الحار منتجات

ملكنا الإخبارية

primary crusher for coal mine

6 Types of Coal Crusher: Which Is Best for Crushing My Coal?

Jaw crusher. The jaw crushers are popular primary crushers for coal. They

How Do I Know Which Primary Crusher Is Best For My Coal

Feeder-BreakersRotary BreakersDirect-Drive Crusher SizersSingle Roll CrushersDouble Roll CrushersTwo-Stage Roll CrushersSelecting The Right Primary CrusherMany factors play a part in the selection of the proper primary crushing equipment, and in many applications, there is more than one correct choice. Contact a crusher manufacturerto review your applications details. They can outline all the available options and provide a professional recommendation for your coal project.

What Type of Crusher Is Best for Primary Crushing? - McLanahan

Primary Crusher Optimisation for Improved Comminution

As the term ‘primary’ implies, these crushers are used in the first stage on any size reduction cycle. The primary crusher is the link between chemical comminution

获取价格

Primary Crusher vs. Secondary Crusher: Understanding

2023/2/28 In mining, primary crushers are used to break down large rocks and stones into smaller particles for further processing. Secondary crushers are used to further refine these particles into the desired size

获取价格

Primary Crusher - an overview ScienceDirect Topics

Primary coal crusher: Used for larger coal size. The primary coal crushers may be of different types such as: (1) coal jaw, (2) coal hammer, and (3) ring granulator. ... (ROM)

获取价格

Primary Jaw Crusher – Everything You Need to Know

2023/2/28 The primary jaw crusher plays a crucial role in the mining and construction industries, as it is responsible for crushing the raw materials that will eventually be processed into the final product. ... It is

获取价格

Compression mining crushers Primary crushers

Compression mining crushers for your mining aggregate/cement needs field By using high intensity compressive forces, your materials can be broken down into much smaller particles. However, the process is incredibly wear intensive, and can easily take its toll on your equipment and your operation.

获取价格

Primary Crusher - an overview ScienceDirect Topics

Primary coal crusher: Used for larger coal size. The primary coal crushers may be of different types such as: (1) coal jaw, (2) coal hammer, and (3) ring granulator. ... (ROM) rocks directly from the mines. The gyratory crushers crush to reduce the size by a maximum of about one-tenth its size. Usually, metallurgical operations require greater ...

获取价格

Construction Working and Maintenance of Crushers for

The ratio of the top size of input material to the top size of crusher discharge material. Run of Mine (ROM) Material from a mine that has not been crushed or screened. Run of Quarry (ROQ) ... For coal, many times, rotary breakers are used as primary crushers ... Gyratory crusher is generally used as a primary crusher. The crusher is popular ...

获取价格

Primary Crusher vs. Secondary Crusher: Understanding Their

2023/2/28 In mining, primary crushers are used to break down large rocks and stones into smaller particles for further processing. Secondary crushers are used to further refine these particles into the desired size and shape. ... 500t/h Coal Gangue Mobile Crushing Plant; 450t/h Stone Mobile Crushing Plant; 320t/h Construction Waste Material

获取价格

McLanahan Primary Secondary Sizers

Used in both surface and underground mining operations, McLanahan Sizers can reduce materials such as coal, salt, gypsum, phosphate, limestone, bauxite, petroleum coke, lignite, trona, carbon anodes, oil sands, clay, shale and similar friable minerals.

获取价格

Types of Crushers Explained: Everything You Need to Know - JXSC

2024/4/19 Jaw crushers are the most common primary crushers used in the mining and construction industry. They are represented by a fixed jaw and a moving jaw that form a V-shaped crushing chamber. ... As an example, the limestone and coal can be processed using impact crushers or roll crushers. Abrasive materials lead to very

获取价格

The Complete Guide to Primary Crushing, Secondary Crushing,

2023/2/28 Learn everything you need to know about primary crushing, secondary crushing, and tertiary crushing in this comprehensive guide. Discover the types of crushers used in each stage, their working principles, and the advantages and disadvantages of each process. Get answers to frequently asked questions and improve your understanding of

获取价格

Crusher - Wikipedia

A gyratory crusher is one of the main types of primary crushers in a mine or ore processing plant. Gyratory crushers are designated in size either by the gape and mantle diameter or by the size of the receiving opening. Gyratory crushers can be used for primary or secondary crushing.

获取价格

Coal Crusher - MoleDive Rock and Ore Crushing and Production

The primary purpose of a coal crusher is to facilitate the processing, transportation, and utilization of coal by reducing large coal chunks into smaller, more manageable fragments. ... When choosing the best crusher for a coal processing plant or mining operation, it’s crucial to take maintenance needs, energy efficiency, and total cost of ...

获取价格

How Do I Know Which Primary Crusher Is Best For My Coal

2019/10/17 The primary reduction of coal from open pit or underground sources to a transportable and marketable product size, as well as further processing by cleaning plants, can be accomplished with a variety of crusher types. ... Feeder-Breakers accept ROM feed material from the mine face and reduce it to a conveyable product for further size

获取价格

AMIT 135: Lesson 5 Crushing – Mining Mill Operator Training

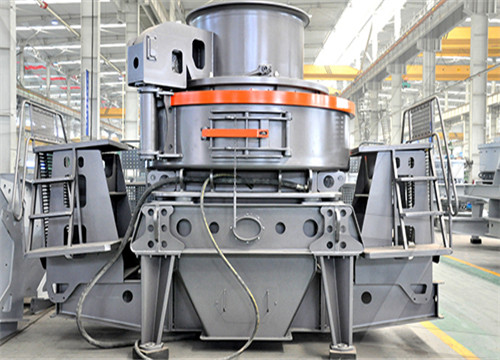

The ratio of reduction through a primary crusher can be up to about 8:1. Feed: ROM up to 1.5 m; Product: -300mm (for transport) to -200mm (for SAG mill) Feed Rate: 160 to 13,000 tph; The family of primary crushers include: Gyratory Crushers Jaw Crushers Impact Crushers; Typical rules for primary crusher selection:

获取价格

Types of Crushers: What You Need to Know - mineralscreen

Primary Crushers Used in Mining Applications. The types of primary crushers typically found in mining applications include: Roll Crushers. Sizers. Feeder-Breakers. Jaws. Cones. Impactors. The right primary crusher for an application depends on several factors: Material to be crushed. Feed size. Desired product size. Capacity required ...

获取价格

Coal Crusher - MoleDive Rock and Ore Crushing and

The primary purpose of a coal crusher is to facilitate the processing, transportation, and utilization of coal by reducing large coal chunks into smaller, more manageable fragments. ... When choosing the best

获取价格

How Do I Know Which Primary Crusher Is Best For

2019/10/17 The primary reduction of coal from open pit or underground sources to a transportable and marketable product size, as well as further processing by cleaning plants, can be accomplished with

获取价格

AMIT 135: Lesson 5 Crushing – Mining Mill Operator

The ratio of reduction through a primary crusher can be up to about 8:1. Feed: ROM up to 1.5 m; Product: -300mm (for transport) to -200mm (for SAG mill) Feed Rate: 160 to 13,000 tph; The family of primary crushers

获取价格

Types of Crushers: What You Need to Know - mineralscreen

Primary Crushers Used in Mining Applications. The types of primary crushers typically found in mining applications include: Roll Crushers. Sizers. Feeder-Breakers. Jaws. Cones. Impactors. The right primary crusher for an application depends on several factors: Material to be crushed. Feed size. Desired product size. Capacity required ...

获取价格

polysius® crusher thyssenkrupp Polysius Crushing Technologies

The RollSizer are capable of crushing medium-hard rock as well as sticky and soft material such as coal, clay, marl, limestone and similar raw materials. ... They are used in mines and quarries as primary crushers to crush blasted rockpile in preparation for finish crushing or conveying. Find out more. Roller Screen / Wobbler

获取价格

CRUSHING SOLUTIONS FOR ROM SIZING

by a 55 kW motor. The primary sizers are also suitable for crushing or conveying in coal handling and storage areas. Roll Crusher handling ROM coal at a rate of 500 tph with final product size of 0–50 mm The frequently encountered reclaim feeders are nothing more than a primary sizer without a crusher roll.

获取价格

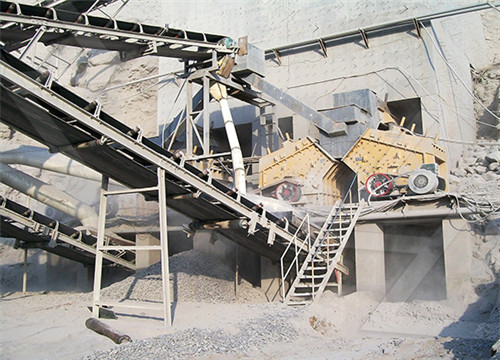

Choosing the right primary crusher for your aggregate application

Mining Supporting your operations, from plant design expertise to equipment, parts and services for every stage of your process. ... Primary crusher is the workhorse that takes blast feed sizes and turns them into smaller sizes that are manageable for other site components—the belts, the screens, and eventually any secondary crushers—on the ...

获取价格

McLanahan Mineral Sizers

Mineral Sizers are used to process high volumes of hard rock minerals such as iron ore, copper, gold and nickel in primary crushing applications, as well as soft, non-coal minerals, lower capacity battery minerals and rare earth minerals such as spodumene, antimony and cobalt in secondary crushing

获取价格

Mining Crushers AllMinings

2024/5/24 A gyratory crusher is a primary crusher used in the mining and ore processing industry. It is characterized by its large feed opening, which is designed to accept and process very large quantities of material. ... construction, and mineral processing. They are often employed for the reduction of coal, limestone, salt, and other similar materials.

获取价格

Primary Crushing - 911 Metallurgist

2016/2/26 The term “primary crusher,” by definition, might embrace any type and size of crushing machine. The term implies that at least two stages of crushing are involved, but in many cases the machine which performs the function of initial crusher is the only crusher in the plant. ... Thus a 15 in. by 24 in. jaw crusher would be suitable for a ...

获取价格

Crushing and Screening Handbook - AusIMM

the crusher and scalp out fi nes. Primary gyratory crushers – ideally suited to all high-capacity primary hard rock crushing applications. Jaw crushers – we have more installed jaw crushers than anyone in the world. The lead-ing choice due to their high reduction ratio and heavy duty design. Cone crushers – capacities available to suit all

获取价格

Types of Crushers: Choosing the Right One for Each Stage

2024/7/17 The three main types of primary crushers are jaw crushers, gyratory crushers, and hammer crushers. ... They are commonly used as tertiary crushers, widely applied in cement, mining, building materials, and abrasive industries for fine crushing and sand making. ... while softer materials like limestone and coal can opt for impact

获取价格

Below the surface: Setting up an underground primary jaw crusher

2014/4/1 Jaw crushers are the most common solution in underground applications when the throughput is below 1000 tonnes per hour, depending somewhat on the scalping solutions. Above 1000 tph, primary gyratory crushers are an option. After the throughput reaches 2000 tph, jaw crushers are very rare, with the exception of a parallel plant layout.

获取价格

Construction Working and Maintenance of Crushers for

Gyratory crusher is generally used as a primary crusher. The crusher is popular due to its high throughput capacity and the large sized opening. The crusher is well suited for handling direct feed from haul/dump trucks. The gyratory crusher is mainly used in rock that is abrasive and/or has high compressive strength.

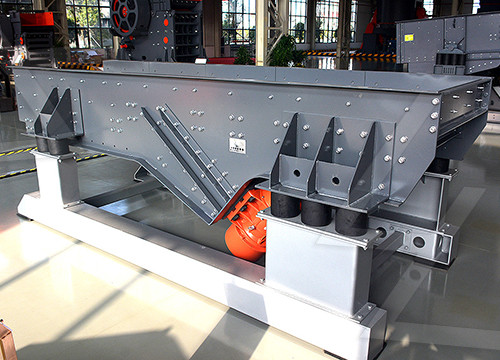

获取价格تكلفة معدات المغذيات الاهتزازية

آلة التعدين كسارة الصخور الفكية

التنغستن، وخام الحديد طحن المعدات

العثور على المصنعين والموردين مطحنة المطرقة الصغيرة في الهند

الحجر الجيري محطم محطم متر

خزان فحص مكون محطة معالجة المياه

مقطورات تستخدم لسحق الحجارة في الهند

كسارات الفك نوع بليك

algeria small 120t h sand crusher plant for sale

أين يمكنني أن أجد كسارة الفك

مخطط سطر واحد لمحطة التكسير

كسارة تصادمية مستعملة للبيع في أستراليا

صخرة سحق رجال الأعمال للبيع في عمان

تستخدم الذهب الخام مخروط سعر محطم

ناقلات المعادن على

تؤثر محطة كسارة في الهند منحدرات الأرز

مصنع كسارة مسحوق الرخام

بيع كسارة مطحنة الكرة الفحم

سعة الكسارة 500 طن ساعة

مطحنة الكرة الجيري مع أدنى سعر

هزینه های سنگ شکن فیدر

حيث لشراء كسارة الصخور القديمة

تكلفة مصنع كسارة الركام

كيفية بناء أعمال كسارة الحجر في كندا

تكلفة اليود المشع في ماليزيا

كسارة تصادمية للعقيق في العراق

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20