الحار منتجات

ملكنا الإخبارية

iron ore magnetic separation method

Magnetic separation: A review of principles, devices, and

Conventional magnetic separation devices are widely used for the removal of tramp iron from a variety of feed materials and for the beneficiation of ferrous ores. These devices

获取价格

Magnetic Separation SpringerLink

2023/4/13 Magnetic separation is widely used. All materials with magnetism in the magnetic field can be treated by magnetic separation, which is the main method to

获取价格

Separations Free Full-Text Application of Magnetic

2024/4/24 Magnetic separation technology is a physical separation method that uses the differences in magnetism between matter to separate them from each other by different motion behaviors in a non-uniform

获取价格

Magnetic Separation: Principles, Devices, and

2023/10/30 With the increasing decline in ore quality and the increasing demand for high-quality raw materials, such magnetic separation technologies with higher separation performance are

获取价格

Physical separation of iron ore: magnetic separation

2022/1/1 The first SLon-2500 vertical ring-pulsating high gradient magnetic separator was designed and built up in 2006. It was installed at the tails dam of Hai Nan Iron

获取价格

Developments in the physical separation of iron ore: Magnetic ...

2015/12/31 Therefore, the ferromagnetism of minerals allows the use of magnetic separation as an iron concentration method [52] [53][54]. As mentioned by Sampaio et

获取价格

Increasing efficiency of iron ore magnetic separation by using ...

The research aims to improve efficiency of iron ore magnetic separation by integrated application of ultrasonic technologies to enhancing technological and structural

获取价格

Ultimate Guide for Magnetic Separation Method

2022/4/26 Magnetic separation is the main beneficiation method for iron ore processing. After the beneficiation of iron ore, the grade is improved, and the content of silica and harmful impurities is reduced,

获取价格

How Magnetic Separation Optimizes Sorting and Process

ply it in a way that creates efficiencies and reduces costs. When done correctly, magnetic separation is a simple, inexpensive method to recover minerals from host ore. r remove

获取价格

An efficient and green method to separate iron and manganese

2022/4/1 Chemical phase analysis was used to determine the distribution of iron and manganese elements in the ore, and the results are shown in Tables 2 and 3. Table 2 shows that the iron element is mainly distributed in hematite; the distribution rate of iron is as high as 98.18%, and the contents of magnetic iron, iron sulfide, and iron carbonate

获取价格

High-Grade Ferronickel Concentrates Prepared from

2023/11/11 In a word, after carbothermal reduction and magnetic separation, high-grade magnetically separable ferronickel concentrates were successfully prepared by using laterite nickel ore, anthracite, and

获取价格

Developments in the physical separation of iron ore: magnetic ...

2015/1/1 Typical flow sheets for iron ore separation9.4.1. Major principles for selection of separation methods. For low-grade iron ore separation, it is very important to develop an optimized flow sheet to achieve the best iron concentrate grade and iron recovery while keeping the cost as low as possible. The major principles are as follows: 1.

获取价格

Wet High Intensity Magnetic Separation - 911 Metallurgist

2017/6/4 WHIM is the short acronym for Wet High Intensity Magnetic Separation. At present, most U.S. iron raw materials are produced from magnetic taconites, which are ground to a nominal minus 270 mesh (53 micrometers), beneficiated by wet low-intensity magnetic separation, and pelletized. The taconite ore bodies generally contain 19 to 25

获取价格

Developments in the physical separation of iron ore: magnetic ...

2015/1/1 To address this problem, a novel centrifugal dry magnetic separation (cDMS) method was proposed to enhance the separation efficiency for fine particles. In this investigation, the cDMS mechanism was theoretically analyzed and the cDMS performance for a pure magnetite-quartz mixture was evaluated. ... Advancing iron ore slimes

获取价格

Physical separation of iron ore: magnetic separation

2022/1/1 This chapter introduces the principle of how low-grade iron ores are upgraded to high quality iron ore concentrates by magnetic separation. Magnetite is the most magnetic of all the naturally occurring minerals on earth and can be readily extracted by low-intensity magnetic separators from magnetite ores.

获取价格

Recovery of iron from pyrite cinder by suspension magnetization ...

Semantic Scholar extracted view of "Recovery of iron from pyrite cinder by suspension magnetization roasting-magnetic separation method: Process optimization and mechanism study" by Wenbo Li et al. ... Suspension magnetizing roasting-magnetic separation technology was used to extract iron from fine-grained complex hematite ore.

获取价格

An efficient and green method to separate iron and manganese

2022/4/1 Larger cracks promoted adsorption of flotation reagents and the separation between iron mineral and P-bearing mineral. Therefore, this innovation contributes to improving the magnetism of weakly magnetic iron ore and enhances the separation effect of Fe extraction and dephosphorization. It has good industrial application potential.

获取价格

Iron recovery from lead smelting water-quenching slag by

2024/4/15 This results in an increase in the grade of the iron concentrate and the small portion of the metallic iron is ground too finely with the chondrites into the magnetic separation tailings. At the grinding time of 45 min, the magnetic separation iron ore concentrate exhibits improved iron grade and recovery rate (93.61% and 90.71%,

获取价格

Recovery of iron from pyrite cinder by suspension magnetization ...

2024/3/20 The results showed that the raw ore for PyC has an iron grade of 56.47%, and after SMR-magnetic separation, magnetic concentrate with an iron grade of 63.24% and an iron recovery of 95.05% could be achieved under conditions of a roasting temperature of 480°C, a reductant concentration of 30% (CO: H 2 = 1:3), a roasting time

获取价格

Iron Ore Magnetic Separation - 911 Metallurgist

2017/4/20 Magnetic Iron Ore Resources. ... 1/16 in., or lower will require the wet method of separation, while for larger sizes the dry method can be most profitably employed. The exact size that determines the method to be used is also somewhat dependent on the amount of moisture contained. Quite fine sizes can be separated if

获取价格

Magnetic Fluid Separation SpringerLink

2023/5/14 Magnetic fluid separation is a separation method that takes magnetic fluid as the separating medium and makes different minerals suspended in layers in the magnetoelectric field and gravity field in accordance with their magnetic intensity (or electric property contrast) and density under the action of an external magnetic field,

获取价格

Centrifugal dry magnetic separation of fine magnetic minerals

2024/4/5 A full-scale cDMS-1000 separator [23] was particularly developed to separate a fine-grained magnetite ore, to confirm the feasibility of this new DMS method.The separator uses a permanent magnet system and its magnetic induction is adjustable. The separator operates in a continuous model, with the processing capacity

获取价格

Development of roasting-acid leaching-magnetic separation

2022/10/16 Utilization of plentiful fine-disseminated iron oxide ores resources attracted increasing attention in these years due to the depletion of easy-dressing iron ore reserves. In this paper, an improved Fe recovery method from the refractory fine-grained iron ores was proposed, and iron can be stepwise recovered by microwave-assisted

获取价格

Iron Ore Magnetic Separation - 911 Metallurgist

2017/4/20 Magnetic Iron Ore Resources. ... 1/16 in., or lower will require the wet method of separation, while for larger sizes the dry method can be most profitably employed. The exact size that determines the

获取价格

Magnetic Fluid Separation SpringerLink

2023/5/14 Magnetic fluid separation is a separation method that takes magnetic fluid as the separating medium and makes different minerals suspended in layers in the magnetoelectric field and gravity field in accordance with their magnetic intensity (or electric property contrast) and density under the action of an external magnetic field,

获取价格

Centrifugal dry magnetic separation of fine magnetic minerals

2024/4/5 A full-scale cDMS-1000 separator [23] was particularly developed to separate a fine-grained magnetite ore, to confirm the feasibility of this new DMS method.The separator uses a permanent magnet system and its magnetic induction is adjustable. The separator operates in a continuous model, with the processing capacity

获取价格

Development of roasting-acid leaching-magnetic separation

2022/10/16 Utilization of plentiful fine-disseminated iron oxide ores resources attracted increasing attention in these years due to the depletion of easy-dressing iron ore reserves. In this paper, an improved Fe recovery method from the refractory fine-grained iron ores was proposed, and iron can be stepwise recovered by microwave-assisted

获取价格

Investigation of Efficiency of Magnetic Separation Methods for ...

2019/5/15 In this research, the efficiency of magnetic separation methods for processing of a low-grade iron pigments ore (red ochre) has been studied. Based on the mineralogical analyses (XRD), thin section and polish studies, the reserve is an iron sedimentary deposit with an average Fe grade of %31.3. The most valuable minerals are

获取价格

An Novel Method for Iron Recovery from Iron Ore Tailings with

2020/3/3 ABSTRACT Iron ore tailing is currently one of the most important secondary mineral resources. Pre-concentration followed by magnetization roasting and magnetic separation process was well recognized to be very effective in recycling iron from iron ore tailings. An iron concentrate containing 66.35% Fe with a total recovery of 57.74% was

获取价格

Increasing efficiency of iron ore magnetic separation by

into iron ore magnetic separation; methods and means of operative control over physical-mechanical and chemical-mineralogical properties of iron ore slurry, as well as methods of improving indices of iron ore magnetic separation. The mathematical model of dynamic effects of high- energy ultrasound impacting solids in the slurry flow is ...

获取价格

The six main steps of iron ore processing - Multotec

When iron ore is extracted from a mine, it must undergo several processing stages. ... This step is repeated two or three times, depending on the desired liberation and iron concentration. 6. Magnetic separation The concentrate collected from the middlings and tails after spiral gravity separation has a lower iron concentration (magnetite) so ...

获取价格

Magnetic Separation Method - 911 Metallurgist

2015/6/24 Magnetic separation has two major applications in mineral processing plants: The removal of tramp iron (which would deleteriously affect subsequent processes) from an ore stream. This is usually achieved by a low intensity magnet suspended above, or at the head of, a conveyor. Separation of magnetic minerals from less magnetic minerals.

获取价格

Magnetic Separation - an overview ScienceDirect Topics

6.3.1 Application of carbon dots in magnetic separation. Magnetic separation is an efficient separation technique in which CDs and iron oxide (Fe 3 O 4) nanocrystals are utilized as doped material embedded in mesoporous silica beads. Silica microbeads are selected due to nano-sized pores, hydrophobic interactions with doped materials, and a ...

获取价格

Magnetic Separator - an overview ScienceDirect Topics

Developments in the physical separation of iron ore. D. Xiong, ... R.J. Holmes, in Iron Ore, 2015 9.5.2 Utilization of subeconomic iron ores. As magnetic separators progress toward larger capacity, higher efficiency, and lower operating costs, some subeconomic iron ores have been utilized in recent years. For example, magnetite iron ore containing only

获取价格

Developing high gradient magnetic separators for greener

2023/12/1 As the primary beneficiation method for iron ore, magnetic separation improves ore grade, reduces silica and harmful impurity content, and facilitates the smelting process [28], [32], [33]. Utilizing magnetic separation is an important step towards achieving green and low-carbon steel production.

获取价格

Novel method for iron recovery from hazardous iron ore tailing

2018/2/10 In this paper, a novel method to recover iron from iron ore tailing (IOT) was studied. The method was induced with carbothermic reduction, followed by magnetic flocculation separation (MFS) and conventional magnetic separation (CMS). The effects of reduction temperature, as well as the amount of coal and sodium carbonate on iron

获取价格

Iron recovery and dephosphorization behaviors from high

2024/5/30 With the depletion of high-quality iron ore resources, high-phosphorus oolitic hematite (HPOH) has attracted great attention due to its large reserve and relatively high iron content. However, HPOH is very difficult to be used in ironmaking process due to its special structure. A two-step method of gas-based direct reduction and magnetic

获取价格چه تجهیزات معدنچیان با استفاده از

آلات البناء في صحار

المعلمات السيطرة على عملية الطحن

ايباي الحجر كسارات

شن و ماسه گزارش پروژه تولید

تكلفة مصنع الاسمنت 1000 طن يوميا

المصنعين مطحنة الكرة في الجزائر

كسارة فكية pex في بروناي

تعدين الفحم في بنسلفانيا

قائمة مصانع خام الحديد في جميع أنحاء العالم

صور كسارات حفار ولوادر

قم ببناء كسارة الصخور

قدرة عالية أفضل جودة كسارة الفك

ما هي المعدات اللازمة لتعدين ركاز الحديد

تشاينا موبايل محطم

شاشات الاهتزاز الفرز البولي يوريثين

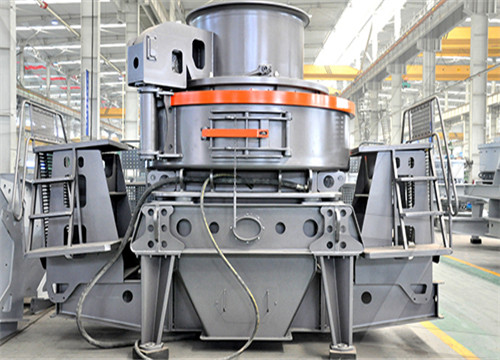

Mobile Crushing Station Jaw Crusher

مبيعات كسارة فكية في دبي

آلات حجرية مستعملة في الجزائر

اندونيسيا الحجر

كسارة الحجر الفك الثابت

العوامل المؤثرة على المطحنة الكروية

مصنع هالة دلو البوكسيت الفك محطم

تصنيع الذهب على نطاق صغير المملكة العربية السعودية

سعر مطحنة طحن المعادن في أستراليا

قائمة فحص محطة تحلية خام الحديد

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20