الحار منتجات

ملكنا الإخبارية

cone crusher design 2 the best

Cone crusher basics in 4 minutes

Cone crusher basics in 4 minutes. This is the starting point for understanding how cone crushers work – and how they can make your mine or quarry more productive. Elsewhere on the site you can find

获取价格

Cone Crusher - an overview ScienceDirect Topics

The cone crusher is a modified gyratory crusher, and accordingly many of the same terms including gape, set, and throw, apply. The essential difference is that the shorter spindle

获取价格

A review of modeling and control strategies for cone crushers in

2021/8/15 The choke level is a function of the liner design, eccentric speed, stroke and CSS. It has been reported that cone crushers work best when choke fed (Bearman

获取价格

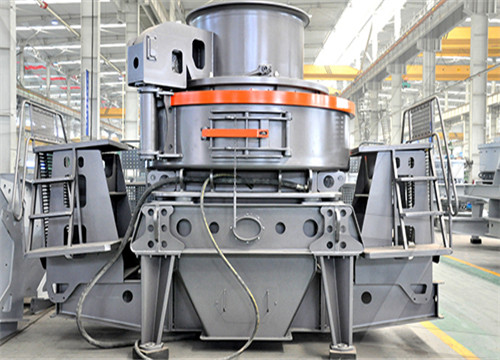

Cone Crushers (Parts of a Cone Crusher) Explained

Cone Crusher Components. Top Shell Spider Cap Assembly. The feed is fed by conveyors to a feed bin above the vertically mounted cone crusher. Feed enters the crusher via an opening in the upper shell. Depending

获取价格

Cone crushers - for demanding crushing needs - Metso

Cone crushers are very suitable for size reduction and shaping in the downstream of a crushing circuit. They reduce the material in a crushing cavity by continuous compression between a fixed element (bowl liner)

获取价格

Maximize your cone crusher productivity Pit Quarry

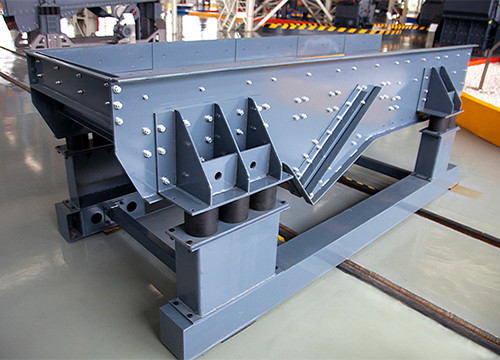

2017/4/28 Providing better crusher feed control for the cone crusher through the use of surge piles, hoppers and variable-speed feeding devices such as belt conveyors or vibrating pan feeders can easily increase

获取价格

4 Types of Cone Crushers: What Are They and How to

2023/4/28 The crushing station has two types: crawler type and tire type. Learn more about the Mobile Crushing Station. The mobile cone crusher is not restricted by the site. It can be easily and flexibly moved

获取价格

(PDF) Cone Crusher Performance - ResearchGate

2015/5/13 cone crusher already at the design stage would enable improvements without full-scale testing. Crushers already existing in crushing plants can be investigated and the best operating parameters ...

获取价格

New developments in cone crusher performance optimization

2009/6/1 Process optimization. 1. Crusher design evolution. Compression cone crusher designs today have evolved from the simple cone crusher first developed in the

获取价格

HP Series cone crushers – High performance

HP Series cone crushers bring together the optimal combination of crusher speed, throw, crushing forces and cavity design. As the name suggests, these proven

获取价格

(PDF) Design of Impact stone crusher machine

2019/5/31 Based on the mechanism used crushers are basically of three types; namely, Cone crusher, Jaw crusher, and Impact Crusher. The main objective is to design impact stone crusher.

获取价格

Primary Crusher Selection Design - 911 Metallurgist

2015/12/23 How you select your primary crusher will be based on factors like moisture content, maximum rock lump size, material density SG, abrasion index, degradability and it being prone to dusting or not. The

获取价格

Understanding the Cone Crusher Working Principle:

2023/2/23 A cone crusher is a powerful tool used in the mining, aggregate, and construction industries to crush materials into smaller pieces. ... To ensure the best performance of the cone crusher, it is

获取价格

HP Series cone crushers – High performance

® HP Series™ cone crushers The world's most popular modern cone crushers HP Series cone crushers bring together the optimal combination of crusher speed, throw, crushing forces and cavity design. As the name suggests, these proven and reliable universal crushers deliver High Performance in quarrying and mining applications.

获取价格

Raptor® Cone Crushers for Mining and Aggregate -

Raptor® cone crushers. RAPTOR® 250. The R250 is our smallest and . lightest weight cone crusher. Its low-profile design makes it a perfect fit for a portable and mobile chassis. RAPTOR® 450. Our R450 model is the . largest of our crushers that . do not require a backliner. It processes more usable and saleable aggregate per ton than ...

获取价格

How Does a Cone Crusher Work and What is It? - JXSC

2024/3/15 Best for high-volume crushing of hard materials with need for precise size control. ... Size Limitations: A cone crusher’s design places a limit on the largest raw material sizes that it can process. Overly large materials can clog pipes or necessitate multiple crushing steps in advance. This increases the cost and processing time overall.

获取价格

QM Series Cone Crushers Propel Industries

CONE CRUSHER QM SERIES . Propel QM series Cone Crushers combine the best power utilization per cone diameter, cavity design of higher density, optimized crusher speed and efficient throw.

获取价格

Cone Crushers – MEKA

MEKA cone crushers are an excellent choice as secondary crushers in combination with a jaw or a primary gyratory crusher or in the third or fourth crushing stage. ... • The design also results in low maintenance costs. ... MEKA uses cookies to improve the services provided and to provide you with the best experience on the website.

获取价格

4 Types of Cone Crushers: What Are They and How to Select

2023/4/28 The single-cylinder cone crusher is a medium and fine crusher with better performance than the Symons cone crusher. It is suitable for crushing soft ores and weathered ores with large output. Many users like to use it to crush granite, basalt, river pebbles, limestone, dolomite, and diabase with a particle size of less than 560 mm.

获取价格

MCC Series Cone Crusher Minyu Machinery Corp.

2023/8/7 As a professional cone crusher manufacturer and supplier, we also offer Customized Crushers, Jaw Crushers, Impact Crushers, Crushing Plant Design, Portable Crushers, and more. Usually, a cone crusher is installed in a crushing circuit as a secondary crusher. Pre-crushed material fed in via the top of the cone crusher flows

获取价格

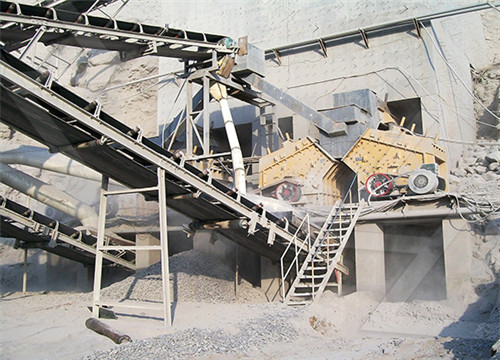

Crushing Plant Flowsheet Design-Layout - 911 Metallurgist

2016/3/10 Short Head (Tertiary) Cone Crusher (Refer to Fig. 2): The Short Head Cone crusher is normally applied as a third stage crusher in plants designed for three or four stages of crushers. Feed opening and product size ranges for the various models of Short Head Cone crushers are as follows: a) Maximum Feed Opening — 250MM (10 In.)

获取价格

CONE CRUSHER MODELLING AND SIMULATION - Chalmers

mining industry. The cone crusher concept was developed in the early 20th century and the basic layout of the machine has not changed dramatically since then. Efforts aimed at developing the cone crusher concept further involve building expensive prototypes hence the changes made so far are incremental by nature.

获取价格

® HP500™ cone crusher - Metso

® HP500™ cone crusher is a versatile rock crushing machine often used in aggregates production, quarrying applications and mining operations. ... from plant design expertise to equipment, parts and services for every stage of your process. ... The efficient crushing action of ® HP500™ gives it the best power utilization ...

获取价格

Gyratory Crushers - 911 Metallurgist

2016/2/17 The below image shows a sectional view of a typical gyratory crusher.This type of machine is, by virtue of chronological priority, known as the “standard” gyratory crusher. Although it incorporates many refinements in design, it is fundamentally the same crusher that first bore the name of “gyratory”; its crushing chamber is very

获取价格

Crushing Plant Flowsheet Design-Layout - 911 Metallurgist

2016/3/10 Short Head (Tertiary) Cone Crusher (Refer to Fig. 2): The Short Head Cone crusher is normally applied as a third stage crusher in plants designed for three or four stages of crushers. Feed opening and product size ranges for the various models of Short Head Cone crushers are as follows: a) Maximum Feed Opening — 250MM (10 In.)

获取价格

CONE CRUSHER MODELLING AND SIMULATION - Chalmers

mining industry. The cone crusher concept was developed in the early 20th century and the basic layout of the machine has not changed dramatically since then. Efforts aimed at developing the cone crusher concept further involve building expensive prototypes hence the changes made so far are incremental by nature.

获取价格

® HP500™ cone crusher - Metso

® HP500™ cone crusher is a versatile rock crushing machine often used in aggregates production, quarrying applications and mining operations. ... from plant design expertise to equipment, parts and

获取价格

Gyratory Crushers - 911 Metallurgist

2016/2/17 The below image shows a sectional view of a typical gyratory crusher.This type of machine is, by virtue of chronological priority, known as the “standard” gyratory crusher. Although it incorporates many refinements in design, it is fundamentally the same crusher that first bore the name of “gyratory”; its crushing chamber is very

获取价格

A Comprehensive Guide to Cone Crusher Types - AGICO

2023/2/15 The single-cylinder hydraulic cone crusher is a compact and simple design that is ideal for smaller operations and crushing applications. It uses hydraulic cylinders to adjust the size of the crushing chamber and control the discharge opening. The single-cylinder hydraulic cone crusher is known for its high efficiency and low

获取价格

Selecting the right crusher for your operations - Quarry

2020/3/19 Best suited for secondary crushing applications, cone crushers are designed to crush pre-sized materials, usually 100mm, 150mm or 200mm, depending on the size of the crusher. Cone crushers can form finished products down to 12mm or less. Like the jaw crusher, the cone crusher provides a relatively low cost crushing solution, but

获取价格

Crushing and Screening Handbook - AusIMM

the crusher and scalp out fi nes. Primary gyratory crushers – ideally suited to all high-capacity primary hard rock crushing applications. Jaw crushers – we have more installed jaw crushers than anyone in the world. The lead-ing choice due to their high reduction ratio and heavy duty design. Cone crushers – capacities available to suit all

获取价格

Cone Crusher Sizing Selection To Maximize Production

2023/8/28 Proper sizing and selection of cone crushers are essential to maximize productivity and efficiency in aggregate and mining operations. Cone crushers are indispensable crushing machines, but their output capacity depends heavily on making the right design choices.Here are some factors to consider: Consider The Type Of Material

获取价格

Our Range of Trio® Cone Crushers Weir

A cone crusher is a type of crusher that is commonly used for processing rocks in mining and aggregate applications. These crushers use compression force to break large rocks (and other materials) into smaller rocks, gravel and sand.. Since its inception, the live-shaft cone crusher design is highly regarded as the benchmark for reliable hard rock cone

获取价格

AMIT 135: Lesson 5 Crushing – Mining Mill Operator Training

Cone Crushers. Originally designed and developed by Symons (1920). Similar to gyratory except the spindle is supported at the bottom of the gyrating cone instead of being suspended. The head to depth ratio is larger than gyratory crushers. Cone angle are flatter and the slope of the mantle and concaves are parallel.

获取价格

Cone Crusher SpringerLink

2023/5/3 Cone crusher is a type of crushing equipment whose crushing cone rotates in the conical cavity within the shell to realize intermediate crushing or fine crushing of material through squeezing, bending, shearing, and impacting. ... Its design combines the features of spring cone crusher and single-cylinder hydraulic cone crusher: A hydraulic ...

获取价格

Cone crusher modelling and simulation using DEM

2016/1/1 The cone crusher is the most common machine for secondary and tertiary crushing stages in both the aggregates industry and minerals processing comminution operations. The performance and efficiency of these machines are hence of great importance to the industry. ... It has been found that the bimodal distribution gives the

获取价格

“Computer Aided Design of Jaw crusher” - 911 Metallurgist

1.1 Single toggle blake type jaw crusher 3 1.2 Double toggle blake type jaw crusher 4 1.3 Dodge Type Jaw crusher 5 1.4 Schematic Diagram of a jaw crusher 8 2.1 Equivalent four bar mechanism diagram 13 2.2 Graph: Crank angle

获取价格

Sandvik CS660 Cone Crusher For High Capacity Applications - SRP

It also has a robust crusher design, adjustable eccentric throw, and a constant intake opening. This crusher is suitable for a high-capacity secondary crushing application. CS660 ... Sandvik CS660 cone crusher has a large intake capability and a high capacity in relation to its size. The Automatic Setting Regulation control system (ASRi ...

获取价格صانع الرمل في ليبيا

تزييت هيدروستاتيكي

آلات التعدين المعادن روسيا

مصنع 60tph كسارة متنقلة

تستخدم كسارة مطرقة صغيرة

كسارة متنقلة مجمعة أفضل جودة

الولايات المتحدة الأمريكية خام البوتاسيوم مطحنة الكرة

الكثافة مقابل الثقل النوعي

قطع الغيار الفك لوحة الفك محطم

كسارة فكية تستخدم في مصنع الفحم الليبي

كيفية فصل غبار الذهب عن الكربون

التوليد المشترك للطاقة في مصنع الأسمنت

آلة محطم فصيلة

كسارة الحديد الزهر المستخدمة لعبة كسارة الصخور

الاستشاريين الحديد محطة إثراء خام في الهند

الحصول على تصريح محطة كسارة في جنوب افريقيا العمود المرفقي

سعر كسارة الحجر 30 طن للتأجير في كارديف

مليون ذهب أفغانستان

قائمة مطحنة الكرة في السويد إثيوبيا

طاحونة تايجر

300tph الفك كسارة الحجر المخروطي

ارتداء قطع غيار لمصادم كليمان

مطحنة الحبيبات الصغيرة في المملكة المتحدة

مطحنة الطوابع العتيقة للبيع

آمریکا شرکت تجهیزات استخراج معادن

دستگاه سنگ شکن معدن استفاده می شود

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20