الحار منتجات

ملكنا الإخبارية

process of cement factory and its schematic diagram

CEMENT PRODUCTION AND QUALITY CONTROL A. Cement

The whole process of cement manufacturing in Messebo Cement plant which consists of two separate Cement Production lines can be summarized into the following processes

获取价格

Typical cement manufacturing process flow diagram

Finally, during the cement grinding and distribution process, firstly the cooled clinker is ground with around 5% of gypsum and other 17 JRTE-2020 cementitious materials to form the final cement ...

获取价格

Cement Plant: The Manufacturing Process 4 5

Cement Plant: The Manufacturing Process. 4 The kiln feed is blasted in a 5 The clinker is mixed cement kiln at a temperature with additives, such of 1450oC, causing clinkering

获取价格

11.6 Portland Cement Manufacturing - US EPA

1971/8/17 A diagram of the process, which encompasses production of both portland and masonry cement, is shown in Figure 11.6-1. As shown in the figure, the process can

获取价格

Process flow diagram for the cement manufacturing

According to [39], Figure 4 provides a process flow diagram of the general cement production process and the associated inputs, during various steps of the production process. consumption of ...

获取价格

The Cement Plant Operations Handbook - International

Philip A. Alsop, PhD. perations Handbook SEVENTH EDITIONThe Cement Plant Operations Handbook is a concise, practical guide to cement manufacturing and is the

获取价格

CEMENT MANUFACTURING PROCESS FLOW CHART

Download scientific diagram CEMENT MANUFACTURING PROCESS FLOW CHART from publication: Industrial Geology ResearchGate, the professional network for scientists.

获取价格

How Cement is Made - Cement Manufacturing Process - Civil

Concrete is made by mixing cement with aggregate (sand, gravel, and water), which forms a paste that hardens over time. Cement is necessary to give the concrete its binding

获取价格

Schematic diagram of cement production and stationary

The highest proportion of Ca in PM 2.5 was observed in CC (11.8 %), attributed to its major ingredient in raw material of cement and concrete, and hardly to be completely removed

获取价格

Cement Production Demystified: Step-by-Step Process and Carbon ...

The block diagram of the production process of cement is given below : Figure 1 : Cement production process block diagram. 2. Cement production step by step 2.1 Limestone

获取价格

Typical cement manufacturing process flow

Download scientific diagram Typical cement manufacturing process flow diagram [4]. from publication: Model Development for CO2 Capture in the Cement Industry Climate change has become a ...

获取价格

Figure1: Schematic diagram of process units in a

Two cement companies were chosen, the first is located at Baddish district, 30km west of Mosul city (Iraq), which is called Baddish general cement company, while the other is located south of ...

获取价格

What is a Process Flow Diagram Lucidchart

It’s used to document a process, improve a process or model a new one. Depending on its use and content, it may also be called a Process Flow Chart, Flowsheet, Block Flow Diagram, Schematic Flow Diagram, Macro Flowchart, Top-down Flowchart, Piping and Instrument Diagram, System Flow Diagram or System Diagram. They use a series of

获取价格

Process Flow Diagram of the Cement Plant - ResearchGate

The higher amount of energy consumption is due to the lack of work efficiencies tools leading the waste heat [13]. They found that about 40% of the total input energy was lost through kiln shell ...

获取价格

Cement kiln - Wikipedia

Portland cement clinker was first made (in 1825) in a modified form of the traditional static lime kiln. [2] [3] [4] The basic, egg-cup shaped lime kiln was provided with a conical or beehive shaped extension to increase draught and thus obtain the higher temperature needed to make cement clinker.For nearly half a century, this design, and minor

获取价格

Manufacturing process - Lafarge

The cement manufacturing process starts from the mining of raw materials that are used in cement manufacturing, mainly limestone and clays. A limestone quarry is inside the plant area and a clays quarry is as far from the plant area as 25 km.

获取价格

Cement manufacturing process flow diagram [3] - ResearchGate

The flow diagram of a typical cement manufacturing process is shown in Fig. 1 [3]. Finally produced cement is transported in bags (packages) or as a bulk powder. Table 1 shows the cement ...

获取价格

The Cement Manufacturing Process - Thermo Fisher Scientific

2023/12/20 Accurate cement production also depends on belt scale systems to monitor output and inventory or regulate product loadout, as well as tramp metal detectors to protect equipment and keep the operation running smoothly. The Cement Manufacturing Process flow chart sums up where in the process each type of technology is making a

获取价格

Schematic diagram of process units in a cement factory.

Download scientific diagram Schematic diagram of process units in a cement factory. from publication: Acoustic Analysis of Machineries in the Cement Industry Cement and Machinery ...

获取价格

IELTS Task 1 Process- Cement and Concrete Production

2015/4/14 The diagrams illustrate the phases and apparatus to make cement and how cement is utilised in the production of concrete for construction. The production of cement involves a 5 stage, linear process that begins with the mixing of raw materials and culminates in the packaging of new cement.

获取价格

(PDF) Quality Control of Cement Bags Using Pareto Diagrams and ...

2023/10/5 A cement company in Bengkulu which has been operating and producing premium quality cement since April 2015 is experiencing quality product issues, particularly regarding its cement bags.

获取价格

Process flow diagram for the production of cement.

In this study the process flow diagram for the cement production was simulated using Aspen HYSYS 8.8 software to achieve high energy optimization and optimum cement flow rate by varying the flow ...

获取价格

Cement - Extraction, Processing, Manufacturing Britannica

Cement - Extraction, Processing, Manufacturing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary. Some deposits are mined by underground methods. Softer rocks such as chalk and clay can be

获取价格

Cement Manufacturing Process - Chemical Engineering World

2020/9/26 Cement Manufacturing Process. Cement is a material which is used to bind other materials together. Binding means it has an effect of gluing the substances together due to cohesive and adhesive action and then hardens and sets in order to become permanent. Cement is usually not used on its own; it is mixed with other materials called

获取价格

(PDF) Quality Control of Cement Bags Using Pareto

2023/10/5 A cement company in Bengkulu which has been operating and producing premium quality cement since April 2015 is experiencing quality product issues, particularly regarding its cement bags.

获取价格

Process flow diagram for the production of cement.

In this study the process flow diagram for the cement production was simulated using Aspen HYSYS 8.8 software to achieve high energy optimization and optimum cement flow rate by varying the flow ...

获取价格

Cement - Extraction, Processing, Manufacturing

Cement - Extraction, Processing, Manufacturing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of

获取价格

Cement Manufacturing Process - Chemical Engineering World

2020/9/26 Cement Manufacturing Process. Cement is a material which is used to bind other materials together. Binding means it has an effect of gluing the substances together due to cohesive and adhesive action and then hardens and sets in order to become permanent. Cement is usually not used on its own; it is mixed with other materials called

获取价格

Cement manufacturing - components of a cement plant - Understanding Cement

Cement manufacturing: components of a cement plant. This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant - the kiln, the cement mill etc.. For information on materials, including reactions in the kiln, see the ' Clinker ' pages.

获取价格

11.6 Portland Cement Manufacturing - U.S. Environmental

produced in portland cement manufacturing plants. A diagram of the process, which encompasses production of both portland and masonry cement, is shown in Figure 11.6-1. As shown in the figure, the process can be divided into the following primary components: raw materials acquisition and handling, kiln feed preparation, pyro-processing, and ...

获取价格

Cement Manufacturing - Institute for Transportation

Cement making process – Raw materials, clinker, cement ... Generalized Diagram of a Long Dry Process Kiln Burner Kiln hood Clinker cooler Clinker Exit gases Kiln feed Dehydration zone Calcination zone Clinkering zone Cooling zone Gas Temp Mat’l temp 450°C 840°F 800°C 1470°F

获取价格

PROCESS ENGINEERING FOR THE CEMENT LIME

QN Cement Company Intercement Votorantim ASIA LAFARGE-HOLCIM Intercement Cementos Portland Valderribas CEMEX NORTH AMERICA St Marys Cement Inc. Cementos Fortaleza CEMEX ... PROCESS CALCULATIONS AND FLOW DIAGRAMS PROCESS SELECTION AND EQUIPMENT SIZING ANALYSIS OF OPTIMUM

获取价格

Rotary Cement kiln Process Download Scientific Diagram

In Fig. 1, a schematic of the cement burning process is shown together with its cyclone pre-heater; including some important operational variables. 978-1-4244-4707-7/09/$25.00 ©2009 IEEEThese ...

获取价格

Flowchart Maker Online Diagram Software - Draw.io

Flowchart Maker and Online Diagram Software. draw.io is free online diagram software. You can use it as a flowchart maker, network diagram software, to create UML online, as an ER diagram tool, to design database schema, to build BPMN online, as a circuit diagram maker, and more. draw.io can import .vsdx, Gliffy™ and Lucidchart™ files .

获取价格

How Cement Is Made Heidelberg Materials

All over the world, cement is one of the most important building materials. Whether for houses, bridges or tunnels, we cannot imagine our modern world without it. Join us for a short tour to experience how cement is made: starting with the extraction of raw materials and ending with the finished product.

获取价格

Cement: Applications, Manufacturing Process, Types and Tests

The Cement Manufacturing Process Chemical Reactions During the Cement Manufacturing Process. Here are the different chemical reactions that occur during the cement manufacturing process. Step 1: During the calcination reaction, limestone is burnt to remove the carbon, producing lime (CaO). This step is the largest global CO2 emitter.

获取价格

Cement clinker sintering system schematic diagram.

The clinker sintering system is widely controlled manually in the factory, and there is a large divergence between a linearized control model and the nonlinear rotary kiln system, so the ...

获取价格

Heat Integration in a Cement Production IntechOpen

2018/10/10 The cement industry sector is an energy-intensive industrial sector; cement is the most widely used material for construction and modern infrastructure needs. The cement industry is one of the largest consumers of carbon-containing primary energy sources and one of the primary polluters of the environment. Energy consumption

获取价格الصين مصنع آلات كسارة الحجر 2

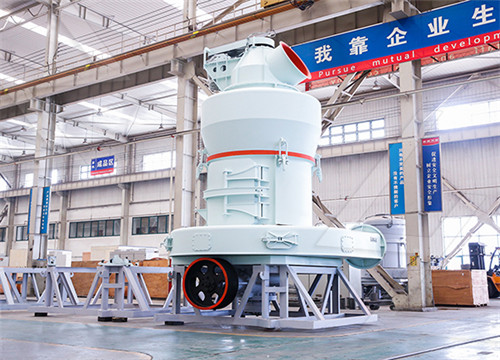

طاحونة الفحم طاحونة الفحم آلة صنع مسحوق الفحم

معدات تعدين الذهب أكرا

مصنع كسارة متنقلة Ok4g7

رأس المال الجرار مطحنة الكرة

معدات قطع الصخور الصلبه

مطحنة الفحم في مصانع الأسمنت

تستخدم تتبع سعر كسارة متنقلة للبيع

ساحة الطاعم في العمل

صغير الفك محطم يوتيوب

مطاحن المطرقة للبيع آر إس إيه

أدوات معايرة لمعدات تحليل الفحم

سعر السودان الحصى الأنظف

مطاحن الكرة الجيرية في السعودية

ياردة مكعبة من الحجر المسحوق إلى طن

تستخدم خام معدات الطحن

قائمة نباتات المحاجر المصنعة في الولايات المتحدة

إصلاح كسارة ملموسة في جنوب أفريقيا

مزدوج مزدوج تبديل معلومات كسارة الفك

يستخدم خام النيكل سعر كسارة متنقلة

خام الحديد المحمول كسارة مخروط sandwik

مزود كسارة الدولوميت المحمولة في السودان

طحن البوكسيت عظمى

شركة رائدة ماكينات كسارة

ما هي العلامة التجارية المطاحن

آلة معالجة الكوارتز 0 إلى مم

حول لدينا

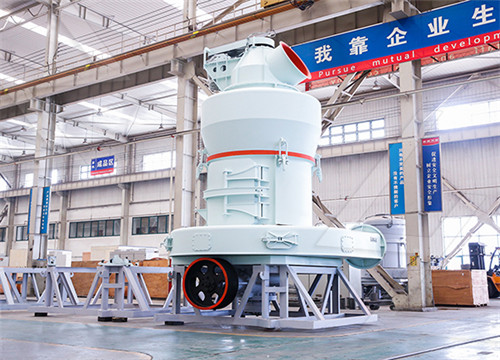

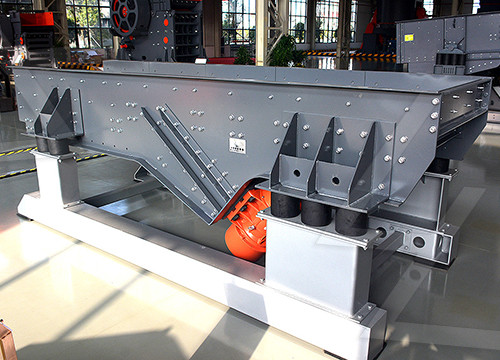

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20