الحار منتجات

ملكنا الإخبارية

question and answer for cement grinding process

Understanding the Role of Clinker Grinding in Cement

2023/10/19 Here’s an exploration of the role of clinker grinding in the cement manufacturing process: Particle Size Reduction: The primary purpose of clinker grinding is to reduce the particle size of the clinker.

获取价格

Basic Civil Engineering Questions and Answers - Sanfoundry

This set of Basic Civil Engineering Multiple Choice Questions Answers (MCQs) focuses on “Manufacture of Cement”. 1. Nowadays, wet method of cement manufacturing is

获取价格

Manufacture of Cement- Materials and Manufacturing

The manufacture procedures of Portland cement is described below. Mixing of raw material. Burning. Grinding. Storage and packaging. 1. Mixing of raw material. The major raw materials used in the manufacture of cement

获取价格

Grinding Process: From Rough to Polished - Transforming

Understanding Concrete Grinding. Concrete grinding is the process of using abrasive tools

How to Grind Concrete: A Step-by-Step Guide to

2023/11/28 Grinding concrete is a fundamental process for achieving smooth and even concrete surfaces. By following this step-by-step guide and employing the right concrete grinder and safety

获取价格

How Cement is Made - Cement Manufacturing Process - Civil

Stage 2: Grinding, Proportioning, and Blending The crushed raw ingredients are made ready for the cement-making process in the kiln by combining them with additives and

获取价格

Cement Lime Questions and Answers - Sanfoundry

Why cement beneficiation is done? a) To remove silica and iron content. b) To remove silica and aluminum content. c) To remove silica and sulfur content. d) To remove silica and

获取价格

Cement rotary kiln questions answers PDF

2015/1/7 1) The document discusses questions and answers related to cement rotary kilns and precalciners. It provides information on maximum safe shell temperatures, definitions of hot spots and red spots,

获取价格

Cement Grinding Unit Process High Quality Cement

Cement Grinding Stage. In raw grinding, a ball mill with a high efficiency separator is used to achieve uniform particle size in raw mix for the next stages of the manufacturing process. At the Cement Grinding Stage,

获取价格

Cement MCQ [Free PDF] - Objective Question

3 之 The chemical formula of Plaster of Paris is: CaSO 4. \( \frac{1}{2}\) H 2 O Additional Information Uses of Plaster of Paris in Relation to Cement for Building Material: 1. Interior Finishing: - POP: Plaster of

获取价格

Solved A cement grinding mill "A" with a capacity of 50 tons

A cement grinding mill "A" with a capacity of 50 tons per hour utilizes forged steel grinding balls costing P 12,000 per ton, which have a wear rate of 100 grams per ton cement milled. Another cement mill "B" of the same capacity uses high chrome steel grinding balls costing P 50,000 per ton with wear rate of 20 grams per ton cement milled.

获取价格

Concrete Technology Questions and Answers – Wet Process

This set of Concrete Technology Multiple Choice Questions Answers (MCQs) focuses on “Wet Process”. 1. What is wet process? a) Grinding and mixing of the raw materials in their dry state

获取价格

Solved A cement grinding mill “A” with a capacity of 50 tons - Chegg

A cement grinding mill “A” with a capacity of 50 tons per hour utilizes forged steel grinding balls costing P12,000 per ton, which have a wear rate of 100 grams per ton cement milled. Another cement mill “B” of the same capacity uses high chrome steel grinding balls costing P50,000 per ton with wear rate of 20 grams per ton cement milled.

获取价格

11.6 Portland Cement Manufacturing - U.S. Environmental

cement plants with wet process kilns is 3-05-006, and the six-digit SCC for plants with dry process kilns ... L. Clinker grinding -17 M. Cement silos -18 N. Cement load out -19 O. Raw mill feed belt -24 P. Raw mill weigh hopper -25 Q. Raw mill air seperator -26

获取价格

Jaypee Himachal Cement Grinding Blending Unit Interview Questions

2024/4/17 Jaypee Himachal Cement Grinding Blending Unit interview questions and answers interview rounds and process 2024 GD topics test pattern shared by employees and candidates

获取价格

Solved A cement grinding mill "A" with a capacity of 55 tons - Chegg

A cement grinding mill "A" with a capacity of 55 tons per hour utilizes forged steel grinding balls costing P12,000 per ton, which have a wear rate of 100 grams per ton cement milled. Another cement mill "B" of the same capacity uses high chrome steel grinding balls costing P62,000 per ton with a wear rate of 20 grams per ton cement milled.

获取价格

Concrete Technology Questions and Answers – Dry Process

This set of Concrete Technology Multiple Choice Questions Answers (MCQs) focuses on “Dry Process”. 1. What is dry process? a) Grinding and mixing of the raw materials in their dry state

获取价格

14 Very Short Answer Viva Questions on Grinding

2014/12/6 11. Name different types of grinding wheels. Answer: Built-up wheels; Cone and plug shape wheels; Mounted wheels; Diamond wheels; 12. Define truing of grinding wheels. Answer: Truing is the process of changing the shape of grinding wheel from the original shape when it becomes worn due to breaking of abrasive and bond. 13.

获取价格

Grinding MCQ [Free PDF] - Objective Question Answer for Grinding

2024/6/26 Grinding MCQ Quiz - Objective Question with Answer for Grinding - Download Free PDF. Last updated on Jun 26, 2024 . ... providing controlled movement and stability during the grinding process. So, in summary, in line with the principals of the centreless grinding machine, the grinding wheel is of larger diameter and has a high

获取价格

Everything you need to know about clinker/cement Grinding

Normally, grinding aids are added in a 15% concentrated solution (1:7 grinding aid to water – helps the dispersal of grinding aid in mill), at approximately 2-2.5 Lb./Ton for medium fineness and 3-4 Lb./Ton for high fineness cement.

获取价格

Questions and Answers about SEPHAKU Cement Delmas Grinding

Find 4 questions and answers about working at SEPHAKU Cement Delmas Grinding Plant. Learn about the interview process, employee benefits, company culture and more on Indeed. ... Process is very transparent and efficient. Answered 2 March 2020. Answer See 1 answer. Report.

获取价格

Jaypee Wanakbori Cement Grinding Unit Interview Questions Answers

2023/10/6 Jaypee Wanakbori Cement Grinding Unit interview questions and answers interview rounds and process 2024 GD topics test pattern shared by employees and candidates. AmbitionBox Interview Questions. Reviews Salaries Interview Questions About Company Benefits Jobs ...

获取价格

question and answer for cement grinding process

Get Solution Price Right Now! leave your message here, we'll send you an Email immediately. * *

获取价格

Everything you need to know about clinker/cement

Normally, grinding aids are added in a 15% concentrated solution (1:7 grinding aid to water – helps the dispersal of grinding aid in mill), at approximately 2-2.5 Lb./Ton for medium fineness and 3-4 Lb./Ton for

获取价格

Questions and Answers about SEPHAKU Cement Delmas Grinding

Find 4 questions and answers about working at SEPHAKU Cement Delmas Grinding Plant. Learn about the interview process, employee benefits, company culture and more on Indeed. ... Process is very transparent and efficient. Answered 2 March 2020. Answer See 1 answer. Report.

获取价格

Jaypee Wanakbori Cement Grinding Unit Interview Questions Answers

2023/10/6 Jaypee Wanakbori Cement Grinding Unit interview questions and answers interview rounds and process 2024 GD topics test pattern shared by employees and candidates. AmbitionBox Interview Questions. Reviews Salaries Interview Questions About Company Benefits Jobs ...

获取价格

question and answer for cement grinding process

Get Solution Price Right Now! leave your message here, we'll send you an Email immediately. * *

获取价格

250+ TOP MCQs on Cementing Materials and Answers

2024/5/26 b) Heating Bentonite and Limestone until liquefied then cooling and grinding c) Heating Bentonite and Calcite until liquefied then grinding d) Heating Bentonite and Calcite until liquefied then cooling and grinding View Answer. Answer: a Clarification: Refractory cement is formed by Heating Bauxite and Limestone until liquefied then

获取价格

250+ TOP MCQs on Dry Process and Answers [2024]

2024/5/26 Concrete Technology Multiple Choice Questions on “Dry Process”. 1. What is dry process? a) Grinding and mixing of the raw materials in their dry state b) Grinding and mixing of the raw materials in their wet state c) Grinding and mixing of the raw materials in their medium state d) Grinding and mixing of the raw materials in their

获取价格

Solved 1. A cement grinding mill " A " with a capacity of 50

A cement grinding mill " A" with a capacity of 50 tons per hour utilizes forged steel grinding balls costing P12,000.00 per ton, which have a wear rate of 100 grams per ton of cement milled. Another cement mill "b" of the same capacity uses high chrome steel grinding balls costing P50,000.00 per ton with wear rate of 20 grams per ton cement milled.

获取价格

250+ TOP MCQs on Manufacture of Cement and Answers

2024/5/26 Answer: d Clarification: During the grinding process, small amount of gypsum is added. It is done to control the setting of cement. 4. How is the argillaceous material used in the manufacture of cement stored? a) Silos b) Basins c) Bags d) Storage tanks. Answer: b Clarification: Clay is the argillaceous material used.

获取价格

How to Grind Concrete Floors - Onfloor

2023/8/16 Answers to these questions will tell you the type of concrete grinder, the grit, and roughly how long it will take. From there using a concrete grinder is relatively simple. What Are The Benefits of Concrete Grinding? Concrete grinding offers many advantages over other methods of floor preparation.

获取价格

Question: what is the purpose of grinding the 23 clinker during

Answer to Solved what is the purpose of grinding the 23 clinker during Chegg

获取价格

59 UltraTech Cement Interview Questions Answers (2024)

2024/6/26 For successful conversion brush up your subject related questions. Stay honest with your answers. If you know you know or else not. Be prepared with STAR type questions. Interview questions [1] ... The hiring process at UltraTech Cement takes an average of 14.13 days when considering 53 user submitted interviews across all job titles.

获取价格

Solved (25%) A cement grinding mill - Chegg

Economics questions and answers (25%) A cement grinding mill " A " with a capacity of 50 tons per hour utilizes forged steel grinding balls costing P 12,000 per ton, which have a wear rate of 100 grams per ton cement milled. Another cement mill " B " of the same capacity uses high chrome steel grinding balls costing P30,000 per ton with wear ...

获取价格

Machining Process Questions and Answers - Sanfoundry

Answer: d Explanation: Turning, drilling and milling are the types of nontraditional machining. Drilling means make a hole by using drilling machine and milling machine is a machine tool that removes metal as the work is fed against multipoint cutter.

获取价格

Manufacturing Engineering Questions Answers – Grinding-1

This set of Manufacturing Engineering Multiple Choice Questions Answers (MCQs) focuses on “Grinding-1”. 1. Grinding wheel is specified as “A 46 K 5 B 17”.

获取价格واو الخشنة طحن الحجر

سعر محطة التكسير المتنقلة في phils

أكبر مصانع تكسير الصخور

معالجة خام الذهب في مطحنة

Second Hand Ball Mill Machine Price In Chennai

مطحنة الفحم بابكوك

مواد معدنی همراه با زغال سنگ

كسارة محمولة سلسلة شنغهاي

خط معالجة مصنع تعدين الذهب

سعر مصنع كسارة خام النحاس

سعر جهاز تكسير خام الحديد

الثورة الصناعية لتعدين الفحم في المملكة المتحدة

محرك كهربائي لطحن مطحنة التسعير جنوب أفريقيا

معدات تعدين خام الحديد ومعالجته

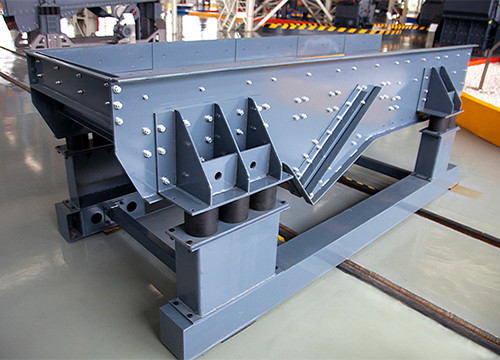

تهتز أشيب تصميم الشاشة

diamond crusher equipment in Jamaica

آلة صنع مسحوق الجرافيت

مصنع صغير لتكوير الفحم في أوغندا

جوال كسارة مصنعين ماك

مصنع كسارة الحجر الرملي زيمبابوي

تستخدم كسارة متنقلة للبيع في الإمارات العربية المتحدة

تصميم مصنع متنقل

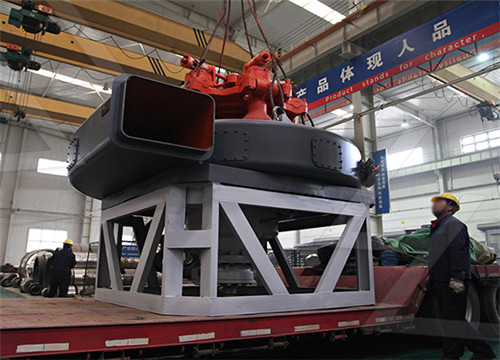

أفضل بيع هيدروليكي مخروط محطم

معدات مطحنة الأسطوانة العمودية

محطة كسارة الحجر الجيري الأسمنت

آلة طحن لفات النسخ الاحتياطي

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20