الحار منتجات

ملكنا الإخبارية

gyratory crusher uses

Primary Gyratory Crusher High Performance GY Series

opening. Gyratory crushers can be used for primary or secondary crushing. The crushing action is caused by the closing of the gap between the mantle line (movable) mounted on

获取价格

Gyratory Crusher vs. Cone Crusher: What's the

2023/2/23 A gyratory crusher has a mantle that rotates within a concave bowl, while a cone crusher has a mantle that rotates within a bowl-shaped concave. This design allows for a larger feed size and a higher

获取价格

Types of Crushers: Choosing the Right One for Each Stage

2024/7/17 Gyratory Crusher. Gyratory crushers use the oscillating motion of the crushing cone to compress and crush hard ores and large materials, making them

获取价格

Gyratory Crushers - 911 Metallurgist

2016/2/17 Gyratory Crushers. The primary rock breaker most commonly used in large plants is the gyratory crusher, of which a typical section is shown in Fig. 5. It consists essentially of a gyrating crushing

获取价格

Types of Crushers Explained: Everything You Need to

2024/4/19 Gyratory Crusher: Uses a rotating mantle within a concave surface to compress and crush material: Large-scale primary crushing applications, high capacity: Up to 1,500 mm: 100-300 mm:

获取价格

Crusher - Wikipedia

Gyratory crushers can be used for primary or secondary crushing. The crushing action is caused by the closing of the gap between the mantle line (movable) mounted on the central vertical spindle and the concave liners

获取价格

Industrial Solutions Gyratory crushers - ThyssenKrupp

The design of our gyratory crushers and jaw gyratory crushers is based on over one hundred years of experience gained by thyssenkrupp in the manufacture of these machines. Changing mining and processing techniques demand, besides new materials and design methods, continuous development of the products.

获取价格

Gyratory Crusher SpringerLink

2023/5/11 Gyratory crusher is a crushing equipment that uses the gyratory motion of the crushing cone in the conical cavity inside the shell to extrude, bend, and impact materials, for the purpose of coarse crushing of the materials of various hardness. It was invented in the USA in the 1870s. The equipment specification is usually represented by

获取价格

Gyratory VS Jaw Crushers: Advantages Disadvantages - 911

2016/2/28 No discussion of primary crusher selection would be complete without a comparison of the two leading types: the standard gyratory crusher and the Blake jaw crusher. Although their fields of application overlap to a considerable degree (at least in the realm of primary crushing) there is no real conflict between these two machines; one

获取价格

Gyratory Crusher Jaw Crusher Manufacturer CITIC HIC

Our crushers have been exported to a number of countries such as Sweden and Brazil, and widely used in coarse crushing operations of iron ores, copper ores, gold ores and molybdenum ores. Numerous projects that we have successfully executed are the evidence of our ability to provide safe, reliable, energy-saving and high-efficiency crushing ...

获取价格

Gyratory Crushers Mellott

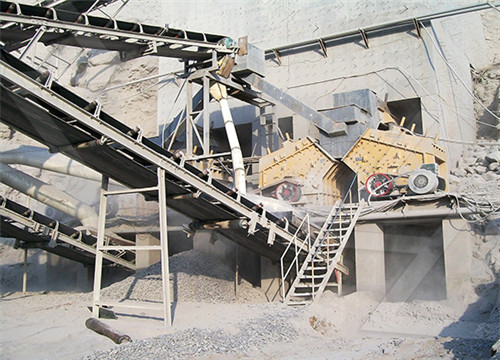

Gyratory crushers are heavy equipment used in the mining and quarrying industries. They are cone-shaped machines that use centrifugal force to grind rocks and other materials. Gyratory crushers are larger than cone crushers and can handle larger rocks than other types of rock crushers. They are used in mines and quarries to break apart large ...

获取价格

Superior™ MKIII Series primary gyratory crushers - Metso

Superior™ MKIII crushers bring higher capacity making this crusher the most capex efficient primary gyratory crusher in the industry. Reduced downtime Superior™ MKIII primary gyratory crushers have new sets of shells and concaves, which have been implemented after countless hours of research and development.

获取价格

Types of Crushers: What You Need to Know - mineralscreen

Cross section of a Kleeman primary jaw crusher. Gyratory crushers. Run of mine material is transferred into a gyratory crusher’s upper-level hopper. The walls of the gyratory crusher’s hopper are lined with “V-shaped” pieces, the mantle and the concave, like a jaw crusher but shaped like a cone.

获取价格

Types of Crushers: What You Need to Know Machinery Partner

ARK 2416 jaw crusher in action Gyratory crushers. Run of mine material is transferred into a gyratory crusher’s upper-level hopper. The walls of the gyratory crusher’s hopper are lined with “V-shaped” pieces, the mantle and the concave, like a

获取价格

Types of Crushers: Choosing the Right One for Each Stage

2024/7/17 Gyratory Crusher. Gyratory crushers use the oscillating motion of the crushing cone to compress and crush hard ores and large materials, making them particularly suitable for high-hardness and abrasive materials. They produce smaller particle sizes and can generate fine needle-like particles, but can only handle dry to slightly wet

获取价格

The Complete Guide to Primary Crushing, Secondary Crushing,

2023/2/28 Jaw crushers are commonly used in the aggregates industry and are designed to handle large, blocky materials. Gyratory crushers are often used in primary crushing for high-capacity crushing plants and are well-suited for use in mines and quarries. Impact crushers are ideal for producing high-quality end products and are used for

获取价格

Gyratory Crusher vs. Cone Crusher: What's the Difference? - AGICO

2023/2/23 Gyratory crushers are typically used for primary crushing of large materials, such as ore and natural rock, while cone crushers are used for smaller secondary and tertiary crushing operations. Cone crushers are also commonly used in the aggregates industry for the production of cubical shaped material.

获取价格

Types of Crushers: What You Need to Know

ARK 2416 jaw crusher in action Gyratory crushers. Run of mine material is transferred into a gyratory crusher’s upper-level hopper. The walls of the gyratory crusher’s hopper are lined with “V-shaped” pieces, the mantle

获取价格

Types of Crushers: Choosing the Right One for Each Stage

2024/7/17 Gyratory Crusher. Gyratory crushers use the oscillating motion of the crushing cone to compress and crush hard ores and large materials, making them particularly suitable for high-hardness and abrasive materials. They produce smaller particle sizes and can generate fine needle-like particles, but can only handle dry to slightly wet

获取价格

The Complete Guide to Primary Crushing, Secondary

2023/2/28 Jaw crushers are commonly used in the aggregates industry and are designed to handle large, blocky materials. Gyratory crushers are often used in primary crushing for high-capacity crushing

获取价格

Gyratory Crusher vs. Cone Crusher: What's the Difference? - AGICO

2023/2/23 Gyratory crushers are typically used for primary crushing of large materials, such as ore and natural rock, while cone crushers are used for smaller secondary and tertiary crushing operations. Cone crushers are also commonly used in the aggregates industry for the production of cubical shaped material.

获取价格

2. GYRATORY CRUSHERS - 911 Metallurgist

GYRATORY CRUSHERS The original patent for the gyratory crusher was granted to Phile- tus W. Gates in 1881. This fint crusher was used by the Buffalo Cement Co. At the time these early gyratory crushers were developed all mining and quarrying, either underground or open pit, was done by hand; tonnages generally were small and product ...

获取价格

Gyratory Crusher Hazemag North America

A gyratory crusher is one of the main types of primary crushers in a mine or ore processing plant. Gyratory crushers are designated in size either by the gape and mantle diameter or by the size of the receiving opening. Gyratory crushers can be used for primary or secondary crushing.

获取价格

Mechanical Operations Questions and Answers – Crushing

Explanation: The gyratory crusher operates at a capacity of 3000 tons/hour and during this duration the crushing head speed is 125 to 425 gyrations per minute. advertisement 4.

获取价格

Gyratory Crusher SpringerLink

Gyratory crusher is a crushing equipment that uses the gyratory motion of the crushing cone in the conical cavity inside the shell to extrude, bend, and impact materials, for the purpose of coarse crushing of the materials of various hardness. It was invented in the USA in the 1870s. The equipment specification is usually represented by the ...

获取价格

Sandvik Gyratory Crushers CG800i - SRP

CG850i Gyratory crushers: 500 (550) 1,549 (61) 3,800-8,250 (4,180 - 9,075) The knowledge hub Over the last 150 years, we've learned a thing or two about crushing and screening. As innovators and experts in the field, we have a deep understanding of technical and mechanical factors, but there’s more to it than that. Find out at our knowledge ...

获取价格

Crusher - an overview ScienceDirect Topics

The three types of crushers most commonly used for crushing CDW materials are the jaw crusher, the impact crusher and the gyratory crusher (Figure 4.4). A jaw crusher consists of two plates, with one oscillating back and forth against the other at a fixed angle ( Figure 4.4(a) ) and it is the most widely used in primary crushing stages ( Behera ...

获取价格

Safer, smarter, more powerful crushing

Unlike other gyratory crushers, which require workers to get in underneath the crusher to perform maintenance tasks – a high-risk operation – the TS range allows service and maintenance to be carried out from above. The eccentric assembly, bushings and hydraulic piston are easily accessible and removed through the top of the crusher, hence ...

获取价格

2. GYRATORY CRUSHERS - Metallurgist Mineral

GYRATORY CRUSHERS The original patent for the gyratory crusher was granted to Phile- tus W. Gates in 1881. This fint crusher was used by the Buffalo Cement Co. At the time these early gyratory crushers were developed all mining and quarrying, either underground or open pit, was done by hand; tonnages generally were small and product ...

获取价格

Gyratory Crusher - Design of mantle and concaves - Crushing,

The majority of gyratory crushers are used as primaries, i.e. they receive the initial feed from the mine or quarry. The same type of crusher with chamber modifications is used as a secondary crusher, particularly when following a large primary crusher. The fine-reduction gyratory crusher can also be used for tertiary crushing.

获取价格

Primary Crusher vs. Secondary Crusher: Understanding Their

2023/2/28 Gyratory crushers are another type of primary crusher that is used for larger rocks and stones. They are more expensive than jaw crushers, but they offer a higher reduction ratio. Gyratory crushers operate by compressing the material between a mantle and concave surface, with the mantle moving up and down to compress the material

获取价格مطحنة الكرة 0 طن في الساعة سعر التكلفة

مطحنة كسارة الصخور المحمولة الصغيرة

مصنع إثراء خام الحديد في كسارة الحجر في الهند

دليل شركات تصنيع معدات التعدين في قطر

طريقة استخراج الحجر الجيري في مصر

مستشار للاسمنت طحن مطحنة

Gyradisc كسارة عمود المناولة الوسيط الخارجي البطانة

مصنع التكسير المحمول المحمول مسبك الرمال

كم هو كسارة الفك 10 × 24

maquinaria de construccion mexico

كسارا ت في المانيا

أسماء المتعلقة بأعمال تكسير الحجارة

كيفية تركيب المطارق على كسارة kumbee

معدات تعدين الذهب للبيع الولايات المتحدة

رسم تخطيطي لمطحنة ريموند

رأى معدات شحذ

الة تكسير الحجر للبيع في المغرب مستعملة

الآلات المستخدمة لإزالة الألغام خام الكروم

تفاصيل حجر الصابون

تصميم جهاز تنقية غاز الفلور لمصنع سوبر فوسفات واحد

انبعاثات تعدين خام الحديد

بيع كسارة متنقلة مستعملة في بيرو

كسارة فكية المغنتيت في البحرين

الحصى والرمل في النهر

مواقع صناعات مناجم الفحم

كسارة متنقلة sgravel في مصر

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20