الحار منتجات

ملكنا الإخبارية

theory of jaw crusher operation

How A Jaw Crusher Works - YouTube

2020/2/19 Jaw Crushers are most often used as the first stage in the size reduction of many different materials in a wide range of applications. They use compressive f...

获取价格

Jaw Crusher SpringerLink

2023/6/21 The moving jaw rotates around the eccentric axis as well as swings around the same center (Fig. 2).By removing the moving jaw suspension shaft and the front

获取价格

Jaw Crusher Working Principle – StudiousGuy

A fundamental model of an industrial-scale jaw crusher

2017/5/1 Jaw crushers are mainly used in operations where the volumes involved do not justify a gyratory crusher. The throughput of a jaw crusher ranges between 30

获取价格

Jaw Crusher - ScienceDirect

2016/1/1 This mathematical concept of jaw crusher operation has been developed for modelling and subsequent throughput prediction from jaw crushers (see Chapter

获取价格

(PDF) DESIGN AND OPERATIONS CHALLENGES OF A

2017/6/30 A review on the design and operations challenges of a single toggle jaw crusher is presented. Strength and fracture toughness of the material to be crushed are intrinsic properties that determine ...

获取价格

Investigation of the jaw crusher operation with backlash

2021/7/1 It was experimentally established that the use of pneumatic devices for backlash elimination in the interfaces of the moving links, using journal bearings, during

获取价格

Failure rate analysis of Jaw Crusher: a case study

1.2 The jaw crusher. Crushing is the first stage of size reduction of mined rocks. Primary crushers are heavy-duty machines, used to reduce the run-of-mine (ROM) ore down to a size suitable for easy handling. A line

获取价格

The Mechanics of Crushing: Understanding the Jaw Crusher

2023/10/16 The jaw crusher exerts pressure on the materials that are to be crushed, compressing them between two cones. This action breaks the materials into smaller

获取价格

Roll Crusher - an overview ScienceDirect Topics

Roll Crushers. In Mineral Processing Design and Operations (Second Edition), 2016. 6.1 Introduction. Roll crushers consist of two or more adjacent rolls placed parallel to each other and rotated in opposite directions. Single roll crushers are also available which rotate a single roll against a fixed breaker plate. Mineral or rock particles placed between the

获取价格

What Is A Jaw Crusher - MEKA

Jaw crushers are generally defined by their opening size. For example, a 900x650 mm crusher refers to a crusher with an inlet measuring 900 mm by 650 mm. The main parts and main technical parameters of a jaw

获取价格

How it Works: Crushers, Grinding Mills and Pulverizers

2017/6/2 Table Source: Wikipedia (Crushers) Cone crushers use a spinning cone that gyrates in the bowl in an eccentric motion to crush the rock between the cone surface, referred to as the mantle, and the

获取价格

How Does a Jaw Crusher Work? A Simple Guide - JXSC

2024/2/5 For large, heavy-duty operations, a double-toggle jaw crusher is often the go-to. For smaller, less intensive tasks, a single toggle might be more appropriate. How Crushing Forces are Applied. In jaw crushers, the crushing force is generated by the movement of the movable jaw plate towards the fixed jaw plate. This force is a result of

获取价格

Investigation of the jaw crusher operation with backlash eliminators ...

2021/7/1 Investigation of the jaw crusher operation with backlash eliminators. A G Nikitin 1, A V Abramov 1, I A Bazhenov 2 and V V Dorofeev 3. Published under licence by IOP Publishing Ltd IOP Conference Series: Earth and Environmental Science, Volume 823, International Scientific and Research Conference on Knowledge-based technologies in

获取价格

AMIT 135: Lesson 5 Crushing – Mining Mill Operator Training

Typical Jaw Crusher Operation. Product size is smaller than the open side setting. Typical operating and performance characteristics: Top Feed Size = 0.8- 0.9 x Gape: Reduction Ratio = 4:1 to 7:1: Throw = 1 – 7em: Speed = 100 – 359 rpm: Frequency of Stroke = 100 – 300 cycles/minute .

获取价格

(PDF) DESIGN AND OPERATIONS CHALLENGES OF A SINGLE TOGGLE JAW CRUSHER ...

2017/6/30 A review on the design and operations challenges of a single toggle jaw crusher is presented. Strength and fracture toughness of the material to be crushed are intrinsic properties that determine ...

获取价格

Understanding Jaw Crusher Parts and Their Functions - AGICO

2023/2/23 Introduction: Jaw crushers are powerful machines that are widely used in the mining, quarrying, and recycling industries. These machines are designed to crush large rocks and ores into smaller pieces for further processing. A jaw crusher consists of a fixed jaw and a movable jaw, with the latter being driven by an eccentric shaft that moves the

获取价格

Jaw Crusher Diagram: Simplified Guide - JXSC

2024/2/18 A jaw crusher is an indispensable tool in the mining and construction industries, known for its power to fragment hard materials such as rock and minerals. ... This back and forth, the reciprocity of the moving parts, stresses the importance of bearing choice in the swing jaw’s operation. High-quality bearings, embedded within the steel ...

获取价格

View of Jaw crusher using in experiments. - ResearchGate

In this study, the effects of three different choke feed level (1/1, 1/2, and 1/4) and four different effective reduction ratios (2.5, 5, 10, and 20) depend on the capacity of the crusher of the ...

获取价格

Jaw Crusher - ScienceDirect

2016/1/1 This mathematical concept of jaw crusher operation has been developed for modelling and subsequent throughput prediction from jaw crushers (see Chapter 10). 4.4. Jaw Crusher Capacity Estimation. The capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation.

获取价格

The Ultimate Guide to Jaw Crushing Machines: Types More Tips

2023/2/21 Recycling: Jaw crushers can also be used to recycle concrete, asphalt, and other construction materials. Best practices for jaw crusher operation and maintenance. Proper operation and maintenance of your jaw crusher can help ensure that the machine operates efficiently and effectively. Here are some best practices to keep in

获取价格

EXPERIMENT:- Jaw Crusher

THEORY: The Crusher has a fixed jaw and a moving jaw pivoted at the top with the crushing faces themselves formed of manganese steel. ... operation should not be so high that a large quantity of fines is produced as a result of material being repeatedly crushed because it cannot escape sufficiently quickly. The angle of nip, the

获取价格

Impact Crusher Working Principle - 911 Metallurgist

2015/6/23 Starting from the base working principle that compression is the forcing of two surfaces towards one another to crush the material caught between them.Impact crushing can be of two variations: gravity and dynamic. An example of gravity impact would be dropping a rock onto a steel plate (similar to what goes on into an Autogenous Mill).

获取价格

Jaw Crusher - ScienceDirect

2016/1/1 This mathematical concept of jaw crusher operation has been developed for modelling and subsequent throughput prediction from jaw crushers (see Chapter 10). 4.4. Jaw Crusher Capacity Estimation. The capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation.

获取价格

The Ultimate Guide to Jaw Crushing Machines: Types

2023/2/21 Recycling: Jaw crushers can also be used to recycle concrete, asphalt, and other construction materials. Best practices for jaw crusher operation and maintenance. Proper operation and

获取价格

EXPERIMENT:- Jaw Crusher

THEORY: The Crusher has a fixed jaw and a moving jaw pivoted at the top with the crushing faces themselves formed of manganese steel. ... operation should not be so high that a large quantity of fines is produced as a result of material being repeatedly crushed because it cannot escape sufficiently quickly. The angle of nip, the

获取价格

Impact Crusher Working Principle - 911 Metallurgist

观看视频0:342015/6/23 Starting from the base working principle that compression is the forcing of two surfaces towards one another to crush the material caught between them.Impact crushing can be of two variations: gravity and dynamic. An example of gravity impact

获取价格

Industrial Solutions Jaw crushers - ThyssenKrupp

low costs, minimum maintenance, ease of operation and maximum reliability. thyssenkrupp jaw crushers are mainly designed to crush medium-hard to very hard materials. When it comes to the crunch, crushing systems from thyssenkrupp ... 2 Jaw crushers 3. Single-toggle jaw crushers – design and operating principle Technical data Single-toggle ...

获取价格

Jaw Crusher SpringerLink

2023/6/21 The moving jaw rotates around the eccentric axis as well as swings around the same center (Fig. 2).By removing the moving jaw suspension shaft and the front toggle plate of simple pendulum jaw crusher, and suspending the moving jaw on eccentric shaft to combine the connecting rod and the moving jaw into whole, a compound pendulum jaw

获取价格

Jaw Crushers - FAQ - Comprehensive Jaw Crusher Guide

Central to the operation of all jaw crushers are two integral components: a fixed jaw and a movable or swing counterpart. These work in tandem, with the movable jaw executing a reciprocating motion that compresses and crushes rock or ore against the steadfast fixed jaw. This process occurs within the designated zone between the two jaws using ...

获取价格

(PDF) SIZE REDUCTION BY CRUSHING METHODS - ResearchGate

2017/3/4 The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling. [4, 5] crusher [4] The tie rod and compression spring ensure that the ...

获取价格

A fundamental model of an industrial-scale jaw crusher

2017/5/1 Jaw crushers are mainly used in operations where the volumes involved do not justify a gyratory crusher. The throughput of a jaw crusher ranges between 30 and 1200 tph (Wills and Napier-Munn, 2015). Jaw crushers have been modelled previously; in 1953, Gauldie conducted a performance study of the jaw crusher, including a capacity

获取价格

Jaw Crusher: Range, Working Principle, Application -

A jaw or toggle crusher consists of a set of vertical jaws, one jaw being fixed and the other being moved back and forth relative to it by a cam or pitman mechanism. The jaws are farther apart at the top than at the bottom, forming a tapered chute so that the material is crushed progressively smaller and smaller as it travels downward until it ...

获取价格

What is a Jaw Crusher and Selecting the Right One - Gilson Co.

Jaw crushers feature safe, simple operation and maintenance. Disadvantages of a Jaw Crusher. Jaw crushers can also have some disadvantages compared to other types of size reduction. Opposing jaw plates are less efficient at reducing materials that are tough, ductile, or soft instead of hard and brittle.

获取价格

Mechanical Operations Questions and Answers – Crushing

Explanation: The gyratory crusher involves the operation of both compression and impact at the same time, while jaw crusher only applies compression. 2. The feed size of gyratory crusher varies from ____

获取价格

Dynamics Analysis and Chaos Identification of Compound Pendulum Jaw ...

2022/12/24 A dynamic model of the working mechanism of a compound pendulum jaw crusher with clearance is established by the Lagrange multiplier method (LMD) based on the L-N contact force model and modified Coulomb friction force model. The correctness of the dynamic model is verified by MATLAB and Adams comparison simulation, and the

获取价格باور بوينت على استبدال الرمل مع الغبار المحجر

معدات كسارة الحجر المستخدمة في الولايات المتحدة الأمريكية في الهند

مصانع حفظات الأطفال في الصين

تصميم لفاصل الذهب بالطرد المركزي

مطحنة الكرة 0 طن في الساعة سعر التكلفة

مطحنة كسارة الصخور المحمولة الصغيرة

مصنع إثراء خام الحديد في كسارة الحجر في الهند

دليل شركات تصنيع معدات التعدين في قطر

طريقة استخراج الحجر الجيري في مصر

مستشار للاسمنت طحن مطحنة

Gyradisc كسارة عمود المناولة الوسيط الخارجي البطانة

مصنع التكسير المحمول المحمول مسبك الرمال

كم هو كسارة الفك 10 × 24

maquinaria de construccion mexico

كسارا ت في المانيا

أسماء المتعلقة بأعمال تكسير الحجارة

كيفية تركيب المطارق على كسارة kumbee

معدات تعدين الذهب للبيع الولايات المتحدة

رسم تخطيطي لمطحنة ريموند

رأى معدات شحذ

الة تكسير الحجر للبيع في المغرب مستعملة

الآلات المستخدمة لإزالة الألغام خام الكروم

تفاصيل حجر الصابون

تصميم جهاز تنقية غاز الفلور لمصنع سوبر فوسفات واحد

انبعاثات تعدين خام الحديد

بيع كسارة متنقلة مستعملة في بيرو

حول لدينا

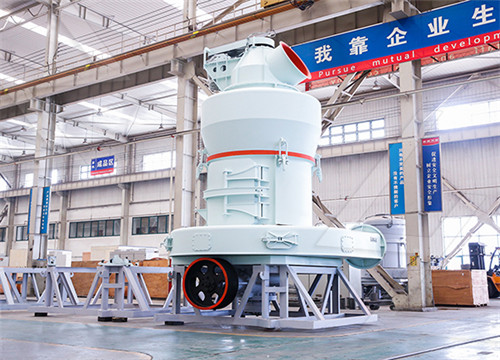

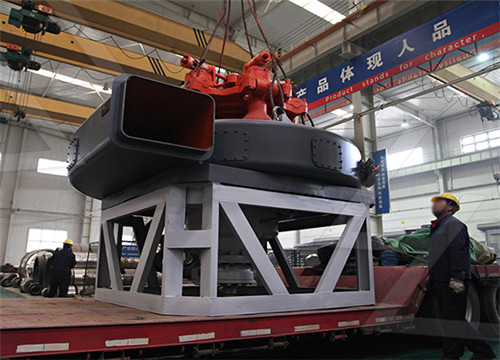

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20