الحار منتجات

ملكنا الإخبارية

Slag Vertical Mill Separator Has High Bearing Temperature

PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTS

The latest information about our over-seas companies is available on our homepage loesche. Loesche GmbH Hansaallee 243 40549 Düsseldorf, Germany Tel. +49 - 211 - 53 53 - 0 Fax +49 - 211 - 53 53 - 500 E-mail: loesche@loesche loesche.

获取价格

Slag grinding with the Polysius Roller Mill in China

2007/2/1 The slag grinding plant in Nanchang is in operation since November 2005. The roller mill is a type RMS-51/26 with an SEPOL RMS-435 separator. For a feed

获取价格

GRINDING Grinding options for slag and pozzolan - PEC

Minerals to be processed may have a high initial moisture content (see Table 1), but undercover storage can reduce moisture before entering the grinding process. If moisture

获取价格

How to maintain the details of the slag vertical mill - Great Wall

The grinding media of the slag vertical mill is highly impact and suitable for materials with high viscosity and difficult to grind. The main purpose is to use the stirring shaft to drive

获取价格

Slag grinding with the vertical Roller Mill in China(二)

2016/2/18 Slag grinding plant with roller mill in Kwangyang, Korea. The first roller mill for this application was put into operation in Korea in 1995. Polysius designed and

获取价格

Typical process and common problems of slag vertical mill

The slag is ground into fine powder inside the vertical mill, and at the same time, the slag is sent to the hot air by the hot blast furnace for drying. The fine powder separated by the

获取价格

Loesche Mills for Cement and Granulated Blast Furnace Slag

2 µm 5 µ. step aheadGrinding of cement clinker and granulated blast furnace slag in roller grinding mills (vertical airswept grinding mills) is a technology introduced. by Loesche.

获取价格

SEPARATE OR INTERGRINDING? - Loesche

new vertical mills were planned from the outset, but other options would have been possible. For example, clinker could be ground in an existing ball mill and GBFS in a

获取价格

Comparison and Analysis of Slag Vertical Mill Selection

2023/6/6 Slag vertical mill selection requires rigorous numerical analysis, equipment price, scale of slag vertical mill manufacturer and after-sales capabilities are all factors

获取价格

The functions of the vertical roller mill separator - Great Wall

2021/8/16 If large-scale grinding mills want to control the fineness of the finished product, the powder separator is a very critical component. The separator of the

获取价格

Slag Grinding Plant GGBS Plant Slag Mill, Slag

A vertical cement mill is also called a vertical slag mill. It has the advantages of high production capacity, low energy consumption, and environmental protection in the field of slag powder grinding. The

获取价格

Granulated blast furnace slag vertical roller mill

Gas sealing system: Tongli granulated blast furnace slag vertical roller mill is equipped with a high-speed centrifugal blower to send high-speed air into the seal of the roller bearing to form a gas seal to prevent dust from entering the roller bearing. By doing this we can greatly improve the bearing service life.

获取价格

Granulated blast furnace slag vertical roller mill

A granulated blast furnace slag vertical roller mill is a specialized equipment used for grinding and processing granulated blast furnace slag, Granulated blast furnace slag is a kind of molten materi

获取价格

Slag Pot/Slag Ladle

Case: Slag pot / slag ladle made by CHAENG (Great Wall Steel Casting Co.,Ltd) has good property. On July 18, 2008, the Great Wall steel casting signed the first contract of slag pot, under the situation of financial crisis and shrinking market, on the same year on December 12 we signed 13 pcs of slag pot with South Korea's posco, since 2008 we have signed

获取价格

Chaeng Vertical roller mill Introduction

2016/10/11 At present, we can produce the supporting raw material vertical mill, coal vertical mill, and cement vertical mill that can cater to 300-5000 t/d cement production line, and the series slag vertical mills with annual production capacity of 0.2 million tons, 0.3 million, 0.45million tons, 0.6 million rons,0.9 million tons and 1.2million tons.

获取价格

Accelerated Carbonation of Steel Slag Compacts: Development of High

2015/12/17 The basic oxygen furnace (BOF) steel slags (fraction 0–3 mm) were provided by ArcelorMittal Gent (Gent, Belgium). Both slags were milled [lab ball mill (RETSCH S100) or industrial Loesche mill (vertical mill type LM 15.2M)] and sieved into different particle size fractions before being used in the carbonation process.

获取价格

Vertical Roller Mills – LNV TECHNOLOGY

Vertical Slag Mill: A vertical slag mill is used for grinding and drying water quenched slag that is generated by blast furnaces into an active material which is then added to the finished cement. Note: Feed moisture <20%, feed size <10mm, final product moisture≤0.5%, final product fineness <4200cm2/g~5000cm2/g, power consumption <33 kWh/t.

获取价格

Cement Milll Separator Cyclone Air Separator in Cement Plant

Cyclone Air Separator Features. Compared to conventional cement mill separators, our cyclone air separators have the following advantages: Separate the material into three parts: coarse powders (d>150um), medium-coarse powders (60um

Simulation of Motion and Heat Transfer Characteristics of

2024/4/5 In the process of gas granulation of blast furnace slag, a cyclone separator serves to cool slag particles and separate them from hot air. This study focuses on modelling the cooling of slag particles in a cyclone separator. Simulations revealed the airflow field, temperature field and particle trajectory distribution within the cyclone

获取价格

How to properly maintain cement and slag vertical mills?

In recent years, cement and slag vertical mills have been widely used. Many cement companies and steel companies have introduced slag vertical mills to grind ... and is carried up by the high-speed upward airflow at the air ring (6~12 m/s). The large particles are folded back to the grinding disc, and the qualified fine powder enters the ...

获取价格

CHAENG GRM vertical roller mill separator - greatwallcasting

CHAENG dynamic high-efficiency vertical mill separator, also known as classifier, is installed on the upper part of the vertical mill and is connected with the middle shell.The separator consists of shell, cage rotor, air guide vane and transmission device. Its internal structure is reasonable, the efficiency of powder selection is high, and the energy-saving

获取价格

Cement Milll Separator Cyclone Air Separator in Cement Plant

Product: Cement mill cyclone air separators Capacity: 10 – 540 tph Condition: Brand new Airflow: 16000 – 800000 m3/h Application: Cement, portland products, new building materials, refractories, glass ceramics, and other production industries

获取价格

Developing high gradient magnetic separators for greener

2023/12/1 To address this, High gradient magnetic separators (HGMS) have been developed. HGMS is the strong magnetic separator consisting of excitation coil, iron yoke, and ferromagnetic matrix. Magnetic particles in the pulp are adsorbed on the surface of the magnetic matrices and carried to the magnetic field-free area where they're washed into

获取价格

coal grinding machine - CHAENG

GRMC series coal vertical grinding mill has higher working efficiency. Compared with the same type of old vertical mill, the output increases by 20-50%, and can greatly reduce the operation power consumption of the coal mill; ... GRMC series coal mill uses the most advanced static and dynamic combined separator which has high classification ...

获取价格

CHAENG GRM vertical roller mill separator

CHAENG dynamic high-efficiency vertical mill separator, also known as classifier, is installed on the upper part of the vertical mill and is connected with the middle shell.The separator consists of shell, cage rotor, air

获取价格

Cement Milll Separator Cyclone Air Separator in

Product: Cement mill cyclone air separators Capacity: 10 – 540 tph Condition: Brand new Airflow: 16000 – 800000 m3/h Application: Cement, portland products, new building materials, refractories, glass ceramics,

获取价格

Developing high gradient magnetic separators for greener

2023/12/1 To address this, High gradient magnetic separators (HGMS) have been developed. HGMS is the strong magnetic separator consisting of excitation coil, iron yoke, and ferromagnetic matrix. Magnetic particles in the pulp are adsorbed on the surface of the magnetic matrices and carried to the magnetic field-free area where they're washed into

获取价格

coal grinding machine - CHAENG

GRMC series coal vertical grinding mill has higher working efficiency. Compared with the same type of old vertical mill, the output increases by 20-50%, and can greatly reduce the operation power consumption of the coal mill; ... GRMC series coal mill uses the most advanced static and dynamic combined separator which has high classification ...

获取价格

An efficient approach to utilize copper smelting slag: Separating ...

2023/12/1 The removal percentage of Cu was determined under different experimental conditions. The removal percentage of Cu is plotted as a function of the amount of CaCl 2, roasting time, roasting temperature, and acidity coefficient in Fig. 2. As the CaCl 2 content increased from 6 to 15 %, the removal percentage of Cu increased

获取价格

vertical mill rocker arm and separetor - LinkedIn

2016/12/15 Vertical Mill Pressure Device Overview: LM Series Vertical mill is from the main structure of separators, roller devices, disc devices, pressure devices, reducer, motor, shell and other components.

获取价格

Particle size controllable jet milling technology for efficiently ...

2020/2/20 1. Introduction. Titanium-bearing blast furnace slag (Ti-BFS) is a by-product produced from the process of ironmaking using vanadium-titanium magnetite (Wang et al., 2018a).Currently, about 70 million tons (Zhou et al., 2018) of Ti-BFS have been dumped, and is still increasing by more than 3 million tons per year in China (Zhang et

获取价格

Modeling of high-tension roll separator for separation of titanium ...

2010/7/26 DOI: 10.1016/J.POWTEC.2010.04.005 Corpus ID: 95641743; Modeling of high-tension roll separator for separation of titanium bearing minerals @article{Tripathy2010ModelingOH, title={Modeling of high-tension roll separator for separation of titanium bearing minerals}, author={Sunil Kumar Tripathy and Y.

获取价格

A review of gas-liquid separation technologies ... - ScienceDirect

2024/1/1 For example, centrifugal separators benefit from their compact structure and high separation performance and are possibly the only separator suitable for underwater applications (Yue et al., 2019, Bhardwaj et al., 2023). However, despite decades of research, their complex hydrodynamic performance is still difficult to predict and it is ...

获取价格

Four Ways To Improve The High Temperature Problem Of Ball Mill

2024/8/14 High-quality lubricants generally have better high-temperature performance and anti-wear characteristics. Reasonable use of equipment: Regularly check the ball mill’s seals, bearings and other key components. Make sure to operate the ball mill correctly and avoid overloading it.

获取价格

MVR vertical roller mill with planetary gearbox - Gebr. Pfeiffer

MVR vertical roller mill with conventional planetary gearbox is the optimum solution from Pfeiffer in terms of economy for small to medium ... MRD/MRE ball mill; SLV high efficiency separator; ... MVR 5300 C-6 with planetary gearbox for granulated blast-furnace slag and granulated blast-furnace slag cement grinding, Cemminerals Ertvelde ...

获取价格

Grinding technology thyssenkrupp Polysius

The proven classical option for cement grinding. Whether employed as a two-compartment separator mill in an independent grinding system, or in combination with a high pressure grinding roll, the Ball Mill is a robust and reliable alternative for cement and granulated blast furnace slag grinding.

获取价格

Technical Notebook CEMENT ADDITIVES FOR VERTICAL MILLS

system’s temperature; • In some cases, high-Blaine blended cements (pozzolan, fly-ash) produced in vertical mills have a relatively high water demand in the final application; • Higher initial investments are needed if compared to traditional Ball Mills. 1 2 3 5 Image 1 - Vertical Mill scheme

获取价格

UBE Vertical Mill|UBE Vertical Mill|PRODUCTS|UBE

Especially its effect on fine products such as slag and slippery materials like oil cokes. 2. 2-way System. For making a stable grinding bed between the roller tire and table liner, UBE Slag Grinding Mill adopts a '2-Way System'. By adopting this '2-Way System', our mills are operated under less vibration achieving better performance.

获取价格آلات صناعية ناجحة

آلة تستخدم في تعدين خام الحديد

خام النحاس بلجيكا تأثير محطم مطرقة

تستخدم الحزام الناقل عمان

تأثير محطم الهيدروليكية لالتنغستن

روسيا الحجر الجيري روسيا

محطم المصنعين الجهاز وشركة تجارية في المملكة العربية السعودية

jual mesin تأثير محطم

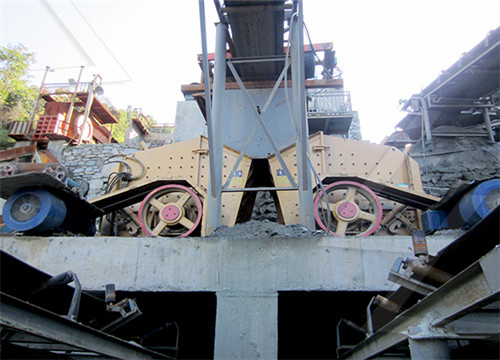

تطبيق كسارة متنقلة في كسارة ملموسة

سحق معدات chinha

عرض التعدين الحزام الناقل

تصميم مصنع الأسمنت

شركة اربين الألمانية لتصنيع المطاحن

مزدوج الأسطوانة حجر محطم

بيع كسارة الحجر

سحقت أو كسر الحجر الجيري التعدين في الولايات المتحدة الأمريكية

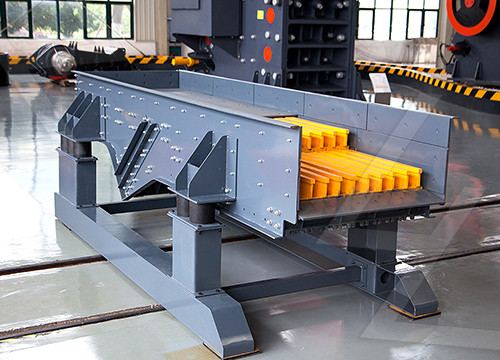

المواصفات الفنية لشاشة الاهتزاز

آلة الطحن والتغذية

مصنع صغير لفصل خام الموليبدينوم

إزالة الألغام

مصنع معالجة الجاذبية للتعدين على نطاق صغير ومتوسط �

iron ore crushed machineries send hand

رسم بياني لآلة كسارة الحجر كسارة tph

chicago industrial mill systems

انواع الغسالات الاتوماتيك الامريكيه الجديده

مصنعي آلة كسارة الفك في ليبيا

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20