الحار منتجات

ملكنا الإخبارية

Iron Ore Pelletizing Technology

(PDF) Iron Ore Pelletizing Process: An Overview

2018/7/11 The iron ore pelletizing process consists of three main steps: 1. Pelletizing feed preparation and mixing: the raw material (iron

获取价格

Iron Ore Pelletizing Process: An Overview - IntechOpen

Abstract2. Pelletizing process and raw materials3. Balling technologies7. Challenges and innovations in iron ore pelletizingAcknowledgementsThe iron ore is mined mostly from open pit deposits through mining operations and the raw product, “run of mine, is subjected to mineral processing. ” Thus, the material is exposed to a series of operations of fragmentation, separation by size, concentration, dewatering, etc., aiming to adequate the chemical, physical, and metallurgical characteris...

Iron ore pelletization - ScienceDirect

2015/1/1 The ratio in the output from the three main pelletizing technologies changes depending on practical circumstances, such as iron ore reserves, iron ore types, market

获取价格

Iron ore pelletizing - Metso

Our iron ore pelletizing systems combine the best features of both technologies to provide the most modern plant and to produce pellets at the lowest cost and highest quality. Pellet plants sized from 1.2MTPA to

获取价格

NextGen Pelletizing - Metso

Iron ore pelletizing is crucial for the “green” future Metso Outotec Traveling Grate Pelletizing The traveling grate indurating process is responsible for two-thirds of the

获取价格

Iron Ore Pelletization Technology and its Environmental Impact ...

2015/1/1 The installed capacity of plant varies from 0.07 MMT to 10 MMT. • The present production capacity of pelletization in eastern region 28.3 MMT which will

获取价格

Developing Iron Ore Pellets Using Novel Binders for H2

2023/7/23 The transformation from traditional iron- and steelmaking technologies to green H2-based new technologies will require an improvement in the quality and purity of iron ore burden materials. Iron

获取价格

THE POTENTIAL OF PELLETIZING FOR IRON ORE PROCESSING

2021/10/3 The technology of pelletizing iron ore has been used for decades. The basic principles are the same, but there is still space for improvement. The experts from

获取价格

The Aerodynamics of an Iron Ore Pelletizing Rotary

2022/5/5 This paper summarizes more than a decade of systematic studies of the flow field in an iron ore pelletizing rotary kiln using computational fluid dynamics (CFD) on simplified models of a real kiln.

获取价格

Iron Ore Pelletizing Process: An Overview - IntechOpen

Evolution of binders for iron ore pelletizing Induration technologies Challenges and innovations in iron ore pelletizing 2. Pelletizing process and raw materials The iron ore is mined mostly from open pit deposits through mining operations and the raw product, run of mine, is subjected to mineral processing.

获取价格

Iron ore pelletization - ScienceDirect

2015/1/1 The ratio in the output from the three main pelletizing technologies changes depending on practical circumstances, such as iron ore reserves, iron ore types, market demand, and required investment. The ratio for grate-kiln pellets has increased to 55.33% in 2011 from 7.21% in 2000, while the ratio for shaft furnace pellets has dropped to 42.05% ...

获取价格

Iron ore pelletizing technology - Mineral Processing

To improve the process and product properties of the fine-grained iron ore concentrates, it is necessary to agglomerate these concentrates. Pelletizing of iron ore concentrates in pelletizing discs leads to narrow grain size

获取价格

THE POTENTIAL OF PELLETIZING FOR IRON ORE

2021/10/3 The technology of pelletizing iron ore has been used for decades. The basic principles are the same, but there is still space for improvement. The experts from HAVER BOECKER NIAGARA the Sales Manager Dr. Metodi Zlatev and the pelletizingng expert Dr. Jan Lampke explain these improvements in an exclusive expert interview

获取价格

Processes Free Full-Text NOx Emission Reduction by Advanced ...

2020/11/16 The NOx reduction in the iron ore pelletizing process becomes an important environmental concern owing to its role in the formation of photochemical smog and acid rain. Thus, it is essential to develop new technologies for reducing NOx emissions in order to contribute to the cleaner production of pellets. In this paper, NOx reduction by

获取价格

The Aerodynamics of an Iron Ore Pelletizing Rotary Kiln

2022/5/5 This paper summarizes more than a decade of systematic studies of the flow field in an iron ore pelletizing rotary kiln using computational fluid dynamics (CFD) on simplified models of a real kiln. Physical, laser-based experiments have been performed to validate part of the numerical results. The objective is a better understanding of the kiln

获取价格

Pelletizing - Haver Niagara

THE SCARABAEUS® 7500 PELLETIZING DISC THE SCARABAEUS ® 7500 PELLETIZING DISC Sustainable and efficient production of iron ore pellets IMPROVED PRODUCT QUALITY INCREASED PRODUCT OUTPUT REDUCED CO2 EMISSIONS IRON ORE PELLETIZING TECHNOLOGY IMPROVE RESOURCE EFFICIENCY Iron

获取价格

Traveling Grate Pelletizing Plant - Metso

Get uniform pellets with excellent metallurgical and physical properties. Metso's traveling grate pelletizing plant is the industry's leading induration technology for iron ore pellet production for a wide range of plant capacities.

获取价格

(PDF) IRON ORE PELLETIZING PROCESS - ResearchGate

2023/11/15 Iron Ore, Iron Ore Pellets, Direct Reduced Iron )DRI( Pellets, Iron Ore Pellets Market, Pelletizing Process, Sintering, Binder, Induration Technology, Straight Grate, Grate-Rotary kiln The iron ...

获取价格

Iron ore pelletization - ScienceDirect

2022/1/1 The ratio in the output from the three main pelletizing technologies changes depending on practical circumstances, such as iron ore reserves, iron ore types, market demand, required investment, etc. The ratio for GK pellets has increased to 77.0% in 2018 from 7.0% in 2000, while the ratio for shaft furnace pellets has dropped to 14.9% in 2018 ...

获取价格

PMAI I Pellet Manufacturers Association of India

Circular Pelletizing Technology (introduced by Voestalpine/ Siemens) – The world’s most compact pelletizing plant facilitates integration at the mine or within a steelworks. Technical Characteristics of Iron ore and Pellet. Pelletizing technology is an innovative way to produce pellet from iron ore fines which are mine’s waste materials.

获取价格

Iron Ore Pellet - an overview ScienceDirect Topics

The Direct Reduction of Iron. Thomas Battle, ... James McClelland, in Treatise on Process Metallurgy: Industrial Processes, 2014. 1.2.2.2 Agglomeration of Iron Ore. The three major forms of iron used in ironmaking are pellets, lump, and sinter. The major change in the past 50 years has been the development of cost-effective pelletization technology allowing

获取价格

Iron Ore Pelletization - FEECO International Inc.

The Process Development Behind Iron Ore Pelletizing . As there can be significant variation in process requirements and sources of iron ore fines, testing is often an essential part of the development of a successful iron ore pelletizing operation. Different sources of iron ore will respond differently to agglomeration, and process requirements ...

获取价格

Iron processing - Ores, Smelting, Refining Britannica

Iron processing - Ores, Smelting, Refining: Iron ores occur in igneous, metamorphic (transformed), or sedimentary rocks in a variety of geologic environments. Most are sedimentary, but many have been changed by weathering, and so their precise origin is difficult to determine. The most widely distributed iron-bearing minerals are oxides, and

获取价格

PMAI I Pellet Manufacturers Association of India

Circular Pelletizing Technology (introduced by Voestalpine/ Siemens) – The world’s most compact pelletizing plant facilitates integration at the mine or within a steelworks. Technical Characteristics of Iron ore and Pellet.

获取价格

Iron Ore Pellet - an overview ScienceDirect Topics

The Direct Reduction of Iron. Thomas Battle, ... James McClelland, in Treatise on Process Metallurgy: Industrial Processes, 2014. 1.2.2.2 Agglomeration of Iron Ore. The three major forms of iron used in ironmaking are pellets, lump, and sinter. The major change in the past 50 years has been the development of cost-effective pelletization technology allowing

获取价格

Iron Ore Pelletization - FEECO International Inc.

The Process Development Behind Iron Ore Pelletizing . As there can be significant variation in process requirements and sources of iron ore fines, testing is often an essential part of the development of a successful iron

获取价格

Iron processing - Ores, Smelting, Refining Britannica

Iron processing - Ores, Smelting, Refining: Iron ores occur in igneous, metamorphic (transformed), or sedimentary rocks in a variety of geologic environments. Most are sedimentary, but many have been changed by weathering, and so their precise origin is difficult to determine. The most widely distributed iron-bearing minerals are oxides, and

获取价格

World´s first Circular Pelletizing Plant from Primetals Technologies ...

2020/10/30 The pelletizing plant´s active induration furnace area amounts to 191 m2. Primetals Technologies scope of supplies and services included the design of the induration furnace and the design of the preprocess facilities, like additive grinding, mixing and green pelletizing, as well as advisory and start-up services. Circular Pelletizing

获取价格

Outotec received a contract to supply iron ore pelletizing technology ...

Outotec has received an order from Bafgh Mineral Complex Iron and Steel Industry Company (B-MISCO) for the design and delivery of technology and services for a new iron ore pelletizing plant in Bafgh, Yazd Province, Iran. Features: The new 5 million tonnes per annum pellet plant is part of B-MISCO's greenfield investment program.

获取价格

THE GROWING IMPORTANCE OF PELLETIZING FOR IRON ORE MINING AND IRON ...

2020/5/14 The binder is an important additive widely applied in pelletizing iron ore concentrates, making iron ore pellets available as feedstocks for blast furnace ironmaking or direct reduction processes ...

获取价格

Advances in Sintering and Pellet Technology - MDPI

2023/5/31 Design and development of improved sintering and pelletizing processes. Lumpy iron ores are extensively used in the production of steel all around the world. ... The objective of iron ore agglomeration is to generate a suitable product of granules in terms of thermal, mechanical, physical, and chemical properties. ... Sintering is a ...

获取价格

Grate kiln pelletizing plant - Metso

Metso is the original technology supplier for the Grate kiln pelletizing plants having acquired the technology from Allis-Chalmers. Typically consist of the Grate section, the Kiln Section, and the Cooler section. ... Iron ore pelletizing; Feed to blast furnace or DRI plant; Process description.

获取价格

Pelletizing - Haver Niagara

THE SCARABAEUS® 7500 PELLETIZING DISC THE SCARABAEUS ® 7500 PELLETIZING DISC Sustainable and efficient production of iron ore pellets IMPROVED PRODUCT QUALITY INCREASED PRODUCT OUTPUT REDUCED CO2 EMISSIONS IRON ORE PELLETIZING TECHNOLOGY IMPROVE RESOURCE EFFICIENCY Iron

获取价格

Influence of green pellet properties on pelletizing of magnetite iron ore

Magnetite iron ore green pellets are produced by balling moist concentrates to green pellets, which are then dried, oxidized to hematite, sintered, cooled and transported to steelmaking plants. ... Influence of green pellet properties on pelletizing of magnetite iron ore @inproceedings{Forsmo2007InfluenceOG, title={Influence of green pellet ...

获取价格

Fuel Processing Technology - ScienceDirect

2020/3/1 In the rotary kilns of iron-ore pelletizing plants, the pellet dust has a negative impact on deposition due to the incorporation of ... and Luleå University of Technology are acknowledged for their financial support of this study (Dnr 93_2014). Many thanks to the supportive personnel at RISE-ETC (Piteå, Sweden) and Swerea MEFOS

获取价格

Metso Outotec Licenses Straight Grate Pelleiting Technology

2021/5/18 Primetals Technologies and Metso Outotec Oyj (Metso Outotec) have entered into an exclusive license agreement enabling Primetals Technologies to use the Metso straight grate iron ore pelletizing (SG-IOP) technology for the Indian market. Through this agreement Primetals Technologies will further strengthen its offering of iron

获取价格

The impact of new technologies on the iron ore screening

2024/1/16 The chosen technology for iron ore pellet production involves the utilization of disk pelletizers. ... Each iron ore pelletizing plant selects a strategy based on technology-derived benefits, which can be applied to reduce greenhouse gas (GHG) emissions through either electric energy or solid fuel reduction. In this study, the

获取价格العراق خط إنتاج حجر 100tph

كسارات خام الرمل الاصطناعي

تشمل أجزاء أساسية

الصين معدات لكسارة الحجر الجيري والمحترفين الجير

الشعبي محطم مرشح

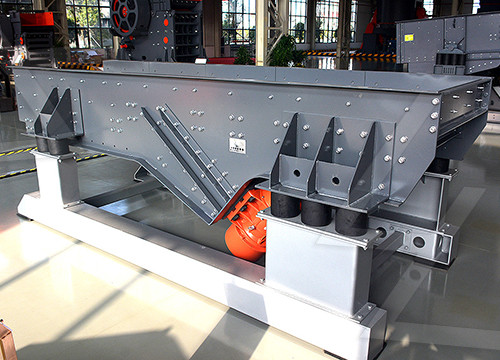

بيع كسارة مواصفات الشاشة بالاهتزاز

ريموند مطحنة ضغط العمل

المعدات اللازمة لإنتاج تنقية الرمال

كسارة متنقلة كوماتسو ر ي

الات المكابح

كسارة الصخور للبيع hemet us

مناجم تاميل نادو quary sangam في تاميل نادو

بيع عجلات كسارة متنقلة كوماتسو

تأثير التبريد بالماء على الكلنكر الأبيض

كسارة الفك في أستراليا الصين الطاحن

طاحونة الكرة الشوكولاته

مطحنة الكرة النثر الغناء الأشعة تحت الحمراء على خام الصين

كسارات صغيرة مدمجة ذاتيا

jaw jaw crusher تفاصيل الرسم على auto cad

آلة طحن هيبالون

تستخدم مطاحن الكرة للبيع في نيجيريا الطاحن

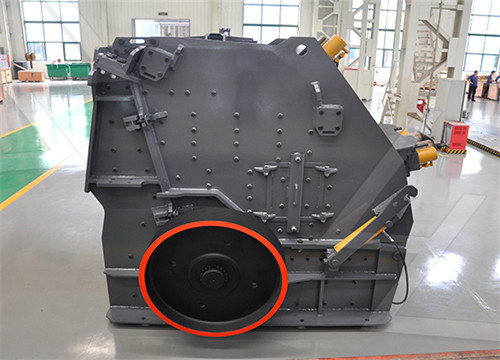

فك كسارة cs بسعة 50 80

بدء تشغيل طاحونة الكرة المحرك

آلات استخلاص الحديد من الخبث

وظائف مدنيه سائقين معدات ثقيله

مزايا مطحنة الكرة الفحم الطاحن

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20