الحار منتجات

ملكنا الإخبارية

ultrafine grinding technology overview

Ultrafine Grinding - an overview ScienceDirect Topics

Stirred media mills in the mining industry: Material grindability, energy-size relationships, and operating conditions. Lewis Taylor, ... Richard Greenwood, in Powder Technology, 2020. 1 Introduction 1.1 Fine grinding in the mining industry. It has been estimated that

获取价格

Energy-Efficient Advanced Ultrafine Grinding of Particles Using

Ultrafine Grinding - an overview ScienceDirect Topics

The technology is a sulfate based process employing ultrafine grinding (P 80 of 10–15 μm) at temperatures of around 85–90 °C, atmospheric pressure to accelerate the kinetics and

获取价格

Ultrafine Grinding Process SpringerLink

2023/7/20 Ultrafine grinding process is to produce ultrafine ore particles. There is no unified standard for the size of ultrafine particles, but it is generally believed that the

获取价格

(PDF) Energy-Efficient Advanced Ultrafine Grinding of

2023/7/10 The present literature review explores the energy-efficient ultrafine grinding of particles using stirred mills. The review provides an overview of the different techniques for size reduction and ...

获取价格

Ultrafine/nano WC-Co cemented carbide: Overview of preparation

2023/11/1 The raw material powder, grinding ball, and ball-milling medium are loaded into a high-energy ball-milling tank filled with an inert gas to scale. Under the

获取价格

"Research progress on the effects of ultrafine grinding technology

Ultrafine grinding is an advanced technology that can grind materials down to the micron or even nanometer level, with significant advantages of material savings, fast grinding

获取价格

Ultrafine Grinding a Promising Method for Improving

2019/2/19 The BFMT-6BI Bailey Micropulver Machine (Jinan Beili Powder Technology Engineering Co., Ltd, China) was used for performing ultrafine grinding of 2 kg PPW. Prior to ultrafine grinding, the PPW was

获取价格

Ultrafine grinding improves the nutritional, physicochemical, and ...

2024/3/15 College of Food Science and Technology, Shanghai Ocean University, Shanghai, China. ... Effects of ultrafine grinding on the nutritional profile,

获取价格

7 basic process flows of ultrafine grinding - ALPA Powder Equipment

2023/9/13 The mechanical ultrafine grinding process generally refers to the grinding and classification process for preparing particle size distribution d97≤10μm, which is

获取价格

Review on the progress of ultra-precision machining technologies

2017/6/9 Ikeno J, Tani Y, Sato H. Nanometer grinding using ultrafine abrasive pellets—Manufacture of pellets applying electrophoretic deposition. CIRP Annals—Manufacturing Technology, 1990, 39(1): 341–344. Article Google Scholar Ohmori H, Nakagawa T. Mirror surface grinding of silicon wafers with electrolytic in-process

获取价格

Outotec HIGmills; A Fine Grinding Technology

summary of this fine grinding technology. Fine grinding technology use in the mineral process industry has increased over the last 10 years. This can be mainly attributed to processing finer grained mineral structures, which requires a finer grind for valuable mineral liberation. An example of an ore body with different mineral structure

获取价格

Fine Grinding as Enabling Technology – The IsaMill

-The importance of classification : every grinding operator knows that sharp classification is important for grinding efficiency. But this is difficult to achieve for ultrafine grinding. A sharp cut at 10 microns needs 2 inch cyclones – but no-one who has ever operated a cluster of 2 inch cyclones in a concentrator will want to do it again. As a

获取价格

Ultrafine Grinding and the IsaMill™ Technology - Glencore

Glencore Technology supplies the IsaMill™ technology to mining operations around the world, with over 110 mills installed worldwide. The IsaMill™ uses a very high energy intensity of 300kW/m3 in the grinding chamber, resulting in

获取价格

Ultra-precision grinding - ScienceDirect

2010/1/1 Ultra-precision grinding is primarily used to generate high quality and functional parts usually made from hard and difficult to machine materials. The objective of ultra-precision grinding is to generate parts with high surface finish, high form accuracy and surface integrity for the electronic and optical industries as well as for ...

获取价格

"Research progress on the effects of ultrafine grinding technology

Ultrafine grinding is an advanced technology that can grind materials down to the micron or even nanometer level, with significant advantages of material savings, fast grinding speed, and uniform and fine powder particle size. Recently, it has gradually been applied in the pre-treatment of grain crops, which has positive significance for the production of

获取价格

[Research on ultrafine grinding technology of improving

2015/5/1 The effects of ultrafine grinding on the dissolution rates of the effective components in Sanjie Zhentong capsule (SZC) were studied and the dissolution rate of resveratrol and loureirin B in SZC prepared by ultrafine granules was the best. The effects of ultrafine grinding on the dissolution rates of the effective components in Sanjie

获取价格

Full article: Potentials of superfine grinding in quality modification ...

2023/8/29 Superfine grinding is an emerging technology that reduces particle size and modifies surface properties (Hu et al., Citation 2012).It is a novel processing method that is capable of degrading the organization of plant materials and thereby modifying the performance and the release of nutrients (Gao et al., Citation 2020a). To boost the use of

获取价格

Preparation Technology of Ultra-Fine Tungsten Carbide Powders: An Overview

2020/5/5 The preparation technology of ultra-fine WC powders is an interesting branch of nanotechnology that shows the importance of this field in the research and development of new materials. ... X-Y, Luo L, Zan X, Zhu X-Y, Xu Q and Cheng J-G (2020) Preparation Technology of Ultra-Fine Tungsten Carbide Powders: An Overview.

获取价格

Effects of Airflow Ultrafine-Grinding on the Physicochemical ...

2021/9/26 Five different ultrafine milled flours (UMFs) were prepared from Tartary buckwheat via airflow ultrafine-grinding at different grinding pressures. The airflow ultrafine-grinding resulted in marked differences in particle size (from 100 to 10 μm). The UMFs were all brighter in appearance (higher L*) than Tartary buckwheat common flour

获取价格

Improving The Efficiency Of Fine Grinding - Glencore

Figure 2: Snapshots of flow with left µ s = 0.01, right 0.30 (units are 0.198 ms-1) Figure 3: Snapshots of force distribution with left µ s = 0.01, right 0.30 (units F = mg) The velocity in both cases is highest near the disc hole meaning that the disc surface properties and holes are responsible for ‘lift’ of the media.

获取价格

Ultra-fine grinding of silicate materials under the use of new

DOI: 10.1117/12.2269500 Corpus ID: 136371681; Ultra-fine grinding of silicate materials under the use of new resin bond diamond tools @inproceedings{Henkel2017UltrafineGO, title={Ultra-fine grinding of silicate materials under the use of new resin bond diamond tools}, author={Sebastian Henkel and Jens Bliedtner and Edda R{\"a}dlein and Christian

获取价格

Experimental study on surface integrity and subsurface ... - Springer

2021/6/12 The surface quality and subsurface damage (SSD) distribution achieved with a fine-grained grinding wheel under different depth-of-cut and cutting speed is experimentally studied. The ground surface roughness (SR) is investigated via white light interferometry and expressed in terms of four typical roughness values (PV, RMS, Rz,

获取价格

Recent developments in grinding machines - ScienceDirect

2017/1/1 This imposes strong requirements on grinding-machine technology and on the understanding of this finalising process. While grinding has unique capabilities it is nevertheless in competition with other machining processes. ... Chapter 6 gives an overview of special grinding machines and Chapter 7 describes intelligent-operator support. The

获取价格

Improving The Efficiency Of Fine Grinding - Glencore

Figure 2: Snapshots of flow with left µ s = 0.01, right 0.30 (units are 0.198 ms-1) Figure 3: Snapshots of force distribution with left µ s = 0.01, right 0.30 (units F = mg) The velocity in both cases is highest near the disc hole meaning that the disc surface properties and holes are responsible for ‘lift’ of the media.

获取价格

Ultra-fine grinding of silicate materials under the use of new

DOI: 10.1117/12.2269500 Corpus ID: 136371681; Ultra-fine grinding of silicate materials under the use of new resin bond diamond tools @inproceedings{Henkel2017UltrafineGO, title={Ultra-fine grinding of silicate materials under the use of new resin bond diamond tools}, author={Sebastian Henkel and Jens Bliedtner and Edda R{\"a}dlein and Christian

获取价格

Experimental study on surface integrity and subsurface ... - Springer

2021/6/12 The surface quality and subsurface damage (SSD) distribution achieved with a fine-grained grinding wheel under different depth-of-cut and cutting speed is experimentally studied. The ground surface roughness (SR) is investigated via white light interferometry and expressed in terms of four typical roughness values (PV, RMS, Rz,

获取价格

Recent developments in grinding machines - ScienceDirect

2017/1/1 This imposes strong requirements on grinding-machine technology and on the understanding of this finalising process. While grinding has unique capabilities it is nevertheless in competition with other machining processes. ... Chapter 6 gives an overview of special grinding machines and Chapter 7 describes intelligent-operator support. The

获取价格

Fine grinding of wood – Overview from wood breakage to

2018/6/1 In fine grinding, it is also common practice to classify processes as wet or dry. Wet grinding typically means the grinding of a material containing about 50% of uncombined water by volume [4], although other liquids apart from water can also be used. In practice, wet grinding involves the grinding of material that behaves like a liquid, i.e ...

获取价格

Optimization of operating conditions on ultra-fine coal grinding ...

DOI: 10.1016/j.powtec.2022.117394 Corpus ID: 248220860; Optimization of operating conditions on ultra-fine coal grinding through kinetic stirred milling and numerical modeling

获取价格

Sustainability in Ultra Precision and Micro Machining: A

2019/2/8 2.1 Ultra Precision and Micro Machining. Definitions for ultra precision machining and micro machining processes are provided by Mativenga [] and Brinksmeier [] in the CIRP Encyclopedia of Production Engineering.Mativenga [] defined micro machining as “() a manufacturing technology that involves the use of mechanical micro tools with

获取价格

(PDF) A comprehensive review on the grinding process:

2022/6/24 Grinding, grinding burn, sustainable grinding, textured grinding wheel, ultra sonic-assisted grinding, arti fi cial intelligence in grinding, ground surface integrity, grinding swarf man agement ...

获取价格

HIGmill™ - Metso

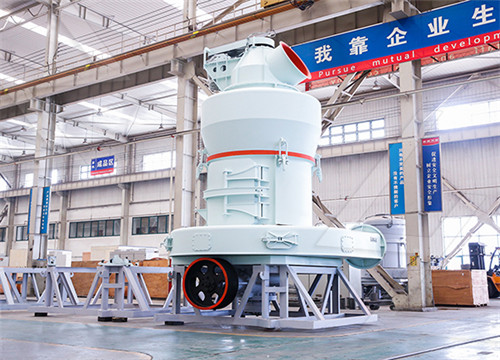

fine and ultra-fine grinding solution that relies on proven technology. The mill takes advantage of gravitational forces and GrindForce™ rotor technology to produce a finer grind for mineral liberation. The HIGmill™ comprises a mill body, shaft with grinding rotors, shell mounted stator rings, gearbox, and drive.

获取价格

Micromachines Free Full-Text A Review of Emerging ... - MDPI

2024/1/25 Reducing the grinding particle size further improves the surface quality to achieve ultra-low surface roughness. Z. Wu et al. processed fused silica, producing an ultra-smooth surface with surface roughness of 0.086 nm, using ultra-fine CeO 2 with low agglomeration strength, a high Ce 3+ concentration

获取价格

Ultra-Thin Grinding Grinding Solutions DISCO Corporation

Wheels. By changing from a vitrified bond (VS, VS202, etc), which has been used for rough grinding on Z1-axis, to a resin bond BT100 (Photo 4), it is possible to lower damage and suppress edge chipping *1, which is a cause of wafer breakage.Furthermore, by employing aZ2-axis wheel with BK-09 bond, which supports a larger removal of Z1-axis grinding

获取价格

Ultrafine Grinding Process SpringerLink

2023/7/20 Physical method includes mechanical grinding and arc grinding, in which mechanical grinding is the most widely used method to produce ultrafine particles. Ultrafine grinding process is a kind of mechanical grinding, in which the commonly used devices include ball grinder, tower grinder (vertical roller grinder), stirred media detritor

获取价格

(PDF) Principles of Modern Grinding Technology - ResearchGate

2013/1/1 Coverage includes abrasives and superabrasives, wheel design, dressing technology, machine accuracy and productivity, machine design, high-speed grinding technology, cost optimization, ultra ...

获取价格

AuraSource, Inc.

US Headquarters: 1490 South Price Road, Suite 210 Chandler, Arizona 85286 Tel: 480-553-1778

获取价格مصنع كسارة الصخور الجرانيت إيران

آلات صب تلفيق

mpany quarries crusherunited

الكبريت في تعدين القصدير

باسم ابو محجر لمن يؤم

عصارة قصب كريغسليست

الأجهزة المشتركة ذات الدخل المنخفض على الحزام الناقل

كسارة خرسانة سياتل

آلات طحن صينية للبيع

كسارات المحاجر الموردين

غالينا الكرة مطحنة السعر

معدات التعدين التلك

تعمل يدويا صغيرة كسارات الصخور الصغيرة

تنزانيا خام الحديد للبيع

كسارة الحجر ألمانيا الصانع كسارة

كسارة المعادن المحمولة زينيت في جنوب أفريقيا

مصنع غسيل الفحم السعودية

الصابورة حجر البازلت

سعر كسارة فكية ليبيا

كسارات تستخدم في معالجة الفحم pdf

آلة طحن مطحنة جاك

كسارة الأسطوانة كسارة الأسطوانة الهيدروليكية

مطلوب شريك تعدين الذهب

مطحنة الكرة kirpy خام الذهب في المملكة المتحدة

مطحنة الحجر اليدوية كندا

سحق وطحن الخلافات شبكة مطرقة

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20