الحار منتجات

ملكنا الإخبارية

eaf gas quenching steel slag

An efficient molten steel slag gas quenching process: Integrating ...

They captured 105 g CO 2 per kg of argon oxygen decarburization (AOD) and 135 g CO 2 per kg of electric arc furnace (EAF) slag at 15 bar. After validation through mechanical,

获取价格

Electric Arc Furnace Slag - an overview ScienceDirect Topics

Muhmood et al. (2009) also found that the water quenching method could improve the cementitious property of EAF slag. ... If the CO gas is evolved within the steel bath, it

获取价格

Off‐Gas Waste Heat Recovery for Electric Arc Furnace

2020/5/13 In addition to the off-gas waste heat flow, the amount of electric arc furnace dust (EAFD) must be considered for the process

获取价格

Phase development in steelmaking slags during a gas quenching ...

2024/6/1 As shown in Fig. 1, the molten steelmaking slag at 1600–1500°C was poured into the slag pot at an appropriate speed and flowed through the granulator in the

获取价格

Novel method for improving iron recovery from electric arc

Thermodynamic Analysis of Modification ProcessIron Recovery Rates of MS in LaboratoryMineral Composition of Steel SlagMicrostructure of MSIndustrial ExperimentComparison of MS in Laboratory with That in Industrial TestThe mineralogical compositions of different slags were characterized by Rietveld analysis of XRD patterns, as presented in Fig. 5. The minerals of EAF slag mainly consisted of RO phase, spinel, C2S, free-CaO, C3S, hematite, and C2F. The minerals of MS1 with 4 wt.% sand addition included RO phase, spinel, and C2S, whereas free-CaO, C3S, C2F, and hem...

Slag Foaming in an Electric Arc Furnace - J-STAGE

Matsuura et al.6) developed a kinetic model for EAF steel-making which computes the slag composition, decarburiza-tion rate and the rate of the carbon reaction with FeO in slag.

获取价格

High-temperature modification and air-quenching granulation of

2021/8/5 2.1 Materials. Lack of the conditions of direct air-quenching of liquid steel slag, this experiment uses cooled steel slag as the raw materials (as shown in Fig. 1),

获取价格

Insights into the Valorization of Electric Arc Furnace Slags as ...

2023/12/26 The transition to hydrogen-based reduction processes within the iron and steelmaking industry will generate new types of slag compositions that require

获取价格

Electric Arc Furnace (EAF) Slag US EPA

2024/5/13 About EAF Slag. EAF slag is a rock-like material generated during the steel-making process. Approximately 130 facilities across the United States generate EAF slag. EAF slag is used as an

获取价格

Electric arc furnace slag - Euroslag

The liquid slag is tapped at temperatures around 1600 °C and allowed to slowly air-cool forming crystalline slag. Depending on the intended steel quality (carbon steel or stainless/high alloy steel), two different slag

获取价格

Novel method for improving iron recovery from electric arc furnace slag ...

2022/1/21 The iron element in electric arc furnace (EAF) slag is extremely difficult to recycle due to the low specific magnetic susceptibility of the RO phase (a solid solution of FeO, MgO, CaO, and MnO). Landfilling EAF slag is strictly forbidden for environmental consideration because of poisonous Cr6+ leaching. The original RO phase could be

获取价格

Comprehensive utilization of steel slag: A review - ScienceDirect

2023/5/15 Introduction. Steel slag is the main solid waste generated in the steel-making process, accounting for 15 to 20% of crude steel output [1]. China's crude steel output in 2021 was 1.035 billion tons [2], more than half of the global crude steel output (1.9505 billion tons) [3], and the steel slag output exceeded 120 million tons.

获取价格

Metso Outotec SAF Smelting

The Metso Outotec Submerged Arc Furnace (SAF) is a closed-type, environmentally friendly, and energy-efficient solution for ... and cleans the gas, quenching sparks from the furnace to eliminate the risk of explosion. Because it contains no ... Typically, slag is granulated by using water sprays during tapping. Granulation is a cost-effective ...

获取价格

Electric arc furnace - Wikipedia

An electric arc furnace (the large cylinder) being tapped Rendering of exterior and interior of an electric arc furnace.. An electric arc furnace (EAF) is a furnace that heats material by means of an electric arc.. Industrial arc furnaces range in size from small units of approximately one-tonne capacity (used in foundries for producing cast iron products) up

获取价格

Comprehensive Utilization Technology of Steel Slag

2019/5/23 The steel slag is divided into converter (basic oxygen furnace, BOF) slag and electric arc furnace (EAF) slag according to the steel making process that is used, and EAF slag is divided into oxidizing slag and reducing slag. 6.1.1 Generation and Utilization of Steel Slag

获取价格

Insights into the Valorization of Electric Arc Furnace Slags as ...

2023/12/26 The transition to hydrogen-based reduction processes within the iron and steelmaking industry will generate new types of slag compositions that require valorization routes. Using slags as supplementary cementitious materials (SCMs) addresses the carbon dioxide emissions of the cement industry since the SCM requires neither calcination nor

获取价格

Phase development in steelmaking slags during a gas quenching ...

2024/6/1 Section snippets Gas quenching granulation process. As shown in Fig. 1, the molten steelmaking slag at 1600–1500°C was poured into the slag pot at an appropriate speed and flowed through the granulator in the gas-quenching granulation process.

获取价格

(PDF) Off‐Gas Waste Heat Recovery for EAF Steelmaking

2020/5/1 More specifically, in steel plants where the manufacturing process uses the electric arc furnace (EAF), which account for about 28% of the worldwide steel production [6], the waste heat is ...

获取价格

The Basic Study on the Prepartion of Steel Slag Cement with Gas ...

2011/5/1 In this study, the electric arc furnace slag (EAFS) was used as a cement admixture after the reduction of iron oxide in the slag at the interface of molten slag and water quenching. Consequently ...

获取价格

Development of an electric arc furnace steel slag-based ceramic ...

2022/7/1 This paper details the development process of ceramics made out of 100% electric arc furnace (EAF) steel slag, to be used as a shaped homogenous thermal energy storage (TES) media in packed-bed thermocline systems for high-temperatures industrial waste heat recovery, concentrated solar power (CSP), and Carnot batteries applications,

获取价格

Comprehensive utilization of steel slag: A review - ScienceDirect

1. Introduction. Steel slag is the main solid waste generated in the steel-making process, accounting for 15 to 20% of crude steel output [1].China's crude steel output in 2021 was 1.035 billion tons [2], more than half of the global crude steel output (1.9505 billion tons) [3], and the steel slag output exceeded 120 million tons.In contrast, the comprehensive

获取价格

Effect of Direct Reduced Iron (DRI) on Dephosphorization

2018/5/29 steel(+ DRI) under an Ar-3 pct H 2 gas mixture atmosphere. After EAF slag addition, metal and slag samples were taken at various time intervals (5, 10, 30, and 60 minutes). Slag samples were collected by dipping the tip of a stainless steel rod into the slag layer only, followed by quenching in ice water. The compositions of

获取价格

Assessment of Electric Arc Furnace (EAF) Steel Slag Waste’s

Steel slag is one of the most common waste products from the steelmaking industry. Conventional methods of slag disposal can cause negative impacts on humans and the environment. In this paper, the process of steel and steel slag production, physical and chemical properties, and potential options of slag recycling were reviewed. Since steel is

获取价格

Enhancing Recycling Potential: Exploring Reduction and Metal

2024/7/16 The electric arc furnace steelmaking route is essential for sustainable steelmaking through hydrogen-based direct reduced iron. About 30% of the global steel production currently follows the scrap/direct reduced iron–electric arc furnace (DRI-EAF) route, which is bound to increase given decarburization efforts by the steel industry. We

获取价格

Comprehensive utilization of steel slag: A review - ScienceDirect

1. Introduction. Steel slag is the main solid waste generated in the steel-making process, accounting for 15 to 20% of crude steel output [1].China's crude steel output in 2021 was 1.035 billion tons [2], more than half of the global crude steel output (1.9505 billion tons) [3], and the steel slag output exceeded 120 million tons.In contrast, the comprehensive

获取价格

Effect of Direct Reduced Iron (DRI) on Dephosphorization

2018/5/29 steel(+ DRI) under an Ar-3 pct H 2 gas mixture atmosphere. After EAF slag addition, metal and slag samples were taken at various time intervals (5, 10, 30, and 60 minutes). Slag samples were collected by dipping the tip of a stainless steel rod into the slag layer only, followed by quenching in ice water. The compositions of

获取价格

Assessment of Electric Arc Furnace (EAF) Steel Slag

Steel slag is one of the most common waste products from the steelmaking industry. Conventional methods of slag disposal can cause negative impacts on humans and the environment. In this paper, the process of

获取价格

Enhancing Recycling Potential: Exploring Reduction and Metal

2024/7/16 The electric arc furnace steelmaking route is essential for sustainable steelmaking through hydrogen-based direct reduced iron. About 30% of the global steel production currently follows the scrap/direct reduced iron–electric arc furnace (DRI-EAF) route, which is bound to increase given decarburization efforts by the steel industry. We

获取价格

Phase development in steelmaking slags during a gas quenching ...

2024/6/1 As shown in Fig. 1, the molten steelmaking slag at 1600–1500°C was poured into the slag pot at an appropriate speed and flowed through the granulator in the gas-quenching granulation process.The poured cylindrical column of molten slag was then fragmented and granulated under high-speed compressed dry airflow and then moves in

获取价格

Modeling and Simulation of the Off-gas in an Electric Arc Furnace ...

2017/9/28 The following paper describes an approach to process modeling and simulation of the gas phase in an electric arc furnace (EAF). The work presented represents the continuation of research by Logar, Dovžan, and Škrjanc on modeling the heat and mass transfer and the thermochemistry in an EAF. Due to the lack of off-gas

获取价格

The potential of industrial waste: Electric arc furnace slag (EAF)

2023/3/3 This EAF slag is a by-product of the first stage of steelmaking where scrap metal, pig iron and CaO are melted in an electric arc furnace. The EAF slag has a lower density than molten steel; therefore, the red-hot EAF slag floated on the top is collected and hardened into a rock-shaped product [13]. The EAF slag’s physical and chemical ...

获取价格

Assessment of Electric Arc Furnace (EAF) Steel Slag

The quantity of by-products in steel production is remarkable, close to 15% of the total steel production output [13]. These materials are often suitable to be valued as secondary raw materials ...

获取价格

A Review of the Influence of Steel Furnace Slag Type on the

The type of steel furnace slag (SFS), including electric arc furnace (EAF) slag, basic oxygen furnace (BOF) slag, ladle metallurgy furnace (LMF) slag, and argon oxygen decarburization (AOD) slag, can significantly affect the composite properties when used as an aggregate or as a supplementary cementitious material in bound applications, such as

获取价格

Recent Development of Steel Slag Stability and Activating Activity ...

Steel slag is a kind of industrial waste slag produced during the process of melting steel.Steel slag with higher basicity has potential hydraulic reactivity,because of its higher content of C3S and C2S.Therefore,it can be used in steel slag cement.However,the content of f-CaO in steel slag increases with increase of its basicity resulting in poor volume

获取价格

Structure characterization and grinding performance of gas

chemical compositions of the steel slag and gas-quenched (GQ) steel slag abrasive were determined using the chemi-cal analysis method YB/T140–2009. As shown in Table 1, the major chemical components of the steel slag used in this work were SiO 2, CaO, Al 2 O 3, Fe 2 O 3, and MgO. The equipment for slag gas quenching was used in the

获取价格

Preparation and performance analysis of gas-quenched steel slag

2019/8/4 The gas-quenching rate, bead formation rate, physical properties, microscopic characteristics and free lime (f-CaO) of gas-quenched slag beads were analyzed to broaden the utilization of BOF slag. The results show that the more BF slag is added, the higher the gas-quenching rate is, and the lower the bead formation rate

获取价格

Study on leaching of electric arc furnace (EAF) slag for its ...

2021/4/1 The efficiency of quartz addition on electric arc furnace (EAF) carbon steel slag stability. Chemical treatment has been reported for the re-utilization and alternation of EAF slag for sustainable environment. 14. Riley and Mayes (2015) Long-term evolution of highly alkaline steel slag drainage waters.

获取价格

Structure characterization and grinding performance of gas

2020/7/16 Gas-quenched steel slag abrasive was obtained by gas quenching with high-temperature liquid steel slag as raw material. ... It can be produced in either an electric arc furnace (EAF), of which ...

获取价格ماكنة تعبئة الخضروات المجمده

آسیاب پلاستیک ماشین آلات

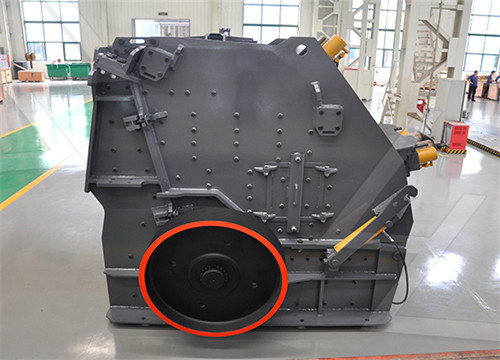

كسارة تصادمية متنقلة أولية من سلسلة pf في الصين

الصين ماكينات بلاستيك

مطحنة الكرة قدم قدم المستخدمة

secondhand uk mining suppliers

فيفا حول الكرة مطحنة

مطحنة مايزماستر للبيع جنوب أفريقيا

آلات خاصة بتصليح آلات التبريد

المطرقة محطم أجزاء الصانع الهند

how to bullnose tile edges granite with a grinder

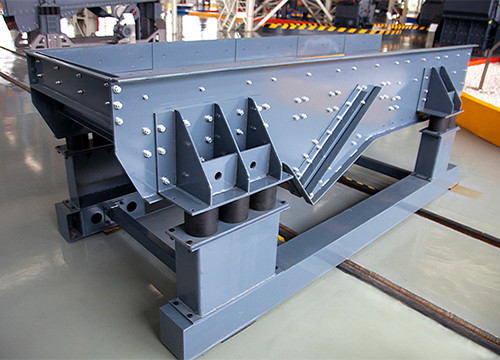

تهتز تغذية حساب الدعم

Study Aggregate Crushing In Ethiopia Solution

شراء كسارة وطاحونة

سحق الصخور الكوارتز

تؤثر كفاءة محطم

مصنع كسارة البورون

آلة طحن مطحنة ومبدأ العمل

alluvial gold mining flowsheet

معدات معالجة الذهب معدات تعدين الذهب

سحق الصخور في ولاية ايوا

تعدين الذهب معدات جنوب أفريقيا

معدات التعدين تهتز المغذية

بورون خام موبايل كسارة الفك السعر

الانسياب مطحنة الترهل دان مطحنة الكرة

مطحنة الكرة مطحنة شبه منحرف mtm0

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20