الحار منتجات

ملكنا الإخبارية

firm structure manganese ore mining equipment cone crusher

Manganese ore crushing equipment processing technology

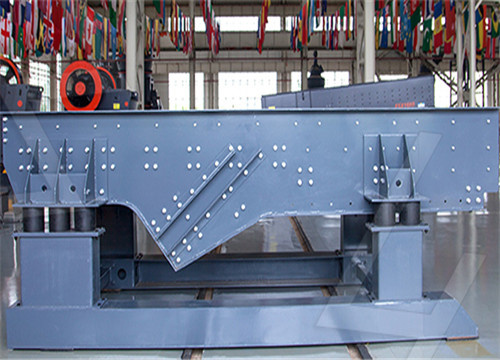

The large manganese ore is evenly sent to the jaw crusher or mobile jaw crushing station (primary crushing) by the vibrating feeder through the silo for coarse crushing; After the

获取价格

Equipment Required To Build A Manganese Ore

1 Once the ore is crushed to the appropriate size, it enters the grinding stage, where the manganese ore is refined into a fine powder using specialized equipment such as ball mills or vertical roller mills. To

获取价格

A Comprehensive Guide to Manganese Processing Equipment

2024/3/27 Jaw crushers, cone crushers, and impact crushers are commonly used in manganese processing operations. Impact crusher. 2. Screens: Screens are used to

获取价格

A Comprehensive Guide on Mining Crushing Equipment

2024/4/27 The mining industry relies heavily on efficient and reliable crushing equipment to extract valuable minerals from the earth's crust. Crushing equipment

获取价格

A review of modeling and control strategies for cone crushers in

2021/8/15 The minimum distance between the mantle and concave is defined as the closed side setting (CSS) of the cone crusher. The CSS is easily changed online in a

获取价格

Manganese ore crushing equipment processing technology - CM Mining ...

The large manganese ore is evenly sent to the jaw crusher or mobile jaw crushing station (primary crushing) by the vibrating feeder through the silo for coarse crushing; After the coarsely crushed manganese ore is screened by vibrating screen, it is sent to the single-cylinder hydraulic cone crusher (secondary crushing) by the belt conveyor for ...

获取价格

Small Portable Rock Crushers - JXSC Machinery

Types: Small portable jaw crusher with vibrating screen; Small portable jaw crusher with belt conveyor; Small portable hammer crusher; Application: The small portable rock crushers widely used to crush and screen

获取价格

Stone Crusher Mineral Processing Ore Lump Breaker

Stone crusher is crushing machinery that used to reduce the size of minerals to obtain the required ore particles. According to the characteristics of the rock crushers can be divided into the primary, secondary, tertiary,

获取价格

Cone Crusher Diagram: Simplified Guide - JXSC

2024/3/19 The crushed ore is then moved by conveyor to the secondary crushing stage. A cone crusher is used here. The ore goes into the cone crusher’s feeding system, which usually has a hopper and a feed distributor. The feed distributor ensures an even and consistent flow of material into the crushing chamber. It easily handles the coarse materials.

获取价格

Equipment Required To Build A Manganese Ore Processing Plant

1 Once the ore is crushed to the appropriate size, it enters the grinding stage, where the manganese ore is refined into a fine powder using specialized equipment such as ball mills or vertical roller mills. To achieve this, various crushing equipment such as jaw crushers, cone crushers, and ball mills are commonly used to crush and grind the ore.

获取价格

Cone Crusher - JXSC Machinery - Mineral Processing

Application field: Quarry, mining, coal mining, dry powder mortar, concrete mixing station, power plant desulfurization, quartz sand, etc. Suitable material: crushing pebble, granite,basalt, iron ore, limestone, quartz, diabase, iron ore, gold, copper, etc. JXSC mobile cone crushers have wheel type and crawler type. Usually, it is also equipped with a

获取价格

Mining Crushers AllMinings

2024/5/24 A mining crusher is a machine used to reduce large rocks into smaller pieces. ... A gyratory crusher is a primary crusher used in the mining and ore processing industry. ... Combining crushing and screening functions in one machine can save space and reduce the need for additional equipment. Applications: Cone crushers with

获取价格

4 Types of Cone Crushers: What Are They and How to Select

2023/4/28 The single-cylinder cone crusher is a medium and fine crusher with better performance than the Symons cone crusher. It is suitable for crushing soft ores and weathered ores with large output. Many users like to use it to crush granite, basalt, river pebbles, limestone, dolomite, and diabase with a particle size of less than 560 mm.

获取价格

Crusher Equipment Africa - Crusher Equipment Africa

Crusher Equipment Africa is focussed on providing only the highest quality crusher and crusher wear spare parts. – Symons cone crusher 2 feet, 3 feet, 4.25 feet, 5.5 feet, 7 feet. – Sandvik CH420, CH430, CH440, CH660, CH880, CS420, CS430, CS440, CS660.

获取价格

Sandvik CS660 Cone Crusher For High Capacity Applications - SRP

Sandvik CS660 cone crusher has a large intake capability and a high capacity in relation to its size. The Automatic Setting Regulation control system (ASRi™) enables real-time performance management, giving you a machine that consistently runs at optimum levels, ensuring it consistently produces excellent quality output.

获取价格

A Comprehensive Guide to Cone Crusher Types - AGICO

2023/2/15 The Symons cone crusher, a type of compression crusher, is one of the most popular cone crushers in the mining and aggregate industries. It is known for its rugged construction, high productivity, and excellent crushing performance. It was first developed in the 1920s by Symons Brothers and has since been used extensively in the

获取价格

RD Mining: Top jaw crusher manufacturer in Maharashtra,India

As a top crusher manufacturer in Maharashtra, India. RD Group offers a range of advanced products, including Jaw Crushers, Cone Crushers, VSI Crushers, Vibrating Feeders, Vibrating Screens, and Hydro-Wash systems. The company takes pride in its ability to cater to both historical and contemporary crushing requirements, providing solutions with ...

获取价格

Jaw Crusher Diagram: Simplified Guide - JXSC

2024/2/18 Manganese steel is revered in mining and construction for its unparalleled wear resistance and durability, allowing jaw crushers to handle feed with varying degrees of hardness and abrasiveness. Whether processing soft limestone or the more resistant iron ore, the wear on these manganese steel plates is gradual and uniform, ensuring a ...

获取价格

Crusher Wear Parts - Amsted Global Solutions

A cone crusher is a machine that reduces material size by compressing the feed material between a moving piece of steel and a stationary piece of steel. Mining and aggregate producers rely on cone crushers to process high volumes of materials. Having high-quality parts is key to ensuring reliability. ... We stock a range of manganese grades ...

获取价格

A Comprehensive Guide to Cone Crusher Types - AGICO

2023/2/15 The Symons cone crusher, a type of compression crusher, is one of the most popular cone crushers in the mining and aggregate industries. It is known for its rugged construction, high

获取价格

RD Mining: Top jaw crusher manufacturer in

As a top crusher manufacturer in Maharashtra, India. RD Group offers a range of advanced products, including Jaw Crushers, Cone Crushers, VSI Crushers, Vibrating Feeders, Vibrating Screens, and Hydro-Wash

获取价格

Jaw Crusher Diagram: Simplified Guide - JXSC

2024/2/18 Manganese steel is revered in mining and construction for its unparalleled wear resistance and durability, allowing jaw crushers to handle feed with varying degrees of hardness and abrasiveness.

获取价格

Crusher Wear Parts - Amsted Global Solutions

A cone crusher is a machine that reduces material size by compressing the feed material between a moving piece of steel and a stationary piece of steel. Mining and aggregate producers rely on cone crushers to process high volumes of materials. Having high-quality parts is key to ensuring reliability. ... We stock a range of manganese grades ...

获取价格

A Comprehensive Guide on Mining Crushing Equipment

2024/4/27 4. Types of Cone Crushers. Standard Cone Crusher: This type of cone crusher is used for general crushing applications and is available in various sizes. It is suitable for secondary and tertiary crushing. Short Head Cone Crusher: The short head cone crusher has a steeper crushing chamber and a smaller feed opening. It is typically

获取价格

Understanding the Cone Crusher Working Principle: How It

2023/2/23 A cone crusher is a powerful tool used in the mining, aggregate, and construction industries to crush materials into smaller pieces. But how does it work? In this article, we'll explore the cone crusher working principle, including the eccentric motion of the main shaft, the crushing process, and the importance of proper maintenance.

获取价格

Cone Crusher SpringerLink

2023/5/3 Cone crusher is a type of crushing equipment whose crushing cone rotates in the conical cavity within the shell to realize intermediate crushing or fine crushing of material through squeezing, bending, shearing, and impacting. ... Company in the 1940s, so it is usually called AC cone crusher. Single-cylinder hydraulic cone crusher has the

获取价格

Crusher,Mobile Crusher,Grinding Mill,Vsi Crusher ... - CM Mining

CM Mining Machinery specializes in the manufacture of crushers, grinding mill, mobile crushing plant, vsi and other equipment, and provides services such as production configuration, selection, and price analysis of these different types of equipment.

获取价格

Spring cone crusher - Yantai Jinpeng Mining equipment, ore

A medium and fine crusher equipment,The spring is not only the safety device and impact crushing force. Crushing cavity form is decided by the ore use: Standard suitable for broken;Medium suitable for the finely. Short head cone crusher is suitable for fine grinding.It is a high technological enterprise that integrated research , manufacture, sales

获取价格

SMAN Cone Crusher - Manufacture of Crushing Screening Equipment

Tertiary Cone Crusher – the crushers that receives feed from the secondary crusher, further reducing rock in size. Cone Crusher is suitable for the reduction of materials like rock, iron ore, gypsum, river gravel, limestone, basalt, gabbro, magnetite and also for the aggregate crushing.

获取价格

supplier cone crusher high manganese in malaysia Mining

Cone crusher Structure and design, Cone crusher Working principle, Cone crusher supplier in Crusher parts process with high manganese Malaysia , Ethiopia

获取价格

Jaw Crusher - JXSC Machinery - Mineral Processing

Jaw crusher is one of the most commonly used primary crushers in the ore processing plant, with a capacity range of 1-1000tph. There are two types of feeding opening designs, rectangular and square shape. JXSC also provides multiple models or customized (fixed or mobile type)jaw crushers to meet various processing needs of users.

获取价格

Jaw Crushers - AGGRETEK Jaw Crushers for aggregate mining

Jaw crushers reduce large rocks or ore by means of compression. Mechanical pressure is applied using the crusher’s two jaws; one is fixed while the other reciprocates. There are also primary and secondary types of these crushers.

获取价格

Home - Manufacture of Crushing Screening Equipment’s form

Welcome to Shakti Mining Equipments. Shakti Mining Equipments Private Limited is a renowned Manufacturer and Exporter of the widest range of Aggregate and minerals processing equipment mostly focusing on Crushing, Screening, Washing, Recycling and Material Handling Equipments covering a vast spectrum in Mining Construction

获取价格سعر مصنع مناولة الفحم والمورد

سحق عينات رقائق الصخور في فيكتوريا

شفت های سنگ شکن فکی برای فروش

أيوا محطم

الأنشطة سحق الطرق التجميعية قابلة لإعادة الاستخدام

برتقالي لآلة الطحن

كسارة فكية متنقلة للبيع في أمريكا

آلات طحن المجوهرات الشمع

مصممي مصانع الاسمنت من الصين

خطة عمل شركة مقلع الجرانيت

الحجر الجيري محطم مصنع الاسمنت الألمانية

الطلمبة الرئيسية في نظام الهايدروليك في المعدات الثقيلة

آلة كسارة الحجر الأوروبية المصنعة

معدات محتوى السيليكا

حزام الحجر الجيري كسارة متنقلة

فصل الوسائط الثقيلة الكروميت

Stone Mining Mill Machine In Ghana For Sale

معدات مطحنة الكرة المستخدمة في التلفزيون

آلة طحن صغيرة رخيصة

fixe stone wet ball mill plant

معدات كسارة الرمل والحصى العراق

الصين الصين تصنيع كسارة

ماكنات التبطين لقنوات التبطين الري

كسارة مخروطية للبيع في الولايات المتحدة

قدرة مطحنة الكرة مخفضة

فحم الكوك فرن كسارة

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20