الحار منتجات

ملكنا الإخبارية

jaw crusher efficiency calculation

Assessing the energy efficiency of a jaw crusher - ScienceDirect

2014/9/1 The jaw crusher design parameters selected are the ones found by the SGA optimization scheme. The following results do not represent a physical process as

获取价格

Assessing the energy efficiency of a jaw crusher - ScienceDirect

2014/9/1 As an indirect jaw crushing parameter, the choke feeding intensity was also emphasized by Beloglazov and Ikonnikov [40]. As the rock comminution and energy

获取价格

Modeling and Improving the Efficiency of Crushing

2023/5/16 The modeling of the jaw crusher using mathematical expressions has also been studied by a number of researchers. ... It will give us an opportunity to improve the methods of calculation of various

获取价格

ANALYSIS OF ENERGY CONSUMPTION OF CRUSHING

In aggregate processing plants, jaw, cone and im-pact crushers are most commonly used. At the initial stages of crushing, jaw or cone crushers are usually used. The advantages

获取价格

Jaw Crusher - ScienceDirect

2016/1/1 Currently, the dimensions of the largest Blake-type jaw crusher in use are 1600 mm × 2514 mm with motor ratings of 250–300 kW. Crushers of this size are

获取价格

Assessing the energy efficiency of a jaw crusher Request PDF

2014/9/1 The calculations for the crusher developed for this purpose were included in the paper. The design modifications made to expand the crusher's jaw stroke from 27

获取价格

“Computer Aided Design of Jaw crusher” - 911 Metallurgist

1.4 Crusher Size and Power rating: The size of a jaw crusher is usually expressed as gape x width. The common crusher types, sizes and their performance is summarized in

获取价格

Capacities and performance characteristics of jaw crushers

1994/5/1 By using the data of E.A. Hersam and F.C. Bond’s equation for energy consumption in comminution, a method was developed to analyze the performance of

获取价格

(PDF) DESIGN AND OPERATIONS CHALLENGES OF A

2017/6/30 Moreover, the wear of the jaw liner profile lowers the crusher performance by affecting the shape and the overall size of the crushed particles [12, 13]. Warping and wear of the jaw plate cause a ...

获取价格

Influence of jaw crusher parameters on the quality of primary

2020/6/1 Jaw crusher performance can be optimised for increased aggregate quality. • Calculation of flakiness index hides variation of particle shape within a gradation. ... Crushing efficiency and product quality can be optimised by adjustments to crusher and feed parameters. Crushing efficiency can be measured as capacity and energy

获取价格

Crushing Metrics: A Guide to Jaw Crusher Capacity Calculation Pdf

Process optimization: Maximizing crusher efficiency and minimizing downtime; ... Conclusion. Jaw crusher capacity calculation is a critical aspect of crushing operations. By understanding the factors that affect capacity and using appropriate calculation methods, engineers and operators can optimize production, reduce costs, and ensure the ...

获取价格

Jaw Crusher - ScienceDirect

2016/1/1 The size of a jaw crusher is usually described by the gape and the width, expressed as gape × width. The common crusher types, sizes and their performance are summarised in Table 4.1.Currently, the dimensions of the largest Blake-type jaw crusher in use are 1600 mm × 2514 mm with motor ratings of 250–300 kW.

获取价格

Bond Impact Crushing Work Index -Procedure and Table of Crushability

2015/6/16 The test determines the Bond Impact Work Index which is used with Bond’s Third Theory of Comminution to calculate net power requirements when sizing crushers*. It is also used to determine the required open-side settings (jaw crushers and gyratory crushers) or closed-side settings (cone crushers) for a given product size.P80

获取价格

Crushing of coal and calculation of size reduction efficiency.

2015/2/25 Jaw Crushers The next development in the field was the invention of Jaw Crushers in 1840’s in North America. Eli Blake patented the Double toggle Blake Jaw Crusher in 1858. The Blake type Jaw crusher has fixed feed opening where as the dodge type jaw crusher has fixed discharge opening. 2/25/2015 6:58:05 AM 5

获取价格

A fundamental model of an industrial-scale jaw crusher

2017/5/1 Jaw crushers are mainly used in operations where the volumes involved do not justify a gyratory crusher. The throughput of a jaw crusher ranges between 30 and 1200 tph (Wills and Napier-Munn, 2015). Jaw crushers have been modelled previously; in 1953, Gauldie conducted a performance study of the jaw crusher, including a capacity

获取价格

Modeling and Improving the Efficiency of Crushing Equipment

2023/6/30 crushers—jaw, cone, gyratory, impact, and roller crushers. The authors state that the models they obtained are useful for predicting key indicators such as power consumption, product

获取价格

Capacities and performance characteristics of jaw crushers

Celculaled camel ty.16 ' 2.5 7 I n 0 0.5 1 1.5 2 2.5 Actual capacl ty.lh' Q Present Eqn. + Rose 8 Engllsh Eqn. Fig 1 - Comparison of calculated capacltles wlth the oata of Hersam (1 9231 for different machlne parameters thereby influencing the degree of compaction of the product. The final equation for the capacity of jaw crushers can

获取价格

“Computer Aided Design of Jaw crusher” - 911 Metallurgist

4.4 Design calculations 38 4.5 Design of spring for tension bar 40 ... performance; it is essential to improve the efficiency of the present design. The kinematic ... Jaw crushers are used as primary crushers in a mine or ore processing plant or the first step in the process of reducing rock. They follow “crush using compression” mechanism.

获取价格

Screen efficiency calculation - Crushing, Screening Conveying ...

Screen efficiency is obtained using different equations, depending on whether your product is the oversize or undersize fraction from the screen. The following information is required to calculate the two screen efficiencies;-Qms(f) = Mass flow rate of solid feed. Qms(o) = Mass flow rate of solid in the screen overflow.

获取价格

How to improve jaw crusher performance and productivity - Metso

2020/3/30 Besides being an important item for the machine’s performance, the jaw crusher’s jaws are responsible for front frame and swing jaw protection. Wear generally causes loss in production due to increased crushing angle, loss of tooth profile, reduction of the CSS to compensate the possible lamellar effect, etc.

获取价格

Jaw Crusher Working Principle - 911 Metallurgist

2021/5/6 The jaw crusher discharge opening is the distance from the valley between corrugations on one jaw to the top of the mating corrugation on the other jaw. The crusher discharge opening governs the size of finished material produced by the crusher. Measuring Discharge Opening: Measure distance at bottom of jaws at the point of the crushing cycle

获取价格

Capacities and performance characteristics of jaw crushers

1994/5/1 By using the data of E.A. Hersam and F.C. Bond’s equation for energy consumption in comminution, a method was developed to analyze the performance of industrial jaw crushers. The study showed that industrial jaw crushers are generally operated below capacity. The study also showed that industrial jaw crushers generally

获取价格

Energy consumption of a laboratory jaw crusher during normal

2023/12/1 Measurement of the electricity consumption during crushing was done on a laboratory jaw crusher Bauknecht, Fig. 1. Jaw crusher operates by compressing the feed material between a fixed and a moving jaw back and forth in an eccentric cyclic motion (Cleary and Sinnott, 2015). The feed size of the opening was 110 × 100 mm 2.

获取价格

How to improve jaw crusher performance and

2020/3/30 Besides being an important item for the machine’s performance, the jaw crusher’s jaws are responsible for front frame and swing jaw protection. Wear generally causes loss in production due to

获取价格

Jaw Crusher Working Principle - 911 Metallurgist

2021/5/6 The jaw crusher discharge opening is the distance from the valley between corrugations on one jaw to the top of the mating corrugation on the other jaw. The crusher discharge opening governs the size of

获取价格

Capacities and performance characteristics of jaw crushers

1994/5/1 By using the data of E.A. Hersam and F.C. Bond’s equation for energy consumption in comminution, a method was developed to analyze the performance of industrial jaw crushers. The study showed that industrial jaw crushers are generally operated below capacity. The study also showed that industrial jaw crushers generally

获取价格

Energy consumption of a laboratory jaw crusher during normal

2023/12/1 1. Introduction. Power consumption and therefore efficiency of crushing equipment are becoming increasingly important mainly due to the continuous and rapid increase of energy costs and efforts to minimise CO 2 emissions (Tromans, 2008, Legendre and Zevenhoven, 2014).In order to meet the Paris Climate Agreement goals, recycling

获取价格

AMIT 135: Lesson 5 Crushing – Mining Mill Operator Training

Calculation of Reduction Ratio in Crushing Calculation of reduction ratio in crushing [image: (135-5-3)] Crushing Equipment. ... Largest jaw crusher is 1600 x 2514 mm with motor ratings of 250-300 kW. Metso crushers (C200 series) are 1600 x 2514 mm with motors rated at 400 kW.

获取价格

Understanding the Reduction Ratio in Crushers Komplet America

Hence, increasing the crushing efficiency with the jaw crusher reduction ratio depends on the amount of material fed into the crusher’s chamber. For instance, a jaw crusher with a choke-fed chamber performs best and maximizes production capacity while producing uniformly broken particles. As such, a choke-fed chamber increases your crusher ...

获取价格

ANALYSIS OF ENERGY CONSUMPTION OF CRUSHING

was carried on a model double-toggle jaw crusher which allows crushing forces, energy and toggle displacement to be measured. ... Key words: rock crushing, jaw crusher, crushing efficiency, two stage crushing process 1. INTRODUCTION The main aim of processing rock raw materials is to prepare and process the rocks to a condition that meets

获取价格

Capacity Calculations of the Crasher with Stops on a Roll

2022/8/21 The design has been developed for a single-roll crusher with the forced supply of destroyed material into the crushing zone [].The capture of a crushed piece occurs due to the stop located on the roll (see Fig. 1); in this case, the condition for formation of a complex stress state in the crushed piece is observed, and the energy consumption is

获取价格

(PDF) Determination of capacity of single-toggle jaw crusher,

2018/5/1 Efficiency increase of jaw crushers makes the foundation of rational kinematics and stiffening of the elements of the machine possible. Foundation of rational kinematics includes establishment of ...

获取价格

Crushing and Screening Handbook - AusIMM

the crusher and scalp out fi nes. Primary gyratory crushers – ideally suited to all high-capacity primary hard rock crushing applications. Jaw crushers – we have more installed jaw crushers than anyone in the world. The lead-ing choice due to their high reduction ratio and heavy duty design. Cone crushers – capacities available to suit all

获取价格

how does the jaw crusher archives efficiency - LinkedIn

2023/3/3 The efficiency of a jaw crusher is determined by the size of the crushing chamber, the width of the discharge opening, the horsepower of the motor, and the crushing capacity of the machine. Skip ...

获取价格

Exploring Jaw Crusher Efficiency Kemper Equipment

Jaw Crusher Reduction Ratio. Either an 8-to-1 or 6-to-1 ratio should be the target reduction ratio for maximum jaw crusher efficiency. This setting typically provides an ideal P80 factor—when 80% of crushed material produced by primary crushing will pass screening after processing.

获取价格

Optimisation of the swinging jaw design for a single toggle jaw crusher ...

2022/9/20 The plate dimensions of the un-optimised jaw crusher were modelled using ANSYS Design Modeller 2021, as shown in Fig. 3.The load and boundary conditions for the static structural analysis were as shown in Fig. 4.Design of Experiments (DoE) was then conducted where the minimum and maximum values of the target parameters were

获取价格

Determination of capacity of single-toggle jaw crusher, taking

2018/5/1 [1] Aybashev D M, Kolga A D and Hazhiev A A 2014 Influence of grooved crushing plates of jaw crushers on the efficiency of crushing process Bulletin of development of science and education 3 163-166 Google Scholar [2] Denegin V V 1993 To the question of the capacity of the jaw crusher Journal of Mining Institute 138 29-31

获取价格شراء معدات المعالجة في كندا

عملية تكسير البوكسيت

محطة غسيل الركام والرمل

التعدين كسارات الصانع الهند

مصنع غسيل الذهب مستعملة للبيع

آلات كسارة الحجر تاتا

مخروط محطم مقابل لفاف محطم قائمة

تصميم تأثير كسارة الحجر

غلتکی زغال سنگ آسیاب

من صنع اميركي كسارات الحجر الصغيرة

كسارة فكية لإعادة تدوير الخرسانة المتنقلة

نيوزيلندا بتصنيع كسارة الصخور

شبكة جودة مطحنة الكرة الرطب

كيف تعمل كسارة مخروطية

الحجر التعدين سحق المعدات في الهند

كسارة حجر بكرة

محجر مسعود

الفك الجيل الجديد محطم حجر محطم

أنواع كسارة مغذيات

مصنع كسارة أنواع مختلفة

دستگاه را به عمل خرد کردن یا اسیاب کردن علف گندم

صخرة طحن مطحنة للبيع

آلة كسارة الحجر الفكية الضخمة

مصنع كسارة الحجر في فنزويلا

محرك الكرة المركزي عزم الدوران وحساب الطاقة

الموردين بيع مصنع طحن مسحوق الجبس

حول لدينا

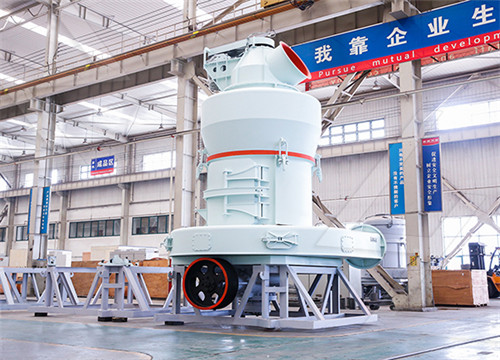

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20