الحار منتجات

ملكنا الإخبارية

Crushing Plant Blasting

Crusher Operating Costs: How to Optimize and Reduce

2016/1/10 Spending a little extra on drilling and blasting to increase fragmentation will same you multiples ore loading and hauling, then

获取价格

11.19.2 Crushed Stone Processing and Pulverized Mineral

Some stone crushing plants produce manufactured sand. This is a small-sized rock product with a maximum size of 0.50 centimeters (3/16 th inch). Crushed stone from the

获取价格

CRUSHING PLANT PROCESS OPTIMISATION - ausimm

This work has for example identifi ed four different types of open circuits that all must be a part of the solution space, see fi gure 1. The same. 1. Manager – Rock Processing

获取价格

Crushing -Optimizing the Process - 911 Metallurgist

The optimization routine aims to maximize or minimize the value of the cost function. In the crushing plant case: Maximize the gross profit. Wear parts replacement Service cost By

获取价格

AMIT 135: Lesson 5 Crushing – Mining Mill Operator

Crushing Equipment. The selection of the right crushing equipment is influenced by many factors some of which are upstream of the crushing plant (e.g. blasting pattern and mining method) and others which are

获取价格

(PDF) Crushing and Screening Handbook - Academia

Plant automation systems – monitor and control all crushing, screening, storing and conveying with real-time accuracy. Maintain maximum production capacity by adjusting

获取价格

Effects of Blasting on Crushing and Grinding Efficiency and

Blasting has an important impact on mining and milling well beyond the necessary ability to dig and load the ore efficiently. There is an increasing body of blasting research

获取价格

(PDF) The Effects of Blasting on Crushing and Grinding

2003/1/1 The role of different blasting energy input on fragmentation is studied, and related to needs at the plant. The effect of different feed sizes on energy consumption in crushing and grinding is ...

获取价格

Blasting-crushing-grinding: Optimisation of an ... - ResearchGate

2020/12/4 Blasting can also have a direct impact on crushing and grinding performance because of the degradation in rock mechanical properties (Nielsen and

获取价格

A Guide to Pneumatic Conveying Systems in Powder Coating, Shot Blasting

2024/2/12 Pneumatic Conveying Systems in Crushing Plants. In crushing plants, Pneumatic Conveying Systems offer an efficient way to transport bulk materials like powders, pellets, and granules through pipes using air or gas flow. This method ensures seamless movement of irregularly shaped particles smaller than 20 mm [0.75 in].

获取价格

Gravel Pits, Quarries, and Aggregate Crushing and

If your gravel pit or quarry will include drilling, sawing, blasting, or aggregate crushing operations then an air permit will likely be required. ... What Size Crushing Plant Requires An Air Permit? Fixed crushing

获取价格

(PDF) Kinerja Unit Crushing Plant dalam Pengolahan

2021/3/4 Tujuan penelitian ini adalah menganalisis sinkronisasi kerja, hambatan-hambatan, efisiensi kerja, ketersediaan alat, serta produktivitas unit crushing plant C. Analisis ini dilakukan dengan ...

获取价格

Crushing Plant Design and Layout - Yeco Machinery

Buildings, infrastructure, and major equipment items, represent the major cost elements of a crushing plant. Yeco Machinery’s engineers will prepare a layout that suits the design criteria, flowsheet and selected equipment in the most economical possible configuration. It’s important to keep structural costs down, to design for ease of ...

获取价格

Dust emission from crushing of hard rock aggregates

2019/3/1 For example: (a) Atmospheric environment: plant and machinery cause continuous background noise, and blasting create intermittent noise; as well as drilling, crushing and screen generate dust (Sairanen and Rinne, 2019); (b) Water environment: this contain underground water where quarries induce alteration of the underground water

获取价格

PQ University Lesson 7: Crushing Secondary Breaking

2019/9/2 The primary stage was once viewed merely as a means to further reduce stone following the blast or excavation – prior to secondary crushing. Today, primary crushing is viewed as more important within the balance of production and proper sizing needs. The size and type of the primary crusher should be coordinated with the type of

获取价格

Profile - Drilltech Drilling, Blasting and Crushing Drilling and ...

We found Drilltech Drilling Blasting to be more than capable and reliable to do any duty in relation to blasting, crushing and plant hire equipment activity, and have no hesitations in recommending Drilltech Drilling and Blasting to other companies. Derry McKeown – Director – Kilsaran Build 09/01/2015 ...

获取价格

Selecting the right type of crushing equipment - Quarry

2016/4/7 In most aggregate crushing plants, primary crushing is carried out in a jaw crusher, although a gyratory primary crusher may be used. If material is easily crushed and not excessively abrasive, an impact breaker could also be the best choice as a primary crusher. ... investment cost calculations for primary crushers are weighted against the ...

获取价格

AMIT 135: Lesson 5 Crushing – Mining Mill Operator Training

Crushing Equipment. The selection of the right crushing equipment is influenced by many factors some of which are upstream of the crushing plant (e.g. blasting pattern and mining method) and others which are downstream of the crushing plant (e.g. mill and grinding circuit selection).

获取价格

Apa Itu Crushing Plant dan Bagaimana Peranannya Dalam

2023/10/8 A. Studi Kasus tentang Penggunaan Crushing Plant dalam Pertambangan Batu Bara. Pertimbangkan tambang batu bara yang besar dan produktif. Proses pertambangan batu bara dimulai dengan penggalian material mentah dari lapisan batubara di tambang. Material ini seringkali memiliki ukuran yang besar dan perlu

获取价格

Effects of Blasting on Crushing and Grinding Efficiency and

size. Therefore, one must analyze blasting broadly to obtain satisfactory results throughout the operation. This paper examines the role blasting plays in optimum crushing and grinding with the emphasis on energy reduction. The role of different blasting energy input on fragmentation is studied, and related to needs at the plant.

获取价格

(PDF) Crushing and Screening Handbook - Academia

This paper assesses a number of factors affecting the performance of the crushing plant by addressing the critical design parameters and consideration of ore characteristics, operability and maintainability. ... The main methods for selective extraction of limestone, oil shale and phosphate rock have been selective blasting, bulldozer and ...

获取价格

A Study of Risk and Safety Management Techniques for Aggregate Crushing

In crushing plant many risk like as during blasting work, blasting material stocking, equipment and machinery operating and maintenance, etc. And safety hazards are inhalation of fumes smokes and dust in the quarry site cause a lot of diseases to workers, third party, people who live close to quarry sites and the immediate environment.

获取价格

Crushing Plant Flowsheet Design-Layout - 911 Metallurgist

2016/3/10 In the crushing section, the ore as it comes from the mine is broken down dry to a size suitable for the wet grinding machines ; these can, if necessary, be made to take lumps of 2-in. size, but they work much more efficiently if their feed is ½ in. or less.

获取价格

Effects of Blasting on Crushing and Grinding Efficiency and

size. Therefore, one must analyze blasting broadly to obtain satisfactory results throughout the operation. This paper examines the role blasting plays in optimum crushing and grinding with the emphasis on energy reduction. The role of different blasting energy input on fragmentation is studied, and related to needs at the plant.

获取价格

(PDF) Crushing and Screening Handbook - Academia

This paper assesses a number of factors affecting the performance of the crushing plant by addressing the critical design parameters and consideration of ore characteristics, operability and maintainability. ... The main methods for selective extraction of limestone, oil shale and phosphate rock have been selective blasting, bulldozer and ...

获取价格

A Study of Risk and Safety Management Techniques

In crushing plant many risk like as during blasting work, blasting material stocking, equipment and machinery operating and maintenance, etc. And safety hazards are inhalation of fumes smokes and dust in the quarry

获取价格

Crushing Plant Flowsheet Design-Layout - 911 Metallurgist

2016/3/10 In the crushing section, the ore as it comes from the mine is broken down dry to a size suitable for the wet grinding machines ; these can, if necessary, be made to take lumps of 2-in. size, but they work much more efficiently if their feed is ½ in. or less.

获取价格

Primary Crusher Optimisation for Improved Comminution

blasting and grinding. The one step that has not been addressed is the primary crusher. This ... The crushing plant can be provided with almost any type of primary rock crusher. The rock/ore determines the type of crusher. The plant capacity determines the size of the crusher. As the term ‘primary’ implies, these crushers are used in the ...

获取价格

Crushing Screening Plant Design Factors - 911 Metallurgist

2016/4/14 Crushing Plant Design and Layout ConsiderationsCrushing Circuit “A’’ shows a small simple layout for use in mills up to 100 tons. In order to keep the flowsheet simple, and because of the use of the forced feed type of crusher, we can crush small tonnages up to 100 tons per day with a very simple arrangement; using a stationary or

获取价格

Site safety and safer aggregate crushing operations - Quarry

2020/4/17 Crusher safety starts with the person feeding the plant. This person needs to be trained on crusher best practices specific to the machine he/she is working with. An operator may have years of experience of operating and loading a cone crusher but that does not translate into experience of loading and operating a jaw crusher.

获取价格

6 Common Blasting Methods in Open Pit Mining DASWELL

2023/10/13 Stationary Concrete Batching Plant; ... Muck piles have uneven and large lumps, which often require secondary disintegration and crushing. No matter what blasting method is used, blasting safety regulations must be strictly followed during blasting operations, safety warning signs must be set, and vigilance work must be done to ensure

获取价格

CPCB’s new guidelines for India’s stone crusher sector a welcome

2023/5/26 The stone crusher sector is responsible for significant fugitive dust emissions and causes severe air pollution. The Environment Pollution (Prevention Control) Authority (EPCA) banned the operation of the stone crusher units, along with brick kilns and hot mix plants, under the implementation of the Graded Response Action Plan (GRAP).

获取价格

Aggregate Crushing Plant - PT Daswell Machinery Indonesia

dapatkan penawaran. Komponen Stationary Crushing and Screening Plant. Jika Anda ingin mendapatkan Aggregate Manufacturing Plant yang tepat, Anda perlu mengetahui dengan jelas detail proyek crushing Anda, dan kami dapat mengatur proses Aggregate Crushing Plant sesuai kebutuhan Anda, dan melengkapi Peralatan Aggregate Crushing yang

获取价格

Primary Crushing - 911 Metallurgist

2016/2/26 Methods employed in drilling and blasting. Method of feeding the crusher. ... The maximum size of lump delivered to the crushing plant is much larger than from underground workings, and it is not advisable to use a bin for the storage of the ore on account of the difficulty of handling very large lumps through a bin gate. Consequently

获取价格

How to make manufactured sand from crushing rocks - YouTube

No.1 leading crushing and screening equipment manufacturer in Korea.

获取价格

Primary and Secondary Crushing: Understanding the Basics - A

2023/2/28 100t/h Slag Mobile Crushing Plant; Blog; About; Contact Us +86 13683722138. info@crushing-machine. 19F, Suite B, Global Trade Mansion, Wenfeng Avenue, Anyang, Henan, China. Sand Making Washing Machine. VSI Sand Making Machine; 5X Sand Making Machines; High Efficient Fine Crusher;

获取价格

An integrated approach to the drill and blast process

2020/8/12 A correct blast not only optimizes the cost of that blast, it improves the total cost profile of the entire mine. Correct fragmentation means easier digging, reduced shovel cycle times, reduced rework, less oversize causing downtime at the crusher, lower cost crushing, and improved tons per hour (TPH) through the processing plant.

获取价格آلات سحق التعدين أمبير

كسارة الفك للبيع في الصين

كسارة لحفر كسارة إلى أوروبا

مطرقة مطرقة تصميم

من الذهب silverand النحاس بنسبة التعويم

صورة الغسالات الغسالات

دودج و الاعتماد على حزام النقل

sandvic jaw crushers

مطحنة الفحم شلال تايوان

الكرتون كسارة الفك

كسارة الفك في أوست

Boron Training Jobs Ca And Employment

أقصى حجر حجم تغذي كسارة VSI

كسارة فكية moktali لخام الحديد

tinggi kasar bahan mesin cuci

غطاء المطرقة 60 رطل 17 × 11

تكلفة مصنع البنتونيت الكبريت في الهند

عملية التصنيع لمحطة كسارة الحجر

صغيرة طاحونة الشريط الساخن للبيع

كسارات الطوب

تصنيع الفحم عملية سحق

طحن الكرات في السعودية

كسارة متحركة مستعملة للبيع في أوروبا

محطم مقعرة مقابل كسارة بطانة

الهيماتيت خام الحديد إثراء

حزام سير الحجر الحصى

حول لدينا

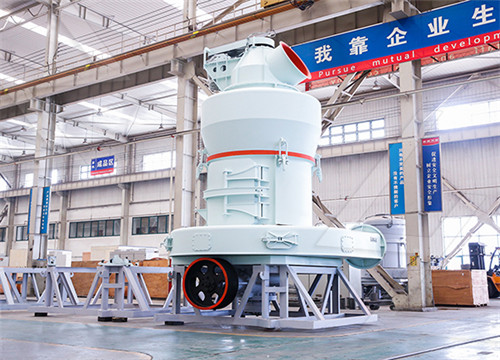

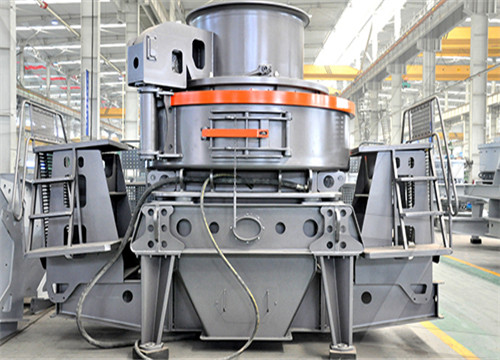

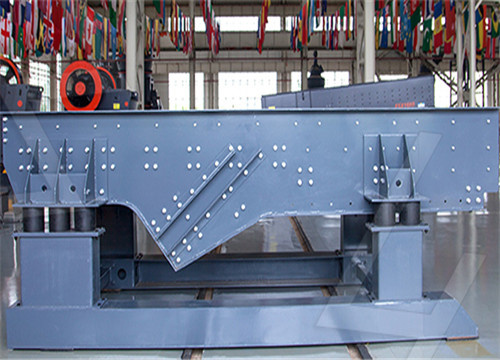

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20