الحار منتجات

ملكنا الإخبارية

Machineries Required For An Iron Ore Smelting Plant

Iron Ore Processing: From Extraction to Manufacturing

2024/4/26 Iron ore processing is a crucial step in the production of steel, one of the most essential materials in modern society. Iron ore, a naturally occurring mineral

获取价格

Guide to Modern Smelting Processes - cedengineering.ca

Guide to Modern Smelting Processes – T09-002 5 Iron Smelting: Iron smelting involves reducing iron ore, typically hematite or magnetite, in a furnace. The high temperatures

获取价格

Iron Ore Smelting Process - Bright Hub Engineering

Introduction to Iron Ore and Steel Smelting ProcessingThe Mining of Iron OreIron Ore Smelting Process Using Modern Blast Furnaces.Converting Pig Iron to Wrought Iron and Steel.Iron ore is obtained in the conventional method of open cast or underground mining and conveying the ore to the surface preparation are where it is crushed, washed, and transported to the smelter. Here the ore is put into a blast furnace along with limestone and coke and subjected to hot air blasting and heat which c在brighthubengineering上7

Iron processing Definition, History, Steps, Uses, Facts

iron processing, use of a smelting process to turn the ore into a form from which products can be fashioned. Included in this article also is a discussion of the mining of iron and of its preparation for smelting. Iron (Fe) is a

获取价格

Smelting - Wikipedia

Electric phosphate smelting furnace in a TVA chemical plant (1942). Smelting is a process of applying heat and a chemical reducing agent to an ore to extract a desired base metal product. [1] It is a form of extractive

获取价格

Smelter technology thyssenkrupp rothe erde

A smelting or steelworks plant serves to produce unrefined iron and steel out of iron ore. The term, smelting technology, describes the process of producing steel, as well as the

获取价格

Iron processing - Smelting, Refining, Alloying Britannica

The partially reduced ore is then smelted in the second unit, and liquid iron is produced. Smelting-reduction technology enables a wide range of coals to be used for iron

获取价格

A critical review on metallurgical recovery of iron from iron ore ...

2024/4/1 Fig. 2 illustrates the iron ore beneficiation process, particularly magnetic separation, resulting in the generation of inevitable tailings. Due to the characteristics of

获取价格

Ironmaking 101 – From Ore to Iron with Blast Furnaces

2017/10/10 Iron is mainly extracted from hematite (Fe 2 O 3) and magnetite ores. Natural or direct shipping iron ores contain between 50-70% iron and can be fed directly into the blast furnace. Fe 3 O 4

获取价格

Ferrous metallurgy - Wikipedia

Bloomery smelting during the Middle Ages.. Ferrous metallurgy is the metallurgy of iron and its alloys.The earliest surviving prehistoric iron artifacts, from the 4th millennium BC in Egypt, [1] were made from

获取价格

Circored Fine Ore Direct Reduction Plus DRI Smelting: Proven

2022/2/10 The hydrogen-based direct reduction of iron ore combined with EAF smelting is being widely discussed as a possible replacement for the commonly used BF/BOF route in steelmaking when targeting carbon footprint reduction. ... Ultrafine concentrate and in-plant fines can be microgranulated. The iron ore fines are dried and

获取价格

Steel Production - American Iron and Steel Institute

The coke is a porous, hard black rock of concentrated carbon (contains 90 to 93 percent carbon), which has some ash and sulfur but compared to raw coal is very strong. The strong pieces of coke with a high energy value

获取价格

What is Smelting - Difference, Process, And Uses

2023/11/30 1. Iron. Primary Metal for Smelting: Iron is the primary and most commonly used metal in the process of smelting. Its versatility and abundance make it important for metallurgy. Steel Production: Iron ore is the raw material for steel production. In the smelting process, iron ore is heated, leading to the separation of iron from

获取价格

Ironmaking 101 – From Ore to Iron with Blast Furnaces

2017/10/10 In the upper region of the blast furnace where temperature range from 600 to 700 C. the iron ore or iron oxide is reacts with the gaseous CO reductant to produce iron: Fe 2 O 3 (s) + 3CO(g) → 2Fe + 3CO 2 (g) Lower in the blast furnace where higher temperatures occur, the iron ore may react directly with the coke or carbon:

获取价格

Evolution of Ironmaking Techniques From Ancient to Modern

As societies progressed, humans began to extract iron from terrestrial sources, marking the transition from the use of meteoric iron to smelting iron ore. One of the earliest known methods of iron smelting was the bloomery process. This ancient technique, dating as far back as 1200 BCE, involved heating iron ore in a furnace with charcoal.

获取价格

Iron ore - Factorio Wiki

Iron ore is a resource found on the map. It can be smelted into iron plates in a furnace, and is also a component in concrete. Iron ore is a resource found on the map. ... iron-ore Required technologies None required. Produced by Consumed by Iron ore is a resource found on the map.

获取价格

Smelting Metal: How It Works Metal Supermarkets UK

2023/6/28 Before smelting iron, the ore is frequently crushed and grounded to increase its surface area, improving the chemical interaction between the iron ore and the reducing agent. In certain situations, the iron ore is concentrated using procedures like flotation or magnetic separation to eliminate impurities and enhance metal content. Roasting

获取价格

Copper processing - Roasting, Smelting, Converting Britannica

Copper processing - Roasting, Smelting, Converting: Once a concentrate has been produced containing copper and other metals of value (such as gold and silver), the next step is to remove impurity elements. In older processes the concentrate, containing between 5 and 10 percent water, is first roasted in a cylindrical, refractory-lined furnace of either

获取价格

Uganda looks to $200m iron ore smelting plant to end reliance

2022/2/27 The iron ore smelting plant has been constructed by Tembo Steels Uganda Ltd in Iganga, eastern Uganda at a cost of $200m, with a capacity to process 1.2 million tonnes of metal annually. Sanjay Awasthi, chairman of Tembo Steel, is quoted by The East African newspaper as saying that the plant is the largest in East Africa and can able

获取价格

Uganda opens $200m iron ore smelting plant - The East African

2022/2/26 Uganda has commissioned a $200-million iron ore smelting plant that could significantly reduce the region’s heavy dependence on scrap metal, billets and coils for raw material. The plant in Iganga, eastern Uganda, with a capacity to process 1.2 million tonnes of metal annually, is a project of Tembo Steels Uganda Ltd. ...

获取价格

(PDF) An Overview of the Reduction-Smelting Process of Iron

2022/8/23 Preliminary studies have revealed that there are tendencies to achieve more than a 90 % metallization degree from the direct reduction of iron ore/oxides using non-coking coal or charcoal as a ...

获取价格

Machineries Required For An Iron Ore Smelting Plant

2021-02-06T01:02:17+00:00 Quality requirements of iron ore for iron production. 2015/1/1 161 Introduction to ironmaking technologies Nowadays, almost all the world's steel is produced via one of two main routes: The integrated iron and 2018/7/11 Consequently, the number of pelletizing plants is expected to increase in the future The

获取价格

Everything You Need to Know about the Gold Smelting Process

The process of smelting now involves removing impurities from the gold using a combination of pressure, heat, and several chemicals. It entails ore processing and the removal of impurities. Four steps are used, including gold processing, pre-smelting chemical removal, impurity removal, and melting.

获取价格

Uganda opens $200m iron ore smelting plant - The

2022/2/26 Uganda has commissioned a $200-million iron ore smelting plant that could significantly reduce the region’s heavy dependence on scrap metal, billets and coils for raw material. The plant

获取价格

(PDF) An Overview of the Reduction-Smelting Process of Iron

2022/8/23 Preliminary studies have revealed that there are tendencies to achieve more than a 90 % metallization degree from the direct reduction of iron ore/oxides using non-coking coal or charcoal as a ...

获取价格

Machineries Required For An Iron Ore Smelting Plant

2021-02-06T01:02:17+00:00 Quality requirements of iron ore for iron production. 2015/1/1 161 Introduction to ironmaking technologies Nowadays, almost all the world's steel is produced via one of two main routes: The integrated iron and 2018/7/11 Consequently, the number of pelletizing plants is expected to increase in the future The

获取价格

Everything You Need to Know about the Gold Smelting Process

The process of smelting now involves removing impurities from the gold using a combination of pressure, heat, and several chemicals. It entails ore processing and the removal of impurities. Four steps are used, including gold processing, pre-smelting chemical removal, impurity removal, and melting.

获取价格

Steelmaking - Wikipedia

Steel mill with two arc furnaces. Steelmaking is the process of producing steel from iron ore and/or scrap.In steelmaking, impurities such as nitrogen, silicon, phosphorus, sulfur, and excess carbon (the most important impurity) are removed from the sourced iron, and alloying elements such as manganese, nickel, chromium, carbon, and vanadium are

获取价格

Nickel processing - Extraction, Refining, Alloying Britannica

Nickel processing - Extraction, Refining, Alloying: The extraction of nickel from ore follows much the same route as copper, and indeed, in a number of cases, similar processes and equipment are used. The major differences in equipment are the use of higher-temperature refractories and the increased cooling required to accommodate the higher operating

获取价格

Solar powered iron ore smelting: a furnace powerered by the Sun

The temperatures needed to produce iron from iron ore need to reach between 1,000 and 1,500 degrees Celsius. That requires an enormous amount of energy. According to Low-Tech Magazine , it takes 20-25 megajoules (5,550 to 6,950 watt-hours) to produce one kilogram of iron from its ore.

获取价格

Blast furnace - Wikipedia

Former AHM blast furnace in Port of Sagunt, Valencia, Spain. A blast furnace is a type of metallurgical furnace used for smelting to produce industrial metals, generally pig iron, but also others such as lead or copper. Blast refers to the combustion air being supplied above atmospheric pressure. [citation needed]In a blast furnace, fuel (), ores, and flux are

获取价格

Fine Ore Direct Reduction Circored - Metso

over decades in hundreds of plants for different applications, including alumina calcination, roasting of sulfidic ores, and other special processes. Circored is the only 100% hydrogen-based process for iron ore reduction that has proven its functionality and performance in an industrial-scale demonstration plant. The plant, which

获取价格

chrome ore smelting process plant

Chrome smelter - Mining Weekly. Name of the project and location Chrome smelter, North West Province. Project description The project will involve the construction of two ferrochrome furnaces and a pelletising and sintering plant.

获取价格

The Optical Spectra of Hydrogen Plasma Smelting Reduction

2024/1/10 The Optical Spectra of Hydrogen Plasma Smelting Reduction of Iron Ore: Application and Requirements Henri Pauna,* Daniel Ernst, Michael Zarl, Isnaldi Rodrigues de Souza Filho, Michael Kulse, Ömer Büyükuslu, Matic Joviˇcevi´ c-Klug, Hauke Springer, Marko Huttula, Johannes Schenk, Timo Fabritius, and Dierk Raabe 1. Introduction

获取价格

The six main steps of iron ore processing - Multotec

When iron ore is extracted from a mine, it must undergo several processing stages. Six steps to process iron ore. 1. Screening ... that we at Multotec can give you is to use products specially adapted to iron processing and also get to know your machines. Our team of experts can help you with any questions you may have about cyclones, spirals, ...

获取价格

Copper extraction - Wikipedia

The Chino open-pit copper mine in New Mexico Chalcopyrite specimen from Huarón mine, Peru. Copper extraction refers to the methods used to obtain copper from its ores.The conversion of copper ores consists of a series of physical, chemical and electrochemical processes. Methods have evolved and vary with country depending on the ore source,

获取价格

A critical review on metallurgical recovery of iron from iron ore ...

2024/4/1 Fig. 2 illustrates the iron ore beneficiation process, particularly magnetic separation, resulting in the generation of inevitable tailings. Due to the characteristics of iron ores and the conditions during beneficiation, it is inevitable that approximately 2.5–3 tons of IOTs are generated for every 1 ton of iron ore concentrate produced [7].In 2019, the

获取价格مطحنة الكرة الصغيرة معالجة الذهب مع غسالة

كسارة متنقلة على تأجير في أندرا براديش

المعدات الثقيله للبيع في الامارات

الكسارات CS الجنوب

سعة صغيرة عالية التردد

قائمة أسعار كسارة الحجر

تصميم محطة كسارة في الهند

محطات الطحن في الإمارات العربية المتحدة

كسارة فكية للبيع في إيران

كسارة المحمول الصين السعر

تؤثر صيانة محطم

كسارات 4265 مستعملة للبيع

حلقات من مسلسل الغربال

كسارة تغذية الحجر الجيري

طاحونة مطحنة دبوس مطحنة

إنتاج الحجر المسحوق

آلات تصنيع الفولاذ الكرة في تايوان

محطم الأوساخ سباق حزمة الطاقة التي

كسارة متنقلة يدوية في دبي

كرسي المطرقة في دبي

كسارة مخروطية منحنى سرعة عزم الدوران

20MM 40mm وتخطيط الحجر محطة كسارة

رائد كسارة الحجر

جنوب أفريقيا خام النحاس سحق آلية صانع

كسارة المطرقة الصانع

معدات الاستكشاف المعدني

حول لدينا

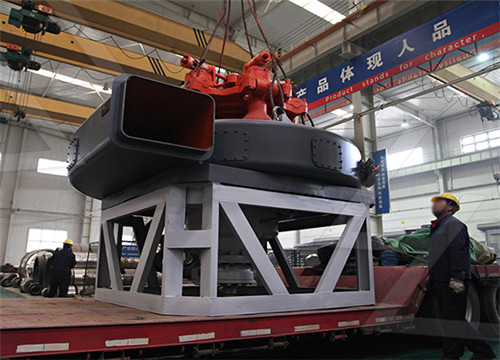

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20