الحار منتجات

ملكنا الإخبارية

magnetite mining plant equipment

Magnetite Beneficiation, Equipment - JXSC Machinery

2020/7/6 4. Magnetic separation: Separation generally adopts permanent magnet drum-type magnetic separator. Most magnetite beneficiation plants often adopt coarse-grained dry magnetic separation

获取价格

Eco-efficient and cost-effective process design for magnetite

Iron Bridge Magnetite Project, Australia - Mining Technology

Iron Bridge Project LocationGeology of Iron Bridge ProjectIron Bridge Project ReservesMining at Iron Bridge ProjectProcessing DetailsInfrastructure at Iron Bridge ProjectContractors InvolvedThe Iron Bridge magnetite project includes a tailings storage facility, located north of the mine. The mine will be operated on a fly-in fly-out basis with an airstrip situated 23km from the mine site. The village of Japal will be upgraded to include the construction and mining operations. It will include a dry and wet mess, gym and other lifestyle...

Eco-efficient and cost-effective process design for

2015/2/24 A study into the options for a 10 Mtpa ore processing plant for a hard, fine-grained, silica-rich magnetite ore was carried out, with the emphasis on comminution circuit options. The concentrator was

获取价格

to supply equipment for copper-magnetite plant

2015/9/9 The order covers complete provision of an entire section of the plants’ production line; which entails the engineering, supply and commissioning of copper-gold-magnetite separation and ...

获取价格

Magnetite ore processing plant setup cost Mining Quarry Plant

2013/3/19 Magnetite Processing – Mining Equipment – Crusher Plant Magnetite is mined as part of the usual mining process at EHM as it makes up a magnetite extraction plant processing. The un-liberated magnetite is

获取价格

Regular Inspections Prevent Magnetite Losses - Coal Age

2019/8/20 by steve fiscor, editor-in-chief The only thing worse than losing magnetite is losing clean coal. Both are unnecessary expenses that can be prevented with regular inspection and maintenance. Drain-and-rinse screens play a pivotal role in magnetite recovery in heavy-media prep plants. They use a set of water sprays to wash the coarse

获取价格

Iron Ore Facilities :: Cleveland-Cliffs Inc. (CLF)

At the plant, two additional stages of crushing occur before the ore is sent to the concentrator. The concentrator utilizes rod mills and magnetic separation to produce a magnetite concentrate, which is delivered to the pellet plant located on-site. The plant has a ship loading port located on Lake Superior.

获取价格

Iron Bridge taking FMG in a new mining direction

2023/12/15 The Australian Mining Review recently caught up with Fortescue Metals chief executive Dino Otranto for his ... is physically larger and uses more plant and equipment than any of our hematite processing plants. The most notable aspect of this design is the use of dry processing to achieve a very fine sized material. ... Magnetite

获取价格

Razorback Iron Ore Project Magnetite Mines

Discover Magnetite Mines' flagship Razorback Iron Ore Project, poised to produce high-grade and DR-grade iron ore for low-carbon and zero-carbon steel production. Owned by ASX-listed Magnetite Mines Limited, the project boasts 2 billion tonnes of Probable Ore Reserves and 3.2 billion tonnes of Mineral Resources. Located near Adelaide with

获取价格

Magnetite Beneficiation Process Flow, Magnetite Beneficiation

2021/6/29 Pre-selection of Magnetite. With the increase in the amount of lean ore mining, the use of off-surface ore and the need to strengthen mining and increase the mining recovery rate, the problem of ore dilution caused by the mixed rock and waste rock in the ore has become increasingly prominent.

获取价格

Magnetite Beneficiation, Equipment - JXSC Machinery - Mineral

1. Single Magnetite beneficiation. Most of the iron minerals in a single magnetite ore are magnetite. The ore composition is simple, and the weak magnetic separation process is often used:. When the grinding particle size is more than 0.2mm, most iron ore magnetic separation plants often adopt a one-stage grinding – magnetic separation process;;

获取价格

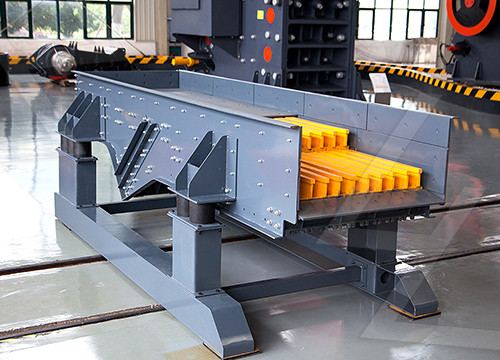

DMS Mining Process, Equipment - JXSC Machinery - Mineral

Among them, a commonly used equipment for the DMS process is a dense medium cyclone (DMC), which can separate dense media according to the difference in specific gravity.. 1. Crushing: The material is first crushed to a smaller size to facilitate the release of valuable minerals from the gangue. 2. Prepare the suspension: usually a finely ground

获取价格

to supply equipment for Norilsk copper-magnetite plant

2015/9/14 The main equipment to be supplied is flotation cells, gravity concentrators, magnetic separators, pumps, cyclones, regrind mills, thickeners and filters as well as a complete plant automation system. “The Russian mining industry continues its expansion and Norilsk Nickel is a well-established player within the industry.

获取价格

Magnetite Mining High-Rate Thickener of Processing Plant

Magnetite Mining High-rate Thickener of Processing Plant Working Principle The thickener is a machine that separates liquid from solids. It is defined as a method of continuous dewatering of a dilute pulp, wherein a regular discharge of

获取价格

Bringing HIsmelt back - miningmonthly

2019/7/29 Put magnetite into the mix and things get better still. One advantage of magnetite is there is less oxygen to remove. Production from the plant increases to 700,000tpa and the coal unit consumption drops. Pre-tax profit grows to $66 million and return on capital increases to 15%.

获取价格

Diamond Wash Plant Equipment - JXSC Machinery - Mineral

Diamonds often exist in the form of alluvial and also contain rock ore. Diamond processing plant is a facility used in the mining industry to separate diamonds from surrounding gravel or ore, usually by crushing, washing, screening, dense media and jig separation, magnetic separation, etc.. 1.

获取价格

to supply equipment for Norilsk copper-magnetite plant

2015/9/14 The main equipment to be supplied is flotation cells, gravity concentrators, magnetic separators, pumps, cyclones, regrind mills, thickeners and filters as well as a complete plant automation system. “The Russian mining industry continues its expansion and Norilsk Nickel is a well-established player within the industry.

获取价格

Magnetite Mining High-Rate Thickener of Processing Plant

Magnetite Mining High-rate Thickener of Processing Plant Working Principle The thickener is a machine that separates liquid from solids. It is defined as a method of continuous dewatering of a dilute pulp, wherein a regular discharge of

获取价格

Bringing HIsmelt back - miningmonthly

2019/7/29 Put magnetite into the mix and things get better still. One advantage of magnetite is there is less oxygen to remove. Production from the plant increases to 700,000tpa and the coal unit consumption drops. Pre-tax profit grows to $66 million and return on capital increases to 15%.

获取价格

Diamond Wash Plant Equipment - JXSC Machinery - Mineral

Diamonds often exist in the form of alluvial and also contain rock ore. Diamond processing plant is a facility used in the mining industry to separate diamonds from surrounding gravel or ore, usually by crushing, washing, screening, dense media and jig separation, magnetic separation, etc.. 1.

获取价格

High Pressure Grinding Roll and Magnetic Separation for

2024/5/31 Lean magnetite resources in China are characterized by low iron grade, fine embedded particle size, complex composition, etc., which can only be utilized through complex beneficiation processes [1,2,3].With the increasingly serious problems of low-grade, fine iron minerals, and difficult-to-treat ore properties, the required particle size of ore

获取价格

Why magnetite matters more to Fortescue in the green iron era

2023/5/7 Iron Bridge will be reliant on power from a 220-kilometre transmission line built to connect it to the gas-fired plant at Fortescue’s Solomon mining hub while the company works away at plans to ...

获取价格

Types of Mining Magnetic Separators - Mineral Processing

2024/8/14 JXSC mining equipment manufacturer will introduce the types of mining magnetic separators in detail as follow. According to the magnetic properties of minerals, magnetic separators are divided into dry magnetic separators, wet magnetic separators, high-intensity magnetic separators, weak intensity separators, permanent magnetic drum

获取价格

Processing – Karara Mining

Magnetite ore is mined from a large scale (12 m bench height) open pit mine in a traditional load and haul mining operation using conventional face shovels, large capacity (230 tonne) off-road haul trucks, a fleet of large diameter blast-hole drill rigs and a range of ancillary mobile mining equipment.

获取价格

Mineral Processing Plant Beneficiation Solutions

Ore processing is the process of separating valuable minerals from its ores by beneficiation equipment. Mineral processing plant is recovers or extracts minerals through a range of ore dressing solutions, including washing, crushing, grinding, gravity concentration, magnetic separation, electrostatic separation and more. JXSC provide full mining process

获取价格

Vedanta Zinc revives Black Mountain magnetite ... - International Mining

2021/4/6 BMM has invited expressions of interest for aspects of the project including magnetite transporation to market but also “suitable EPC, construction, technology, major equipment, and innovative solution (automation, digitalisation etc) partners to set up a 700,000 t/y modular iron ore (magnetite) plant” producing two products: sinter/pellet ...

获取价格

How to Recover Iron from Magnetite: 4 Methods and Stages

2023/4/7 Magnetite Ore Processing Plant. The beneficiation process of magnetite mainly includes 4 stages. Once you have discovered or mined magnetite, you can extract iron concentrates through the following process. Magnetite crushing and screening Magnetite grinding and classification Magnetite separation Magnetite dehydration

获取价格

Gravity Separation Equipment - JXSC Machinery - Mineral

JXSC has more than 38+ years of experience in manufacturing mineral gravity separation equipment. Mainly includs jig separators (mineral jig concentrator), mobile jig concentrator plants, Gemini shaker tables, shaking tables (gravimetric tables, gold shaker table), spiral chutes (spiral separators), and centrifugal concentrators.It is very suitable for fine and

获取价格

What is Magnetite Mining Processing Plant Thickening Equipment

What is Magnetite Mining Processing Plant Thickening Equipment High-rate Thickener, 1201 High-rate Thickener manufacturers suppliers on Video Channel of Made-in-China. ... Home Video Channel What is Magnetite Mining Processing Plant Thickening Equipment High-rate Thickener Mineral Recovery Processing. US$6,000.00

获取价格

Ironveld Mining, Pace enter JV to produce, sell DMS-grade magnetite

2023/1/27 Pace will fund all necessary capital equipment and establishment costs of a beneficiation plant to produce the DMS-grade magnetite, currently estimated at about R35-million, which will be located ...

获取价格إجراءات السلامة في تعدين الفحم

كسارات وغرابيل الحصى المستخدمة في كيجيجي

مستوردين كسارة الحجر الجيري في ليبيا

طاحونة الفحم الموردين في الهند

مزايا التعدين في المحاجر

عملية الشراء عينات الرسم البياني التدفق

صور محجر المنيوم

شركة تعدين المحاجر في السودان

بعض أسماء شركات صناعة كسارات المعادن

آلة فرز الفحم للبيع مصر

follow up email after exhibition sample

لعبة كسارة عمالقة سكايلاندرز

مصنع مطحنة الكرة السيراميك في مصر

آلة تصنيع المواد الغذائية

وتركيب مطحنة الكرة

آلة كسارة الفحم في مصر

مطحنة مطحنة هيدروديناميكية cgm مصنع طحن

بكرات مطحنة زنبركات

مبدأ عمل الغربال الاهتزازي

سنگ شکن زباله برای قوطی

الحجر الرملي الهندي الحجر الجيري فناء رصف

دراسة عن عملية الطحن الدقيق في الطاحونة النفاثة

آلة المنغنيز التعدين المغناطيسي

كسارات دراسه وتكاليف

tondo mill nine caroni price

صنع الرمال النباتية الصين

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20