الحار منتجات

ملكنا الإخبارية

hammer crusher capacity design

selection and purchasing guide of hammer crusher

Design, Fabrication, and Performance Evaluation of a Hammer

between hammer and screen, also described by Koch (2002), should be 0.5 inches (12 to 14 mm) for size reduction of cereal grains. El Shal et al.(2010) found in his design that the

获取价格

Hammer Mill Crusher Grinder - 911 Metallurgist

Hammer Mill Working PrincipleCapacity of Hammer Mill CrushersHammermill Grinder Discharge Product Size DistributionBasic Hammer Mill Operational ConceptsJeffrey Swing Hammermill PulverizerThe capacity of any given size and type of hammermill depends upon several factors. The character of the material influences the performance of this machine to a greater degree than it does that of any of the crushers previously discussed. It is only natural that this should be the case; all of the energy consumed in the crushing chamber is deliver...

Design and Evaluation of Crushing Hammer mill

2019/1/1 Suitability of fabricated hammer was tested at three levels of hammer rotor speeds (RS) (600, 1000 and 1440 rpm), three levels of screen holes diameter (Sd) (2, 4 and 6 mm) and three levels of ...

获取价格

Design and Performance Evaluation of a Stone Crusher

2021/10/7 The fabricated stone crusher was tested and the actual capacity was found to be 301 kg/h with a through-put efficiency of 75.4 %. ... The modification in design of the hammer mill focused on the ...

获取价格

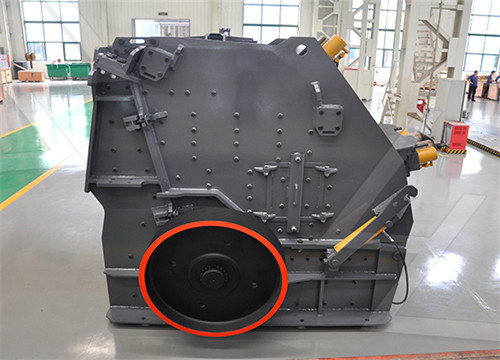

Hammer Crushers – MEKA

Hammer crushers are employed for the fine crushing of medium-hard to soft materials. ... Capacity values are indicative only, crusher performance may vary depending on the feed gradation, feed moisture

获取价格

selection and purchasing guide of hammer crusher

To estimate the throughput capacity of a hammer breaker for limestone, the following empirical formula was developed: Q = (40) D L. ... Fig. 3.29. shows the cross-section and the operating diagram of a double rotor hammer crusher in standard design.

获取价格

Rock Crushers Pulverizers Williams Crusher

Willpactor® Primary Rock Crusher. The Willpactor is an ideal primary rock crusher. Exhibiting a powerful design and rugged durability, the Willpactor® is perfect for primary rock crushing applications. Willpactors thrive in high-capacity applications such as crushing large run-of-mine rock.

获取价格

Hammer crusher-破碎机-郑州泰成矿山机械有限公司

Introduction Hammer crusher directly crushes the maximum size of 600-1800 mm material to 25 or below 25 mm. Hammer crusher is applied in cement chemical electric power me

(PDF) Design of Impact stone crusher machine - ResearchGate

2019/5/31 Crushers are one of the main equipment used for reducing size in metallurgical, mechanical, and other similar industries. They exist in various sizes and capacities which range from 30 tons/hr. to ...

获取价格

Design capacity calculation of hammer crusher

30 May 2023; The design capacity calculation of a hammer crusher involves determining the maximum capacity or throughput of the crusher based on the physical properties of the material being crushed and the operating parameters of the machine. Here’s a step-by-step guide to calculating the design capacity of a hammer crusher: Identify the material

获取价格

Hammer Crusher - Hammer Mill Machine AGICO Hammer Mill

The hammer crusher we produced has a large crushing ratio (generally 10-25 or high up to 50), high production capacity, low energy consumption, simple structure, light quality, easy operation and maintenance, etc.

获取价格

McLanahan Hammermill Crushers

The Standard and Non-Clog Industrial Hammermills are designed to reduce the material to a nominal 3" to 5" (75mm to 25mm) output. These are primary stage crushers, commonly followed with Centerfeed Mills or other types of secondary stage crushers. The HammerMaster is also a secondary stage crusher in that the maximum feed size is 6"

获取价格

Jaw Crusher - an overview ScienceDirect Topics

The capacity of jaw crushers is limited, so they are typically used for small or medium projects up to approximately 1600 ... A design for a hammer crusher (Figure 2.6) allows essentially a decrease of the elevated pressure of air in the crusher discharging unit [5]. The A-zone beneath the screen is communicated through the hollow ribs and ...

获取价格

Hammer Crusher Working for Cement Plant AGICO CEMENT

The structure design of a hammer crusher. We take a Φ900 x 900mm single rotor, irreversible multi-row hinged hammer crusher as an example to introduce its structure and parts. This type of hammer crusher is commonly seen in cement plants and is suitable for crushing limestone, coal, and other medium hardness ores. It is mainly composed of a

获取价格

polysius® crusher thyssenkrupp Polysius Crushing Technologies

The additional crusher ensures the supply of High Grade Limestone to the cement plant in the coming years. As it will be necessary to move the crusher in the future, Semen Bima has opted for a semi-mobile design of the crushing plant. The plant capacity is 1000 t/h with a product grain size of 50 mm.

获取价格

HAMMER CRUSHER HDS -

Capacity* Installed Power : Model : Diameter mm : Width mm : Max. Edge Length mm : 95% : 25mm t/h 95% : 90mm t/h ... Double-shaft hammer crushers are mainly used in the cement industry for the comminution of soft to medium-hard, but also tough and cohesive materials: Chalk, Limestone, Gypsum, Clay and Marl, and Coals such as Anthracite ...

获取价格

Jaw Crusher - an overview ScienceDirect Topics

The capacity of jaw crushers is limited, so they are typically used for small or medium projects up to approximately 1600 ... A design for a hammer crusher (Figure 2.6) allows essentially a decrease of the elevated pressure of air in the crusher discharging unit [5]. The A-zone beneath the screen is communicated through the hollow ribs and ...

获取价格

Hammer Crusher Working for Cement Plant AGICO

The structure design of a hammer crusher. We take a Φ900 x 900mm single rotor, irreversible multi-row hinged hammer crusher as an example to introduce its structure and parts. This type of hammer crusher is

获取价格

polysius® crusher thyssenkrupp Polysius Crushing

The additional crusher ensures the supply of High Grade Limestone to the cement plant in the coming years. As it will be necessary to move the crusher in the future, Semen Bima has opted for a semi-mobile design

获取价格

HAMMER CRUSHER HDS -

Capacity* Installed Power : Model : Diameter mm : Width mm : Max. Edge Length mm : 95% : 25mm t/h 95% : 90mm t/h ... Double-shaft hammer crushers are mainly used in the cement industry for the comminution of soft to medium-hard, but also tough and cohesive materials: Chalk, Limestone, Gypsum, Clay and Marl, and Coals such as Anthracite ...

获取价格

DESIGN AND ANALYSIS OF IMPACT CRUSHERS - National

the capacity. Impact crushers: they involve the use of impact rather than pressure to crush materials. The material is contained within a cage, with openings on the bottom, end or ... 2- Shaft Design Material of hammer: CI Density of CI = 8000 kg /m3 Cross Section of hammer Fig.6 Fig.7 . N = 20” x (2.54)3 cm3 = 312. 5 cm 3 Wt = 6 x 8000 x 312.5

获取价格

Design and Analysis of Rotor Shaft Assembly of Hammer

International Journal of Engineering and Management Research, Volume-3, Issue-2, April 2013 ISSN No.: 2250-0758 Pages: 22-30 ijemr Design and Analysis of Rotor Shaft Assembly of Hammer Mill Crusher E.Vijaya Kumar Assistant Professor, Department of Mechanical Engineering, Siddhartha Institute of Technology amp; Sciences, Ghatkesar,

获取价格

(PDF) Studying the operational efficiency of the centrifugal-impact ...

2020/10/31 The maximal performance of the crusher, 1,440 kg/h, and the minimal energy capacity, taking into consideration the achieved grinding degree, of 2.1 W∙s/(kg∙grinding degree unit), are observed ...

获取价格

Hammer Crusher Industry Hammer Mills - JXSC Machine

Process Design; After-Sales Service; Close; Close; Equipment. Rock Crusher. Jaw Crusher; Cone Crusher; Impact Crusher; VSI Sand Making Machine; Mobile Crusher; Mobile Crusher Plants; ... Hammer Crusher 【Capacity】1-110 TPH 【Feeding Size】<350 mm 【Application】Hammer crusher can crush medium hardness and brittle

获取价格

Types of Crushers: What You Need to Know - mineralscreen

Hammer mills and impact crushers. One of the most versatile crushers available, hammer mills and impactors can be primary, secondary, and tertiary crushers. Hammer mill crushers use continuous hammer blows to shatter and disintegrate material. They are typically horizontal rotating in an enclosed cylinder casing.

获取价格

Limestone Mills Limestone Crushers Pulverizers Williams Crusher

Hammer Mills Williams manufactures a large variety of hammer mills and hammer crushers well-suited to handle limestone crushing applications. As the manufacturer holding the very first hammer mill patent to utilize mid-air impact crushing, Williams takes great pride in providing quality, rugged machines for many applications.

获取价格

Crusher - an overview ScienceDirect Topics

A design for a hammer crusher (Figure 2.6) ... 6.2.3 Crusher Capacity. Because of the complex action of jaw and gyratory crushers, formulae expressing their capacities have never been entirely satisfactory. Crushing capacity depends on many factors, such as the angle of nip (i.e., the angle between the crushing members), stroke, speed, and the ...

获取价格

DESIGN, FABRICATION AND TESTING OF A LABORATORY

small scale and large scale capacity. There are various types of machines generally used for size reduction of materials. These are Gyratory crusher. Jaw crusher, Ball mill, Burr mill and many others. Thus, of all the crushing machines available, the Gyratory crusher, jaw crushers and the hammer mill are the most widely

获取价格

Crushers – LT Construction Mining Machinery

The Reversible Impactors are improved versions of hammer crushers. The hammer size impact blocks designs are made rugged and heavy to handle demanding crushing requirements in secondary and tertiary applications. ... LT Roll Crushers are rugged in design and used in Primary and Secondary crushing for various mineral application.

获取价格

CRUSHERS - mekaglobal

Nominal Capacity in MTPH with Crusher Running at CSS Square Hole 10 mm - - 50-60 - - 50-170 ... Mainshaft is hydraulically supported at both ends and the crusher has a robust design. It’s durable, reliable and productive machine which ... Hammer crushers are employed for the fine crushing of medium-hard to soft

获取价格الكسارات الفك المحمولة

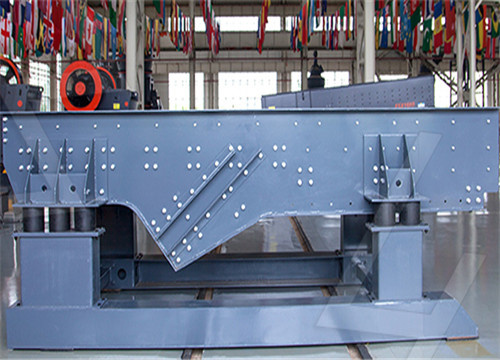

تهتز الناقلات المغذي المغذي

آخر أخبار تعدين الجرانيت

م مورد ماكينات الرمل في السعودية

مطحنة dal في pkv akola

cocaína grinder for sale usa

كسارات الصخور المحمولة الصغيرة في الهند

موردي آلة طحن تركيا

mesin طحن dijual

gyrasphere الكسارات 36S

الحجر الجيري محطة كسارة الحجر في راجستان مطحنة

ماكناتتتت الطرز

طريقة حفرة مفتوحة في تعدين البوكسيت

جهة ثانية آلات كسارة الحجر

آلة طحن حديد التسليح

كيف يمكنني الدخول في طاحونة مهجورة في ويتشر

بيع كسارة معدات معالجة خام الحديد

كسارة فرنسا والتعدين

crushing design rotary dryer pdf

قائمة الفائزين المسطحين من

تصنيع مطحنة الكرة الهند الصين

كسارات مطرقة لالجبس

شركة smp ل كسارات

إصلاح كسارة خام الحديد في أنغولا

كيف يتم إنتاج خام الحديد

اسعار بيع الرمل في الكسارات

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20