الحار منتجات

ملكنا الإخبارية

Crush Coal Vs Pulverized Coal

How to Process Coal into Pulverized Coal in 5 Steps?

Crush the coal rock. The coal pulverization steps begin with an initial crushing. This

Study on coal pulverization characteristics and gas desorption ...

2024/5/30 Based on the new surface theory, the internal of coal smashing is that the coal rock mass obtains power and produces a new surface [9, 11, 12, 37].The physical

获取价格

Comparison of Circulating Fluidized Bed Boiler and

The key differences are listed below. PC firing utilises coal ground to a very fine powder sprayed into the furnace for combustion. CFB uses coal

获取价格

A complete review based on various aspects of

2019/2/14 Coal is the most abundant energy source, and around 40% of the world's electricity is produced by coal combustion. The

获取价格

Pulverised Coal - an overview ScienceDirect Topics

3.1 Pulverized Coal Combustion. Pulverized coal (PC) combustion is presently the system of choice for coal-fired power-generating plants. In PC combustion, the coal is dried and

获取价格

Understanding pulverised coal, biomass and waste combustion –

2015/1/5 This paper outlines the developments in PC combustion and the new techniques that have been developed to enhance our understanding of the processes

获取价格

Energies Free Full-Text Technique to Investigate

2021/11/4 The amount of energy required to crush the coal depends on the grain size of the raw material and the required degree of grain grinding. The use of fine coal grains obtained for this purpose, for

获取价格

Physico-chemical characteristics of pulverized coals and their ...

2021/11/26 Characteristics of pulverized coals have significant influence on the spontaneous combustion and explosion processes. This paper presents an experimental

获取价格

The Production of Electricity Power from Coal - University

Pulverized coal is converted to electricity through the Rankine cycle: 1. The coal is blown into the furnace, becomes airborne, and is burned. 2. The heat generated from the burning heats water flowing through tubes in the furnace. 3. The water turns into pressurized steam which exits the furnace. 4. The steam turns the blades of a turbine.

获取价格

Comparison of Circulating Fluidized Bed Boiler and

PC firing utilises coal ground to a very fine powder sprayed into the furnace for combustion. CFB uses coal crushed to sizes of around 3 to 6 mm. The time energy and facility required to crush coal is much lesser than

获取价格

1.1 Bituminous And Subbituminous Coal Combustion - U.S.

In pulverized coal-fired (PC-fired) boilers, the fuel is pulverized to the consistency of talcum powder (i.e., at least 70 percent of the particles will pass through a 200-mesh sieve) and pneumatically injected through the burners into the furnace. Combustion in PC-fired units takes place almost entirely while the coal is

获取价格

Pulverized Coal Pipe Testing and Balancing - Storm

pulverized coal at the same velocity as it is flowing in the fuel line. Our sampler probes have a specially designed tip that improves the sample collection process. It is the same area opening as the ASME sampler, but the tip has a built-in internal deflector. This design eliminates the bouncing out or rebounding

获取价格

A complete review based on various aspects of pulverized coal ...

2019/2/14 Coal is the most abundant energy source, and around 40% of the world's electricity is produced by coal combustion. The emission generated through it put a constraint on power production by coal combustion. There is a need to reduce the emissions generated through it to utilize the enormous energy of coal for power production.

获取价格

Advantages and Disadvantages of Pulverized Coal Firing

2022/11/27 In a pulverized coal system, the coal is ground into a fine powder using grinding mills, then blown into the furnace, where it is burned. This allows for more efficient and complete combustion of the coal, which can

获取价格

Coal Crushers Coal Pulverizers Mills Williams Crusher

Coal is crushed to desired fineness between spheres or cylindrical rollers. After that, air from the boiler is heated to around 330°C (650°F). The raw coal is then fed into the pulverizer where it is ground into fine coal particles. What are the Advantages of Pulverized Coal? Pulverized coal produces a larger amount of heat than traditional coal.

获取价格

Coal dust - Wikipedia

For use in thermal power plants, coal is ground into dust using a device called a powdered coal mill. [1] The resulting product, called powdered coal or pulverized coal, is then generally used in a fossil fuel power plant for electricity generation.Pulverized coal is a significant dust explosion hazard, as large quantities are suspended in air for transfer

获取价格

Pulverized Coal-Fired Boilers and Pollution Control

The primary air pollutants regulated from coal-fired power plants worldwide are carbon monoxide (CO), sulfur dioxide (SO 2), oxides of nitrogen (NO and NO 2, which are referred to as NO X), and particulate matter (PM) [].In general, CO emissions from pulverized coal-fired power boilers are low (<50–200 ppmv) as the combustion system tends to be

获取价格

New Technologies of Pulverized Coal Combustion. Partial

2022/10/8 In case of pulverized coal combustion, reduction in CO 2 emissions in commonly used technologies is achieved by partial replacement of coal with less carbon-intensive fuels, such as natural gas and non-standard coal. The last decade saw a significant increase in the combustion of coal mixed with biomass, the carbon dioxide

获取价格

How it Works: Crushers, Grinding Mills and Pulverizers

2017/6/2 Table Source: Wikipedia (Crushers) Cone crushers use a spinning cone that gyrates in the bowl in an eccentric motion to crush the rock between the cone surface, referred to as the mantle, and the crusher bowl liner.Gyratory crushers are very similar to cone crushers, but have a steeper cone slope and a concave bowl surface. As the gap

获取价格

A complete review based on various aspects of pulverized

pulverized coal furnaces, ash formation and deposition, and carbon capture and sequestration (CCS) technologies to outline the progress made in these aspects. Both experimental and numerical ...

获取价格

Pulverized Coal as a Fuel - ASME Digital Collection

2023/12/14 The use of pulverized coal in stationary boiler plants is discussed, five determining factors in the successful operation of such a plant being taken up in detail. As compared with mechanical-stoker plants the advantages of the pulverized-coal plant are enumerated and certain precautions to be observed with the latter type of plant are

获取价格

Fundamental Experiments of Coal Ignition for Engineering Design of Coal ...

2012/1/13 Figure 2. Examples of detailed calculated results of pulverized coal combustion. Figure 2 shows the temperature distribution (a) and streamlines (b) in a burner neighborhood. A recirculation flow is formed around the burner exit. Pulverized coals are ignited by the high temperature gas in the recirculation flow.

获取价格

How it Works: Crushers, Grinding Mills and Pulverizers

2017/6/2 Table Source: Wikipedia (Crushers) Cone crushers use a spinning cone that gyrates in the bowl in an eccentric motion to crush the rock between the cone surface, referred to as the mantle, and the

获取价格

A complete review based on various aspects of pulverized

pulverized coal furnaces, ash formation and deposition, and carbon capture and sequestration (CCS) technologies to outline the progress made in these aspects. Both experimental and numerical ...

获取价格

Pulverized Coal as a Fuel - ASME Digital Collection

2023/12/14 The use of pulverized coal in stationary boiler plants is discussed, five determining factors in the successful operation of such a plant being taken up in detail. As compared with mechanical-stoker plants the advantages of the pulverized-coal plant are enumerated and certain precautions to be observed with the latter type of plant are

获取价格

Fundamental Experiments of Coal Ignition for Engineering Design of Coal ...

2012/1/13 Figure 2. Examples of detailed calculated results of pulverized coal combustion. Figure 2 shows the temperature distribution (a) and streamlines (b) in a burner neighborhood. A recirculation flow is formed around the burner exit. Pulverized coals are ignited by the high temperature gas in the recirculation flow.

获取价格

Coal burner - Wikipedia

Coal burner working as a component of an asphalt plant in Thailand. A coal burner (or pulverized coal burner) is a mechanical device that burns pulverized coal (also known as powdered coal or coal dust since it is as fine as face powder in cosmetic makeup) into a flame in a controlled manner. Coal burners are mainly composed of the pulverized coal

获取价格

Pulverized coal versus circulating fluidized-bed boilers

Keywords: circulating fluidized bed, pulverized coal, emissions Abstract—Power generation in South Africa has historically and continues to depend on the use of pulverized coal combustion. The pulverized coal boilers are used by the majority of power stations around South Africa. Although other types of technologies, such as

获取价格

Developments in Pulverized Coal-Fired Boiler Technology

1996/4/10 A new generation of pulverized coal-fired boiler technology is currently under development which will permit generating efficiencies in excess of 42%. This paper highlights some of today’s ...

获取价格

Numerical Simulation of Coal Combustion in a Tangential Pulverized

2021/4/8 The tangentially fired pulverized coal boiler considered in this study is a typical 210 MW unit widely used in the Indian power sector and is shown schematically in Fig. 1.It has a length of 13.5 m, width of 10.5 m and a height of 43 m.

获取价格

Advantages and disadvantages of pulverized coal firing

Advantages and disadvantages of pulverized coal firing: Advantages of pulverized coal firing: Pulverized coal produces more amount of heat. By arranging the pulverized unit away from the furnace, the repairs can be solved easily. With the help of pulverized coal, the combustion takes place successfully. By using a pulverized coal the work can ...

获取价格

Biocoal vs. Traditional Coal: A Comparison of Properties and ...

2024/3/26 Properties of Biocoal vs. Traditional Coal. One of the primary differences between biocoal and traditional coal lies in their chemical composition and physical properties. While both fuels contain carbon as their primary constituent, biocoal typically has a lower sulfur content and higher moisture content compared to traditional coal.

获取价格

Why Pulverized Coal is Used in a Power Plant - Bright Hub

Why Pulverized Coal is Used in a Power Plant. Categories : Energy power plants ; Tags : Mechanical engineering ; Coal for Power Plants. The coal fired power plant converts energy in coal to electricity. The basic input into the system is the fuel that is coal. All other systems and equipment only aid in this conversion process.

获取价格

Vertical Grinding Mill (Coal Pulverizer) Explained - saVRee

Pulverized Coal Outlet/Discharge - pulverized coal flows out of an outlet duct. ... This type of grinding can be compared to when a hammer hits an object e.g. a piece of coal. Crush – the coal is forced between two bodies. This type of grinding has the same effect as a rolling pin when rolling across salt granules on a table.

获取价格

Physico-chemical characteristics of pulverized coals and their ...

2021/11/26 Characteristics of pulverized coals have significant influence on the spontaneous combustion and explosion processes. This paper presents an experimental and theoretical framework on physico-chemical characteristics of coal and their interrelations from spontaneous combustion and explosion perspectives. The chemical

获取价格

Fire and Explosion Prevention in Coal Pulverizing Systems

Proper design and operation of the pulverized coal burners protects the pulverizing system from ignition from the furnace fire. The coal/ air mixture enters the furnace through a burner nozzle at velocities in excess of the flame speed. Thus, the flame front is held stable at a distance away from the end of the nozzle where

获取价格ماكينات ومعدات تعدين الذهب

آلة مع المرفقات تعيين فترات زمنية محددة

آلات الصين الرمل المغسول

کتابچه راهنمای کاربر برای سنگ شکن

مصانع معدنية في مصر

معالجة خام الذهب وخطوات الجر

مطحنة ريمون mtm160 نوع

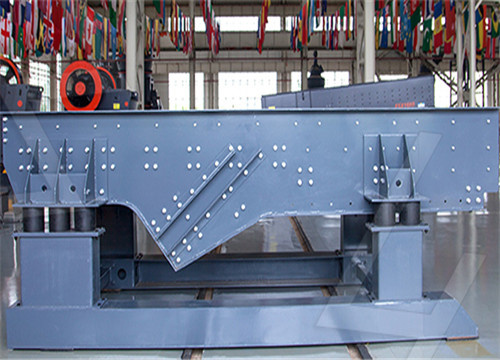

شاشة تهتز خطية عالية الجودة

مصنعي كسارات الحجر في دلهي

مطحنة الأسمنت أليس تشالمرز

سوبر مطحنة طحن شبه منحرف

مطحنة صغيرة متناهية الصغر المنزلية

كسارة الضغط

الطاحن محطة للطاقة مطحنة

قوات الدفاع الشعبي البنتونيت حلبة طحن

طرق الفصل في التعدين

كسارات متنقلة صغيرة نوع الزاحف للبيع

خط إنتاج قوالب الطوب

الكسارات 26amp 3b محطات الفرز الركام

فاصل الأرز آلة الهند

من جهة ثانية عملية سحق الفحم

سعر مطحنة الكرة السعودية

كسارة Gyratory ميانمار للبيع

الماركات محطم المحمولة

سحق وطحن التعليم العالي

تثمين وحدة تكسير الحجارة

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20