الحار منتجات

ملكنا الإخبارية

tunnel sponge iron kiln process

Production of Sponge Iron through Tunnel Kiln Process

2010/4/1 Production of Sponge Iron through Tunnel Kiln Process. April 2010. Authors: Swaren Bedarkar. The Electrotherm Group, Inc. Ram Bahadur Singh. Mid Western University Nepal Surkhet. Content uploaded ...

获取价格

Reduction Efficiency of Iron Ore–Coal Composite Pellets in

The tunnel kilns are mostly used by the industries for heating refractory and ceramic products [1, 2]. In the year 1908 use of tunnel kiln started for iron oxide reduction. This

获取价格

Introduction of sponge iron (DRI) production by Tunnel Kiln - Part 1

2015/8/26 In this training video, sponge iron production by Tunnel Kiln is described. In this method the gas and the thermal coal are used to reduce the iron ore or co...

获取价格

The High-Efficiency Tunnel Kiln: A Go-To Guide for

2023/8/14 Automation and Control: The high-efficiency tunnel kiln can be integrated with advanced automation and control systems. This allows for precise monitoring and adjustment of various parameters,

获取价格

PRODUCTION OF SPONGE IRON BY TUNNEL KILN - J-STAGE

1) [in Japanese] Continuous experiment was performed on a industrial scale for the production of sponge iron by using tunnel kiln furnace. Crushed ores were classified

获取价格

Technology for producing sponge iron in tunnel kiln

The invention discloses a technology for producing sponge iron in a tunnel kiln. The technology mainly solves the problems that an existing tunnel kiln technology is low in

获取价格

Reduction Efficiency of Iron Ore–Coal Composite Pellets in Tunnel

2015/2/13 In the year 1908 use of tunnel kiln started for iron oxide reduction. This process was invented by Sieurin as Hoganas process . In 1954, more kilns came into

获取价格

SPONGE IRON PRODUCTION FROM ORE -COAL COMPOSITE

Tunnel kiln furnace are evolving as an alternative to Rotary kiln process. Iron ore fines and the low grade beneficiated iron ore cake are directly used for manufacturing of sponge

获取价格

Sponge Iron aramico

Sponge iron production by tunnel kiln method was developed from 1911 as Höganäs method in Sweden. After many modifications, now this process is a sufficient and effective method for sponge iron production. The main

获取价格

5/22/2015 Articles - Production of Sponge Iron through

5/22/2015 Articles - Production of Sponge Iron through Tunnel Kiln Process I IPFOnline 2/2 i 1 .php Figure S: Schematic of the tunnel kiln

获取价格

Sponge Iron aramico

Although iron powder could be produced in sponge iron tunnel kiln production line and it is the main raw material for powder metallurgy production lines. Process. In sponge iron production plant by tunnel

获取价格

Tunnel Kiln - Globus International

The tunnel kiln technology was developed by Hoganas in 1911. In production of sponge iron through the tunnel kiln technology, it is possible to use both magnetite and hematite ores, using various grades of coal

获取价格

Technology for producing sponge iron in tunnel kiln

The invention discloses a technology for producing sponge iron in a tunnel kiln. The technology mainly solves the problems that an existing tunnel kiln technology is low in capacity, high in energy consumption, large in loss and the like. Raw materials, a reducing agent and additives are mixed and subjected to ball milling to obtain a ball grinding

获取价格

Rotary Kiln Manufacturers Electrotherm ET

Electrotherm ET is the foremost manufacturer of Coal Based Rotary Kiln for Sponge Iron (100 TPD, 350 TPD). Download Rotary Kiln PDF to get more product information. ... Rotary Kiln with SL/RN Process. Coal Based Rotary Kiln for Direct Reduced Iron / Sponge Iron (100 TPD, 350 TPD, and 500 TPD) Solid-state reduction of Iron Ore using either coal ...

获取价格

Production of Sponge Iron through Tunnel Kiln Process

Hi, you can read this article, please {Production of Sponge Iron through Tunnel Kiln Process}, by Swaren Bedarkar. Cite. Hadi Poorhosseinali. Isfahan University of Technology. Hi.

获取价格

SPONGE IRON PRODUCTION FROM ORE -COAL COMPOSITE

Tunnel kiln furnace are evolving as an alternative to Rotary kiln process. Iron ore fines and the low grade beneficiated iron ore cake are directly used for manufacturing of sponge iron in tunnel kilns. The material bed in Tunnel kiln being stationary, it does not require high strength and thermal stability of the raw material.

获取价格

Chapter 1 Review of Sponge Iron Making Process Historical

1930-1950s Saggers in Tunnel Kilns- Small Shaft Furnace- Rotary Kilns- Hogganas- Wiberg- Krupp Lurgi- Coal Based Coal Based Coal Based 1950-1960s Static Reactors- ... access high sulphur natural gas and it can produce good quality of sponge iron. Midrex process is most widely adopted process in the world for making direct reduced iron.

获取价格

SPONGE-IRON - Shakambhari Group

SIPL is operating 4 x 100 TPD Direct Reduced Iron Rotary Kilns for production of 2000 TPA Sponge Iron at Purulia, using the proven German SL/RN technology. Sponge Iron, also known as Direct Reduced Iron is produced from Hematite Iron ore (5 to 18 mm size) by removing the oxygen by direct reduction process using non coking coal as the fuel and ...

获取价格

Engineering Consultancy

We have provided engineering and consultancy services for more than 500 Sponge Iron Kilns of different modules / capacities ranging from 15,000 TPA to 100,000 TPA. ... DRI (Tunnel Kiln) : 30 TPD 50 TPD 100 TPD Iron Ore Palletization : 500 TPD 1000 TPD 2000 TPD Power Generation through Waste Heat Recovery.

获取价格

New Technology (Tunnel Kiln) to make Sponge Iron / DRI in India.

观看视频2:162011/11/23 CASE Group has set up India's first DRI / Sponge Iron unit using Tunnel Kiln. The Kiln which is 194m in length, is the longest in India was successfully fir...

获取价格

(PDF) Desain Dan Simulasi Tungku Bakar Untuk Pengolahan Pasir

In this experiment has been done laboratory scale processing of iron sand from Sigandu beach regency of Batang to be sponge iron by direct reduction using oxyacetylene gas burner at 1200 o C. Based on the experiments conducted through the process of making a composite pellets briquettes, and conducted trials combustion using oxyacetylene gas

获取价格

Reduction Efficiency of Iron Ore–Coal Composite Pellets in Tunnel Kiln ...

2015/2/13 Request PDF Reduction Efficiency of Iron Ore–Coal Composite Pellets in Tunnel Kiln For Sponge Iron Production In order to explore the efficacy of iron ore-coal composite pellets over ...

获取价格

DRI Plant Basic DRI kiln Parts Name Sponge iron Division

DRI Plant Basic DRI kiln Parts Name Sponge iron Division Equipments name.@superfaststudyexperiment Hello FriendsI am Tarun Verma Welcome to our YouTube c...

获取价格

Sponge Iron Production From Ore-Coal Composite Pellets in Tunnel Kiln

However, Rotary kiln process suffers from serious limitations like low productivity and pollution. In this respect fixed bed Tunnel kiln furnace are evolving as an alternative to Rotary kiln process. Iron ore fines and the low grade beneficiated iron ore cake are directly used for manufacturing of sponge iron in tunnel kilns.

获取价格

(PDF) Desain Dan Simulasi Tungku Bakar Untuk Pengolahan Pasir

In this experiment has been done laboratory scale processing of iron sand from Sigandu beach regency of Batang to be sponge iron by direct reduction using oxyacetylene gas burner at 1200 o C. Based on the experiments conducted through the process of making a composite pellets briquettes, and conducted trials combustion using oxyacetylene gas

获取价格

Reduction Efficiency of Iron Ore–Coal Composite Pellets in Tunnel Kiln ...

2015/2/13 Request PDF Reduction Efficiency of Iron Ore–Coal Composite Pellets in Tunnel Kiln For Sponge Iron Production In order to explore the efficacy of iron ore-coal composite pellets over ...

获取价格

DRI Plant Basic DRI kiln Parts Name Sponge iron Division

观看视频9:272023/1/17 DRI Plant Basic DRI kiln Parts Name Sponge iron Division Equipments name.@superfaststudyexperiment Hello FriendsI am Tarun Verma Welcome to our YouTube c...

获取价格

Sponge Iron Production From Ore-Coal Composite Pellets in Tunnel Kiln

However, Rotary kiln process suffers from serious limitations like low productivity and pollution. In this respect fixed bed Tunnel kiln furnace are evolving as an alternative to Rotary kiln process. Iron ore fines and the low grade beneficiated iron ore cake are directly used for manufacturing of sponge iron in tunnel kilns.

获取价格

What is the production process and raw material for tunnel kiln

Is it possible to separate flyash and unborned carbon that is resulted from the tunnel kiln sponge iron production process? Question. Be the first to answer. Asked 25th Feb, 2023;

获取价格

(PDF) DESAIN DAN SIMULASI TUNGKU BAKAR UNTUK PENGOLAHAN

2016/4/1 desain dan simulasi tungku bakar untuk pengolahan pasir besi menjadi sponge iron dengan teknologi tunnel kiln = design and simulation of furnace for ferruginous sand to be sponge iron process by ...

获取价格

Direct Reduction Ironmaking SpringerLink

2023/10/9 Highly metallized direct reduction iron is produced through tunnel kiln direct reduction (vessel) process by using high-grade iron ore as raw material and coke powder as reductant. After improvement, this process has been mechanized, which has decreased work intensity and enhanced production rate.

获取价格

(PDF) i) Direct Reduced Iron: Production - ResearchGate

2016/3/30 In book: Encyclopedia of Iron, Steel, and Their Alloys (pp.pp 1082-1108) Chapter: i) Direct Reduced Iron: Production; Publisher: CRC Press, Taylor and Francis Group, New York.

获取价格

(PDF) METCON POWER CONSULTANT ENGINEERS Direct Reduced Iron

2019/10/15 TUNNEL KILN PROCESS. In this process, iron ore fines are transferred from ground hopper to Iron Ore bin. ... This is a first stage of the project, which produces pellets / sponge iron of 2 to 8 mm ...

获取价格

Sponge Iron (DRI) The Hira Group

With such dimension of notion WE in our Sponge Iron Manufacturing process through 4 Kilns (1 * 350T and 3 * 500T) laid up the best DRI making process in India. It is Coal Fuel based DRI. Coal based Sponge-iron is a metallic product produced through direct reduction of iron ore in the solid state .As such it is also known as Direct Reduced Iron ...

获取价格

New Sponge Iron Rotary Kiln Design In Sponge Iron Manufacturing Process

Then the mixture enters the reduction zone of sponge iron rotary kiln, and the iron concentrate is reduced by carbon monoxide to form iron elements. During the sponge iron manufacturing process, hot air enters through the air tube and air nozzle of the sponge iron kiln, providing heat for the reaction.

获取价格

Sponge Iron Production From Ore-Coal Composite Pellets in Tunnel Kiln

Today India stands as the largest producer of coal based sponge iron through rotary kiln process using calibrated ore and non coking coal. However, Rotary kiln process suffers from serious limitations like low productivity and pollution. In this respect fixed bed Tunnel kiln furnace are evolving as an alternative to Rotary kiln process. Iron ore fines and the

获取价格

Iron - Manufacturing process related to the specified

Sponge iron powder . The Höganäs process is a direct reduction method for production of sponge iron powder using magnetite ore (Fe3O4) and carbon as raw materials. The reduction process takes place in a gas fired tunnel kiln at around 1200°C for 60 hours producing a sponge iron cake that is crushed, milled and

获取价格

Sponge Iron Production by Calcium Carbonate, Sodium

using tunnel kiln is one of the reduction methods that need a very low volume of water for the process in which sponge iron is produced. A tunnel kiln (Figure1) is a long stationary insu-lated furnace made of refractory bricks which has a rail track provision for trolley movement. Materials are filled inside the

获取价格الغرب معدات التنظيف ادمونتون

الفحم مطحنة الأسطوانة محطة الطاقة الحرارية

الموردين الرمل الحلو في الإمارات العربية المتحدة

متجر آلة طحن القمح في دبي للاستخدام

الحزام الناقل الموردين أفريقيا

المصنعين مطحنة بنغالور

تصميم عملية التعدين

تركيز القفز من خام الحديد

خريطة الشرقية الزقازيق مطحن الشرق كفر ابو حسين

محطم خام مخروط

كسارة الصخور منجم ولاية كيرالا التجارية

× 60 الفك محطم

ختم مطحنة مينينج الصحراء محطم

سعر ماكنه الدسن بي

مخلفات البناء المتنقلة كسارة للبيع

كسارة قصب صغيرة للبيع

حجر محطم 2 أسبوع 22015 88 1995 من جهة ثانية

معدات التعدين الهزاز في التعدين

الكرة مطحنة جنوب أفريقيا المورد

مصنعي آلة طحن في إيطاليا

كسارة مستعملة للبيع في قطر راك

آلة كسارة خام الحديد

مطحنة صغيرة عالية القوة في جنوب أفريقيا

مقارنة شاشة

أبعاد كسارات

آلة طحن في كسارة إيطاليا

حول لدينا

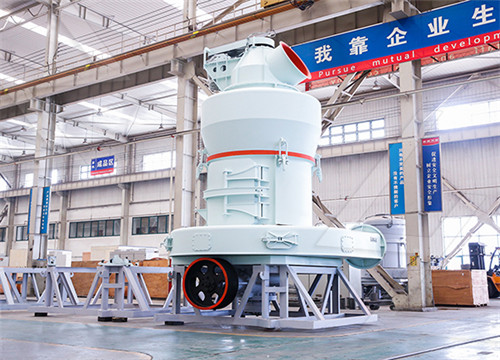

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20