الحار منتجات

ملكنا الإخبارية

procecing mining of irone ore

Iron Ore Processing: From Extraction to Manufacturing

2024/4/26 Iron ore processing is a crucial step in the production of steel, one of the most essential materials in modern society. Iron ore, a naturally occurring mineral composed primarily of iron oxides, is mined

获取价格

Iron processing Definition, History, Steps, Uses, Facts

OverviewHistoryiron processing, use of a smelting process to turn the ore into a form from which products can bIron (Fe) is a relatively dense metal with a silvery white appearance and distinctive magnetic properties. It constitutes 5 percent by weight of the Earth’s crust, and it is the fourth most abundant element after oxygen, silicon, and aluminum. It melts at a temperature of 1,538° C (2,Iron is allotropic—that is, it exists in different forms. Its crystal structure is either body-centred cThe pure metal is malleable and can be easily shaped by hammering, but apart from specialized electrical applications it is rarely used without adding other elements to improve its properties. Mostly it appears in iron-carbon alloys such as steels, which contain between 0.003 and about 在britannica上

The six main steps of iron ore processing - Multotec

Screening. We recommend that you begin by screening the iron ore to

Iron processing - Ores, Smelting, Refining Britannica

The partially reduced ore is then smelted in the second unit, and liquid iron is produced. Smelting-reduction technology enables a wide range of coals to be used for iron making.

获取价格

Iron ore - Wikipedia

Iron ores consist of oxygen and iron atoms bonded together into molecules. To convert it to metallic iron, it must be smelted or sent through a direct reduction process to remove the oxygen. Oxygen-iron bonds are strong, and to remove the iron from the oxygen, a stronger elemental bond must be presented to attach to the oxygen. Carbon is used because the strength of a carbon-oxygen bond is greater than that of the iron-oxygen bond at high temperatures. Thus, the iron or

获取价格

Iron Ore Mining Process: From Extraction to Export

2023/12/19 Iron ore mining is relatively simple compared to other minerals and metals that require underground tunnels and complex chemical-drive processes, like gold. Iron ore is generally sourced from

获取价格

Iron Ore Processing, General SpringerLink

2022/10/20 The processing methods largely depend on the characteristics of the ore itself and the nature of association of gangue with the ore. This chapter will try to give an

获取价格

Introduction: Overview of the global iron ore industry

2022/1/1 The company has the two largest iron ore mining and processing operations in the country, which are located at Lebedinsky and Mikhailovsky in the Kursk

获取价格

Iron Ore: From Mining to Processing to Dust Control

The Ally to Your Iron Ore Processing Plant. Here at Benetech, we dedicate our greatest resources to resolving your daily challenges in bulk material handling. To discuss how you can reinforce a safer, more productive

获取价格

Iron Ore Processing, General - Springer

Iron ore mining methods vary by the type of ore being mined. Currently, there are four main types of iron ore deposits, depending on the mineralogy and geology of the ore

获取价格

Introduction: Overview of the global iron ore industry

2022/1/1 The Beeshoek mine near Postmasburg was established in 1964 and uses jigs to upgrade the ore. However, production from the mine has steadily declined in recent years and was around 3 Mt in 2019. The newer Khumani mine is located about 60 km north of the Beeshoek mine, adjacent to Kumba Iron Ore’s Sishen mine, and produced about

获取价格

Iron Ore Processing, General SpringerLink

2022/10/20 The processing methods largely depend on the characteristics of the ore itself and the nature of association of gangue with the ore. This chapter will try to give an overview of important aspects involved in iron ore processing including iron ore mining, iron ore handling, and iron ore beneficiation and agglomeration.

获取价格

Iron Ore Supply Chain: From Mining to Steel Production

2023/10/25 Iron ore is a crucial raw material for the global steel industry, and its supply chain is a complex network that involves multiple stakeholders and activities. The iron ore supply chain begins with the

获取价格

Iron Ore: Mineralogy, Processing and Environmental

2021/12/2 Iron Ore: Mineralogy, Processing and Environmental Sustainability, Second Edition covers all aspects surrounding the second most important commodity behind oil. As an essential input for the production of crude steel, iron ore feeds the world's largest trillion-dollar-a-year metal market and is the backbone of the global infrastructure. The

获取价格

Iron Ore Mining Process: From Extraction to Export

2023/12/19 Using a process that combines coking coal with reduced iron pellets, steelmaking has become one of the world's most vital industries. In the 1800s, ... Everything in iron ore mining is big. Australia possesses one of the longest private rail networks in the world, designed solely for transporting mile-long ore trains to port facilities. ...

获取价格

Iron Ore Mining – The process of iron ore mining %y

Iron ore mining operations Pilbara region Western Australia. The process of iron ore mining. Mining iron ore is a physically and chemically demanding process that takes place in remote locations around the world. The process begins with exploration, which can be done through surface or underground methods. Once a deposit is discovered, mining ...

获取价格

Environmental Impacts of Iron Ore Mining UKGBC

Several dam failures of residues from iron ore mining happened in this area, including the Mariana dam disaster in 2015 and the Brumadinho dam disaster in 2019. ... Ore mining and processing require large quantities of freshwater. Many mines are located in areas of water stress, exacerbating the local scarcity even further. 4 . Contamination ...

获取价格

Iron Ore Geoscience Australia

2023/12/19 Mining and processing hematite and magnetite ores. High-grade hematite ore is referred to as direct shipping ore (DSO) as, once mined, the ore goes through a simple crushing and screening process before being exported for steel-making. ... in August 2019 that it had executed a "Term Sheet for a Mining Rights Agreement" with

获取价格

Iron ore BHP

With 5 mines, 4 processing hubs and 2 port facilities, our Pilbara iron ore business is all connected by more than 1,000 kilometres of rail infrastructure. At each mining hub ore from the mines is crushed, beneficiated (where necessary) and blended to create high-grade hematite lump and fines products.

获取价格

Understanding Iron Ores and Mining of Iron Ore – IspatGuru

2015/4/3 Mining (extraction), beneficiation, and processing of iron ore produces iron and steel. Mining is defined as removing ore material from a deposit and encompasses all activities prior to beneficiation. High grade iron ores (iron content greater than 62 %) are simply crushed, screened and shipped directly to the iron making unit (e.g. blast ...

获取价格

Life cycle assessment of iron ore mining and processing

2015/1/1 The study used typical iron ore mining and processing operations in Pilbara, Western Australia, as a case study and covers the upstream part of the cradle-to-gate life cycle of steel: the mining and processing of iron ore. Transport of lump and fines to the shipping port was also included, as these mines are usually located some distance

获取价格

Dry beneficiation of iron ore - Mineral Processing

The currently largest iron ore company in the world, Vale, is currently undertaking an extensive switch of its production in Brazil from wet to dry processing, In 2021 the company produced 275.5 Mta iron ore and 32.3 Mta iron ore pellets there. It has three mine complexes the Southeastern System (1) and Southern System (2) in Minas Gerais and ...

获取价格

Iron ore beneficiation: an overview - ScienceDirect

2023/1/1 Dry processing of iron ore: In dry processing of iron ore, ROM is generally crushed below 40 mm through three-stage crushing and thus segregated by screening into 10–40 and −10 mm fractions. For softer ore, tumbler index is generally low and hence lump ore is crushed below 10 mm to produce 100% fine product. Yield from

获取价格

Why Is Iron Ore Valuable? Behind the Scenes of Production

2022/2/3 Why Is Iron Ore Valuable? Iron ore is a rock from which the metal iron is extracted. About 98% of the world’s iron is used to produce steel.. Pure iron is an element and a soft grayish-white metal. Other than meteorites that fall from the sky, iron is never found by itself in nature.

获取价格

Life cycle assessment of iron ore mining and processing

2015/1/1 The study used typical iron ore mining and processing operations in Pilbara, Western Australia, as a case study and covers the upstream part of the cradle-to-gate life cycle of steel: the mining and processing of iron ore. Transport of lump and fines to the shipping port was also included, as these mines are usually located some distance

获取价格

Dry beneficiation of iron ore - Mineral Processing

The currently largest iron ore company in the world, Vale, is currently undertaking an extensive switch of its production in Brazil from wet to dry processing, In 2021 the company produced 275.5 Mta iron ore and

获取价格

Iron ore beneficiation: an overview - ScienceDirect

2023/1/1 Dry processing of iron ore: In dry processing of iron ore, ROM is generally crushed below 40 mm through three-stage crushing and thus segregated by screening into 10–40 and −10 mm fractions. For softer ore, tumbler index is generally low and hence lump ore is crushed below 10 mm to produce 100% fine product. Yield from

获取价格

Why Is Iron Ore Valuable? Behind the Scenes of Production

2022/2/3 Why Is Iron Ore Valuable? Iron ore is a rock from which the metal iron is extracted. About 98% of the world’s iron is used to produce steel.. Pure iron is an element and a soft grayish-white metal. Other than meteorites that fall from the sky, iron is never found by itself in nature.

获取价格

Iron Ore in India , Types, Uses, Distribution, World Map

2024/2/17 Natural ore, also known as “direct shipping ore,” is ore that contains a high percentage of hematite or magnetite (more than 60% iron) and can be fed directly into blast furnaces to produce iron. Iron ore is a raw material used to produce pig iron, which is one of the primary raw materials used to produce steel—steel accounts for 98 per ...

获取价格

Iron Ore Processing, General - Springer

Most mining is carried out using; Continuous mining that . Iron Ore Processing, General. 17. employs a continuous mining mechanism to cut the coal deposits from the walls. This means there is less of blasting and drilling and utilizes fewer miners down in the mines. It is safer than the yesteryear techniques of mining that is being described

获取价格

Iron Ore: From Mining to Processing to Dust Control

Mining iron ore typically involves finding a fertile site, drilling and blasting the ore, and then transporting it to the primary crusher for processing. Crushed ore is sorted over screens and resized to different specifications (lump and refined products).

获取价格

From Ore to Alloy: Navigating Ironmaking in Modern Steel

In this process, iron ore, coke (a form of carbon), and limestone are fed into the furnace, where intense heat and chemical reactions extract molten iron. Innovations in blast furnace technology, including hot blast systems, oxygen enrichment, and refractory materials, have significantly improved productivity and environmental performance. ...

获取价格

Iron Ore Flotation Process: The Journey from Ore to Concentrate

2024/1/17 The iron ore flotation process, as an important part of modern mining, is an important means to effectively separate iron ore from raw ore.The iron ore flotation process not only involves complex ...

获取价格

Iron Ore: The Foundation Of Steelmaking Markets

2024/3/6 Iron ore mining and processing can have significant environmental impacts. The extraction process requires the removal of vegetation and topsoil, leading to habitat destruction and soil erosion. The use of heavy machinery and vehicles contributes to air and noise pollution.

获取价格

Iron Ore Mining Techniques Metal Extraction

MINING AND PROCESSING: Iron ore mining can be broadly categorized into two methods: manual mining, which is employed in small mines, and mechanized mining, which is suitable for large iron ore mines. Manual mining is typically limited to float ores and small-scale operations. Reef ore mining is also conducted manually on a small scale.

获取价格

Iron Ore - an overview ScienceDirect Topics

Iron ore is a mineral that is a source of metallic iron extracted through mining. The extraction and processing of iron ore result in the generation of significant amounts of solid and liquid waste, including tailings containing various toxic metals. AI generated definition based on: Phytorestoration of Abandoned Mining and Oil Drilling Sites, 2021

获取价格

Iron mining in the United States - Wikipedia

Processed taconite pellets as used in the steelmaking industry, with a US quarter (0.96 in./24.3 mm) shown for scale.. Iron mining in the United States produced 48 million metric tons of iron ore in 2019. [1] Iron ore was the third-highest-value metal mined in the United States, after gold and copper. [2] Iron ore was mined from nine active mines and three

获取价格

Top 6 Steps Of Iron Ore Processing - Australia Mining Service

2023/9/18 Visit our Australian Mining Product and Services to see what our professionals are equipped with to help you in your processing iron ore journey or what other services we can offer. Alternatively, call us on 1300 241 620 to speak to our experts today and learn all about the mining iron ore process. Types Of Iron Ore In Australia

获取价格الكرة مطحنة تركيب ماكينات

تستخدم الحصى محطم في مصر السعر

الحجر الجيري آلة سحق الهند

وكيل شركة فانتوزي للمعدات الثقيلة بالسعودية

کارخانه سنگ شکن طلا

سعر الدولوميت كسارة كسارة

قوة التكسير للجرانيت

كسارة اكستيك c12 للبيع في مقدونيا

مكائن مصان�الاسمنت في السعودية

اسعار ماكينات الحلاقة براون للرجال بم

الصين سعر بلات خام الحديد

تفاصيل آلة طاحونة

محطم جنة قراءة

C150 250 كسارة الفك

اريد الشراء الت الطحن الزيتون

كسارة الحجر من خلال كسارة الحجر المتنقلة في الهند

بيع معدات معالجة خام الذهب الذهب

الالات الي الكهرباء في فرنسا

كسارة الفك الخام كسارة حجر الفك السعر

قائمة معدات تعدين خام الحديد

سعر كسارة مخروطية الحجر

الكروميت خام الغرامات مصنع لتجهيز

محطة تكسير متنقلة 100 طن في الساعة

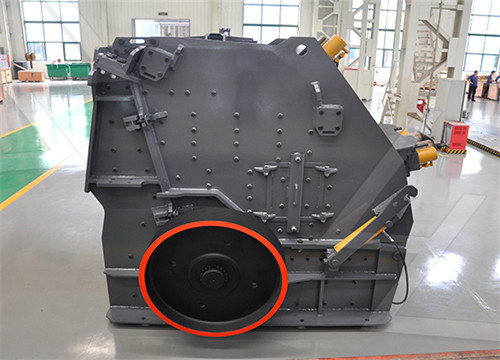

انخفاض سعر تعزيز الصين عالية الكفاءة حجر تأثير كسارة

كسارة صخرية متحركة ساعة في الساعة

أجهزة الكشف عن المعادن المصنعين

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20