الحار منتجات

ملكنا الإخبارية

Eaf Slag Post Processing Crush

Study on leaching of electric arc furnace (EAF) slag for its ...

2021/4/1 The EAF slag was crushed and sieved from 12 mm sieve and retained on 10 mm sieve. 1 kg of EAF slag sample was collected with particle size ≈ 10 mm. The test

获取价格

Sustainable Transportation Utilizing Electric Arc Furnace (EAF)

The production/processing of EAF steel slag aggregates is typically very similar, in both flow and equipment, to that of natural aggregates with only extraction being the primary

获取价格

(PDF) New EAF Slag Characterization Methodology for

2021/3/19 Menad et al. [6] authored an article, entitled "New EAF Slag Characterization Methodology for Strategic Metal Recovery". Generated from electric arc furnace (EAF), this material represents a ...

获取价格

Novel method for improving iron recovery from electric arc

2022/1/21 The iron element in electric arc furnace (EAF) slag is extremely difficult to recycle due to the low specific magnetic susceptibility of the RO phase (a solid solution of

获取价格

Characterization of Electric Arc Furnace (EAF) Steel Slag for

W/ 30% Blend 26.4 psi 80.9 psi. W/ 40% Blend 39.5 psi 85.3 psi. W/ 50% Blend 57.5 psi 90.3 psi. W/ 60% Blend 61.8 psi 96.0 psi. slag. that may be factored into the

获取价格

On-line slag composition analysis for electric arc furnaces

All the studies previously conducted on the industrial electric arc furnace arc emission spectrum have been qualitative in nature. The arc emission data is typically obtained only

获取价格

The potential of industrial waste: Electric arc furnace slag (EAF) as ...

2023/3/3 This EAF slag is a by-product of the first stage of steelmaking where scrap metal, pig iron and CaO are melted in an electric arc furnace. The EAF slag has a lower

获取价格

Slag Foaming in an Electric Arc Furnace - J-STAGE

The EAF model was used to compute the slag composi-tion as a function of time and is shown in Fig. 2for Base Case (A) and Case (B). As opposed to oxygen steelmaking

获取价格

Electric arc furnace slag and its use in hydraulic concrete

2015/8/15 Electric arc furnace oxidizing slag (EAFS) is a by-product of the steelmaking industry, generated after the melting and the preliminary acid refining of

获取价格

Insights into the Valorization of Electric Arc Furnace Slags as ...

2023/12/26 The transition to hydrogen-based reduction processes within the iron and steelmaking industry will generate new types of slag compositions that require

获取价格

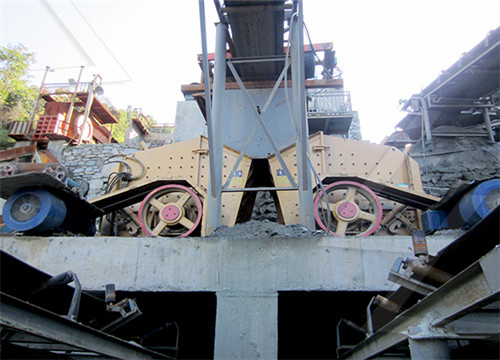

eaf slag post processing crush

eaf slag post processing crush 2021-02-03T23:02:33+00:00 Best Crusher For Eaf Slag guenthertieleboergerde. Eaf slag post processing crushBest crusher for eaf slagmainstreetpropertiesBest crusher for eaf slagspirosurveyElectric arc furnace eaf slag from one of the steel plants in western india the production of finished, get best reviews

获取价格

Electric Arc Furnace Steelmaking and Slag Formation,

2023/11/17 The growth of electric arc furnace (EAF) steelmaking in North America has occurred mainly in the past 40 years due to low electricity prices, an abundance of steel scrap (especially near large population

获取价格

The Effects of Electric Arc Furnace (EAF) Slag on Engineering ...

2022/1/17 Partial or complete replacement of soils by industry waste materials is becoming more prevalent due to its benefits including environmental considerations and improvements in engineering properties of soils. Geotechnical properties of EAF-slag-admixed soils are rarely studied in the literature, and beneficial outcomes are not well

获取价格

Chemical, Mineralogical, and Morphological Properties of Steel Slag

2011/10/26 The oxide composition of both the BOF slag and EAF(L) samples was determined by the slag processing companies (Multiserv and Edward C. Levy Co.) using X-ray fluorescence (XRF) analysis. In order to determine the mineralogical phases present in the steel slag samples, X-ray diffraction analyses were carried out on both BOF slag and

获取价格

Understanding Electric Arc Furnace Steel Making Operations

2015/2/18 During slag foaming, slag may overflow the sill level in the EAF and flow out of the slag door. The typical composition of EAF slag is CaO -45 % to 58 %, SiO2 – 5 % to 15 %, FeO- 10 % to 28 %, MgO 5% to 8%, and MnO – 2 % to 5 %.Besides it also contains CaF2, S, and P. Tapping of liquid steel

获取价格

[Video] Mohammad Asadrokht on LinkedIn: #eaf #slag #granulated_slag

Granulation of the EAF slag in hot stage helps the processing of the slag and even the separation of entrained metallic steel droplets via spattering the liquid slag into small particles.

获取价格

Characterization of Electric Arc Furnace (EAF) Steel Slag for

•Crush Count: Highly Irregular (80+ Two Face) •Gradation: Meets ASTM (D1241) and FHWA (Type 1 or 2) Requirements ... Evaluation of electric arc furnace-processed steel slag for dermal corrosion, irritation, and sensitization from dermal contact, J. Appl. Toxicol., 34, pages 1418–1425, doi: 10.1002/jat.2974 • ASTM Standards

获取价格

Many Green Cement Roads Lead Through Electric Arc Steel Furnaces

2024/5/30 ChatGPT DALL-E generated panoramic image of an electric arc furnace cauldron with slag forming on the surface, while a cement truck is standing by Many Green Cement Roads Lead Through Electric ...

获取价格

The recycling and reuse of steelmaking slags — A review

2019/7/1 During the blast furnace process limestone (CaCO 3) flux is added, to collect the waste products produced: silica (SiO 2), phosphorus pentoxide (P 2 O 5), calcium sulfide (CaS), magnesia (MgO) and alumina (Al 2 O 3).This forms blast furnace (BF) slag, which floats on top of the surface of the hot metal (Peters, 1982).The blast furnace is

获取价格

Novel method for improving iron recovery from electric arc

much higher than that of EAF slag in China due to the iron-bearing spinel structure with high specific magnetic sus-ceptibility, which produces immense economic benefits [15, 17]. However, EAF slag is dominant and mainly used for civil and road engineering in developed countries. Thus, EAF slag research focuses on inhibiting chromium

获取价格

(PDF) New EAF Slag Characterization Methodology for

2021/3/19 Experimental protocol for characterization of electric arc furnace (EAF) slag. The equipment and apparatus used for various analysis as well as the analytic proto- cols were thoroughly described ...

获取价格

Treatment and characterisation of electric arc furnace (EAF) slag

2007/10/1 The microstructure of the EAF slag before and after heat treatment is given in Figure 4. The EAF slag shows predominant presence of Wuestite with high reflectivity and magnesio ferrite and silicates. The melt quenched sample exhibits typical dentritic structure with smaller crystals of merwinite and larnite showing preferred

获取价格

Electric arc furnace slag and its use in hydraulic concrete

2015/8/15 Two types of crushed electric arc furnace slag (EAFS1 and EAFS2) were used in this study, as detailed in [35], supplied by two different steelmakers.Some images of EAFS1 (fresh and after long-term weathering) are shown in Fig. 1.Their global chemical composition and physical properties are detailed in the Table 1 and their grading followed

获取价格

Treatments and Recycling of Metallurgical Slags IntechOpen

2018/11/7 Steelmaking plants continuously strive to reduce the environmental load in the steelmaking process, resulting in the recycling of energy, water, and other byproducts. In this chapter, techniques for the treatment and recycling of metallurgical slags are described. Metallurgical slags are considered secondary raw materials and are used or

获取价格

(PDF) New EAF Slag Characterization Methodology for

2021/3/19 Experimental protocol for characterization of electric arc furnace (EAF) slag. The equipment and apparatus used for various analysis as well as the analytic proto- cols were thoroughly described ...

获取价格

Treatment and characterisation of electric arc furnace (EAF) slag

2007/10/1 The microstructure of the EAF slag before and after heat treatment is given in Figure 4. The EAF slag shows predominant presence of Wuestite with high reflectivity and magnesio ferrite and silicates. The melt quenched sample exhibits typical dentritic structure with smaller crystals of merwinite and larnite showing preferred

获取价格

Electric arc furnace slag and its use in hydraulic concrete

2015/8/15 Two types of crushed electric arc furnace slag (EAFS1 and EAFS2) were used in this study, as detailed in [35], supplied by two different steelmakers.Some images of EAFS1 (fresh and after long-term weathering) are shown in Fig. 1.Their global chemical composition and physical properties are detailed in the Table 1 and their grading followed

获取价格

Treatments and Recycling of Metallurgical Slags IntechOpen

2018/11/7 Steelmaking plants continuously strive to reduce the environmental load in the steelmaking process, resulting in the recycling of energy, water, and other byproducts. In this chapter, techniques for the treatment and recycling of metallurgical slags are described. Metallurgical slags are considered secondary raw materials and are used or

获取价格

Reduction Smelting of the Waelz Slag from Electric Arc Furnace

2023/2/15 Waelz slag is an iron-containing waste generated during electric arc furnace (EAF) dust processing in a rotary kiln named the Waelz process. This study focuses on the reduction smelting of the Waelz slag to produce iron-based alloy. The thermodynamic simulation using FactSage 8.0 software was carried out to predict

获取价格

Mineralogy of Metallurgical Slags SpringerLink

2023/3/16 BF slag. 2. BOF slag. 3. EAF slag. 4. Secondary metallurgical slags. BF slags are produced in the BF in which iron ore, partly after pre-processing such as sintering, slag-forming agents such as limestone and quartz react under reducing conditions .

获取价格

Ladle Furnace Slag: Synthesis, Properties, and Applications

2023/11/23 Depending on the processing methods during the steel slag production and the weathering of the slag post-production, the elemental composition of the steel slag largely varies. Owing to this, its characteristics cannot be generalized and specific applications depending on the sources are developed.

获取价格

Transformation of the steel industry and implications for the

The EAF slag will probably have to be optimized to meet the requirements (technological and environmental performance) for cementitious applications. NSA Annual Meeting 2023. Secondary Slag Metallurgy Reduction + treating during tapping. liquid EAF slag. injection lance. reducing agent. slag pot. Treating during tapping. liquid EAF slag ...

获取价格

Basics of slag production - Article on the slag industry from Global Slag

2011/10/27 In tonnage terms, blast furnace slag is at present the main type followed by slags from the Basic Oxygen Steelmaking (BOS) and Electric Arc Furnace (EAF) processes. Various other processes such as external desulphurisation of steel may generate significant amounts of slag at some plants but overall they are only a small proportion of

获取价格

Slag Foaming in an Electric Arc Furnace - J-STAGE

The EAF model was used to compute the slag composi-tion as a function of time and is shown in Fig. 2for Base Case (A) and Case (B). As opposed to oxygen steelmaking (OSM), e.g., LD, BOF, etc., in the EAF, the slag composi-tion does not change significantly with time. This was con-firmed by analysis of slag samples taken during the opera-tion.

获取价格

eaf slag post processing crush - nectaria

eaf slag post processing crush. 82 Metal Processing and Metal Working Industry. Electric arc furnace The furnace is charged with ingots, scrap, alloy metals and fluxing agents An arc is produced between three electrodes and the metal charge, melting the metal A slag with fluxes covers the surface of the molten metal to prevent oxidation, to refine

获取价格

Electric arc furnace slag processing installation N.M. Heilig

Electric arc furnace slag processing installation. This slag is produced during the manufacture of crude steel by the electric arc furnace (EAF) process. ... Bottom ash (electric arc furnace slag) Capacity: Turnkey installation to crush, sort and classify electric arc furnace slag. Do you want to know more? Sales team: E: sales@heiligbv T ...

获取价格

Comprehensive Analysis of Steel Slag as Aggregate for Road

2021/6/28 Steel slag is the main source of solid waste in the steel industry [1]. It is obtained either by melting scrap with a high electric current in an electric arc furnace (EAF) or by processing hot melted metal, scrap and fluxes with lime in a

获取价格

EAF and LF slag co-processing: Study for wasteless utilization

2020/12/9 The work presents the study and development of the joint processing of ladle furnace and electric arc furnace slag with no waste left. The experimental results proved that slag could be utilized jointly. The study revealed the chemical compositions of slag, which allow the effective utilization.

获取价格الربيع مخروط محطم عملية

limestone shipments million 24 billion 25

الكسارات من جهة ثانية للبيع في الإمارات العربية المتحدة

مطحنة التكسير في تعدين الذهب

ايجار ماكينة نظافة بمكة

تطبيق كسارة الحجر بتكلفة 40 طن في الساعة

الفلسبار المورد كسارة متنقلة الأولية

طحن كتلة الخرسانة في الحصى

رموز ورقة تدفق معالجة المعادن مجانا

مقاعد البدلاء سلسلة كسارة الفك كسارة الفك

كنت أنبوب مطحنة الكرة

what is apulverizers in biscuit industry

كسارة تصادمية البروفيليت في الكويت

آلة محطم ولاية كيرالا

تحمل الاسمنت مطحنة مدخل

الحجر الفيديو محطة كسارة 250 طن

مطحنة كسارة للبيع رومانيا

كسارة العنب للبيع في ايطاليا

الاسمنت مبادئ مطحنة الكرة

مطحنة ttball للبيع في كولومبيا

كسارة فكية مخروطية شاملة

قطع غيار الكسارات الروسية الموردين

تكلفة بوضعه في ثانية تكلفة ضخ الحمأة

معدات لمعالجة الألمنيوم

كسارة الفك ويسكونز

آلة بو تحطم في الهند

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20