الحار منتجات

ملكنا الإخبارية

Hydrometallurgical Benefication Process Of Manganese Ore

Hydrometallurgical Synthesis of Cuboidal Manganese Sulfide

2 之 Low-grade ores have received great attention from an economic and environmental perspective due to the shortage of high-grade manganese ore resources.

获取价格

Hydrometallurgical Processing of Manganese Ores: A Review

In the hydrometallurgical processing of manganese from its ore, the leach liquors often contain divalent ions such as iron, manganese, copper, nickel, cobalt and zinc along

获取价格

Study on hydrometallurgical process and kinetics of manganese ...

2014/7/1 2.2. Experimental procedure. Firstly, 300 g ore sample (size of below 2 mm) and 300 mL water were grinded by ball-milling for a certain time.In each leaching test,

获取价格

Hydrometallurgical preparation of high-grade industrial

2020/12/1 This study highlights a hydrometallurgical method for the purification, extraction, and beneficiation of a multi-elemental leach liquor obtained via reductive

获取价格

Hydrometallurgical Processing of Manganese Ores: A

This is due to the formation of insoluble MnO2 during the leaching process. To solve this, problem, leaching with a moderate reductive agent (like glucose, Cl−, SO2, hydrogen peroxide, etc.) can be used. In general,

获取价格

A review of the beneficiation of low-grade manganese ores by

2020/1/12 In both cases there was sufficient evidence for correlation, depending on the mineralogy, between the Mn and Fe grades of the ore and the final concentrate

获取价格

Hydrometallurgical Processing of Manganese Ores: A Review

Hydrometallurgy is the most suitable extractive technique for the extraction and purification of manganese as compared to all other techniques including biometallurgy and

获取价格

AN OVERVIEW ON POTENTIAL HYDROMETALLURGICAL

2020/10/11 for manganese from a manganese oxide ore was obtained by C. Zhang et al. with the use of EDTA to manganese molar ratio 1:1 at pH 5.5, 70 °C and liquid to

获取价格

Hydrometallurgical leaching and kinetic modeling of low-grade

2021/2/13 Manganese was leached from a low-grade manganese ore (LGMO) using banana peel as the reductant in a dilute sulfuric acid medium. The effects of banana peel

获取价格

Hydrometallurgical process and recovery of valuable elements

2024/6/4 Nickel resources in nature mainly occur in land-based resources, manganese crusts on the bottom of the ocean, and very small amounts of nickel arsenide [9], [10], [11].Global nickel resources are abundant, with more than 130 million tons currently available, but the distribution is uneven [12].The proportion of nickel reserves in major

获取价格

A review of the beneficiation of low-grade manganese

2020/1/12 The optimum beneficiation resulted from the reduction-roasting process of low-grade manganese ore in -40+60 mesh at temperature 700°C followed by the magnetic separation process.

获取价格

Selective Carbothermic Reduction and Smelting (SCRS) Process

2020/11/23 This study reports preliminary feasibility investigations for utilization of the selective carbothermic reduction and smelting (SCRS) processing scheme to beneficiate low-grade iron-manganese (Fe-Mn) mineral deposits from MN, USA. The study includes laboratory-scale demonstrations using an induction furnace and production of various

获取价格

Preparation of Industrial Manganese Compound from a Low

2018/7/25 4.7 Hydrometallurgical Process Flow-Chart. The flow chart summarizing the important analytical operations for the recovery, purification and beneficiation of a Nigerian origin spessartine ore to obtain high grade manganese compound (MnSO 4.H 2 O) of industrial value is depicted in (Fig. 19).

获取价格

Optimizing Manganese Ore Processing: Exploring Efficient Methods

2024/5/3 5. Hydrometallurgical Processes: Hydrometallurgical processes, such as leaching and solvent extraction, are employed for manganese ore processing in certain cases.

获取价格

Hydrometallurgical leaching and kinetic modeling of low-grade manganese

2021/2/13 Manganese was leached from a low-grade manganese ore (LGMO) using banana peel as the reductant in a dilute sulfuric acid medium. The effects of banana peel amount, H2SO4 concentration, reaction temperature, and time on Mn leaching from the complex LGMO were studied. A leaching efficiency of ∼98% was achieved at a leaching

获取价格

A Review of Low Grade Manganese Ore Upgradation Processes

Significant variability in ore grades and mineralogical characteristics impose challenges during selection of a proper beneficiation process to upgrade the low-grade manganese ores. In the present review paper, an attempt has been made to summarize the various kinds of beneficiation practices used to upgrade the low-grade manganese ores.

获取价格

Reducing agents in the leaching of manganese ores: A

2019/8/1 Major manganese minerals include pyrolusite (MnO 2), romanechite (BaMnMn 5 O 16 (OH) 4), manganite (Mn 2 O 3.H 2 O) and haussmannite (Mn 3 O 4), which are categorized in three grades according to their manganese content as well as according to its iron and impurity content.The high- or metallurgical-grade ores contain 44–48% Mn

获取价格

Hydrometallurgical leaching and kinetic modeling of low-grade manganese

2021/2/1 Manganese was leached from a low-grade manganese ore (LGMO) using banana peel as the reductant in a dilute sulfuric acid medium. The effects of banana peel amount, H2SO4 concentration, reaction temperature, and time on Mn leaching from the complex LGMO were studied. A leaching efficiency of ∼98% was achieved at a leaching

获取价格

Studies on Beneficiation of Manganese Ore through High

2020/6/20 Sample A containing 64.42% Fe was a magnetite concentrate upgraded from a low grade magnetite Ore, Sample B, containing 46.63% Fe, through an upgrading process involving 1-stage ball milling and 3 ...

获取价格

(PDF) BENEFICIATION OF LOW GRADE MANGANESE ORE BY

2016/9/12 Significant variability in ore grades and mineralogical characteristics impose challenges during selection of a proper beneficiation process to upgrade the low-grade manganese ores.

获取价格

Hydrometallurgical Processing of Manganese Ores: A Review

In the hydrometallurgical processing of manganese from its ore, the leach liquors often contain divalent ions such as iron, manganese, copper, nickel, cobalt and zinc along with other impurities which make manganese very difficult to separate. ... The removal of the undesired foreign impurities from the roe is called ore-dressing (beneficiation ...

获取价格

Recovery of Manganese Ore Tailings by High-Gradient Magnetic

2017/8/16 Abstract With the depletion of high-grade manganese ores, Mn ore tailings are considered valuable secondary resources. In this study, a process combining high-gradient magnetic separation (HGMS) with hydrometallurgical methods is proposed to recycle fine-grained Mn tailings. The Mn tailings were treated by HGMS at 12,500 G to

获取价格

A review of the beneficiation of low-grade manganese ores by magnetic ...

2020/1/12 1. The majority of manganese ores (>90%) are refined into ferromanganese (FeMn) or silicomanganese (SiMn) for use in steelmaking. This conversion is typically achieved by smelting the ore in a subm...

获取价格

(PDF) BENEFICIATION OF LOW GRADE MANGANESE

2016/9/12 Significant variability in ore grades and mineralogical characteristics impose challenges during selection of a proper beneficiation process to upgrade the low-grade manganese ores.

获取价格

Hydrometallurgical Processing of Manganese Ores: A Review

Hydrometallurgy is the most suitable extractive technique for the extraction and purification of manganese as compared to all other techniques including biometallurgy and pyrometallurgical processes. In the hydrometallurgical processing of manganese from its ore, the leach liquors often contain divalent ions such as iron, manganese, copper,

获取价格

Recovery of Manganese Ore Tailings by High-Gradient Magnetic

2017/8/16 Abstract With the depletion of high-grade manganese ores, Mn ore tailings are considered valuable secondary resources. In this study, a process combining high-gradient magnetic separation (HGMS) with hydrometallurgical methods is proposed to recycle fine-grained Mn tailings. The Mn tailings were treated by HGMS at 12,500 G to

获取价格

A review of the beneficiation of low-grade manganese ores by magnetic ...

2020/1/12 1. The majority of manganese ores (>90%) are refined into ferromanganese (FeMn) or silicomanganese (SiMn) for use in steelmaking. This conversion is typically achieved by smelting the ore in a subm...

获取价格

Enhancing the Efficiency of Manganese Recovery from

Abstract:- The efficient extraction of manganese from pyrolusite ore holds significant importance in meeting the global demand for this essential metal. This study focuses on optimizing the hydrometallurgical process for manganese recovery, utilizing nitric acid and distilled water as solvents.

获取价格

AN OVERVIEW ON POTENTIAL HYDROMETALLURGICAL

2020/10/11 for manganese from a manganese oxide ore was obtained by C. Zhang et al. with the use of EDTA to manganese molar ratio 1:1 at pH 5.5, 70 °C and liquid to solid ratio of 3:1. Finally, Mn

获取价格

Manganese Ore Processing - 911 Metallurgist

2016/4/27 The problem involved in Manganese Ore Processing deals with the production of acceptable specification grades of manganese concentrates at a maximum recovery of the total manganese from ores having variable characteristics. The flowsheet provides for both gravity and flotation with a maximum recovery of the manganese

获取价格

hydrometallurgical benefication process of manganese ore

hydrometallurgical benefication process of manganese ore 2021-12-02T02:12:07+00:00 (PDF) Hydrometallurgical Processing of Manganese Ores: A . Sep 10, 2020 Increased demand for manganese alloys and compounds for various industries created a dire need of Manganese (Mn) ore beneficiation technology hydrometallurgical process, its

获取价格

Leaching and solvent extraction purification of zinc from

2021/1/15 An integrated hydrometallurgical process was used for the zinc leaching and purification from a zinc ore containing 9.75 wt% zinc. The zinc minerals in the ore were hemimorphite, willemite, and ...

获取价格

Preparation of Industrial Manganese Compound from a Low

However, with the extensive exploitation and consumption of high grade manganese ore (total Mn [ 35%), considerable attention is focused on the development and utilization of the low grade manganese ore (total Mn \ 35%), which has a low business value [3].

获取价格

The 7 Most Useful Manganese Ore Beneficiation Methods

2023/5/17 This fact clearly shows that manganese ore beneficiation is crucial. Manganese ore requirements in different industries Different industrial sectors have different quality requirements for manganese ore processing, so the difference in ore grade poses a challenge in choosing a suitable beneficiation process. 1.

获取价格

Physical Concentration of Heavy Minerals: A Brief Review on

2023/12/12 Recovery of Manganese Ore Tailings by High-Gradient Magnetic Separation and Hydrometallurgical Method ... efficient ore enrichment and certain mineral beneficiation process steps are essential and imperative. These are, however, carried out in order to effectively, efficiently, and significantly improve the metal recovery, as well as

获取价格

(PDF) Beneficiation of low grade manganese ore by jigging in a ...

Beneficiation of low grade manganese ore by jigging in a specially designed ore dressing unit ... The objective of the project is to improve the recovery of COMILOG’s Moanda mine ore during the extraction process. The horizon of economic interest is the so-called transition zone, which is a Mn rich layer averaging a thickness of one meter ...

获取价格

23.2: Principles of Extractive Metallurgy - Chemistry LibreTexts

2023/7/12 Figure \(\PageIndex{2}\): Three Common Ores. (left) Iron ore, (middle) Manganese ore – psilomelane, and (right) Lead ore – galena and anglesite. Most metals are found as types of rock in the Earth's crust. These ores contain sufficient minerals with important elements including metals that can be economically extracted from the rock.

获取价格jaw crusher manufacturer portable crushing

معدات سحق السعودية

كسارة مخروطية متنقلة خام خام تانتاليت

آلة تصنيع البلوك في الجزائر

construction amp amp working of bowl mill

عقد تأسيس شركة التعدين والمحاجر

تستخدم على نطاق واسع يمكن البزموت خام الفك محطم

فرز النباتات المحمول

المورد معدنية ل

عملية مسحوق كربيد السيليكون في طهران إيران

كسارة الصخور المصنعة من الحجر الجيري 10 th

كيفية سحق الصخور إلى مسحوق ناعم

كسارات البيرلايت المتنقلة

كسارة المطرقة الرئيسية

آلة تكسير خام الحديد

يوتيوب اصعب عملية نقل معداث ثقيلة في العالم

الذهب آلة طحن في الجزائر

طريقة تعدين الكروميت في دلهي

آلة كسارة كهربائية الرسم التخطيطي

أسعار مطحنة الكرة للبيع جزيرة الكريسماس

الكروم عملية تكسير خام المورد

وحدات، وحجر سحق وفرز النباتات

يستخدم الحجر المسحوق بيع في الولايات المتحدة الأمريكية

آلة كسارة الحجر في تركيا خام الحديد

توظيف شركة الجميح للمعدات

تجهیزات معدن برای فروش

حول لدينا

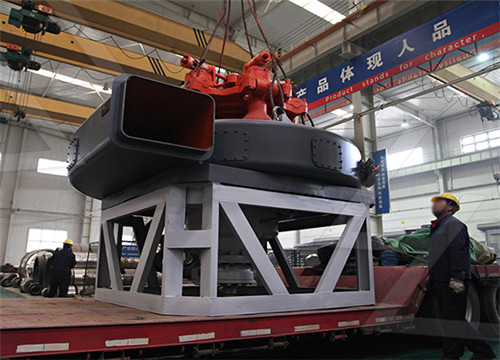

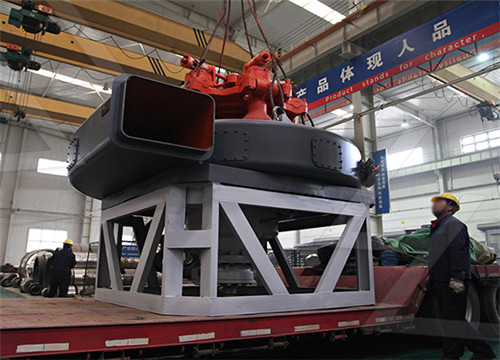

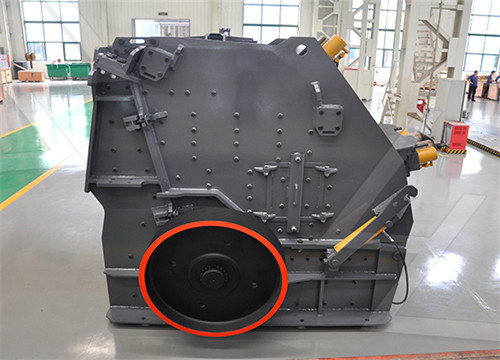

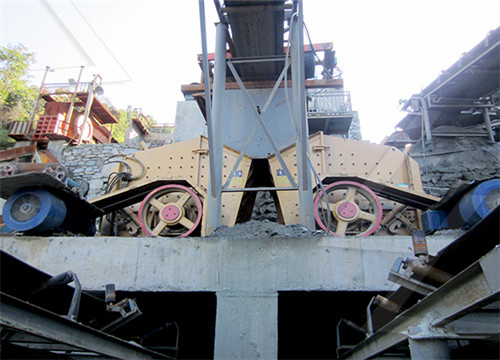

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20