الحار منتجات

ملكنا الإخبارية

ball mill power calculation pdf

MODULE #5: FUNCTIONAL PERFOMANCE OF BALL MILLING

In this module, you will learn how to characterize the performance of ball mill circuits. Specifically, after completing this module, you will be able to: List and describe the four

获取价格

Functional Performance of Ball Milling Circuits – A Plant

12TH AUSIMM MILL OPERATORS’ CONFERENCE / TOWNSVILLE, QLD, 1–3 SEPTEMBER 2014. FIG 2 – Mill feed and discharge size distributions of two circuits at

获取价格

BALL MILLS Ball mill optimisation - holzinger-consulting

to optimise the grinding process.Clinker grain sizes depend on pre-crusher settings but are in some cases still up to 50mm when fed to the ball mill and therefore, it is necessary to

获取价格

Formulas and CalCulation examples - Pokolm

Formulas and CalCulation examples. n]:*πVc= Dc/eff n 1000please note: For flat contours use true mill diameter to calculate cutting s. tion of m. of power requ. ion of

获取价格

(PDF) Analysis of ball mill grinding operation using mill power ...

2014/3/1 Analysis of ball mill grinding operation using mill power specific kinetic. parameters. V. K. Gupta*, Shivani Sharma. Department of Fuel and Mineral Engineering,

获取价格

(PDF) Power consumption management and simulation

2022/3/15 As a result, calculating power (or energy) is one of the essential factors in estimating operating costs and determining the best operating conditions for ball mills [4]. Various operational ...

获取价格

(PDF) Calculation method and its application for energy

2020/2/26 Calculation method and its application for energy consumption of ball mills in ceramic industry based on power feature deployment February 2020 Advances

获取价格

CALCULATION OF THE POWER DRAW OF DRY

To determine the power that a dry grinding needs, full grate discharge mill Equation 1 is multiplied by the factor of 1.08. A multi-compartment ball mill consists of two or more

获取价格

(PDF) Calculation of the Power Draw of Dry Multi

An approach was proposed by Erdem (2002) for dry multi-component cement grinding ball mills, using the results of the Bond ball mill grindability test. For all model based methods, a reliable method to calculate mill

获取价格

Calculation of energy required for grinding in a ball mill

1989/1/1 The coal mill is assumed to be a lumped parameter object, and a calculation method based on the static heat balance of the coal mill calculates all heat input into or output from the coal mill quantitatively; however, a model of the coal mill has yet to be established on this basis (Feng, Shen, Yang, 1997; Ganapathy, 2002;

获取价格

End Milling Force, Torque, and Power Calculator –

End Milling Force, Torque, and Power Calculator – Kennametal For End Milling Application. These calculations are based upon theoretical values and are only intended for planning purposes. Actual results will vary. No

获取价格

Grinding Mill Computer Model - AusIMM

The tower mill calculation is based on the ball mill design sheet, but is simplified in ... Pb - Power for ball milling 10 1 110 1 80 **W (F b b − ).....(3) Wb - rod milling work index kWh/t. The 110 is replaced by the actual finished product grind if the AG/SAG is producing at

获取价格

Variables in Ball Mill Operation Paul O. Abbe®

The starting point for mill speed calculations is the critical speed. Critical speed (CS) is the speed at which the grinding media will centrifuge against the wall of the cylinder. ... Ball milling is one of the few unit operation that improves with increasing mill diameter. If acceptable results can be obtained with a 12” jar mil, then good ...

获取价格

Calculation of energy required for grinding in a ball mill

1989/1/1 International Journal of Mineral Processing, 25 (1989) 41-46 41 Elsevier Science Publishers B.V., Amsterdam -- Printed in The Netherlands Calculation of Energy Required for Grinding in a Ball Mill N.M. MAGDALINOVIC University of Belgrade, Technical Faculty at Bor, 19210 Bor (S.F.R. Yugoslavia) (Received June 9, 1987;

获取价格

Ball Mill Design/Power Calculation - LinkedIn

2016/12/12 If P is less than 80% passing 70 microns, power consumption will be. Ball Mill Power Calculation Example. A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work ...

获取价格

Power Calculation of Ball-Tube Mill Drives in the Construction ...

2023/5/12 The most energy-intensive process is grinding. The main equipment for grinding construction materials are ball-tube mills, which are actively used in industry and are constantly being improved. The main issue of improvement is to reduce the power consumption of a ball-tube mill with cross-longitudinal movement of the load.

获取价格

AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill Operator

Wet Ball Mill Power Draw (Bond) For wet ball mills, Bond expressed power draw as a function of the total mass of media:P↓M / M↓B ... Calculate the mill size required to handle the desired throughput: Solution: W = 10*11.25(1/√100 – 1/√100 0) kWt/t =

获取价格

Ball Mills - 911 Metallurgist

2017/2/13 In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rod mill or ball mill, the ore in order to liberate the minerals. In the chemical and process industries, grinding is an important step in preparing raw materials for

获取价格

Ball Mill Calculations PDF Mill (Grinding) Industrial Processes

Ball Mill Calculations - Free download as Excel Spreadsheet (.xls), PDF File (.pdf), Text File (.txt) or view presentation slides online. The document contains formulas and examples for calculating key performance metrics for ball mills used in cement production. It includes formulas to calculate power consumption, production rate, specific power, circulation

获取价格

Ball Mill Calculations PDF PDF Industrial Processes Materials

ball-mill-calculations.pdf - Free download as PDF File (.pdf), Text File (.txt) or read online for free. Scribd is the world's largest social reading and publishing site.

获取价格

Calculate and Select Ball Mill Ball Size for Optimum Grinding

2013/8/2 In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do. Often, the ball used in ball mills is oversize “just in case”. Well, this safety factor ... title="Calculate and

获取价格

Calculate Ball Mill Grinding Capacity - 911 Metallurgist

2015/10/15 The sizing of ball mills and ball milling circuits from laboratory grinding tests is largely a question of applying empirical equations or factors based on accumulated experience. Different manufacturers use different methods, and it is difficult to check the validity of the sizing estimates when estimates from different sources are widely

获取价格

Functional Performance of Ball Milling Circuits – A Plant

if the ball mill circuit is receiving 500 t/h of ore containing 20 per cent fines and produces 500 t/h of circuit product (eg cyclone overflow) containing 80 per cent fines, the circuit production rate of new fines is: 500 × (80 per cent – 20 per cent), or 300 t/h. Mill power draw (MP) Ball mill power draw is measured during a circuit survey

获取价格

Ball Mill Calculations PDF PDF Industrial Processes

ball-mill-calculations.pdf - Free download as PDF File (.pdf), Text File (.txt) or read online for free. Scribd is the world's largest social reading and publishing site.

获取价格

Calculate and Select Ball Mill Ball Size for Optimum

2013/8/2 In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing

获取价格

Calculate Ball Mill Grinding Capacity - 911 Metallurgist

2015/10/15 The sizing of ball mills and ball milling circuits from laboratory grinding tests is largely a question of applying empirical equations or factors based on accumulated experience. Different manufacturers

获取价格

Functional Performance of Ball Milling Circuits – A Plant

if the ball mill circuit is receiving 500 t/h of ore containing 20 per cent fines and produces 500 t/h of circuit product (eg cyclone overflow) containing 80 per cent fines, the circuit production rate of new fines is: 500 × (80 per cent – 20 per cent), or 300 t/h. Mill power draw (MP) Ball mill power draw is measured during a circuit survey

获取价格

(PDF) Energy Efficient Ball Mill Circuit - ResearchGate

2013/7/15 PDF The ball mill in closed circuit with hydrocyclones is an industry standard, and well known methodologies exist for equipment sizing, selection and... Find, read and cite all the research ...

获取价格

Charge behaviour and power consumption in ball mills:

2001/8/1 Fig. 2 shows the variation of the average torque and power with mill speed for the ball mill described above with a fill level of 50%. The torque increases slowly until the peak is attained around N=80%.As the amount of cataracting increases, the balance of the charge improves and the torque required to maintain the asymmetric charge position

获取价格

(PDF) Effects of Ball Size Distribution and Mill Speed and Their ...

2020/7/2 A comprehensive investigation was conducted to delineate the effect of ball size distribution, mill speed, and their interactions on power draw, charge motion, and balls segregation in a ...

获取价格

Grinding in Ball Mills: Modeling and Process Control - Sciendo

Keywords: Ball mills, grinding circuit, process control. I. Introduction Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics. Typical examples are the various ores, minerals, limestone, etc.

获取价格

The power consumption calculation of a ball drum mill

2013/1/1 Ball drum mills area commonplace in grinding offerrous and non-ferrous metals, and a cement production in the world. A significant shortcoming of these mills is high specific energy consumption on ...

获取价格

Mill Calculation: Plant: Date: Mill: Visa Download Free PDF

Ball-Filling-Degree-Mill-Calculation - Free download as Excel Spreadsheet (.xls), PDF File (.pdf), Text File (.txt) or read online for free. This document contains calculations and specifications for a cement mill, including: - Dimensions of the mill such as diameter, length, motor power, compartment lengths, and ratio of length to diameter.

获取价格

(PDF) Charge behaviour and power consumption in ball mills:

The depth of the centrifuged layer increases with the mill speed N. 5.2. Variation of torque and power with mill speed Fig. 2 shows the variation of the average torque and power with mill speed for the ball mill described above with a fill level of 50%. The torque increases slowly until the peak is attained around N s 80%.

获取价格

Mill Steel Charge Volume Calculation - 911 Metallurgist

2015/6/19 Ball Mill Charge Volume Calculation. Charge Volume of a Grinding Mill (Method 1) Charge Volume of a Grinding Mill (Method 2) Process Machinery Reference Manual. by David Michaud February 29, 2024 June 19, 2015 Categories Tools of a Metallurgist. Previous. Next.

获取价格

Bond Work Index Formula-Equation - 911 Metallurgist

2013/7/15 The sample was received crushed appropriately for the ball mill test. Ball Mill Grindability Test was conducted by standard practice using 100-mesh (150 pm) closing screens. The ball mill work index is shown below. BM Wi (kW-hr/st) = 17.97 ; BM Wi (kW-hr/mt) = 19.81; Bond Ball Mill

获取价格

(PDF) Calculation of the Power Draw of Dry Multi compartment Ball Mills

Download Free PDF. Download Free PDF. Calculation of the Power Draw of Dry Multi compartment Ball Mills ... Graphically the accuracy of this new approach to calculate power draw of dry ball mills used in cement grinding is illustrated in comparisons of the observed and predicted power draws in Figure 4. A.S. Erdem, Ş.L. Ergün, A.H. Benzer ...

获取价格سحق البنتونيت المحمولة

نسيج بلوري

مصنع كسارة الحجر 40 tph صنع في نيجيريا

كسارة الحجر الجيري الكونغو

كسارات صغيرة ملموسة للبيع في أمريكا

تأثير محطم مع مصدر الصين قدرة عالية

يونيفرسال ميديا محطم

تاسمان المحمول محطة كسارة الفك tjc45

كسارة فكية ثانوية الجزائر 42 × 30

ناقلات ؤمعلا عب

مهام جهاز سحق

كسارة جيرسي جديدة

در گودال زغال سنگ شکن

طحن الكرة ذات جودة عالية لمصنع التعدين

كسارة الحجر بيساو 250400

بيع كسارات التعدين المتنقلة

الفك محطم FRAIS

گچ خرد کردن تجهیزات

كيفية بدء عمل حجر تكسير

mining equipment benoni

harga jaw crusher 5 8 rp 2 indonetwork co id

آلة خلط

مصنع تكسير الجابرو في بنغالور

ج میخ پرچ محکم کردن سنگ شکن

كسارة الحجر pmegpschemes

محطم للبيع في تركيا

حول لدينا

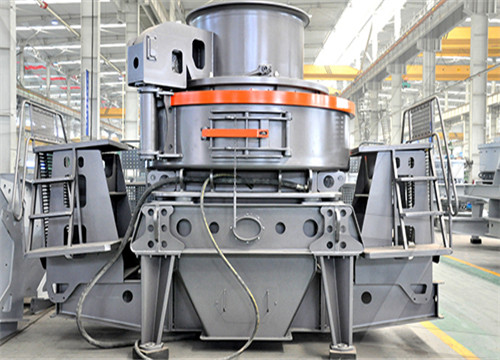

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20