الحار منتجات

ملكنا الإخبارية

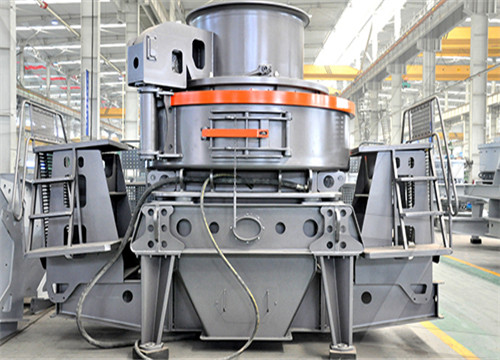

Primary Crushing Stone Crushing Equipment Rock Crusher

Primary Crusher vs. Secondary Crusher: Understanding

2023/2/28 A primary crusher is a machine that breaks down large rocks and stones into smaller particles for further processing. It is the first stage in the crushing process and is essential in the mining and

获取价格

Types of Rock Crushers Quarry Crushing Equipment

Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above. Compression-style jaw, cone, impact

获取价格

Types of Crushers: Choosing the Right One for Each Stage

2024/7/17 1. Primary crushing equipment Primary crushing is the first stage of the stone crushing process. At this stage, raw materials extracted through blasting or

获取价格

AMIT 135: Lesson 5 Crushing – Mining Mill Operator Training

Rock Crushing 101: A Beginner's Guide Senya Crushers

An advanced rock crusher with dust suppression features can help you reduce this risk and keep your employees safe. High initial investment: For most aspiring rock crushers, the

获取价格

Selecting the right type of crushing equipment - Quarry

2016/4/7 Most crushers used for aggregate production can be categorised as one of three main types: Compression crushers – which squeeze the material until it breaks. Impact crushers – which use the

获取价格

Primary and Secondary Crushing: Understanding the

2023/2/28 Secondary crushing is the second stage of crushing that takes place after the primary crushing. The secondary crusher is the equipment that reduces the size of the materials further, after they have

获取价格

Primary Crusher Selection Design - 911 Metallurgist

2015/12/23 How you select your primary crusher will be based on factors like moisture content, maximum rock lump size, material density SG, abrasion index, degradability and it being prone to dusting or not. The

获取价格

Types Of Rock Crushers And When To Use Them

2023/1/16 Tertiary rock crushing is the last stage of the crushing process, where the crushed material from the secondary crusher is further reduced in size by a tertiary crusher to produce a product with a desired

获取价格

What Is Primary, Secondary, and Tertiary Crushing?

2020/7/10 Primary crushing is the first stage of material reduction and can sometimes be the only stage needed to generate the desired product for a job. Depending on the setup, primary crushing will take

获取价格

Rock Crusher - Eastman Rock Crusher

Stone rock crushers are widely used in many sectors such as mining, smelting, building materials, highways, railways, water conservancy, and chemical industries.At present, there are two types of stone crushing

获取价格

Crushing Equipment Superior Industries U.S.

Liberty® Jaw Crusher. Primary. Maximum Feed Size 47″ (1,194mm) Maximum Reduction Ratio 6:1. Maximum Production Rate 1,595 STPH (1,446 MTPH) — Materials: Ore/Hard Rock, Quarried Stone, Recycled

获取价格

What Type of Crusher Is Best for Primary Crushing? - McLanahan

2021/3/25 In a triple-roll configuration, the primary stage of crushing occurs in the top stage of the crusher and features a single roll configuration that performs the initial crushing. A double-roll arrangement on the bottom stage of the machine accepts the sized material from the top stage and sizes it further.

获取价格

Types of Crushers: What You Need to Know Machinery Partner

Run of Mine (ROM) materials are brought directly from blasting projects and crushed a primary crusher for the first round of crushing. At this point, the material receives its first reduction in size from its raw state. Primary crushing produces materials ranging from 50" to 20" on average. The two main types of primary crushers are: Jaw crushers

获取价格

Types of Crushers: Choosing the Right One for Each Stage

2024/7/17 1. Primary crushing equipment Primary crushing is the first stage of the stone crushing process. At this stage, raw materials extracted through blasting or mining are crushed to a size suitable for conveyor transport and downstream processing. The three main types of primary crushers are jaw crushers, gyratory crushers, and hammer

获取价格

AMIT 135: Lesson 5 Crushing – Mining Mill Operator Training

Primary Crushing. The purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding circuit. The ratio of reduction through a primary crusher can be up to about 8:1. Feed: ROM up to 1.5 m; Product: -300mm (for transport) to -200mm (for SAG mill) Feed Rate: 160 to 13,000 tph ...

获取价格

What Are the Differences Between The 7 Types of Crushers?

2024/7/15 The ultimate mission of primary crusher is done. Horizontal shaft impact crusher (HSI) VS cone crusher Horizontal shaft impact crusher adopts impact force created by high-speed rotating hammer to strike and throw material. Then the crushed material will hit aprons again in the crushing chamber, which is "stone on stone"

获取价格

Choosing the right crusher for rock, stone, concrete and asphalt

These crushers generate an enormous amount of power and are able to crush a variety of materials including hard abrasive stone like granite. Impact Crushers. Impact crushers rely on velocity and sudden impact inside the crusher to break the rock and stone. They provide a high reduction rate, but because of how they crush, they’re best suited ...

获取价格

Jaw Crusher - Eastman Rock Crusher

Jaw crusher is a compression style rock crusher, useful in crushing the medium-hard to very hard material into a smaller particle size at primary crushing stage in the crushing circuit. Applications mining, quarry, construction waste recycling, aggregate making, etc. Materials Limestone, cobblestone, cobblestone, quartz, basalt, iron ore, granite, shale,

获取价格

Stone Crusher Machines In Philippines - For Different Crush Stages

The primary crushing stage aims to reduce the size of large rocks, ores, or other materials to a size suitable for further processing. The material is typically in its natural state and has not undergone any prior treatment, such as . Common type of stone crusher equipment used for primary crushing is stone jaw crusher machine.

获取价格

How to Get Started in Concrete Crushing and Rock Crushing

Cone crushers or impact crushers are preferred for secondary and tertiary rock crushing, because they are effective at producing a very fine, uniform aggregate material. Screen your aggregate. During the concrete crushing or stone crushing process, the material is broken down into smaller and smaller pieces of various sizes.

获取价格

Crushing and Screening Handbook - AusIMM

TABLE OF CONTENTS Chapter Subject / section name Preface Table of Contents Metso’s Mining and Construction Technology 1 Quarry Process + Process Integration and Optimization (PIO) 2 Feeders 3 Crushing Equipment 3 C-Series Jaw Crushers 3 Superior MK-II Primary Gyratory Crushers 3 GP Series Cone Crushers 3 MP Series Cone

获取价格

Primary Crushing - 911 Metallurgist

2016/2/26 The term “primary crusher,” by definition, might embrace any type and size of crushing machine. The term implies that at least two stages of crushing are involved, but in many cases the machine which performs the function of initial crusher is the only crusher in the plant.

获取价格

Stone Crusher Machines In Philippines - For Different

The primary crushing stage aims to reduce the size of large rocks, ores, or other materials to a size suitable for further processing. The material is typically in its natural state and has not undergone any prior treatment,

获取价格

How to Get Started in Concrete Crushing and Rock

Cone crushers or impact crushers are preferred for secondary and tertiary rock crushing, because they are effective at producing a very fine, uniform aggregate material. Screen your aggregate. During the concrete

获取价格

Crushing and Screening Handbook - AusIMM

TABLE OF CONTENTS Chapter Subject / section name Preface Table of Contents Metso’s Mining and Construction Technology 1 Quarry Process + Process Integration and Optimization (PIO) 2 Feeders 3 Crushing Equipment 3 C-Series Jaw Crushers 3 Superior MK-II Primary Gyratory Crushers 3 GP Series Cone Crushers 3 MP Series Cone

获取价格

Primary Crushing - 911 Metallurgist

2016/2/26 The term “primary crusher,” by definition, might embrace any type and size of crushing machine. The term implies that at least two stages of crushing are involved, but in many cases the machine which performs the function of initial crusher is the only crusher in the plant.

获取价格

Primary Crusher Selection Design - 911 Metallurgist

2015/12/23 How you select your primary crusher will be based on factors like moisture content, maximum rock lump size, material density SG, abrasion index, degradability and it being prone to dusting or not. The crusher capacities given by manufacturers are typically in tons of 2,000 lbs. and are based on crushing limestone

获取价格

The Ultimate Guide to Rock Crushers Mellott

2024/5/30 So, let’s embark on this journey to understand rock crushing equipment better. Understanding Rock Crushing Equipment Rock crushing equipment is a broad term. It refers to any machine that reduces large rocks into smaller pieces. These machines work by applying force to break rocks. They are essential in industries like mining and

获取价格

Crusher - Wikipedia

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust.. Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be

获取价格

Crushing in Mineral Processing - Eastman Rock Crusher

2020/4/20 What equipment are used in crushing process? In the pre-industrial era, crushers were usually hand-held stones. The weight of the stone would help give the user more power. Querns and mortars are examples of the earliest crushers. Nowadays, machinery used for crushing usually hold materials between two solid surfaces that are

获取价格

Types Of Rock Crushers And When To Use Them - Mellott

2023/1/16 Crushing helps to reduce the size of mined material, making it easier to process and transport. Rock crushers come in three main types: primary, secondary, and tertiary crushers. Primary Rock Crushing; Primary rock crushers are typically used for the initial stage of crushing large rocks and objects into more manageable sizes. They

获取价格

Primary Crusher - an overview ScienceDirect Topics

Handbook of Conveying and Handling of Particulate Solids. G. Lodewijks, ... A. Newman, in Handbook of Powder Technology, 2001 2.1 The primary crusher. The primary crusher is located in the quarry and consists of a McLanahan 48″x72′ Shale King Crusher rated at 1,000 TPH (Tons Per Hour). The driving flywheel has a diameter of 2.5 meters and is

获取价格

Understanding the Different Types of Crushers Agg-Net

2018/9/10 Jaw crushers are mainly used in primary crushing stages and are rarely used for secondary crushing. As a compression crusher, this type of machine generally produces the coarsest material because it breaks the rock along its natural lines of weakness. Jaw crushers are an excellent primary stage solution to prepare rock for

获取价格

Primary Crusher Optimisation for Improved Comminution

the primary crusher. DEFINITION The primary crusher selection is the key to the success of any mining operation that involves the reduction in size of the ore. The crushing plant can be provided with almost any type of primary rock crusher. The rock/ore determines the type of crusher. The plant capacity determines the size of the crusher.

获取价格

Jaw crushers, Stationary Jaw crusher series - SRP

Sandvik Jaw crushers come with everything you need for plug-and-play primary crushing operations. Each jaw crusher comes with feed hopper, feed hopper interface, drive and subframe with v-belt guard and motor bracket, our unique guarding retraction arrangement and toggle plate stop.

获取价格

Stone Crushers: A Technical Review on Significant Part of

2022/5/14 A single type of crusher is not sufficient enough to convert the large size rock into required size stone. So, the crushing process involves primary, secondary and tertiary crushers during the whole crushing cycle to achieve the required dimension. ... 2.1 Primary Crusher. Primary crushers are heavy duty rugged machines used for

获取价格آلة مطرقة

محطم مبيعات ميانمار في بريسبان

صخرة عالية الأداء الفك محطم

محطات تكسير الصخور

الكسارات المتنقلة الحجر

المطاحن المطرقة بروكس

تستخدم آلة تكسير الحجر في مصر

قيمة التكسير القياسية للركام

gold mining development contact management

التركيز في معالجة النحاس

سوق الالات الثقيلة بوكلين في الجزاءر

كسارة محطة متنقلة المعلمة

نموذج آلة طحن لا ورقة بيانات

تشغيل الكسارة صيانة

الحجر الجيري المسحوق أستراليا

كيفية العثور على الكسارة الصدمية الثقيلة المستخدمة

كسارة لمعالجة نفايات البناء

معدات ثقيله للبيع في اليابان معدات ثقيله للبيع في اليابان كوماتسو كات

آلة تعدين الذهب عمان

تصميم مطحنة الكرة Ls

مطحنة رطبة أوتساف في بنغالور

stone crusher video control system

ما هو الرمل معدات الرمل

مصنعي مصنع طحن الرماد

ماكنة تدوير قضبان الحديد

كسارة الصخور اليدوي لآلة كسارة الحجر الذهبي

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20