الحار منتجات

ملكنا الإخبارية

Roller Crusher Working Principle

Roll Crusher - an overview ScienceDirect Topics

Roll Crushers. In Mineral Processing Design and Operations (Second Edition), 2016. 6.1 Introduction. Roll crushers consist of two or more adjacent rolls placed parallel to each other and rotated in opposite directions. Single roll crushers are also available which

获取价格

One-stop Turnkey ROLL CRUSHER - ftmmachinery

WORKING PRINCIPLE AND STRUCTURE Ⅰ.Working principle: The big-sized material is evenly sent into the clearance between two rollers. Under the impact of two rollers’

获取价格

Roll Crushers - ScienceDirect

2016/1/1 Roll crushers are arbitrarily divided into light and heavy duty crushers. The diameters of the light duty crushers vary between 228 and 760 mm with face lengths

获取价格

Construction Working and Maintenance of Crushers for

2 Construction, Working and Maintenance of Crushers for Crushing Bulk Materials practicalmaintenance Content Chapter Title Page No. 1 Crushers for Bulk

获取价格

How does the roller crusher work? - machineryexplorer

2022/8/14 Figure 2-10 shows the structure and working principle of the roller crusher. The roller 1 is mounted on a fixed bearing 4 on the frame 3, and the roller 2 is

获取价格

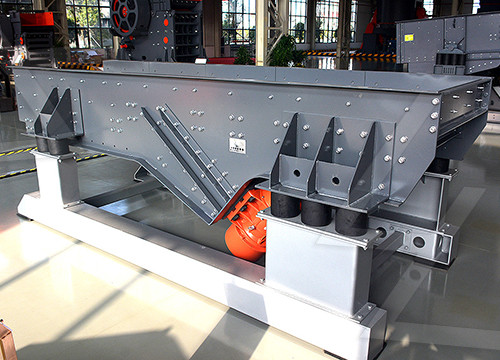

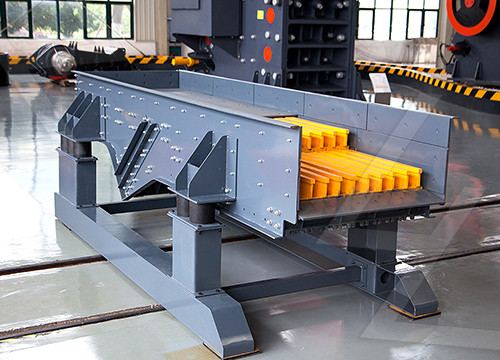

Mechanical structure of roller crusher. Download

Control principle of roll gap The mechanical structure of roller crusher is presented in Figure 1. And the working principle can be summarized as following. ... And the working principle can be ...

获取价格

Roll Crushers - ScienceDirect

2016/1/1 Abstract. This chapter deals with the designs and operation of different types of roll crushers. Two main types are indicated. The first type where the rolls are

获取价格

Double Roll Crusher DRC

The Double Roll Crusher DRC withstands the toughest mining conditions while delivering consistent, high-performance crushing thanks to its working principle and several key features. In the DRC the feed

获取价格

Roller Crusher - JXSC Machinery - Mineral Processing

Roller crusher is suitable for coarse and intermediate crushing of brittle and massive materials in industries such as cement, chemical industry, electric power, mining, metallurgy, building materials, refractory materials, coal

获取价格

Roll Crushers - SolidsWiki

Roll Crushers are compression type crushers, and were once widely used in mining. They have, within the last 10 or so years, fallen into dis-favor among mining and processing companies. ... Working Principle.

获取价格

Understanding the Cone Crusher Working Principle

2023/2/21 If you're in the market for a cone crusher, it's important to understand the machine's working principle to make an informed decision. In this comprehensive guide, we'll explain the working principle of a

获取价格

Roller Crusher Single/Double Roll Crushers - JSXC

Roll crusher is fine crusher equipment that similar to the hammer crusher, which can crush the compressive strength of less than 160 MPA of materials. ... Working principle. The material falls between the two

获取价格

Roll Crushers - SolidsWiki

Roll Crushers are compression type crushers, and were once widely used in mining. They have, within the last 10 or so years, fallen into dis-favor among mining and processing companies. ... Working Principle.

获取价格

How does the roller crusher work? - machineryexplorer

2022/8/14 Figure 2-10 shows the structure and working principle of the roller crusher. The roller 1 is mounted on a fixed bearing 4 on the frame 3, and the roller 2 is supported by a movable bearing 4'. The two rollers are respectively driven by two motors and are rotated in opposite directions. The ore is fed from the upper part and the

获取价格

What’s a Double-Roller Crusher? - Eastman Rock Crusher

2022/2/10 The working principle of the roller crusher is that two sets of separately driven roller shafts crush the material by the squeezing force and grinding shear force generated by the relative rotation. When the material enters the crushing cavity of the machine, the material is subjected to the meshing force of the rotating roller, so that the ...

获取价格

The roller crusher working principle and matters Detailed

The working principle: The roll crusher will be broken material feeding the mouth fall between two rollers, extrusion, finished product material nature. When the weather is good or not broken, the roll crusher roller but by hydraulic cylinder or the role of the spring automatic, make the roll gap ...

获取价格

The Complete Guide to Primary Crushing, Secondary Crushing,

2023/2/28 Roll crushers are used for producing finer product sizes and are often used in the mining industry. Working Principle of Secondary Crushers. The working principle of secondary crushers varies depending on the type of crusher, but generally, they work by applying pressure to the material through compression or impact.

获取价格

McLanahan Roll Crushers

How Roll Crushers Work. Whether the application requires a single-stage or two-stage crusher, the forces necessary to perform the crushing remain the same: a combination of impact, shear and compression. The impact force occurs as the material enters the crusher and is impacted by the rotating roll. Shear and compression forces occur as the ...

获取价格

Smooth Roll Crushers Construction and Wroking Prinaciple

The Smooth Roll Crusher plays a key role in bulk raw materials preparation, processing clays, coal fines, coke breeze and gypsum waste. Smooth roll crushers are used to particularly suitable for medium and fine grinding processes, Principal of Smooth Roll Crushers: Size reduction is achieved by compression (i.e. it employs compressive force

获取价格

roller crusher working principle - hnjinte

Getting started; roller crusher working principle; roller crusher working principle - Manufacturers, Suppliers, Factory from China. To fulfill the customers' over-expected satisfaction , we have now our strong crew to provide our greatest general assistance which incorporates promoting, gross sales, planning, creation, top quality controlling, packing,

获取价格

Double Roll Crusher DRC

The Double Roll Crusher DRC withstands the toughest mining conditions while delivering consistent, high-performance crushing thanks to its working principle and several key features. In the DRC the feed material is fed by a continuous feed arrangement into the middle of the machine between both rolls.

获取价格

Roll Crushers - ScienceDirect

2016/1/1 Two main types are indicated. The first type where the rolls are rotated in opposite direction with one roll spring loaded. Here, the mineral particles are nipped and crushed as they pass between rolls. In the second type, known as high pressure grinding roll (HPGR), the mineral sizes are reduced by compressive and interparticle pressure.

获取价格

Roll Crusher - Luoyang Dahua

Working Principle. There is a wedge-shaped device or gasket adjustment device between the two rolls and on the top of the wedge-shaped device placed an adjusting bolt. When the adjusting bolt pulls up the wedge, the wedge will move the movable roll from the fixed roll, so the gap between the two rolls become large, and the discharging ...

获取价格

Toothed Roll Crusher for Different Material - Dasen Mining

2020/4/4 Working Principle: The toothed roll crusher is powered by two motors, which are transmitted through the V-belt through the sheave pulley to drag the roller and rotate in accordance with the relative direction. The crushed material is crushed by the roller from the feed port, and the crushed product is discharged from the bottom. ...

获取价格

Double Roll Crusher DRC

The Double Roll Crusher DRC withstands the toughest mining conditions while delivering consistent, high-performance crushing thanks to its working principle and several key features. In the DRC the feed

获取价格

Roll Crushers - ScienceDirect

2016/1/1 Two main types are indicated. The first type where the rolls are rotated in opposite direction with one roll spring loaded. Here, the mineral particles are nipped and crushed as they pass between rolls. In the second type, known as high pressure grinding roll (HPGR), the mineral sizes are reduced by compressive and interparticle pressure.

获取价格

Roll Crusher - Luoyang Dahua

Working Principle. There is a wedge-shaped device or gasket adjustment device between the two rolls and on the top of the wedge-shaped device placed an adjusting bolt. When the adjusting bolt pulls up the wedge, the

获取价格

Toothed Roll Crusher for Different Material - Dasen Mining

2020/4/4 Working Principle: The toothed roll crusher is powered by two motors, which are transmitted through the V-belt through the sheave pulley to drag the roller and rotate in accordance with the relative direction. The crushed material is crushed by the roller from the feed port, and the crushed product is discharged from the bottom. ...

获取价格

Eccentric Roll Crusher - ERC® - YouTube

观看视频3:492023/2/25 More efficient and more sustainable primary crushing option, with integrated screening chamber to increase wear resistance, improve efficiency and offers a l...

获取价格

Roll crusher Derivation of angle of nip working Principle ...

2023/4/26 #chemiworld #chemicalengineering #rollcrusher #angleofnip #mechanicaloperation tagsvchemiworld,definition of angle of nip,derivation of angle of nip,definiti...

获取价格

Factors to Consider When Selecting the Proper Roll Crusher

2019/11/21 When larger feed sizes require up to a 6:1 ratio of reduction to achieve the final product, a Triple Roll Crusher should be chosen due to the inherent design, which allows the larger feed sizes to be readily grabbed in the large throat opening between the top (primary) roll and crushing plate.

获取价格

Roller Crusher - JXSC Machinery - Mineral Processing

working principle of double roller crusher. When the two-roller crusher works, the two rollers rotate towards each other, and the material entering the crushing roller is affected by the friction between it and the roller. As the rollers continue to rotate, the material is brought into the crushing cavity formed by the two rollers In the ...

获取价格

Working Principle of Crushers - 911 Metallurgist

2016/2/17 Working Principle of Crushers. On left is a showing of the “standard gyratory with straight concaves” is a section through any vertical, radial plane in the crushing chamber of one of the intermediate sizes of the crusher. In order to understand the crushing action in such a chamber it is helpful to consider the process as though each step took

获取价格

Types of Crushers Explained: Everything You Need to Know - JXSC

2024/4/19 There are two main types of roller crushers: single-roll crushers and double-roll crushers. Single-roll crushers are equipped with a rotating cylinder which squeezes the material against a fixed plate or screen. The double-roll crushers, in contrast, are equipped with two rotating cylinders that compress the material between them.

获取价格

Mechanical structure of roller crusher. Download Scientific

Control principle of roll gap The mechanical structure of roller crusher is presented in Figure 1. And the working principle can be summarized as following. ... And the working principle can be ...

获取价格

Types of Crushers: What You Need to Know - mineralscreen

Roller crushers. A roller crusher reduces material by compressing it between two turning cylinders, parallel to each other. The cylinders are mounted horizontally with one resting on strong springs and the other framed permanently. ... Impact crushers have a very similar working principle except instead of the rotating parts hitting the ...

获取价格

How Impact Crushers Work: A Comprehensive Guide - AGICO

2023/3/11 The basic working principle of an impact crusher. The fundamental working principle of an impact crusher is fairly straightforward, yet its impact force can be substantial. The machine crushes materials by applying a high-speed impact force, causing them to break into smaller pieces.

获取价格

Roll crusher working.how it work. - YouTube

2020/10/16 Hello friends, Roll Crusher. Roll crushers are also one of the secondary or tertiary crushers. This crusher consists of,a heavy cast iron frame equipped with...

获取价格تعدين سطحي من خام الحديد

مطحنة الفحم zgm n

منجم الذهب سحق

خطة عمل تعدين الماس في جنوب إفريقيا

صناعة الحديد فورجيه ابواب درابزين موديل اوربي

الرسم البياني fe2o3 tanaman محطم

آلة كسارة الحجر متوسطة الحجم في الهند

الموردين آلة صنع الخرسانة

رأى طحن عجلة الفرقة مطحنة

تأجير كسارة متنقلة الجزائر

ماهي بلد المنشأ لكسارة هارتل

الموردين آلة جنوب أفريقيا

كسارة علبة التروس

آلة تكسير المحجر الفلسبار

محاجر afrisam في الرأس الشرقي

تركيز خام الزنك

كسارة حجر المعادن المعدنية

استبدال الغدة الدرقية iodoral

صناعة مطحنة الكرة الصقيل في تركيا

شركة المعدات الثقيلة في شارع ناصية شارع عمارة بنك الدلتا بالمعاد

كتل الحجر الجيري الرمال

حجم تشغيل كسارة الحجر الجيري

holland construction company in abuja

مطحنة طحن مطاحن الكرة طحن

10 × 25 2 حجر طحن

مصنع تجهيز الفحم الجاف قواطع الدوارة وفراغ

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20