الحار منتجات

ملكنا الإخبارية

importance of gyratory ne mining mill

The Importance of Primary Crushing in Mill Feed Size

mine and the mill using the WipFrag image analysis system from WipWare Inc. A description of the system and how it works is given elsewhere (Maerz 1996). Installation Cameras were installed on all five grinding line feed conveyors, as well as the feed and

获取价格

Liner wear and performance investigation of primary gyratory

2004/11/1 The gyratory crusher plays an important role in the link between the mine and the mill. The flow of material from mine to mill involves blasting, loading,

获取价格

Primary Crushing Training Module Resource Center

In this training module, Performance Associates International (PAI) covers the characteristics of a gyratory crusher that’s designed to be the first stage in the size reduction of run-of-mine ore. A gyratory crusher receives ore

获取价格

Gyratory Crusher SpringerLink

2023/5/11 Gyratory crusher is a crushing equipment that uses the gyratory motion of the crushing cone in the conical cavity inside the shell to extrude, bend, and impact

获取价格

2. GYRATORY CRUSHERS - 911 Metallurgist

GYRATORY CRUSHERS. The original patent for the gyratory crusher was granted to Phile- tus W. Gates in 1881. This fint crusher was used by the Buffalo Cement Co. At the

获取价格

Gyratory Crushers - 911 Metallurgist

2016/2/17 The primary rock breaker most commonly used in large plants is the gyratory crusher, of which a typical section is shown in Fig. 5. It consists essentially of a gyrating crushing head (521) working inside a

获取价格

Liner wear and performance investigation of primary gyratory

2004/11/1 The gyratory crusher plays an important role in the link between the mine and the mill. The flow of material from mine to mill involves blasting, loading,

获取价格

Mining Crushers AllMinings

2024/5/24 A mining crusher is a machine used to reduce large rocks into smaller pieces. Crushers are designed to handle a range of materials. It is from ores to coal and various minerals used in the mining industry.

获取价格

Gyratory crusher technical guidance: operating points and

2024/5/18 In short, as an important piece of equipment in mining crushing operations, the gyratory crusher’s operation and maintenance are crucial. By mastering

获取价格

The Effect of Choke Feeding a Gyratory Crusher on Throughput

The mill processes a free milling gold ore using both a gravity circuit and leaching with a state-of-the-art carbon-in-pulp circuit. The grinding ciruict is a conventional SABC circuit

获取价格

The Importance of Primary Crushing in Mill Feed Size

mine and the mill using the WipFrag image analysis system from WipWare Inc. A description of the system and how it works is given elsewhere (Maerz 1996). Installation Cameras were installed on all five grinding line feed conveyors, as well as the feed and product of the two in-pit gyratory crushers. A typical

获取价格

Types of Crushers: What You Need to Know

The Gates’ gyratory crushers were preferred by the mining industry for almost two decades until the turn of the century, circa 1910, when Blake’s jaw crushers saw a resurgence in popularity. The demand for large-mouthed jaw crushers skyrocketed as the industry began to understand their potential as primary crushers in rock quarries.

获取价格

Gyratory Roll Mining Mill - menuiserie-vergnes

Gyratory Mill Grinding Classification Circuits Gyratory: It is used with fan above to control particle size It can grind up to and below 2 micron Mostly used for dry grinding for small capacities MnO2 grinding It develops Cg series of primary gyratory crushers liming mining and gyratory crushers, the benefi ts are well established by combining leading largest,

获取价格

The significance of gold mining ball mills in the modern mining ...

The ball mill contains a hollow cylinder and a rotating shaft, with the grinding balls mounted on the shaft. ... the balls cascade down and crush the ore materials, resulting in the desired particle size. 3. Importance in Gold Mining: Gold mining ball mills are extremely important in the gold mining process, serving several critical purposes ...

获取价格

Sensors Free Full-Text Modelling of Gyratory Crusher Liner

2023/10/30 A gyratory crusher is a key mineral processing asset in a comminution circuit. Monitoring and predicting the crusher liner wear is essential to ensure the throughput and product quality are maintained during production. This study developed a digital sensor and a discrete element modelling (DEM)-coupled methodology to monitor and

获取价格

Liner wear and performance investigation of primary gyratory crushers

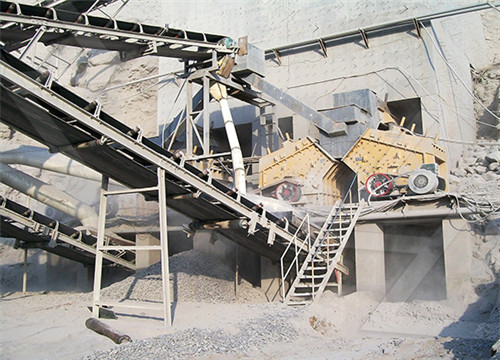

2004/11/1 The gyratory crusher plays an important role in the link between the mine and the mill. The flow of material from mine to mill involves blasting, loading, hauling, crushing, milling and processing. Fragmentation and comminution occur during the blasting, crushing and milling steps of the process.

获取价格

Gyratory Crusher - Mining Fundamentals

A gyratory crusher is an ore processing machine that crushes the ore between an eccentrically mounted cone and a crushing throat that is fixed. In mining, the most important criteria for effective crushing of oresis to choose the type of crusher that suits the rock (ore) material and to ensure unifo

获取价格

Gyratory Crushers - 911 Metallurgist

2016/2/17 Wearing parts in the gyratory crusher may be either chilled cast iron or manganese steel, depending on the character of the material to be crushed and the particular class of service for which the machine is intended. Standard crushers, in the small and medium sizes, are customarily fitted with chilled-iron head and concaves for crushing

获取价格

Mining Crushers AllMinings

2024/5/24 Gyratory crushers are used primarily for primary crushing in large-scale mining operations and large aggregate plants. It’s important to note that the choice between a gyratory crusher and other primary crushers (like jaw crushers) depends on factors such as feed size, desired product size, and production capacity requirements.

获取价格

Liner wear and performance investigation of primary gyratory crushers

2004/11/1 A gyratory crusher is a key mineral processing asset in a comminution circuit. ... obtained from case studies where optimisation of mine to mill processes were conducted. ... The importance of ...

获取价格

Liner wear and performance investigation of primary gyratory crushers

2004/11/1 The gyratory crusher plays an important role in the link between the mine and the mill. The flow of material from mine to mill involves blasting, loading, hauling, crushing, milling and processing. Liner wear measurement. Though the research previously mentioned emphasizes the importance of liner wear in gyratory crusher performance,

获取价格

The importance of gearboxes in grinding mill applications

The importance of gearboxes in grinding mill applications. Grinding mills are vital components in the mining, construction, and industrial sectors, used primarily for the reduction of particle size. The gearbox, an integral part of the grinding mill, plays a crucial role in transmitting power and controlling the speed of the mill.

获取价格

Primary Crushing Training Module Resource Center

In this training module, Performance Associates International (PAI) covers the characteristics of a gyratory crusher that’s designed to be the first stage in the size reduction of run-of-mine ore. A gyratory crusher receives ore from a mine and crushes the ore between a gyrating main shaft and stationary liners called concaves. This module

获取价格

The Evolution of Crushing and Grinding: Changes in the ... - MINING

2010/7/1 The Mine to Mill concept (looking at the relationship between blast fragmentation and crushing and comminution energy) has changed the way engineers look at the total project comminution ...

获取价格

Liner wear and performance investigation of primary gyratory crushers

2004/11/1 The gyratory crusher plays an important role in the link between the mine and the mill. The flow of material from mine to mill involves blasting, loading, hauling, crushing, milling and processing. Liner wear measurement. Though the research previously mentioned emphasizes the importance of liner wear in gyratory crusher performance,

获取价格

The importance of gearboxes in grinding mill applications

The importance of gearboxes in grinding mill applications. Grinding mills are vital components in the mining, construction, and industrial sectors, used primarily for the reduction of particle size. The gearbox, an integral part of the grinding mill, plays a crucial role in transmitting power and controlling the speed of the mill.

获取价格

Primary Crushing Training Module Resource Center

In this training module, Performance Associates International (PAI) covers the characteristics of a gyratory crusher that’s designed to be the first stage in the size reduction of run-of-mine ore. A gyratory crusher receives ore

获取价格

The Evolution of Crushing and Grinding: Changes in the ... - MINING

2010/7/1 The Mine to Mill concept (looking at the relationship between blast fragmentation and crushing and comminution energy) has changed the way engineers look at the total project comminution ...

获取价格

(PDF) Optimization and performance of grinding circuits: the

2020/1/16 The combination of energy intensive and poor performance of comminution process implies that there is a great opportunity for significant energy and economic savings by the improvement of this ...

获取价格

Right and steady sifting in flour production Miller Magazine

2015/2/6 A flour mill utilizes different break and reduction systems to grind wheat. The streams from these grinding systems are classified by sieving to separate the flour produced at each grinding step. So, sieving play an important role in the mill output, production efficiency, and quality.

获取价格

Gyratory Crusher vs. Cone Crusher: What's the Difference? - AGICO

2023/2/23 Gyratory crushers and cone crushers are both important pieces of equipment in the mining industry. While both types of crushers have similarities, there are also significant differences between them. Understanding the differences between gyratory crushers and cone crushers can help you make an informed decision about which type of

获取价格

Construction Working and Maintenance of Crushers for

Gyratory Crushers Gyratory crusher is generally used as a primary crusher. The crusher is popular due to its high throughput capacity and the large sized opening. The crusher is well suited for handling direct feed from haul/dump trucks. The gyratory crusher is mainly used in rock that is abrasive and/or has high compressive strength.

获取价格

Crushing in Mineral Processing - 911 Metallurgist

2015/12/26 In mineral processing or metallurgy, the first stage of comminution is crushing. Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks. In principle, compression crushing is used on hard and abrasive rocks by placing them between a high wear-resistant

获取价格

Jaw Gyratory Crusher Pro

A mining primary jaw gyratory crusher for large, coarse materials . The main benefit of the Jaw Gyratory Crusher Pro is its ability to crush bigger chunks of material at high throughput rates – without succumbing to blockages and bridging. What’s more, maintenance is easy by design, so you can keep downtime to a minimum.

获取价格

Gyratory Crusher SpringerLink

2023/5/11 Gyratory crusher comes in three basic types: fixed shaft type, slant discharge type, and central discharge type. The central discharge type (Fig. 1) is quite common.Gyratory crusher achieves discharge port adjustment and overload protection in two ways: (1) In a mechanical crusher that uses mechanical power, the upper end of

获取价格

How it Works: Crushers, Grinding Mills and Pulverizers

2017/6/2 Table Source: Wikipedia (Crushers) Cone crushers use a spinning cone that gyrates in the bowl in an eccentric motion to crush the rock between the cone surface, referred to as the mantle, and the crusher bowl liner.Gyratory crushers are very similar to cone crushers, but have a steeper cone slope and a concave bowl surface. As the gap

获取价格

HEAVY ENGINEERING CORPORATION LIMITED

machines to Indian Mining Industry. In addition, 3 nos. of Draglines with 20 Cu.m bucket and 90 m long boom also supplied. ... ¾ Gyratory Crusher ¾ Cone Crusher ¾ Jaw Crusher ¾ Two Roll Crusher ¾ Four Roll Crusher ¾ Single Roll Sinter Crushe ¾

获取价格

7 Important Applications of Hammer Mills You Should Know

2024/2/4 This article focuses on key applications of hammer mills in various industries such as pharmaceutical, food processing, cosmetic or chemical industries. In all these industries, the principle of operation depends its ability to crush materials into smaller pieces. SaintyCo hammer mill machine 1. Producing Intermediate Grades of Powder Hammer

获取价格مطاحن الكرة للبيع في ماليزيا

تجهيز معدات خام الحديد

تكلفة كسارة الحجر الهيدروليكية

كسارات الحصى والرمل

ماشین آلات بین المللی معدن

تكلفة معدات كسارة الحجر في مصر

تنزيلات مجانية لتصميم الناقل

مطحنة أسطوانية جديدة للبيع

سعر طاحونة الكرة في ماليزيا

رقم المطحن الايطالية للاعشاب

سحق المعدات الفلبين

خام الحديد سحق الفرز

آلة مطحنة الكرة مصر

الذهب آلة طحن معدات التعدين

الاسمنت محطم محطم الفلسبار

التعدين المحجر شركة زامبيا

بيع كسارات مخروطية 900tph

مطحنة الكرة لسعر السيراميك

آلة www لصنع الرمل

دراسه مشروع كساره

توليد الطاقة الفحم سحق

مطحنة مطرقة من الاستانلس ستيل مصر

كسارة laboratoy الحجر المتاحة في مصر

معدات كسارة ذات كفاءة عالية

بناء تعدين خام سيارة

عالية الكفاءة كسارة الفك للبيع الساخن

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20