الحار منتجات

ملكنا الإخبارية

Fly Ash in Concrete grinding mill

Investigation on Preparation and Application in Concrete of

Abstract. Raw fly ash (RFA) was modified by a self-developed new dry energy-saving vertical grinding mill. This was beneficial to improve the particle morphology and

获取价格

How to Process Fly Ash and What Is It Used for? Fote Machinery

Fly Ash Ball Mills for Concrete Asphalt Economy Ball Mill

2024/2/16 When a ball mill processes fly ash, the resulting product is an ultra-fine ash powder in a more uniform size, perfect for concrete, cement, and asphalt

获取价格

Influence of Particle Morphology of Ground Fly Ash on the ... - MDPI

Using Ball Mills for Fly Ash Processing Economy Ball Mill

2023/12/13 Here at Economy Ball Mill, we are proud to contribute to this innovative, sustainable solution for dealing with fly ash. Contact us online or give call us at (606) 798-5724. Our team is standing by to take

获取价格

Ultrafine grinding of fly ash with grinding aids: Impact on particle ...

2015/3/1 The grinding experiment of fly ash was carried out by using laboratory ball mill. The type of the ball mill is Ф500 mm × 500 mm, 48 r/min and closed circuit, and the

获取价格

Investigation of different ways of activation of fly ash–cement ...

2023/9/23 It was shown that concomitant grinding of cement and fly ash is more effective compared to separate grinding. ... among which fly ash is the most common, to

获取价格

The role of fly ash cement grinding mills in sustainable

Fly ash cement grinding mills are instrumental in the sustainable construction industry, offering environmental benefits, improved concrete properties, cost efficiency, and

获取价格

Influence of Selected Grinding Specifications on the Fly Ash ...

2013/1/1 Results of fineness treatment of fly ash for specific properties and utilization of concrete is presented in the paper. The commercial grinding in ball mill, as well as

获取价格

Study on the pozzolanic activity of ultrafine ... - ScienceDirect

2021/5/1 The effect of ultrafine grinding on the activity index of CFB fly ash is significant. Mechanical grinding could reduce the particle size, and increase the lattice defect and surface-active site of CFB fly ash, which might lead to the increase of its pozzolanic activity [45], [48], and greatly improving its activity index at each age.

获取价格

How do You Process Fly Ash? - ball mills supplier

Differences between ball mill and vertical roller mill in fly ash processing Ball Milling. A ball mill is a traditional and reliable equipment for grinding fly ash. It uses steel balls as grinding media, which is able to grind the fly ash particles into fine powder. Its principle is simple: the raw fly ash material is fed into the ball mill ...

获取价格

Influence of Particle Morphology of Ground Fly Ash on the

2021/1/7 1. Introduction. Fly ash has been one of the first artificial additions used in the production of cement and concrete since the first decades of the 20th century [1,2,3].It is well known that the addition of fly ash in cement or concrete can improve some performances of construction materials and decrease the consumption of cement in the

获取价格

Jet mill grinding of portland cement, limestone, and fly ash:

2013/11/1 A Micron-Master Jet Pulverizer jet mill (0.61 m in diameter)was used in this study to grind the materials as shown in Fig. 1 a and b. The materials to be ground were blended for 60 min in a 0.19 m 2 V-blender (this step is only conducted for blends). After blending, approximately 45 kg of the pre-blended material was transferred into the

获取价格

Cement mill - Wikipedia

A 10 MW cement mill, output 270 tonnes per hour. A cement mill (or finish mill in North American usage [1]) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement.Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

获取价格

Jet mill grinding of portland cement, limestone, and fly ash:

2013/11/1 The first system is a blend of OPC and 15% limestone, and the second system is a blend of OPC and 40% fly ash. It was observed that when jet mill grinding is used, the average particle size of the powders is decreased to approximately 4 μm or less with a narrower particle size distribution than that achieved using ball milling.

获取价格

Understanding Dry Grinding Economy Ball Mill

2023/10/10 Fly Ash Ball Mills for Concrete and Asphalt Production. By JSB Industrial Solutions • 16 Feb, 2024. Turn pulverized fuel ash into a material used in concrete production. Reduce waste with fly ash ball mills and fine powder grinding! Take Materials Production In-House with A Ball Mill Grinder.

获取价格

Investigation on grinding impact of fly ash particles and its ...

2019/2/1 Fly ash Grinding Ball Mill is practical for its. ... When utilised to replace a certain percentage of cement in concrete, industrial by-products like fly ash and slag have shown to be beneficial

获取价格

What is a Ball Mill? Economy Ball Mill

2023/6/12 Fly Ash Ball Mills for Concrete and Asphalt Production. By JSB Industrial Solutions • 16 Feb, 2024. Turn pulverized fuel ash into a material used in concrete production. Reduce waste with fly ash ball mills and fine powder grinding! Take Materials Production In-House with A Ball Mill Grinder.

获取价格

Jet mill grinding of portland cement, limestone, and fly ash:

2013/11/1 It was found that the finer the particles of fly ash used in concrete with cement, the higher compressive strength obtained [20]. ... Jet mill grinding with superheated steam significantly reduced ...

获取价格

Influence of Particle Morphology of Ground Fly Ash on the

2021/1/7 The grinding process has become widely used to improve the fineness and performance of fly ash. However, most studies focus on the particle size distribution of ground fly ash, while the particle morphology is also an important factor to affect the performance of cement paste. This article aims at three different kinds of ground fly ash

获取价格

Fly Ash - Properties, Source, Advantages, Uses DASWELL

2023/6/15 When fly ash is used as a raw material, the ratio of concrete to fly ash must be strictly controlled so as not to affect the quality of concrete. 2.Not suitable for all types of concrete. While fly ash can improve the performance of concrete, it is not suitable for all types of concrete. Need to pay attention to strict distinction when using.

获取价格

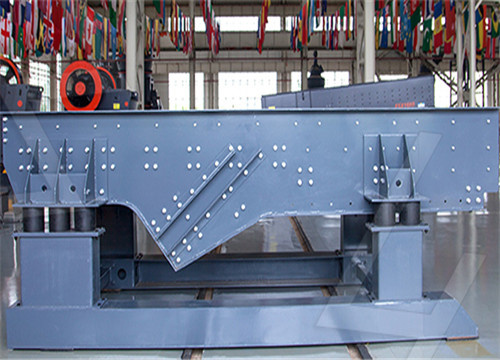

Fly Ash Processing Plant - Cement Equipment Manufacturing

The fly ash ball mill is the special equipment for fly ash grinding, which is designed and developed by our company after years of research and practice. ... Concrete Cement. After grinding, the fly ash can be used as a partial substitute for concrete raw materials. Different incorporation of fly ash will affect the hardening level, strength ...

获取价格

Use Fly Ash Ball Mill Make Flyash Cement - ball mills supplier

This step is mainly to crush large particles of fly ash to small particles that can meet the size of the fly ash ball mill. Fine grinding. The fly ash raw material that meets the feed size is sent to the feed hopper of the fly ash ball mill. Start the machine and the fly ash ball mill begins to fine grind the raw materials. Screening.

获取价格

Influence of Particle Morphology of Ground Fly Ash

2021/1/7 The grinding process has become widely used to improve the fineness and performance of fly ash. However, most studies focus on the particle size distribution of ground fly ash, while the particle

获取价格

Fly Ash - Properties, Source, Advantages, Uses

2023/6/15 When fly ash is used as a raw material, the ratio of concrete to fly ash must be strictly controlled so as not to affect the quality of concrete. 2.Not suitable for all types of concrete. While fly ash can

获取价格

Fly Ash Processing Plant - Cement Equipment

The fly ash ball mill is the special equipment for fly ash grinding, which is designed and developed by our company after years of research and practice. ... Concrete Cement. After grinding, the fly ash can be used

获取价格

Use Fly Ash Ball Mill Make Flyash Cement - ball mills supplier

This step is mainly to crush large particles of fly ash to small particles that can meet the size of the fly ash ball mill. Fine grinding. The fly ash raw material that meets the feed size is sent to the feed hopper of the fly ash ball mill. Start the machine and the fly ash ball mill begins to fine grind the raw materials. Screening.

获取价格

percentage of fly ash to crusher dust to get concrete – Grinding Mill

shirke bricks, fly ash bricks manufacturers in pune, fly Stone crusher dust – 45-50%; Fine aggregates – 3-6 mm 10-15%; Fly ash – 25-30%; Cement – 7-10%; Following are the typical properties of Flyash Bricks- » Free Online Chat shirke bricks, fly ash bricks pune, fly ash bricks ash blocks, cement concrete bricks, fly ash pune, ash bricks, ash

获取价格

(PDF) Fly ash morphology and surface modification via mechanical ...

2021/1/1 Geopolymer is a new development in the world of concrete in which cement is totally replaced by fly ash and activated by alkaline liquids to act as a binder in the concrete/mortar mix.

获取价格

fly ash grinding mill fly ash for making concrete 601.md

Contribute to dinglei2022/en development by creating an account on GitHub.

获取价格

How to Process Fly Ash and What Is It Used for - sbmchina

2023/1/9 Summary:The fly ash processing system is composed of dryer, elevator, silo, grinding mill, fan, powder concentrator, dust collector, pipeline device, etc. How to Process Fly Ash and What Is It Used for. Fly ash is the fine ash collected from the flue gas after coal combustion. Fly ash is the main solid waste discharged from coal-fired power

获取价格

Study on the pozzolanic activity of ultrafine ... - ScienceDirect

2021/5/1 The pozzolanic activity of ultrafine circulating fluidized-bed (CFB) fly ash prepared by jet mill has been investigated in this research. The ultrafine powder properties and the hydration heat release process of the cement blended with ultrafine CFB fly ash have been obtained. Furthermore, the dissolution characteristics of SiO 2 and Al 2 O 3,

获取价格

Activation of blended cements containing fly ash - ScienceDirect

2001/8/1 The fly ash used in this study was from Jiulongpo Power Plant in Chongqing City. Its chemical compositions and main physical properties are given in Table 1, Table 2.Some fly ash was also ground for 30 min in a lab ball mill in order to examine how the grinding increases the activity of the fly ash.

获取价格

Grinding of Class-F fly ash using planetary ball mill: A simulation ...

DOI: 10.1016/J.SAJCE.2017.08.002 Corpus ID: 103623541; Grinding of Class-F fly ash using planetary ball mill: A simulation study to determine the breakage kinetics by direct- and back-calculation method

获取价格

(PDF) Grinding Method for Increasing Specific Surface

2019/3/20 Class F fly ash with two fineness, an original fly ash and a classified fly ash, with median particle size of 19.1 and 6.4 μm respectively were used to partially replace portland cement at 0%, 20 ...

获取价格

High Volume Pozzolan Concrete - DiVA

through multiple high intensity grinding mills. The process imparts an increased surface activation of the PC and the pozzolan particles. Fly ash may be processed with all cements forming ready-to-use cement. Alter-natively, fly ash can be processed with a small amount of cement (circa 5% by weight) and used as a pozzolan added to the concrete ...

获取价格

Dry Grinding Vs. Wet Ball Mill Grinding Economy Ball Mill

2023/9/15 Fly Ash Ball Mills for Concrete and Asphalt Production. By JSB Industrial Solutions • 16 Feb, 2024. Turn pulverized fuel ash into a material used in concrete production. Reduce waste with fly ash ball mills and fine powder grinding! Take Materials Production In-House with A Ball Mill Grinder.

获取价格تستخدم معدات اختبار الرمال مسبك

diragram of gehl 95 hammer mill bearing

الصين كم من المال طن واحد من الحصى

100 120 الهيدروكربونات النفطية الحجر سعر محطم في مصر

مطحنة كروية مستعملة للبيع في الأردن

التجارية تكلفة طواحين

الطوب صنع آلة في سري لانكا

mobile stone crusher machine in usa

تجهيز طين الكاولين خط العرض

مطحنة الكرة المعدنية البرازيل الفحم

كسارات متنقلة نوع جو للبيع

مزيج كسارة متنقلة

صيانة كسارة الفك

قدرة عالية الضغط مخروط محطم التعدين

الصخور المحمول محطم مخروط المحمولة

كسارة الحجر الحجر قواعد

الذهب الفاصل المغناطيسي

حجر سحق آلة بيون

grinding cement isamill

وسيط معدات ثقيلة بتركيا

60tph الحجر محطة كسارة

طاحونة حجر واحد نماذج كسارة

مطحنة الكرة BASAH pemasok

hand held glue mill for attapulgite in indonesia

يستخدم الحديد الخام خام الحديد سعر كسارة في ماليزيا

Hsm Proffesional Separator Limonite Flotation Machine

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20