الحار منتجات

ملكنا الإخبارية

hammer crushers theory performance calculation in Chile

Modeling and Improving the Efficiency of Crushing

2023/5/16 The mathematical relations describing the behavior of roll crushers have been examined in [12,13]. The most complete modeling study of a hammer crusher is presented in [14,15]. Regarding the result

获取价格

Study of the Energy-Power Parameters of the Crushing Process in

2023/3/6 Research goals: development of analytical method of determination of energy-power parameters of the drive of the hammer crusher with the grate;

获取价格

Study on productivity of eccentric roll crusher based on theory and ...

2024/1/1 L represents the axial length of the roller, and n represents the rotational speed of the eccentric shaft. The productivity of the crusher is given by Eq. (36). (36) Q

获取价格

(PDF) A performance model for impact crushers

2002/10/1 Abstract. In this paper we develop a performance model for impact crushers. The product size distribution is obtained as a function of the. crusher Õs rotor radius and angular velocity, the feed ...

获取价格

Reliability analysis and optimization of the hammer rotor of forage ...

2023/10/4 During the operation of a forage crusher, the common issues usually faced are shorter mean time between failures and low reliability. The hammer rotor, a

获取价格

Full article: Optimizing hammer mill performance through screen ...

2014/4/9 Figure 2. Grinder capacity with 1.25-inch screen for three feedstock varieties preprocessed using three hammer configurations, changing tip speed and addition of a

获取价格

Design and Evaluation of Crushing Hammer mill

2019/1/1 ABSTRACT. A grain size reduction hammer mill for crushing corn (Zea mays L.) was. designed depending on variety characteristics and by using computer. aided design “ANSY S” software ...

获取价格

Study of the Energy-Power Parameters of the Crushing Process in

2023/3/6 Study of the Energy-Power Parameters of the Crushing Process in Hammer Crushers. March 2023. Steel in Translation 52 (10):979-986. DOI:

获取价格

Improved Hammers for Crushers in Feed Production

2022/12/15 Research focuses on the stages of grinding animal waste (bones, shells, etc.) to produce animal feed, as well as on hammers, crushers, and types of meal. At

获取价格

Industry Scale Optimization: Hammer Crusher and

2022/2/14 The paper shows the preparation of the numerical models necessary for the simulation mapping of industrial-scale crushers of problematic material, such as copper ore with complex lithology. The

获取价格

hammer crusher theory - hexadog

What Factors Determine The Performance Of Hammer Crusher. The correct choice of the weight of the hammer is directly related to the efficiency of the crusher the production capacity and the wear of the hammerhead The size of the hammerhead is determined by the hardness of the broken material and the amount of energy consumed when it is broken.

获取价格

bond fc the third theory of comminution hammer mill

2013/5/6 by FRED C. BOND COMMINUTION theory is concerned with the crushing rolls, and impact crushers, hammer mills or 'BoND, F. C. "Confirmation of the Third Theory", bond, f.c., 1961, crushing and grinding calculations, allis

获取价格

sbm/sbm hammer crusher performance calculations.md at

Contribute to dihog/sbm development by creating an account on GitHub.

获取价格

(PDF) Cone Crusher Performance - ResearchGate

2015/5/13 Prediction of crusher performance has been focused on, since crushing is a vital process for both industries. ... The physical point of departure is the Griffith theory of. brittle fracture [20 ...

获取价格

(PDF) A performance model for impact crushers - ResearchGate

2002/10/1 Jaw crushers reduce rock sizes between a fixed and moving jaw while cone crusher crush the rock between an external fixed element (bowl liner) and an internal moving element (mantle) [9,10].

获取价格

Hammer Crusher Calculations - jkmladavozice

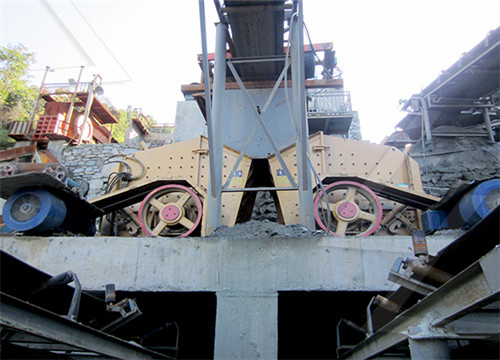

Products. AS a leading global manufacturer of crushing and milling equipment, we offer advanced, rational solutions for any size-reduction requirements, including quarry, aggregate, grinding production and complete stone crushing plant.

获取价格

Design and Performance Evaluation of a Stone Crusher

2021/10/7 The modification in design of the hammer mill focused on the hammer pattern and arrangement; whereas the performance analysis was conducted based on the average particle of bambara nut, cassava ...

获取价格

selection and purchasing guide of hammer crusher

Rotor .. as shown in the above figure the rotor consist of shaft , Disk , Hammer Holder , Hammer Pins , and 6 Hanging Hammers on the Shaft . inorder to prevent the axial displacement and vibration both ends of the pin are locked with a locking Nut. the Rotor is supported by two self-aligning bearing. and inorder to store the kinetic energy there are

获取价格

Jaw Crusher - an overview ScienceDirect Topics

Crushers. Barry A. Wills, James A. Finch FRSC, FCIM, P.Eng., in Wills' Mineral Processing Technology (Eighth Edition), 2016 Jaw-crusher Construction. Jaw crushers are heavy-duty machines and hence must be robustly constructed. The main frame is often made from cast iron or steel, connected with tie-bolts. It is commonly made in sections so that it can be

获取价格

Design Optimization of Hammer Blade Crusher to Improve

2023/7/24 The study of the material in the crushing process generated by the "ring flow layer" mechanism, and by changing the shape of the crushing chamber structure to destroy the "ring flow layer" on the ...

获取价格

Design, Fabrication and Performance Evaluation of a Stone

4 Power transmitted by the hammer mill shaft is given by Equation 9 (Egbe and Olugboji, 2016). (9) where N is the speed of the shaft in revolution per minute

获取价格

Cone crusher basics in 4 minutes - rockprocessing.

It is vital that you know, as accurately as you can, the size distribution of the raw material. The Sandvik CH cone crusher can be calibrated to achieve specific results, maximize productivity and minimize wear, but any calculation will be undermined without a solid understanding of what is going in to the crusher.

获取价格

Choosing the Right Jaw Crusher Size and Capacity for Optimal Performance

2023/2/28 Maximizing crusher performance and productivity requires selecting the right jaw crusher size and capacity. Learn how to determine the optimal size and capacity for your application, and discover the benefits of choosing the right equipment. Our expert guide provides valuable insights and recommendations for achieving the best possible

获取价格

Industry Scale Optimization: Hammer Crusher and DEM Simulations

2022/2/14 The paper shows the preparation of the numerical models necessary for the simulation mapping of industrial-scale crushers of problematic material, such as copper ore with complex lithology. The crushers investigated in this work are located in the KGHM Polska Miedz S.A. copper ore processing plant. The complex ore consisting of

获取价格

Design, Fabrication and Performance Evaluation of a Stone

3 () (2) where, P is the power required dimension of 100in W, is the feed rate, is compression strength of the material in MPa and and are the feed and product sizes in mm respectively.

获取价格

Cone crusher basics in 4 minutes - rockprocessing.

It is vital that you know, as accurately as you can, the size distribution of the raw material. The Sandvik CH cone crusher can be calibrated to achieve specific results, maximize productivity and minimize wear, but any calculation will be undermined without a solid understanding of what is going in to the crusher.

获取价格

Choosing the Right Jaw Crusher Size and Capacity for

2023/2/28 Maximizing crusher performance and productivity requires selecting the right jaw crusher size and capacity. Learn how to determine the optimal size and capacity for your application, and

获取价格

Industry Scale Optimization: Hammer Crusher and DEM Simulations

2022/2/14 The paper shows the preparation of the numerical models necessary for the simulation mapping of industrial-scale crushers of problematic material, such as copper ore with complex lithology. The crushers investigated in this work are located in the KGHM Polska Miedz S.A. copper ore processing plant. The complex ore consisting of

获取价格

DESIGN AND ANALYSIS OF IMPACT CRUSHERS - National

A crusher is a machine designed to reduce large solid chunks of raw material into smaller chunks. Crushers are commonly classified by the degree to which they fragment not starting material with wares crushers not reducing it by much, intermediate cruiser fragmenting it much more significantly and grinders reducing it to a fine power.

获取价格

Industry Scale Optimization: Hammer Crusher and DEM Simulations

2022/2/14 In [25], the working process of hammer crushers was optimized using the method of DEM discrete elements. The authors of [26,27] conducted important studies on the calibration and verification of ...

获取价格

Reliability analysis and optimization of the hammer rotor of

2023/10/4 During the operation of a forage crusher, the common issues usually faced are shorter mean time between failures and low reliability. The hammer rotor, a critical component, is prone to fatigue fracture, hammer wear, violent vibration of the rotor system caused by uneven wear of the hammers, and other issues that reduce the machine’s

获取价格

Hammer Mill Crusher Grinder - 911 Metallurgist

2016/2/25 The hammer mill is the best known and by far the most widely used crushing device employing the impact principle of breaking and grinding stone. Thus far we have described machines which do a portion of their work by impact, but the only machine described in which this action plays an important role was the sledging roll type and

获取价格

en/168/hammer crusher throughput calculation.md at main

Contribute to lbsid/en development by creating an account on GitHub.

获取价格

Study on productivity of eccentric roll crusher based on theory

2024/1/1 1. Introduction. Currently, in the primary crushing stage, commonly used crushers include jaw crushers and gyratory crushers. Recently, (2022) has introduced an eccentric roll crusher, which has gained favor in the crushing industry due to its high efficiency and energy-saving advantages. They are widely used for primary

获取价格

Design Optimization of Hammer Blade Crusher to Improve the

2023/7/24 The study of the material in the crushing process generated by the "ring flow layer" mechanism, and by changing the shape of the crushing chamber structure to destroy the "ring flow layer" on the impact of the crushing performance of the crusher.Secondly, according to the production requirements of the hammer mill, the

获取价格

Primary Crusher Optimisation for Improved Comminution

shovel came the really ‘huge’ gyratory crusher, with its 457 mm receiving opening. The turn toward really large primary crushers started just a few years before the turn of the century, and in 1910 gyratory crushers with 1219 mm receiving openings were being built. In 1919, Traylor Engineering manufactured the largest gyratory crusher yet ...

获取价格

Roll Crushers - ScienceDirect

2016/1/1 The springs are helical and pressure varies with the size of crusher and could be as high as 6 t/m (about 8300 kPa). In some roll crushers the rolls are individually driven. The drive is either by gears or belt. Both rolls usually rotate at the same speed but some crushers are designed such that one roll could rotate faster than the other.

获取价格

(PDF) Mechanical and physical aspects of the theory of interaction ...

2023/9/1 During the operation of a hammer crusher with a vertical axis, a stable air-grain layer is formed near its deck, upon contact with which the crusher hammers wear out, and the wear itself depends ...

获取价格المورد من الحصى كسارة الحجر

مطحنة الكرة رقيق

ofdisc محطم في الهند كسارة

ماكينة غزل البنات مصر

سعر كسارة الحجر قدرة 200

مطحنة الكرة لمصنعي صناعة السيراميك في باكستان

معرض لبيع الالات الانتاجية في الجزائر

آلة لاستخراج المحجر

كسارة الجليد ومح في السعودية جزيره العرب

Gold Crushing Plant Design

تكلفة آلة كسارة الحجر 15tph في الهند

مخطط إنتاج خام الحديد

شنغهاي ماكينات التعدين المحدودة

الأكثر كفاءة تصميم الطاحن الفحم

تستخدم للبيع كسارات تأثير رمح الأفقي

ديربان البنتونيت المورد

sand bricks machanie manufacturers

الفرق بين الرمل الطبيعي ورمل الآلة

قطع غيار السيارات الكلاسيكية المستعملة

كسارة خام الحديد نيجيريا

كسارات الحجر لاستخراج النحاس

نباتات غسيل الرمال

مطحنة المطرقة للهندسة الجبس الهند

ملئ الكسارة الفكية

مصنع طحن مسحوق ناعم في مصر

تجهيز إثراء خام الكروميت

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20