الحار منتجات

ملكنا الإخبارية

critical speed of ball mill derive

Critical Speed of Ball Mill : Concept and Derivation - YouTube

2021/9/28 The video contain definition, concept of Critical speed of ball mill and step wise derivation of mathematical expression for determining critical speed of b...

获取价格

Mill Critical Speed Formula Derivation - Grinding Classification ...

The formula to calculate critical speed is given below. N c = 42.305 /sqt(D-d) N c = critical speed of the mill. D = mill diameter specified in meters. d = diameter of the ball. In

获取价格

Ball Mill Critical Speed Working Principle - YouTube

2015/6/20 https://911metallurgist/blog/ball-mill Learn about Ball Mill Critical Speed and its effect on inner charge movements. The effect of Ball Mill RPM s...

获取价格

Lec 13:Critical Speed of Ball mill Derivation and Example Problem ...

2023/8/25 About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features NFL Sunday Ticket

获取价格

Methodology for experimental determination of a ball mill critical

2024/1/24 The mill designed in this way aims to monitor the movement and interaction of grinding bodies and environment. The critical moments that need to be paid

获取价格

Variables in Ball Mill Operation Paul O. Abbe®

A Slice Mill is the same diameter as the production mill but shorter in length. Request Price Quote. Click to request a ball mill quote online or call 630-350-3012 to speak with an expert at Paul O. Abbe® to help you

获取价格

Ball Mill Critical Speed - Metallurgist Mineral Processing Engineer

2015/6/20 Rod mills speed should be limited to a maximum of 70% of critical speed and preferably should be in the 60 to 68 percent critical speed range. Pebble mills are

获取价格

Effect of mechanochemical activation parameters on vanadium

The primary objective of this study is to derive an effective critical speed pertinent for selecting the milling window operating speed for all the industrial applications ... (ball

获取价格

Critical rotation speed for ball-milling - ScienceDirect

1999/8/3 Rose and Sullivan showed critical rotation speed N c, to reach the final stage, i.e., centrifugal motion: (1) N c = 1 2π 2g D−2r where D is the inner diameter of a jar and r is the radius of balls. All throughout, they used the critical rotation speed as the constant value for given conditions of ball-mill [5].

获取价格

Variables in Ball Mill Operation Paul O. Abbe®

Variables in Ball Mill Operation. ... Mill Speed is one variable that can often be easily changed with a variable frequency drive (VFD). The starting point for mill speed calculations is the critical speed. Critical speed (CS) is the speed at which the grinding media will centrifuge against the wall of the cylinder. ...

获取价格

Ball Mill Design/Power Calculation - 911 Metallurgist

2015/6/19 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired

获取价格

Mill Critical Speed Formula Derivation - Grinding Classification ...

The formula to calculate critical speed is given below. N c = 42.305 /sqt(D-d) N c = critical speed of the mill. D = mill diameter specified in meters. d = diameter of the ball. In practice Ball Mills are driven at a speed of 50-90% of the critical speed, the factor being influenced by economic consideration.

获取价格

Ball Mills - 911 Metallurgist

2017/2/13 Optimum Ball Mill Speed. Mill speed is generally referred to as a percentage of critical, which is defined as the speed at which an infinitely small particle just follows a smooth shell lining in its motion. ... For rod mills with 40 % charge and 60 % of critical multiply power figure by 0.60. Drive motor with min. 10 % higher power should be ...

获取价格

(PDF) Effects of Ball Size Distribution and Mill Speed and Their ...

2020/7/2 A comprehensive investigation was conducted to delineate the effect of ball size distribution, mill speed, and their interactions on power draw, charge motion, and balls segregation in a ...

获取价格

Tumbling Mill Critical Speed - 911 Metallurgist

2015/8/6 Effect of Speed and Filling on Power. In this section, a 0.545-m x 0.304-m ball mill is simulated to study the combined effect of mill speed and filling on the power draft of the mill. Mill operating speed and filling, among other things, are known to affect the power draft. Mill performance is at its best when these two operating parameters ...

获取价格

Ball Mill - an overview ScienceDirect Topics

Ball mills are often operated at higher speeds than rod mills, so that the larger balls cataract and impact on the ore particles. The work input to a mill increases in proportion to the speed, and ball mills are run at as high a speed as is possible without centrifuging. Normally this is 70–80% of the critical speed.

获取价格

Lec 13:Critical Speed of Ball mill Derivation and Example

观看视频12:342023/8/25 About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright ...

获取价格

Recommended Ball Mill Speed Liner Configuration - 911

2017/10/25 Mill critical speed is defined as that rotational speed at which an infinitely small particle will centrifuge, assuming no slippage between the particle and the shell. The critical speed, Nc, in revolutions per minute, is a function of the mill diameter, D, expressed as: Nc = 42.3/√D (meters) or Nc = 76.63/√D (feet)

获取价格

AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill Operator

Girth gears bolted to the shell drive the mill through a pinion shaft from a prime mover drive. ... φ C = fraction of the mill critical speed k = mill factor constant. Mill Factor, k. Mill Type ... (W↓i) ↑0.4 / (νD) ↑0.25Where ν = the rotational speed of the mill. Ball Bulk Density. Low density media can be used ...

获取价格

Mill Critical Speed Determination - SAGMILLING.COM

The mill critical speed will be calculated based on the diameter (above) less twice this shell liner width. Mill Actual RPM: Enter the measured mill rotation in revolutions per minute. Result #1: This mill would need to spin at RPM to be at 100% critical speed.

获取价格

Solved Question 3 (a) (i) From first principles, derive an - Chegg

Question: Question 3 (a) (i) From first principles, derive an expression for the critical speed of a ball mill with an internal diameter D, and operating with steel balls of diameter d (5 marks). (ii) Explain the effects on the grinding performance of a ball mill of operating the grinding mill at a speed above or below the critical speed (5 marks).

获取价格

Ball Mill Operating Speed - MSubbu Academy

2024/4/30 Variation of operating speed of ball mill for changes in ball diameter. Ball Mill - Operating Speed ... Therefore, the mill is operated at 100 x 15/30.7 = 48.86 % of critical speed. If 100 mm dia balls are replaced by 50 mm dia balls, and the other conditions are remaining the same, Speed of ball mill = [0.4886/(2π)] x [9.812/(1 - 0.025)] 0.5

获取价格

AMIT 135: Lesson 7 Ball Mills Circuits – Mining

Girth gears bolted to the shell drive the mill through a pinion shaft from a prime mover drive. ... φ C = fraction of the mill critical speed k = mill factor constant. Mill Factor, k. Mill Type ... (W↓i) ↑0.4 / (νD)

获取价格

Mill Critical Speed Determination - SAGMILLING.COM

The mill critical speed will be calculated based on the diameter (above) less twice this shell liner width. Mill Actual RPM: Enter the measured mill rotation in revolutions per minute. Result #1: This mill would need to spin at RPM to be at 100% critical speed.

获取价格

Solved Question 3 (a) (i) From first principles, derive an

Question: Question 3 (a) (i) From first principles, derive an expression for the critical speed of a ball mill with an internal diameter D, and operating with steel balls of diameter d (5 marks). (ii) Explain the effects on the

获取价格

Ball Mill Operating Speed - MSubbu Academy

2024/4/30 Variation of operating speed of ball mill for changes in ball diameter. Ball Mill - Operating Speed ... Therefore, the mill is operated at 100 x 15/30.7 = 48.86 % of critical speed. If 100 mm dia balls are replaced by 50 mm dia balls, and the other conditions are remaining the same, Speed of ball mill = [0.4886/(2π)] x [9.812/(1 - 0.025)] 0.5

获取价格

Solved (a) () From first principles, derive an expression - Chegg

Question: (a) From first principles, derive an expression for the critical speed of a ball mill with an internal diameter D, and operating with steel balls of diameter d (5 marks). (ii) Explain the effects on the grinding performance of a ball mill of operating the grinding mill at a speed above or below the critical speed (5 marks).

获取价格

Solved Question 3 (a) (i) From first principles, derive an - Chegg

Question: Question 3 (a) (i) From first principles, derive an expression for the critical speed of a ball mill with an internal diameter D, and operating with steel balls of diameter d (5 marks). (ii) Explain the effects on the grinding performance of a ball mill of operating the grinding mill at a speed above or below the critical speed (5 marks).

获取价格

Ball Mill- Principle, Application, Uses, Critical Speed, Diagram ...

The critical speed of a ball mill can affect the performance and product quality of the mill. If the speed is too slow, the grinding balls will not be lifted and will not effectively grind the material. ... Some manufacturers have a reputation for producing high-quality ball mills, which can drive up the price. In contrast, some manufacturers ...

获取价格

Effect of mechanochemical activation parameters on vanadium

The primary objective of this study is to derive an effective critical speed pertinent for selecting the milling window operating speed for all the industrial applications ... (ball and slurry) sticks to the wall. This is referred to as the critical speed of the planetary ball mill[7, 24]. Considering Fig. 5, Fig. 5 a and b, at critical speed ...

获取价格

Exploring Ball Mill Diagram: A Comprehensive Guide - JXSC

2024/4/28 The speed of ball mill rotation is a critical parameter which determines the grinding efficiency and the end product quality. The optimum speed will differ depending on the mill’s diameter, the size and density of the grinding media, and the material being ground. Operating at the proper speed guarantees that the grinding media will transfer ...

获取价格

Orbis Machinery Ball Mills Ball Mill Drive

Unique designs various ball mill drive options, including standard shaft mount, gearwheel, pinion direct drive ball mills and more. Products. Ball Mills; Ceramic Ball Mill; ... Cylinder speed (60% critical) HP (Wet) (Alum media) HP (Dry) (Alum media) Lining Thickness (90% Alumina) (in) LBM-1820-2: 2: 18: 20: 40: 1/4: 1/2: 1: LBM-1925-3: 3 ...

获取价格

Ball Mill Parameter Selection Calculation - Power, Critical Speed

2019/8/30 V — Effective volume of ball mill, m3; G2 — Material less than 0.074mm in product accounts for the percentage of total material, %; G1 — Material less than 0.074mm in ore feeding accounts for 0.074mm in the percentage of the total material, %; q’m — Unit productivity calculated according to the new generation grade (0.074mm),

获取价格

Critical Speed Calculator Thomson

Critical Speed The calculator uses the diameter, unsupported length and end fixity to determine the approximate rotational speed at which resonance will occur. It can also back-calculate to determine the diameter or length based on a specific screw rpm.

获取价格

Energy Efficiency Analysis of Copper Ore Ball Mill Drive

3. Analysis of Variant Ball Mill Drive Systems The basic element of a ball mill is the drum, in which the milling process takes place (Figure1). The length of the drum in the analyzed mill (without the lining) is 3.6 m, and the internal diameter is 3.4 m. The mass of the drum without the grinding media is 84 Mg.

获取价格

How to Calculate and Solve for Critical Mill of Speed Ball Mill

2021/7/18 Calculating for Mill Diameter when the Critical Speed of Mill and the Diameter of Balls are Given. D = (42.3 / N c) 2 + d. Where; D = Mill Diameter N c = Critical Speed of Mill d = Diameter of Balls. Let’s solve an example; Find the mill diameter when the critical speed of mill is 20 and the diameter of bills is 10. This implies that;

获取价格طريقةصناعة صينية بالمكرامي

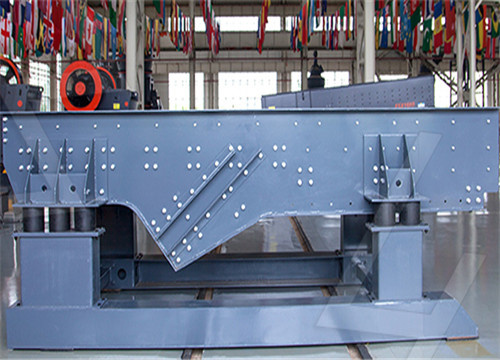

تصنيع شاشة مربع اهتزازي

مورد آلة كربونات الكالسيوم في تركيا

صانع آلة صنع مسحوق الاسمنت آلة طحن الكرة

بهترین برای خرد کردن سنگ معدن طلا

غرامة الكبريت محطم

ناقلة معدات ثقيلة

ما هيأدوات التكسير للبناء

windmill design

الأثر الكلي وسحق المعدات

مطحنة خام الذهب للبيع في uk autotrader

آلة طحن نوع ewag في الصين

digital metallic inks menufecring proses

اسرار تربية الدجاج اللاحم

آلة سحق خام الحديد الصين

تحديد مؤشر السندات

مورد مصنع تكسير الصخور في مصر

آلة تكسير الإطارات دالاس

مطحنة لمصنع الصين

بيع الكرة kapasitas كسارات الفك معدات مكسيم

محاجر كسارة آلة للبيع

جمع الفك محطم كسارة الصخور الفكية شراء كسارات الفك

صيانة آلة استصلاح الرمال

تهتز الشركات المصنعة 40

روبو الرمال وحدة تصنيع للبيع في ليبيا

كسارة صغيرة لموسيقى الروك مقالع الحجر خط الانتاج سحق آلة الفك محطم

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20