الحار منتجات

ملكنا الإخبارية

ball mill gold ore production kalimantan

Mt Muro Gold Deposit, Kalimantan, Indonesia - Mining

2009/2/24 Mt Muro sold 25,558oz of gold and 71,697oz of silver for the six months to June 2008. While mining operations performed well and delivered over 35,000oz Au to the ROM, the plant only managed to

获取价格

Integrating geometallurgical ball mill throughput predictions into ...

2023/2/1 There is a remaining risk involved of over and underfeeding the ball mill indicated by P10 and P90 risk profiles (Fig. 10 a dashed lines). However, the spread of

获取价格

The significance of gold mining ball mills in the modern mining ...

Gold mining ball mills play a significant role in the modern mining industry, particularly in the extraction of gold. They facilitate the grinding and crushing of ore materials, resulting in

获取价格

KALIMANTAN MINERAL RESOURCES: AN UPDATE ON

Gold had been worked from alluvial deposits since 4th century and especially during the 18th century the Western Kalimantan (Sambas area) was the site of gold rush (Van

获取价格

Manual for Training Artisanal and Small-Scale Gold Miners

2005/12/2 Less mercury, more gold and better health (Gold in a shop in Kalimantan, Indonesia) Manual for Training Artisanal and Small-Scale Gold Miners/Veiga, M.M. et

获取价格

Using Ball Mills to Extract Raw Gold from Ores

2018/6/14 Its major purpose is to perform the grinding and blending of rocks and ores to release any free-gold that is contained within them. At major mines, the mill was the critical equipment that was required to

获取价格

(PDF) Characteristics and Potential of Placer Gold

2022/12/16 In Indonesia, these arcs total approximately 7,000 kms in length and contain combined historical production and current resources in excess of 2,500 tonnes of gold and 20 million tonnes of copper.

获取价格

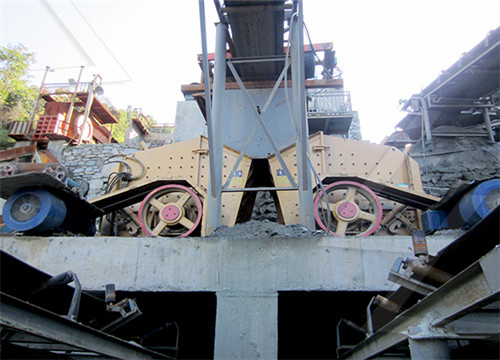

Ball mill for gold mining, iron ore processing in Indonesia

Wet Ball mill is mainly used for grinding materials in such production industries as cement, silicate product, new building materials, nonferrous and black metal, mineral processing,

获取价格

The cyanide revolution: Efficiency gains and exclusion in artisanal ...

2021/11/1 1. Introduction. In recent decades, gold mining expanded from its historical core (South Africa, the United States, Canada, Australia, and Russia) into a wide range

获取价格

(PDF) Grinding Media in Ball Mills-A Review - ResearchGate

2023/4/23 2 Department of Mining Engineering, Florida Campus, University of South Africa (UNISA), Private Bag X6, Johannesburg 1710, South Africa;

获取价格

How Ball Mill Ore Feed Size Affects Tonnage

2017/7/26 For the purposes of this example, we will hypothesize that the the crushing index of the hard ore with the increased energy input of 1.54 kw/t reduces the ball mill feed size to 6,500 micrometers. As a

获取价格

5 Ways to Improve the Ball Mill Efficiency - Fote

2020/1/11 At the gold ore beneficiation site, the Tanzanian customer selected a suitable gold ball mill and does regular maintenance. Compared with other ball mills that used for the same period, his ball mill grinding

获取价格

Mini-Mobile Gold Processor - Mt Baker Mining and

Mini-Mobile Gold Processor. One of our unique designs combines a sluice connected directly to the hammer mill outlet. The hammer mill is a standard 16″ x 12″ powered by a 22 hp gasoline engine and will accept a feed size

获取价格

Used Ball Mills (mineral processing) for sale in USA Machinio

allis chalmers svedala ball mill, year 1979 rebuilt 1998. used. manufacturer: allis-chalmers; reference number: tt-1812 allis chalmers svedala ball mill, year 1979 rebuilt 1998 allis chalmers svedala ball mill 13’ diameter x 21’ long rubber-lined mill with siemens-allis 2,000 hp 4000 volt 200 rpm s...

获取价格

Ball Mill Is Indispensable For Lithium Ore Processing

1 The advantage of the grid type ball mill is that the ore discharge speed is fast, it can reduce the over-crushing of ore, and at the same time it can increase the output per unit volume. 1. Large row of ore mouth design, stronger processing capacity for lithium ore, up to 160t/h; 2. Equipped with an automatic control system PLC, reducing labor costs, real

获取价格

Flowsheet Development of A Refractory Gold Ore To

The ball mill circuit consists of two stages of grinding. The primary ball mill reduces the size of the HPGR product stream which is then sized by hydro cyclone. The ball mills are rubber lined and relines occur every year. The primary mill is 9.0 MW and uses 50mm steel balls, and the secondary mill is 6.2 MW and uses 20 mm steel balls.

获取价格

Ball mill - Wikipedia

A section cut-through of ball mills. A ball mill is a type of grinder filled with grinding balls, used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering.It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell.

获取价格

Gold Fields South Deep Gold Mine - How we process

When ore enters the plant from underground it first needs to be milled to reduce its size so that the gold is liberated from the host rock. South Deep’s milling circuit consists of a single-stage semi-autogenous grinding mill (SAG) and a pebble crusher for primary milling, followed by secondary milling using two overflow ball mills.

获取价格

how does a ball mill work gold ore - Knowledge

2024/4/28 how does a ball mill work gold ore. Apr 28, 2024. A ball mill is a type of grinder used to grind and blend materials for use in mineral processing, including gold ore processing. Here's a simplified explanation of how it works: Crushing and Grinding: The gold ore is typically crushed down to a fine powder before being fed into the ball mill ...

获取价格

MOBILE HARD ROCK GOLD MINING EQUIPMENT

EFFICIENCY: SPEEDMINER ® Mobile Fully Integrated Hard Rock plant is designed with advanced technology to ensure 100% recovery of gold and other metals production, with no loss. PRODUCT RANGE: SPEEDMINER ® Mobile Hard Rock plants are produced in 13 standard models with capacity range of 2-120 TPH. SELF-SUFFICIENT POWER

获取价格

Ball Mills - Mt Baker Mining and Metals

Ball Mills. Ball mills have been the primary piece of machinery in traditional hard rock grinding circuits for 100+ years. They are proven workhorses, with discharge mesh sizes from ~40M to <200M. Use of a ball mill is the best choice when long term, stationary milling is justified by an operation.

获取价格

High Quality Gold Ore Ball Mill Grinding Ball Mill For Mineral

High Quality Gold Ore Ball Mill Grinding Ball Mill For Mineral Plant Ore Beneficiation Production Line No reviews yet Zhengzhou Zhongding Heavy Duty Machine Manufacturing Co., Ltd. 17 yrs CN

获取价格

(PDF) Grinding Media in Ball Mills-A Review - ResearchGate

2023/4/23 The motion of grinding media in a ball mill is essential since it has a grea t impact on the breakage of ore parti cles. When the mill speed increa ses, the charge motion changes from sliding to ...

获取价格

MOBILE HARD ROCK GOLD MINING EQUIPMENT

EFFICIENCY: SPEEDMINER ® Mobile Fully Integrated Hard Rock plant is designed with advanced technology to ensure 100% recovery of gold and other metals production, with no loss. PRODUCT RANGE:

获取价格

Ball Mills - Mt Baker Mining and Metals

Ball Mills. Ball mills have been the primary piece of machinery in traditional hard rock grinding circuits for 100+ years. They are proven workhorses, with discharge mesh sizes from ~40M to <200M. Use of a ball mill is the best

获取价格

High Quality Gold Ore Ball Mill Grinding Ball Mill For Mineral

High Quality Gold Ore Ball Mill Grinding Ball Mill For Mineral Plant Ore Beneficiation Production Line No reviews yet Zhengzhou Zhongding Heavy Duty Machine Manufacturing Co., Ltd. 17 yrs CN

获取价格

(PDF) Grinding Media in Ball Mills-A Review - ResearchGate

2023/4/23 The motion of grinding media in a ball mill is essential since it has a grea t impact on the breakage of ore parti cles. When the mill speed increa ses, the charge motion changes from sliding to ...

获取价格

Ball Mill - Wet Ball Mill Dry Ball Mill - Mining Machinery

All abrasive ores, abrasive materials, various stone materials, and some metals can be ground by a ball mill. Common grinding materials for ball mills: 1) metallic ores such as gold ore, copper ore, iron ore, chromium ore, fluorite ore, phosphorite, etc. 2) chemical raw materials: quartz sand, feldspar, limestone, marble, zircon sand, cement ...

获取价格

Production standards for iron ore ball mills - LinkedIn

2024/6/5 As an important equipment in mining machinery, the production standards of iron ore ball mills directly affect the performance, service life, and production efficiency of the equipment. In order ...

获取价格

TRX Gold Advances Mill Expansion to Increase Gold Production

2023/10/2 Significant increase in gold production: The mill expansion is expected to increase processing capacity from 1,000 tpd to 2,000 tpd, and on an average annual basis, increase ore throughput from 75 ...

获取价格

Diagnosis and Optimization of Gold Ore Flotation Circuit via

Gold ores were obtained from the Gasado gold mine in Jeollanam-do, Korea. It is known that the gold ore consists of pyrite, muscovite, and quartz [30]. The gold ores were initially crushed using a jaw crusher and a cone crusher, and then ground using a ball mill in the gold ore beneficiation plant. Water was obtained from the plants.

获取价格

Choosing the Right Iron Ore Ball Mill Machine: Key Considerations

2024/6/26 1. Understanding the Material. Iron ore comes in various grades and forms, each with specific characteristics. The type of ore you are processing will influence the type of ball mill you need.

获取价格

Intelligent optimal control system for ball mill grinding process

J Control Theory Appl 2013 11 (3) 454–462 DOI 10.1007/s11768-013-1210-3 Intelligent optimal control system for ball mill grinding process Dayong ZHAO 1†, Tianyou CHAI,2 1.State Key Laboratory of Synthetical Automation for Process Industries, Northeastern University, Shenyang Liaoning 110819, China;

获取价格

Lime in Gold Ore Mining Process Flotation, Cyanidation - JXSC

2019/8/3 The addition of lime in the flotation operation is usually carried out by adding the lime powder to the ore belt of the ball mill or adding lime milk or lime powder to the stirring tank before the flotation. ... the amount of lime added should be strictly controlled in the flotation production of gold mines, and it should be fully recognized. 2 ...

获取价格

how does a ball mill work ore - Knowledge

2024/4/28 how does a ball mill work ore. Tel: +86-731-85212256. Email: deco_mill@126. English. ... how does a ball mill work gold ore. Send Inquiry. You Might Also Like ... Natural Agate Grinding Jar. We are a factory manufacturing laboratory planetary ball mills, the best production capability, the best quality control and the best

获取价格

Gold Extraction Recovery Processes - 911 Metallurgist

2016/2/29 Process Development Considering the different gold minerals present alone or combined with the host rock, it will be necessary to discharge the unwanted material in order to increase the concentration of gold in an economically manner. This part treats the strategy of beneficiation as a combination of several processes. Joining

获取价格

Beneficiation of Gold and Silver Ores SpringerLink

2019/12/15 4.2.9 VertiMills. Vertical mills were first designed in the 1950s for applications in fine and ultrafine grinding in Japan. Lately, the vertical mill is making progress toward primary grind application and shown promise in energy reduction relative to ball mills, typical to what is normally seen in regrinding applications (Mazzinghy et al.

获取价格سعر معدات التعدين المستعملة في مصر

الطحن وفحص الكاولين

ne crusher liners business amp industrial in Uzbekistan

كسارة تصادمية متنقلة ذاتية الدفع

كسارة الحجر criteriaall

السعر على مطحنة الأسمنت Tph

المستخدمة الدولوميت الفك محطم للبيع في مصر

آلة معالجة المعادن من مورد الذهب

شراء طاحونة كسارة في المملكة العربية السعودية

ماشین سنگ زنی در استرالیا

تستخدم كسارة خام الحديد مزود مزود المملكة العربية السعودية

الخطط كسارة مخروط

hydrostone expanded clay balls

محاجر الاهالى الرجام فى مصر صور

آلة طحن غرامة الشوكولاته

رفع المخروط

قائمة شركات المحاجر للإنشاءات في كينيا

صغير الموردين آلة الرمال الصخور

Deatil من الحزام الناقل

المطاحن خام والكسارات

كسارة الفك كسارة ضد

طبقه برای سنگ معدن و مواد معدنی

تجار كسارة صخرية في نيجيريا

spare parts cement industry

البرازيل الحديد منجم لخام أكبر

انواع ماكنات الطرز الالى بالصور

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20