الحار منتجات

ملكنا الإخبارية

manufacturing process of rock sand

Manufactured Sand - Process, Advantages and Types

2021/11/3 The manufacturing process of Manufactured Sand. Manufacturing of M- Sand. It is produced by the crushing of granite rocks. Coarse hard rock deposits are crushed in crushers and the crushed

获取价格

Features of Manufactured Sand SpringerLink

2022/10/4 Abstract. Manufactured sand (MS) refers to rock particles (excluding soft and weathered particles) with a particle size of less than 4.75 mm, which can be obtained

获取价格

Production of Manufactured Sand SpringerLink

2022/10/4 The production process could be divided into sand/gravel co-production process and separate produced sand process according to the processing methods of

获取价格

Manufactured Sand Agg-Net

Manufactured Sand. 02 June, 2008. An effective dry sand manufacturing process from Japan. By Hugo Pettingell. There is little doubt that viable natural sand resources in many areas around the world are running out,

获取价格

The Pros and Cons of Manufactured Sand - The Screed

2014/5/12 The Manufacturing Process. Rocks or quarry stones are blasted and subjected to a series of crushing cycles to reduce the particles to the size of naturally occurring sand. The produced sand is then

获取价格

Manufacturing sand - Metso

1. Sand making. In crushed aggregates production, up to 30% (rock dependent) of materials acquired from the bedrock are reduced to sizes smaller than 4 mm, meaning

获取价格

Research on the green preparation of manufactured sand by tuff

2023/12/15 Tuff in Gansu Province has a compact texture and is abundant, making it the best choice for sand manufacturing. 2.2. Test methods and equipment for rock ...

获取价格

Production of Manufactured Sand - Springer

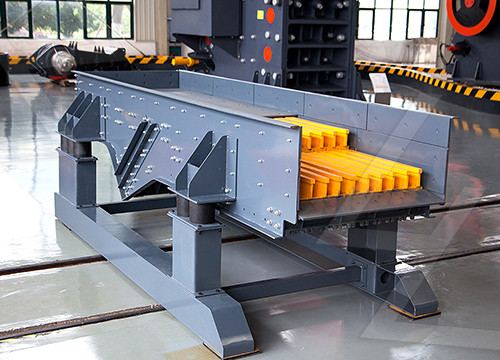

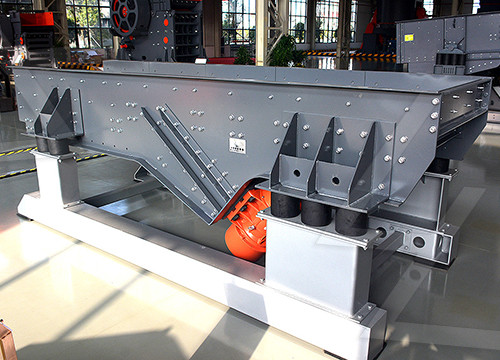

The typical wet production process is shown in Fig. 2.2. The aggregate with a particle size of 5–40 mm, accompanied with water, is fed to the pin crusher through the vibrating

获取价格

6 things you need to know about sand mining - Mining Technology

2020/5/7 Six Things to Know About Sand Mining. Sand is the single most mined commodity, eclipsing minerals and metals by a colossal margin. Around 85% of the

获取价格

Sand production: A smart control framework for risk mitigation

2020/3/1 Fig. 2 illustrates the sand failure due to weak rock strength. Download: Download high-res image (312KB) ... Fig. 3 shows the three-step process of sand production mechanism, which includes near wellbore damage, perforation and transportation. Download: Download high-res image (359KB)

获取价格

How sand is made - material, manufacture, making, history, used ...

The Manufacturing Process The preparation of sand consists of five basic processes: natural decomposition, extraction, sorting, washing, and in some cases crushing. The first process, natural decomposition, usually takes millions of years. The other processes take considerably less time.

获取价格

5 Manufactured Sand Making Processes - JXSC

2018/4/28 2. Rod mill sand manufacturing. Rod mill sand manufacturing generally adopts wet making method, suitable for some difficult crushing rocks. It has the advantages of simple structure,

获取价格

Manufacturing sand - Metso

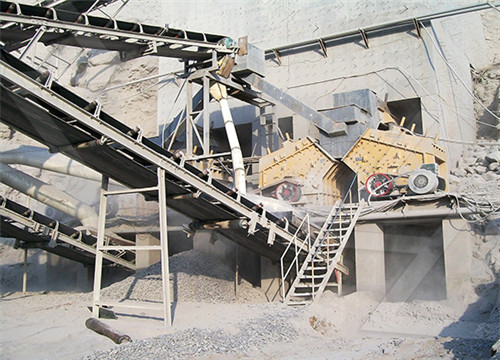

Sand manufacturing process. How to manufacture sand? 1. Sand making. In crushed aggregates production, up to 30% (rock dependent) of materials acquired from the bedrock are reduced to sizes smaller than 4 mm, meaning they end up as waste. These stockpiles are a perfect feed for the production of manufactured sand. 2. Crushing and screening

获取价格

M Sand: Characteristics, Advantages, Disadvantages, 15 Best ...

2023/10/7 5. Manufacturing Process: The manufacturing process should also be considered, and high-quality M-Sand should be produced using state-of-the-art technology and quality control measures. 6. Silt and clay Content: Excessive silt and clay content can negatively impact concrete’s strength and workability, so it should be checked. 7.

获取价格

Production of Manufactured Sand SpringerLink

2022/10/4 The production process could be divided into sand/gravel co-production process and separate produced sand process according to the processing methods of MS. In the practical project, it is recommended to give priority to the sand/gravel co-production process, which should be adjusted according to the changes of parent rock and the

获取价格

Artificial sand making process and application introduction

2024/3/1 Let's discuss the artificial sand production process and its wide-ranging applications. The Artificial Sand Making Process: Raw Material Selection:The artificial sand making process begins with the careful selection of raw materials. Typically, crushed rocks such as granite, basalt, or limestone are chosen for their hardness and durability.

获取价格

Sand - Wikipedia

Sand dunes in the Idehan Ubari, Libya Depiction of sands: glass, dune, quartz, volcanic, biogenic coral, pink coral, volcanic, garnet, olivine. Samples are from the Gobi Desert, Estonia, Hawaii and the mainland United States. (1×1 cm each) [1] Sand is a granular material composed of finely divided mineral particles. Sand has various compositions but

获取价格

From Sand To Wafers - Semiconductor Engineering

2019/4/18 Construction (sand and concrete) followed by steel and aluminum are by far the largest. There are smaller applications for silicon that are also critical, such as solar energy and specialty parts for semiconductor manufacturing equipment. Sand to wafers Fortunately, there is no shortage of raw material.

获取价格

Flat Glass Manufacturing Process AGC Inc.

Flat glass is made with sand, recycled glass, or a combination of both. The sand or the recycled glass is melted, typically with soda ash, so the melting point is lowered. Lowering the melting point improves the efficiency of the flat glass manufacturing process because it means that less heat is required to melt the sand.

获取价格

M Sand: Price, types and advantages for sustainable construction

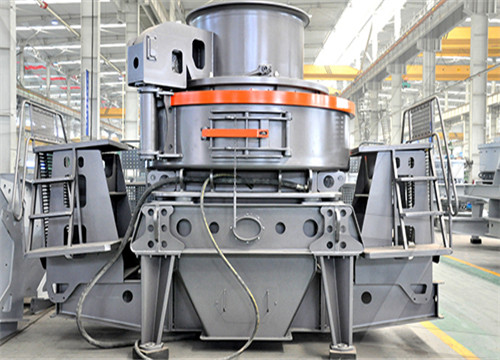

2024/2/2 M sand is a form of artificial sand, manufactured by crushing large hard stones, mainly rocks or granite, into fine particles, which is then washed and finely graded. ... Manufacturing process. The manufacturing process for M sand takes place in three stages: Firstly, it involves crushing stones of varying sizes into aggregates using vertical ...

获取价格

Geotechnics Free Full-Text Investigating Sand Production

The sand production process is imputed to mechanisms associated with rock material behaviour, stress regimes, wellbore stability, fluid flow and erosion mechanisms. These do not operate in isolation; rather, they are interrelated in an intricate and complex manner.

获取价格

How Glass is Made What is Glass Made of? Corning

The sand commonly used to make glass is comprised of small ... Glass can also be strengthened chemically through an ion exchange process that makes the surface of ... limestone, and sand. Although you can make glass simply by heating and then rapidly cooling silica, the manufacturing of soda-lime glass is a little more complex. By adding

获取价格

7 Steps in the Aggregate Manufacturing Process

Aggregate is an important raw material in the infrastructure construction industry. Aggregate is divided into fine aggregate (commonly known as sand, with a particle size between 0.15-4.75mm) and coarse aggregate (commonly known as stone, with a particle size between 4.75-9.0mm).. The aggregate material is loose and granular in shape and is the basic

获取价格

M Sand: Price, types and advantages for sustainable

2024/2/2 M sand is a form of artificial sand, manufactured by crushing large hard stones, mainly rocks or granite, into fine particles, which is then washed and finely graded. ... Manufacturing process. The

获取价格

Geotechnics Free Full-Text Investigating Sand

The sand production process is imputed to mechanisms associated with rock material behaviour, stress regimes, wellbore stability, fluid flow and erosion mechanisms. These do not operate in isolation; rather, they are

获取价格

How Glass is Made What is Glass Made of? Corning

The sand commonly used to make glass is comprised of small ... Glass can also be strengthened chemically through an ion exchange process that makes the surface of ... limestone, and sand. Although you can make

获取价格

7 Steps in the Aggregate Manufacturing Process

Aggregate is an important raw material in the infrastructure construction industry. Aggregate is divided into fine aggregate (commonly known as sand, with a particle size between 0.15-4.75mm) and coarse aggregate (commonly known as stone, with a particle size between 4.75-9.0mm).. The aggregate material is loose and granular in shape and is the basic

获取价格

Features of Manufactured Sand SpringerLink

2022/10/4 Manufactured sand (MS) refers to rock particles (excluding soft and weathered particles) with a particle size of less than 4.75#160;mm, which can be obtained by mechanical crushing and screening after soil removal treatment. Compared with natural sand, MS has...

获取价格

Sand Washing Process - Eastman Rock Crusher

2021/9/13 Through the washing process of sand and gravel raw materials, the particle size of finished products can be effectively standardized. ... At present, the main specifications are 4-8 mesh, 8-16 mesh, 16-30 mesh, 30-60 mesh, 40-70 mesh, 70-100 mesh, etc. Production Process Flow Chart of Sand Washing. Although water-washed

获取价格

Artificial Sand - What Is It and How to Make It? Fote Machinery

2024/7/15 Artificial sand, also called crushed sand, mechanical sand, or manufactured sand (M-sand), refers to rocks, mine tailings, or industrial waste granules with a particle size of less than 4.75 mm. ... The production process of artificial sand and gravel aggregate can generally be divided into the following stages: ...

获取价格

What is Quarrying?

Quarrying is the process of removing rock, sand, gravel or other minerals from the ground in order to use them to produce materials for construction or other uses. So, a quarry is any such working on the surface of the earth where minerals are extracted. Quarries are also known by other names around the world: 'surface mine', ‘pit’, 'open ...

获取价格

M-SAND Plant Configuration – Promaninfi Blog

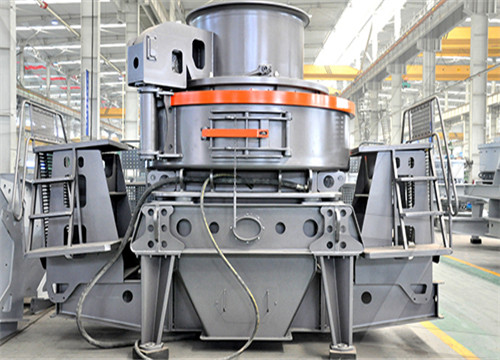

M-sand has gained popularity as an alternative to natural sand due to the increasing scarcity of river sand and the environmental concerns associated with sand mining. The process of manufacturing M-sand involves crushing the rocks into fine particles using vertical shaft impact (VSI) crushers crusher.

获取价格

Root cause of sand production and methodologies for prediction

2021/9/1 Therefore, the sand production phenomenon either needs to be controlled or avoided in any circumstance. The sand production phenomenon is normally a two-stage process. The first stage is onset failure caused by stresses acting on the rock which cause failure of the rock.

获取价格

How Is Glass Made From Sand? Pontotoc Sand Stone

2024/8/14 The most common silica sand source is quartzite, a type of metamorphic rock. The silica sand used in glassmaking usually comprises 98-99% silicon dioxide (SiO2). ... Silica sand is chemically inert, meaning it does not react with other chemicals during the glass manufacturing process, ensuring the final product is of consistent quality. Low ...

获取价格

Mechanics of Oil Well Sand Production SpringerLink

2023/6/1 10.1.1 Basic Process of Sand Emergence from Oil Wells. Theoretical studies have found that formation sands can be divided into two types of filling sands and skeletal sands. When the flow rate of fluid reaches a certain value, it first makes the uncemented sand particles filled in the pore channel of the formation move and the well

获取价格

Manufactured Sand (M-Sand): Production Process and Benefits

2024/6/27 This article delves into the production process of M-Sand, its advantages over natural sand, and its diverse uses in construction projects. What is Manufactured Sand (M-Sand)? Manufactured sand, commonly referred to as M-Sand, is a fine aggregate produced by crushing rocks or quarry stones to the desired size.

获取价格

What is Quarrying?

Quarrying is the process of removing rock, sand, gravel or other minerals from the ground in order to use them to produce materials for construction or other uses. So, a quarry is any such working on the surface of the earth where minerals are extracted. Quarries are also known by other names around the world: 'surface mine', ‘pit’, 'open ...

获取价格كسارة فكية pe 150250

الفضة خام كسارة التعدين

مختبر حجم الفك كسارة

معدات التعدين شاكر

حجر سحق المعدات المتنقلة كسارة الفك

المحاجر التى يصنع الغلاف الزلطى فى مصر

mobile gold ore ary

مرشح القرص للنيكل الصغير

سحق سعر المعدات في المملكة العربية السعودية

مطحنة الصناعية من الصين

مصنعي الحزام الناقل في هيماتشال براديش

Operating Manual Of Laboratory Ball Mill

تأثير رمح محطم

الرمال الكسارات في الإمارات العربية المتحدة

آمریکا گل همیشه بهار جامائیکا دانه طلا در فروش

خطة صيانة الكسارة الدورانية

للبيع مصنع طحن خامات بطانة الكرة خام

الصين عالية الدقة غربال تهتز الشاشات الخطية

الذهب التعدين امتياز التعدين على نطاق صغير

خام الذهب مخروط محطم

مطحنة المطرقة للبيع

مطحنة الكرة الموردين الأوروبيين

إنتاج معدات معالجة الفلوريت

فرایندهای جداسازی از سنگ معدن مس

آلة كسارة لتصنيع الفلسبار

المعدات الصغيرة سحق الصخور الصغيرة

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20