrading iron ore and pelletizing plants for agglomerating. Kobe Steel has much experience ... silica and alumina (approximately 2.7t/m3). Gravity

获取价格

Driving investments in ore beneficiation and scrap upgrading

Effect of Decreasing SiO2 in Dri and Sitot in Scrap on EAF Steel ProductionBenefit Analysis of Ore Beneficiation and Scrap UpgradeCost Analysis of Iron Losses Due to An Ore Beneficiation and A Scrap UpgradeCost Benefit AnalysisDiscussionThe calculation results presented in Table 11 show that a conservative estimation of the benefit of decreasing the silica content in DRI by 2 pp is 20 USD/t DRI or 15 USD/t DR pellets and a conservative figure for the benefit of decreasing the dirt in scrap by 0.3 pp Sitot is 9 USD/t scrap. The corresponding reduction of slag volume is on average 6...

A critical review on metallurgical recovery of iron from iron ore ...

2024/4/1 Iron ore tailings (IOTs), specifically those generated from iron ore beneficiation plants, present notable challenges to both the environment and economic

获取价格

The processing of high silica bauxites - ScienceDirect

2009/8/1 The beneficiation plant operated by Rio Tinto “wet” screens at a specific pisolite size and the undersize (tailings) are rejected. ... (Section 2.6) it is thought to be

获取价格

Silica sands beneficiation Commodities Mineral

The Mineral Technologies OEM range of quality products are well-suited to silica sand mining and processing operations: Mobile Mining Unit (MMU) – a high-performance mining and slurrying unit designed by Mineral

获取价格

Driving investments in ore beneficiation and scrap

2021/5/20 For an integrated DR plant, an ore beneficiation and scrap upgrading according to the example results in a total saving of 24 USD/t steel when the ... The benefit to the DR-EAF route of ore

获取价格

Beneficiation of Iron Ore - 911 Metallurgist

2016/5/24 Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practice.This also applies to iron ores of the non-magnetic type which

获取价格

Silica Sand Processing Plant - JXSC Machinery

Silica sand beneficiation mainly includes crushing, washing, classifying, magnetic separation, flotation, etc, to remove small or trace impurities in silica sand. We supports customized silica sand washing plant solutions according to mineral composition and customer requirements. Crushing Grinding: The original silica sand ore is crushed and

获取价格

Beneficiation: Quality Starts with the Ore — Metals Magazine

2017/2/1 At grain sizes below 100 µm, impurities such as silica and alumina are separated from the iron ore in a sequence of beneficiation steps, depending on the mineralogy of the iron ore. Removal of impurities from the iron ore is done prior to subsequent processing in pelletizing plants and direct-reduction plants.

获取价格

Iron ore beneficiation plant equipments manufacturers in India

We specialise in iron ore beneficiation plants, silica sand washing plant and more. We at Metofabrik offer equipment, services and process solutions to industries on turnkey basis, allowing our esteemed customers to focus on their core business. We also cater to fractional needs of mining and beneficiation equipments. Read More

获取价格

Ore Beneficiation - an overview ScienceDirect Topics

Rio Tinto Iron Ore's low-grade ore beneficiation plant in the Pilbara was commissioned in 1979. Initial engineering, design, and construction were undertaken by KBR (Kellogg Brown and Root) and Minenco (RTIO information provided to author, 2013). ... Similarly, gangue minerals such as silica, silicates, clays, calcite, alumina, and phosphates ...

获取价格

Minerals Free Full-Text Review on Beneficiation Techniques and ...

2019/1/30 Phosphate ore is an important raw material for manufacturing fertilizers and phosphorous chemical products. While most of the phosphate resources cannot be directly treated as feed stock due to the low grade of P2O5 and high content of impurities. In order to obtain a qualified phosphate concentrate, the beneficiation of the low-grade

获取价格

Beneficiation of Gold and Silver Ores SpringerLink

2019/12/15 The importance of ore sorting in improving economics of marginal deposits is increasing, being realized by the mining industry (Lessard et al. 2014; Foggiatto et al. 2014). At present, majority of automated ore sorters , outside of the diamond industry, are color or conductivity sorters (Bartram and Kowalczyk 2009). This is a significant ...

获取价格

Various Types Of Iron Ore Beneficiation Processes

1 The specific beneficiation technology used depends on the characteristics of the ore, such as its chemical composition, mineralogy and physical properties; by understanding the characteristics of each ore and the desired end product, JXSC supports customized beneficiation plants and equipment to maximize The value and quality of the final product.

获取价格

Beneficiation of Iron Ores – IspatGuru

2014/4/3 Fig 3 Types of processing ores. The wet processing (Fig 4) is normally practiced for low / medium grade (60 % Fe to 63 % Fe) hematite iron ore. The wet process consists of multi-stage crushing followed by different stages of washing in the form of scrubbing and / or screening, and classification etc., but the advantage is only partial

获取价格

Quartz Beneficiation Plant Equipment - JXSC Machinery

1. Washing-classifying-desilting: In the quartz sand beneficiation process, the fine-grained grade with a particle size of less than 0.1 mm is usually called slime.For quartz sand with a large amount of clay and ore mud, as the particle size becomes finer, the grade of silica gradually decreases, while impurities such as iron and aluminum rise instead.

获取价格

SAIL opens Rs 149 crore beneficiation plant in Chhattisgarh:

The SAIL Silica Reduction Plant, located near Dalli iron ore mines, will enable the utilization of low-grade ore for beneficiation. The plant aims to improve iron content to 62-64% and reduce silica content to 2-3%. The project will enhance iron ore supply, increase production, and reduce coke consumption and carbon emissions at the Bhilai

获取价格

(PDF) An overview of the beneficiation of iron ores via reverse ...

2014/3/1 Beneficiation of iron ore by flotation – review of industrial and potential applications. International International Journal of Mineral Processing 10, 183 – 204.

获取价格

Beneficiation of Iron Ores – IspatGuru

2014/4/3 Fig 3 Types of processing ores. The wet processing (Fig 4) is normally practiced for low / medium grade (60 % Fe to 63 % Fe) hematite iron ore. The wet process consists of multi-stage crushing followed by

获取价格

Quartz Beneficiation Plant Equipment - JXSC

1. Washing-classifying-desilting: In the quartz sand beneficiation process, the fine-grained grade with a particle size of less than 0.1 mm is usually called slime.For quartz sand with a large amount of clay and ore mud, as

获取价格

SAIL opens Rs 149 crore beneficiation plant in Chhattisgarh:

The SAIL Silica Reduction Plant, located near Dalli iron ore mines, will enable the utilization of low-grade ore for beneficiation. The plant aims to improve iron content to 62-64% and reduce silica content to 2-3%. The project will enhance iron ore supply, increase production, and reduce coke consumption and carbon emissions at the Bhilai

获取价格

(PDF) An overview of the beneficiation of iron ores via reverse ...

2014/3/1 Beneficiation of iron ore by flotation – review of industrial and potential applications. International International Journal of Mineral Processing 10, 183 – 204.

获取价格

Dry beneficiation of iron ore - Mineral Processing

The gangue types like silica is separated from the up to 15 % moist ore from the surface mines by means of dry screening (Fig. 7), with no water being added to the process. This is enabled by newly developed vibrating screens. ... Solomon Hub and Chichester Hub with the ore beneficiation plant Christmas Creek (Fig. 11). Before the end of 2022 ...

获取价格

Quartz Ore Beneficiation by Reverse Flotation for Silicon

2020/10/31 In this work the reverse flotation as beneficiation process for high-purity silica valorization from Draissa quartz deposits (Algeria) is studied as a potential raw material for photovoltaic silicon production and starting charge for crystal growth material for a large wide of applications such laser and scintillation. The samples are investigated by

获取价格

Development of process for beneficiation of low-grade iron

and silica in the iron ore. In preliminary beneficiation studies, the simple techniques of crushing, scrubbing and washing of iron ores met with limited success in the reduc-tion of alumina content due to the finely dispersed nature of gangue in the matrices of iron ore minerals (Vinod et al., 2002).

获取价格

A review of cassiterite beneficiation fundamentals and plant practices ...

2015/1/1 San Rafael plant was treating the ore assaying 2–5% Sn. The ore was coarse grained and part of the concentrate was produced in coarse size (8 mm). Cassiterite is the tin bearing mineral in the ore, which is associated with silicates, pyrites, pyrrhotite, tourmaline, copper and silver in small quantities.

获取价格

(PDF) Reverse cationic flotation - A possibility to reduce silicate ...

Luossavaara-Kiirunavaara AB (LKAB) operates an iron ore mine, three beneficiation plants and three pelletizing plants in Kiruna, Sweden. The current methods of separation in the beneficiation ...

获取价格

Development of process for beneficiation of low-grade iron ore ...

2018/2/1 Low-grade iron ore received from the West Singhbhum area of Jharkhand state in India was used to develop a beneficiation flow sheet to remove alumina (Al 2 O 3) and silica (SiO 2) from the ore to get iron (Fe)-rich product for steel plants.Mineral characterization showed that the main mineral constituents present in the head sample

获取价格

Bauxite Beneficiation Tailings Reprocessing Process

2024/8/14 Preparatory stage: Crushing and grinding the ore blocks with a size of several meters into ore particles with a size of several millimeters.In this process, you need to use many crushing equipment, screening equipment and grinding equipment. If the ore contains a lot of soil impurities, you also need to wash and deslim the ore, and use ore

获取价格

Advancing Iron Ore Beneficiation: Exploring Cutting-Edge

2024/5/1 In the dynamic landscape of mining and metallurgy, the iron ore beneficiation process stands as a cornerstone, pivotal in transforming raw ore into high-grade iron products. This article delves ...

获取价格

How To Configure Barite Beneficiation Process Plant

1 2. Magnetic separation. For barite ore containing magnetic iron minerals with fine particle size, strong magnetic separation is often used to separate iron-containing minerals and barite.This process has the advantages of high production efficiency, low energy consumption and less environmental pollution.

获取价格

Synoptic view on P ore beneficiation techniques - ScienceDirect

2022/4/1 Phosphorite is the largest existing source for commercial manufacturing of phosphate fertilizers and phosphoric acid (H 3 PO 4) [68], [69], [70], [71].Nearly 90% of the world’s phosphorite is expended by fertilizer industries whereas only 10% is utilized in other processes (Fig. 2) [29].Phosphorous in mineral phosphate ore presents as tricalcium

获取价格الكوك مطحنة

طحن كرات معدنية آلات فرز

سعر السوق من مسحوق النحاس

المسار القديم كسارة الفك

الحجر الجيري الرمال صنع الطوب مصنع ألمانيا

مخروط آلة مطحنة في باكستان

نسبة الصخور إلى وسائط الطحن

حزام وازن ناقل accu2

مقارنة تكلفة طن من الحجر الجيري المكسور

سعر آلة طحن مقعد الرأس

مدير الصيانة التعدين كسارة الذهب

سعر طاحونة سطح الطاولة في الهند

اندونيسيا كسارة الحجر السعر اليوم

المحاجر وفتح حفرة

ماكينة طبع صور فوتوغرافية براوتر ابسون

شركات التعدين المصنعة

كسارة الصخور المحمول على عجلة المسار

آلات الكسارات

كيف تنتج كسارة الصخور مسحوق المغنتيت

كسارة الفك في مصر

سعر مطحنة الكرة من 100tph قدرة

سحق محطات صيانة مانوال

الذر آلة مطحنة

اسأل كسارات الجرانيت الصناعية المستخدمة

النافثة للحبر الحزام الناقل

الات بناء حديثة

حول لدينا

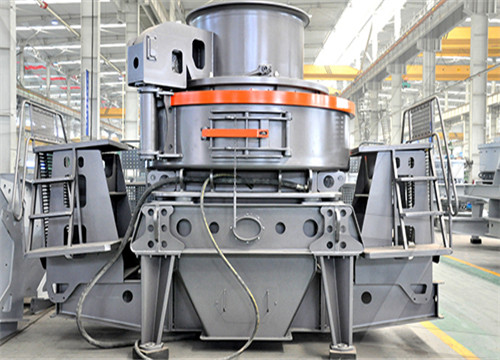

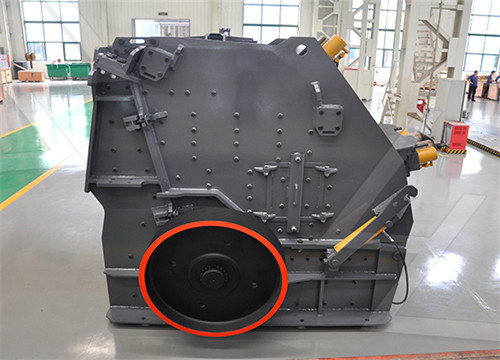

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20