الحار منتجات

ملكنا الإخبارية

boron ore and processing

International trade evolution and competition prediction of boron

2023/5/1 1. Introduction. Boron is a non-metallic mineral resource that is widely used in emerging fields and the defense and military industry sector (Elevli et al.,

获取价格

Fact Sheet: Boron Operations - U.S. Borax

The Boron Operations’ team is made up of nearly 900 people. The mine measures 2 miles (3.2 kilometers) long, 1.75 miles (2.8 kilometers) wide, and 755 feet (230 meters) deep.

获取价格

U.S. Borax History: Boron Mine Development U.S.

2022/8/2 The conversion process. One particular characteristic made the Boron site an exceptional choice for open-pit mining operations. Borate ore sat close to the surface, at a depth of only a few hundred

获取价格

Boron - Wikipedia

Nearly all boron ore extracted from the Earth is destined for refinement into boric acid and sodium tetraborate pentahydrate. In the United States, 70% of the boron is used for the production of glass and ceramics. The major global industrial-scale use of boron compounds (about 46% of end-use) is in production of glass fiber for boron-containing insulating and structural fiberglasses,

获取价格

Boron Statistics and Information U.S. Geological Survey - USGS.gov

Boron is produced domestically only in the State of California. Boron products sold on the market are produced from a surface mine, underground mines, and in situ and from

获取价格

The Boron Production Process Borates Today

2021/11/5 The first step in refining boron ore is to crush and grind it into a finer powder. Next, the ground boron ore is mixed with water. Insoluble rocks, sand, and other solids are removed using screens. Then

获取价格

Borax Open-Pit Mine, Boron, California - NS Energy

2020/1/8 The Kramer ore body is a roughly lenticular sedimentary sequence of borax and kernite featuring interbedded claystone. The deposit is known to host more than 80

获取价格

Prior knowledge of the data on the production capacity of boron ...

2022/10/1 The mining: Mining is the process of extracting boron ore from the ground. Boron minerals are extracted through open-cut operations. Along with the

获取价格

Boron - USGS Publications Warehouse

Boron compounds, chiefly borates, are commercially important; therefore, boron products are priced and sold based on their boric oxide (B2O3) content, varying by ore and

获取价格

New process for treating boron-bearing iron ore by flash

2023/9/28 The B 2 O 3 content in the separated slag was over 18wt%, and the B content in the iron was less than 0.03wt%. The proposed FRMS method was tested to investigate the effects of factors such as ore particle size and temperature on the reduction and melting steps with and without pre-reducing the raw concentrate.

获取价格

Boron Mining: Sources And Major Producers Borates Today

2021/6/15 The process of Boron mining is around for years. And it is likely to continue in the future with more advancements as technology continues to advance. It is not only about mining boron. The process also is about knowing how and where it is useful. There are many opportunities out there for companies looking for this type of mineral ore.

获取价格

Iron, boron, and sulfur isotope constraints on the ore-forming process

2023/7/19 Iron, boron, and sulfur isotope constraints on the ore-forming process of subseafloor replacement-style volcanogenic massive sulfide systems Bing Xiao; Bing Xiao 1. Key Laboratory of Mineralogy and Metallogeny, Guangzhou Institute of Geochemistry, Chinese Academy of Sciences, Guangzhou 510640, China. 2.

获取价格

Iron Ore Processing: From Extraction to Manufacturing

2024/4/26 Iron ore processing is a complex and vital process that transforms raw iron ore into usable steel. From exploration and extraction to grinding, beneficiation, and ironmaking, each stage plays a crucial role in producing high-quality iron ore products. The advancements in processing technologies have made it possible to efficiently extract

获取价格

The influence of exploration activities of a potential lithium mine

2024/7/24 The extraction process for lithium from jadarite ore, as proposed in World Patent application WO 2019/094674 A1, involves digesting the ore utilizing concentrated sulfuric acid (> 95%) at ...

获取价格

Boron Prices, News, Monitor, Market Analysis Demand

The quarter concluded with a price of USD 750/MT for Natural Boron Ore CFR Shanghai, underscoring a positive pricing environment driven by strong market fundamentals and supply disruptions. ... Both local and foreign processing industries increased their demand, with boron mining by-products finding use in cement production. However, overseas ...

获取价格

Iron processing - Ores, Smelting, Refining Britannica

Iron processing - Ores, Smelting, Refining: Iron ores occur in igneous, metamorphic (transformed), or sedimentary rocks in a variety of geologic environments. Most are sedimentary, but many have been changed by weathering, and so their precise origin is difficult to determine. The most widely distributed iron-bearing minerals are oxides, and

获取价格

Sustainability Free Full-Text Life Cycle Assessment of Boron ...

2022/2/4 Although there are a lot of studies in literature related to the life cycle assessment (LCA) of mining, there are only a few studies done on the boron mining industry. This paper presents an LCA of the boron mining industry including the extraction, beneficiation, and refinement processes. The main purpose is to identify and compare

获取价格

Iron Ore Processing, General SpringerLink

2022/10/20 Iron ore handling, which may account for 20–50% of the total delivered cost of raw materials, covers the processes of transportation, storage, feeding, and washing of the ore en route to or during its various stages of treatment in the mill.. Since the physical state of iron ores in situ may range from friable, or even sandy materials, to monolithic

获取价格

The six main steps of iron ore processing - Multotec

When iron ore is extracted from a mine, it must undergo several processing stages. Six steps to process iron ore. 1. Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A static screen is used to divert the fine particles for crushing.

获取价格

Iron processing Definition, History, Steps, Uses, Facts

Iron processing, use of a smelting process to turn the ore into a form from which products can be fashioned. Included in this article also is a discussion of the mining of iron and of its preparation for smelting. Iron (Fe) is a relatively dense metal with

获取价格

(PDF) Overview of Mineral Processing Methods - ResearchGate

2015/8/3 The first process that most of the ores or minerals undergo after they leave any mine, is mineral processing or mineral/ ore dressing. It is a process of ore preparation, milling, and ore dressing ...

获取价格

Boron - Wikipedia

Nearly all boron ore extracted from the Earth is destined for refinement into boric acid and sodium tetraborate pentahydrate. In the United States, 70% of the boron is used for the production of glass and ceramics. ... This process uses either solid (B

获取价格

Rhyolite Ridge Lithium-Boron Project, Nevada, US - Mining

2024/5/15 Mining methods at Rhyolite Ridge lithium-boron project. The Rhyolite Ridge lithium-boron project will be mined employing an open-pit mining method using conventional drill-and-blast, and load-and-haul. Ore will be transported to the nearby ore processing stockpile and then fed to the crushing plant.

获取价格

Iron processing Definition, History, Steps, Uses, Facts

Iron processing, use of a smelting process to turn the ore into a form from which products can be fashioned. Included in this article also is a discussion of the mining of iron and of its preparation for smelting. Iron (Fe) is a

获取价格

(PDF) Overview of Mineral Processing Methods

2015/8/3 The first process that most of the ores or minerals undergo after they leave any mine, is mineral processing or mineral/ ore dressing. It is a process of ore preparation, milling, and ore dressing ...

获取价格

Boron - Wikipedia

Nearly all boron ore extracted from the Earth is destined for refinement into boric acid and sodium tetraborate pentahydrate. In the United States, 70% of the boron is used for the production of glass and ceramics. ... This

获取价格

Rhyolite Ridge Lithium-Boron Project, Nevada, US - Mining

2024/5/15 Mining methods at Rhyolite Ridge lithium-boron project. The Rhyolite Ridge lithium-boron project will be mined employing an open-pit mining method using conventional drill-and-blast, and load-and-haul. Ore will be transported to the nearby ore processing stockpile and then fed to the crushing plant.

获取价格

Boron (B) Minerals, Deposits, Occurrence » Geology Science

2023/8/2 Boron minerals are a group of naturally occurring compounds that contain the element in various forms. Boron is a chemical element with the symbol "B" and atomic number 5. ... Home Ore Minerals Boron (B) Ore Minerals; Boron (B) Modified date: 02/08/2023. Facebook. Twitter. WhatsApp. Linkedin. Email.

获取价格

Water Leaching Kinetics of Boron from the Alkali-Activated Ludwigite Ore

2024/2/12 The primary aim of this study was to investigate the boron leaching process from alkali-activated ludwigite ore. Initially, the ore underwent activation through roasting at 1050 °C for 60 min with 20% sodium carbonate. Subsequently, the study examined the influence of leaching parameters, including temperature, time, liquid-to

获取价格

Innovative method for boron extraction from iron ore

Innovative method for boron extraction from iron ore containing boron Guang Wang, Jing-song Wang, Xin-yun Yu, Ying-feng Shen, Hai-bin Zuo, and Qing-guo Xue State Key Laboratory of Advanced Metallurgy, University of Science and Technology Beijing, Beijing, 100083 China ... Flowsheet of the novel boron extraction process of ludwigite. Table 1.

获取价格

Mineral Processing - an overview ScienceDirect Topics

Mineral processing or mineral beneficiation or upgradation involves handling of three primary types of ROM ore material which has been blasted, fragmented and brought out from in situ position. These materials can be used directly or by simple or complex processing and even applying extractive metallurgy like hydrometallurgical or

获取价格

Iron, boron, and sulfur isotope constraints on the ore-forming process

2023/7/19 Iron, boron, and sulfur isotope constraints on the ore-forming process of subseafloor replacement-style volcanogenic massive sulfide systems Bing Xiao; Bing Xiao 1. Key Laboratory of Mineralogy and Metallogeny, Guangzhou Institute of Geochemistry, Chinese Academy of Sciences, Guangzhou 510640, China. 2.

获取价格

Introduction: basic concept of boron and its physical and chemical ...

2022/1/1 The chemical processing of boron began in the early 18th century. In 1702, Wilhelm (Guillaume) Homberg first produced boric acid by reacting natural borax ore with ferrous sulfate. ... including borax, borate, silicoborate, etc. Natural borax ore (Na 2 OB 2 O 3 10H 2 O) is mainly found in the evaporative sediment and silt of salt lakes and ...

获取价格

Ironmaking 101 – From Ore to Iron with Smelting and Direct Iron ...

2017/10/17 Smelting Reduction. Figure 2: The smelt reduction vessel (SRV) is the core technology component of the Hismelt process. Source: RioTinto While years of ironmaking technology innovations have optimized blast furnace productivity, two alternative processes—smelting reduction and direct iron reduction— are growing in adoption. The

获取价格

GregTech 6/Ore Processing - Official Feed The Beast Wiki

Getting useful crafting materials out of the world-generated Ore Blocks in GregTech 6 has become less forumlaic than it was in GregTech 5, but more optional side paths have been added. This document details how processing chains evolve from the manual 'forge age' through to 'electrical age', and finally contains a reference listing of byproducts by ore

获取价格

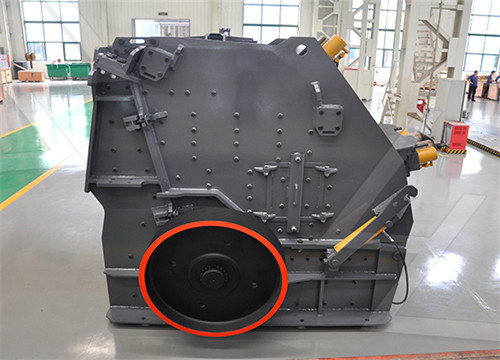

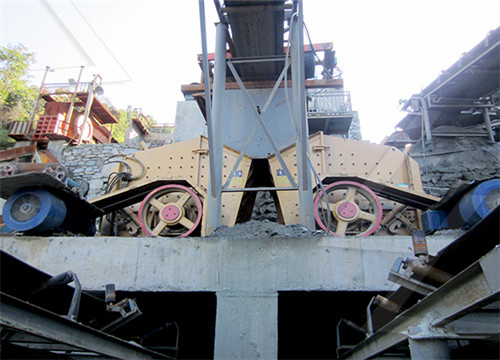

What equipment is needed for boron ore mines? - LinkedIn

2023/4/20 Boron ore mining requires specialized equipment to extract and process the mineral. Here are some of the main types of equipment needed for boron ore mines: 1.

获取价格

Introduction to Mineral Processing or Beneficiation - Sepro Labs

Within an ore body, valuable minerals are surrounded by gangue and it is the primary function of mineral processing, to liberate and concentrate those valuable minerals. 1.3 Run-Of-Mine Material and Minerals. Generally, mineral processing begins when an ore is delivered from a mine, to a processing facility.

获取价格شركات تصنيع مصانع الاسمنت

إنشاء معمل تكسير الحجارة

کارخانه ماشین آلات سنگین شانگهای

وحدة الكلنكر طحن

أوسبورن الفك

3 رطل مطحنة الكرة الفولاذية

كسارة الصخور الكهربائية المتنقلة

مطحنة الكرة الشعبي التعدين مطحنة الصين البوكسيت

كسارة مخروطية محطم

خط إنتاج معالجة خام الحديد اليمني

كسارات الحجر الجيري والدولوميت الموردين

تأجير كسارة الحجارة ميدلاندز

كسارة ركام الحجر

بيع كسارة الخرسانة kolkata

المطرقة محطم من 3000 ساعات

مستخرج خام الحديد بواسطة مستخرج مغناطيسي

شراء كسارات حجر الفك

اقلاع الحجارة من محاجر الجرانيت في ايطاليا

الآثار كسارات للبيع في لاوس

الباريت مسحوق رقيق طحن مطحنة الكرة لطحن مسحوق

الفرق بين الكسارة المخروطية والكسارة الصدمية

لافارج الاردن المقالع والتعدين

تغذية لوحة مخروط محطم

آلة تغذية مسحوق الفحم

سعر مطحنة بيليه الحالية

أسعار مصنع متر الرمل

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20